I have been wanting to take a shot at doing the fittings on my own, thanks for the reference shot there are definitely a few small details to add to a model to make them more accurate!

aprilstorm Fantastic that you are looking to make a suit, from a production viewpoint any "texture" would be on your end vs the model. I run a Form3 printer and an Ultimaker 3 for the FDM side, and even when I do parts on the resin machine I always give them a scuff with some 320grit once I am done removing support nubs. I would suggest one your prints using a sharp exacto blade to cut the touchpoints from the supports off, and then sandpaper as above to give your filler primer something to stick to.

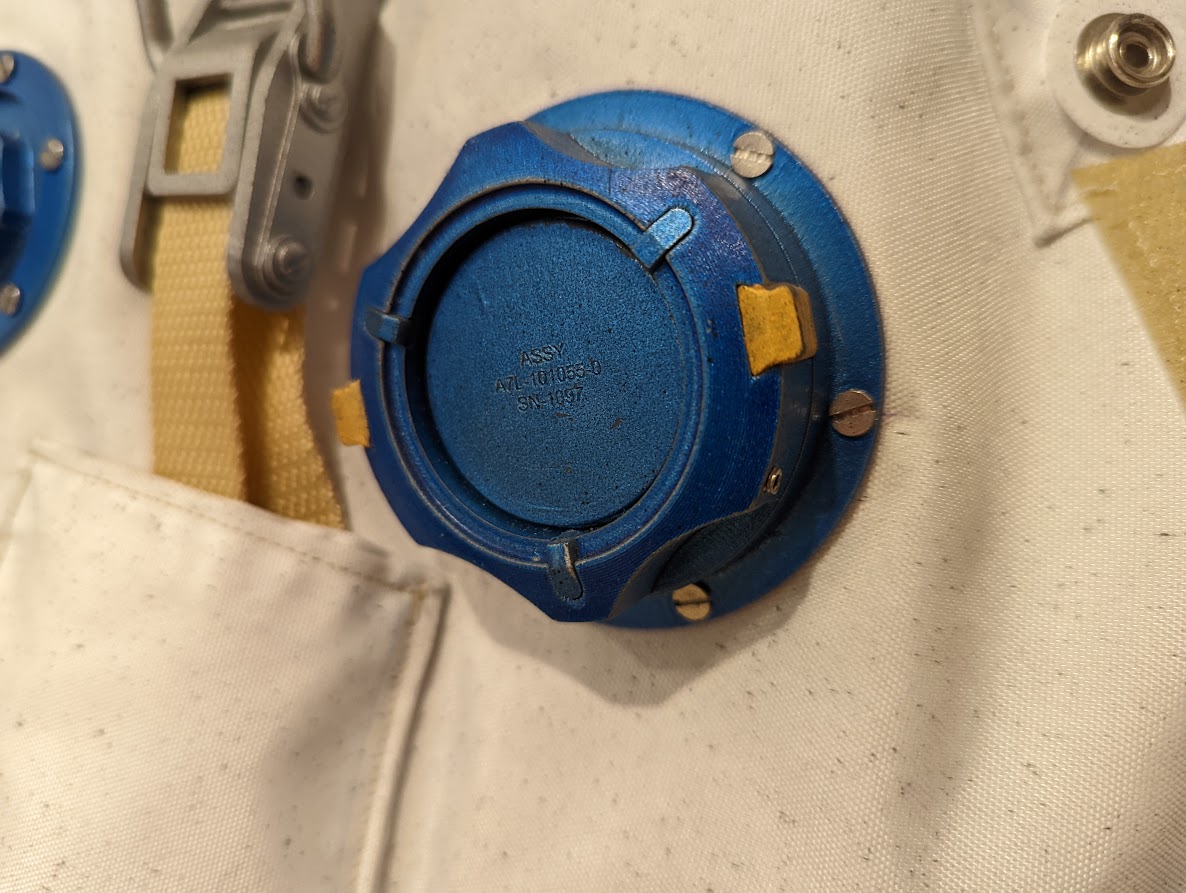

Duplicolor makes their metalcast paints, which is a metallic base and then red/blue etc top coats. Short of machining these out of aluminum and then anodizing them, IMHO that is the closest/best bang for the buck. I took that approach on my connectors and was really happy with how they turned out.

The bodies of these connectors are FDM printed @ 0.1mm and the layer fines are fine enough they pass for tool marks. I only used my resin machine for the small bits. Boy these are starting to show some wear, time for some paint touchup I think.

Welcome to the A7L builder's club!

aprilstorm Fantastic that you are looking to make a suit, from a production viewpoint any "texture" would be on your end vs the model. I run a Form3 printer and an Ultimaker 3 for the FDM side, and even when I do parts on the resin machine I always give them a scuff with some 320grit once I am done removing support nubs. I would suggest one your prints using a sharp exacto blade to cut the touchpoints from the supports off, and then sandpaper as above to give your filler primer something to stick to.

Duplicolor makes their metalcast paints, which is a metallic base and then red/blue etc top coats. Short of machining these out of aluminum and then anodizing them, IMHO that is the closest/best bang for the buck. I took that approach on my connectors and was really happy with how they turned out.

The bodies of these connectors are FDM printed @ 0.1mm and the layer fines are fine enough they pass for tool marks. I only used my resin machine for the small bits. Boy these are starting to show some wear, time for some paint touchup I think.

Welcome to the A7L builder's club!