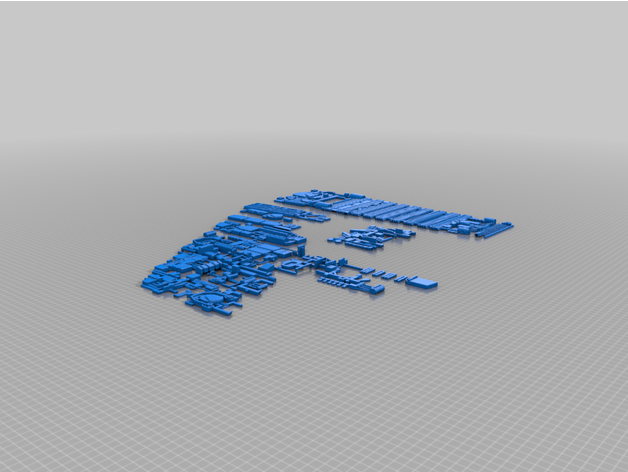

Well, it's been a long time since I last updated this and I still don't have an update as such as I am currently building a mojo restoration kit, but my steel strip and metal brackets arrived whilst I was away and after having it in my hands, I am again up in the air about which way to mount this ship.

I am torn between using A) the steel plate and then finding a way to create a connection between it and the ship or; B) using a tube which I'd bend to shape (and if it crushes, grind it all level etc and then use Milliput to reshape the bend).

There are benefits and disadvantages to both methods. The plate would by much more stable because the tube method would also require a support stand up front to prevent the ship from just pitching forward.

Using a tube, I would be limited to just 2 separate power plugs and therefore, less lighting options: 1) the engines and 2) the superstructure.

Whereas using the plate, I'd have more lighting options using 4 power pins:

1) the main engines

2) the sub-light engines

3) the superstructure and

4) the sidewall flood lights.

The biggest issue with the plate is that I am unsure on how to attach said 4 pin plug to the end of the plate as the pins are the exact same size as the plate.

The benefits of the tube is mainly aesthetic as I think it would look smarter and less industrial with a tube. Wires would also be easier to hide. The entry point int the ship would just be a round hole and would require less work to make it happen.

So, a bit of a conundrum really. I would be more than happy to hear anyone's thought's on this. What would you guys do?