Sounds like we both use the same material. It is very thin, somewhat stretchy, looks dull white up close (it is missing the protective clear layer) and gives that bright, warm reflection when front-lit. All the details are matching with what Jon told me about the original 3M material they used for the props.Is this the white 3M graphic film that is slick and has sticky backing but looks grainy upon closer look? I used it too!

I havent smashed it though - good to hear it makes those marks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ANH Obi Wan special effects lightsaber replica project

- Thread starter vadermania

- Start date

Mouse Vader

Sr Member

All the photographs I've seen the blades are matt. That looks to have a shiny surface ?

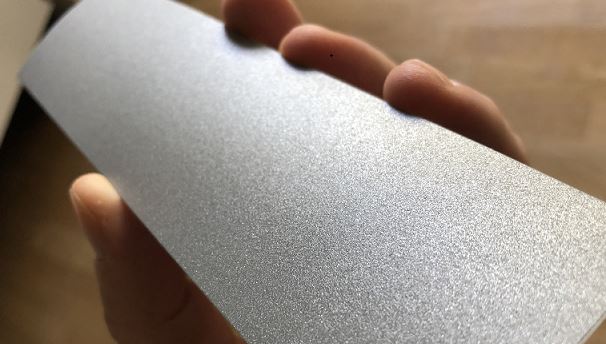

Here are some pics of the 3M 7610 material that I'm using for my blades:

It has a matt silver-greyish surface, and it looks very grainy.

This is the back side, which is extremely sticky.

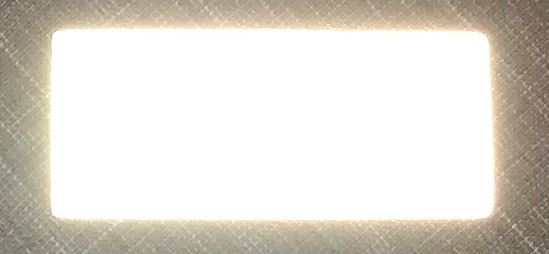

The glowing effect - picture taken with iPhone 8.

It has a matt silver-greyish surface, and it looks very grainy.

This is the back side, which is extremely sticky.

The glowing effect - picture taken with iPhone 8.

Mouse Vader

Sr Member

That looks great.Here are some pics of the 3M 7610 material that I'm using for my blades:

Welsh Pirate

Active Member

Here are some pics of the 3M 7610 material that I'm using for my blades:

View attachment 1296190

It has a matt silver-greyish surface, and it looks very grainy.

View attachment 1296191

This is the back side, which is extremely sticky.

View attachment 1296192

The glowing effect - picture taken with iPhone 8.

View attachment 1296193

That looks like the same stuff we'd put on our cranials in the Navy. I can't believe that never occurred to me as an option before.

UPDATE 2: constructing a special effects lightsaber blade

The first lightsaber blade I ever made consisted of a thin wooden strip coated with green fluorescent paint from a Revell model ghost ship kit. That was back in 1978 - I was 11 years old and got a lot of trouble with my father because I sawed off part of his broomstick for the lightsaber handle.

Some time later, when I learned that the special effects technicians used “frontlight projection material” for the lightsaber blades, the “same material that traffic signs are coated with”, guess what little Tom did to get that mysterious material…

During recent conversations Jon Bunker told me that he used round, untapered balsa wood blades which were painted black and then covered with 3M “Scotchlite” material, leaving a black line for the flickering effect. The reason for using balsa wood for the blades was simple – safety for actor Alec Guinness. I confronted Jon with the fact that we can see different lightsaber blades on screen during the fight, some longer, some shorter, some tapered, some not. Jon replied that he was not the only person working on those sabers, and that different blades were used for filming.

Personally, I’m a fan of strong, lightweight and tapered stunt/special effects lightsaber blades – like the carbon fiber golf club shaft I had laying around for some time. Nevertheless, I bought a round balsa wood stick, about 1 m long with a diameter of 15 mm. It was not that easy to find one which was completely straight, most of them were somehow bent.

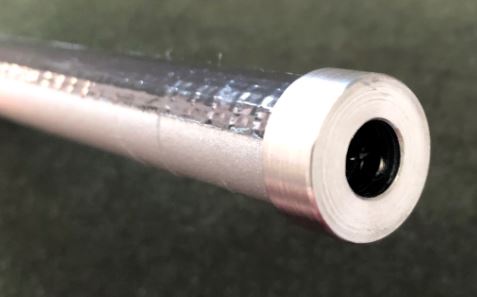

I decided to work on my carbon fiber blade first and make some sort of an “idealized” blade. Here is the final result:

The shaft was slightly shortened and outfitted with a steel tang. After that, I completely covered it with 3M 7610 reflective material and added a strip of black tape.

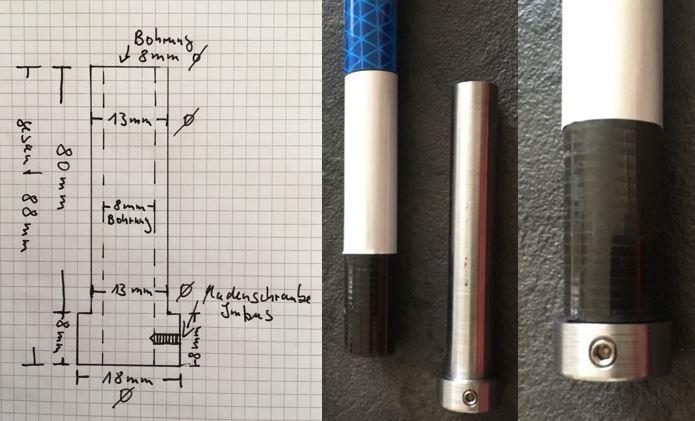

Construction of the steel tang:

I am not 100% sure if such a construction was used for the blades seen on screen. Based on my research and the available information, I felt comfortable with it. The steel tang was glued into the shaft using superglue.

Compare my idealized carbon fiber blade to the two blades encircled on the table at Lucasfilm archives:

The first lightsaber blade I ever made consisted of a thin wooden strip coated with green fluorescent paint from a Revell model ghost ship kit. That was back in 1978 - I was 11 years old and got a lot of trouble with my father because I sawed off part of his broomstick for the lightsaber handle.

Some time later, when I learned that the special effects technicians used “frontlight projection material” for the lightsaber blades, the “same material that traffic signs are coated with”, guess what little Tom did to get that mysterious material…

During recent conversations Jon Bunker told me that he used round, untapered balsa wood blades which were painted black and then covered with 3M “Scotchlite” material, leaving a black line for the flickering effect. The reason for using balsa wood for the blades was simple – safety for actor Alec Guinness. I confronted Jon with the fact that we can see different lightsaber blades on screen during the fight, some longer, some shorter, some tapered, some not. Jon replied that he was not the only person working on those sabers, and that different blades were used for filming.

Personally, I’m a fan of strong, lightweight and tapered stunt/special effects lightsaber blades – like the carbon fiber golf club shaft I had laying around for some time. Nevertheless, I bought a round balsa wood stick, about 1 m long with a diameter of 15 mm. It was not that easy to find one which was completely straight, most of them were somehow bent.

I decided to work on my carbon fiber blade first and make some sort of an “idealized” blade. Here is the final result:

The shaft was slightly shortened and outfitted with a steel tang. After that, I completely covered it with 3M 7610 reflective material and added a strip of black tape.

Construction of the steel tang:

I am not 100% sure if such a construction was used for the blades seen on screen. Based on my research and the available information, I felt comfortable with it. The steel tang was glued into the shaft using superglue.

Compare my idealized carbon fiber blade to the two blades encircled on the table at Lucasfilm archives:

Mouse Vader

Sr Member

Certainly looks right. Did you paint the inside of the tang black?

It appears like that on the picture, but it‘s plain steel.Certainly looks right. Did you paint the inside of the tang black?

Mouse Vader

Sr Member

Interesting. Noted for future pic ref's.

I use a slightly different setup for my balsa blade, an 18mm diameter, 8mm high aluminum "nipple" with a grub screw and a 10cm long, 10mm diameter aluminum tube which is glued into the corresponding hole in the balsa stick. The nipple will then be superglued to the aluminum tube and the end of the balsa blade. Will post pics once ready.

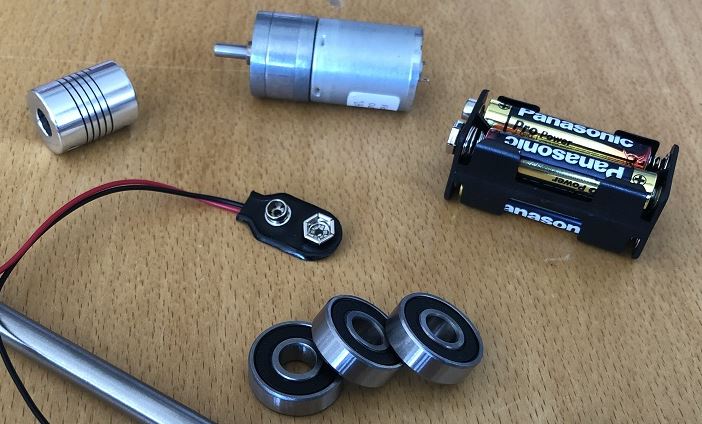

UPDATE 3: motor, bearings, bushing, steel rod, battery pack – the inner workings:

I kept the inner workings as simple as possible. We even decided not to install an ON/OFF switch, one just installs a fresh battery, screws the pommel back on the saber and off we go.

I kept the inner workings as simple as possible. We even decided not to install an ON/OFF switch, one just installs a fresh battery, screws the pommel back on the saber and off we go.

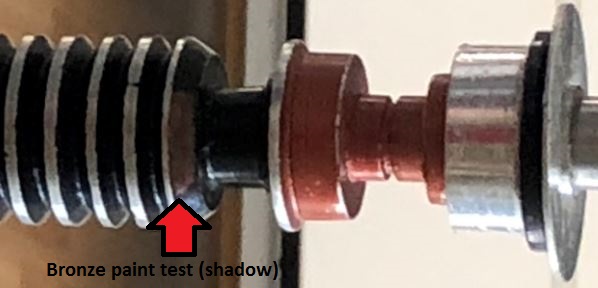

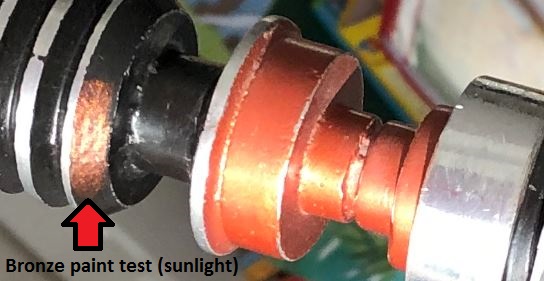

Did some paint tests for the bronze/copper color - what do you think?

Screen used OWK special effects lightsaber reference:

Paint tests:

Screen used OWK special effects lightsaber reference:

Paint tests:

It‘s an off the shelf piece.Did you make that bushing from scratch or is that a off the shelf piece?

Similar threads

- Replies

- 3

- Views

- 805

- Replies

- 43

- Views

- 3,029

- Replies

- 5

- Views

- 872

- Replies

- 4

- Views

- 876