You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:6 Scale Darth Vader and Star Wars Projects

- Thread starter Too Much Garlic

- Start date

curiouslysophie

Well-Known Member

The Lychee fixer is very hit or miss. I normally insert the mesh into fusion 360 and use the mesh fix in that, especially for more complex models.Lychee Slicer keeps saying any model I load in there has errors, but it refuses to show what those errors are. And when it "repairs" the non existing errors/holes, it messes up the file. I have checked the file in all sorts of 3D software and there are no holes or errors or double polygons or overlapping planes, so has anyone else had this issue with Lychee Slicer and were you able to fix it?

Too Much Garlic

Master Member

Thanks. I'll try that.

Too Much Garlic

Master Member

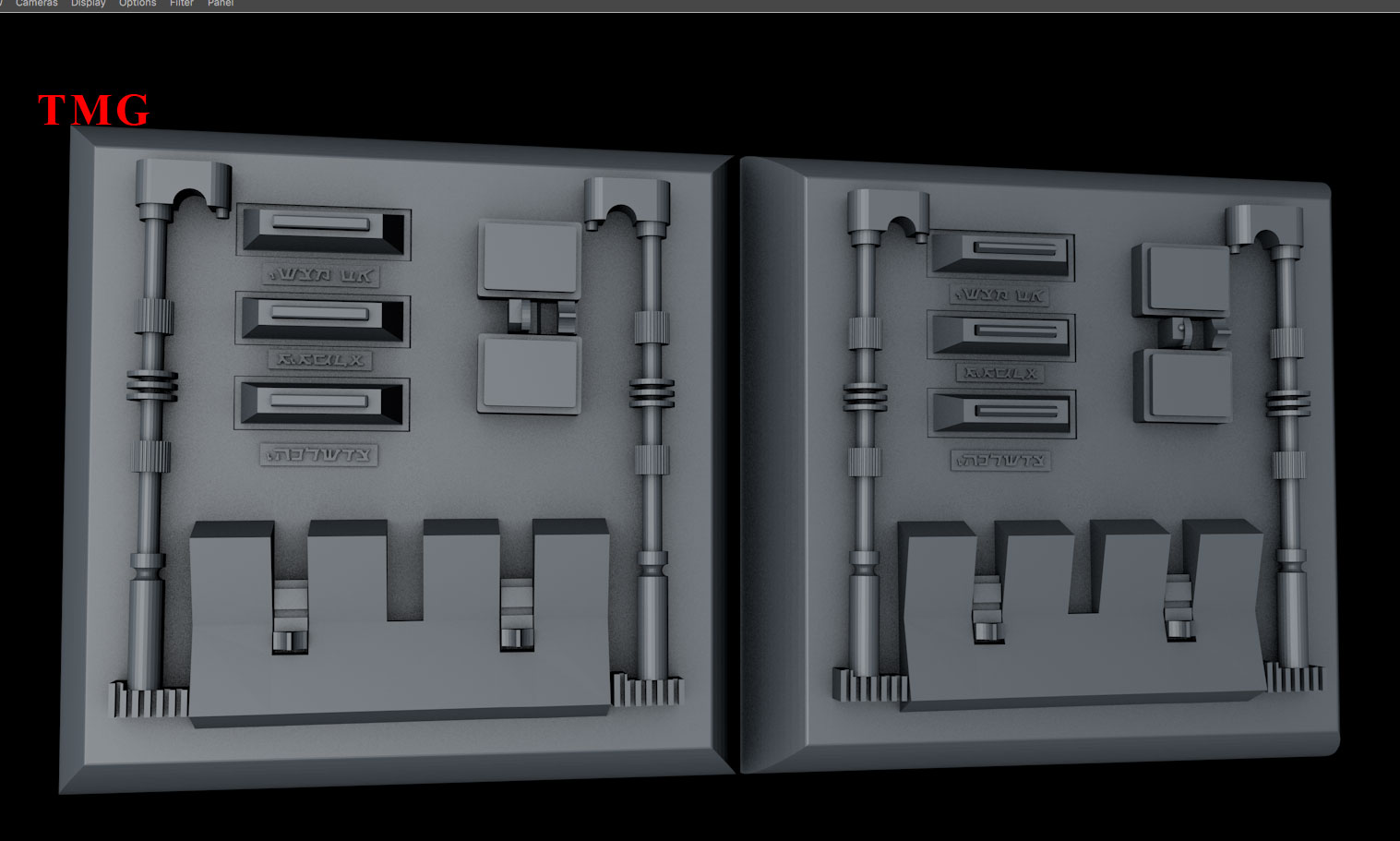

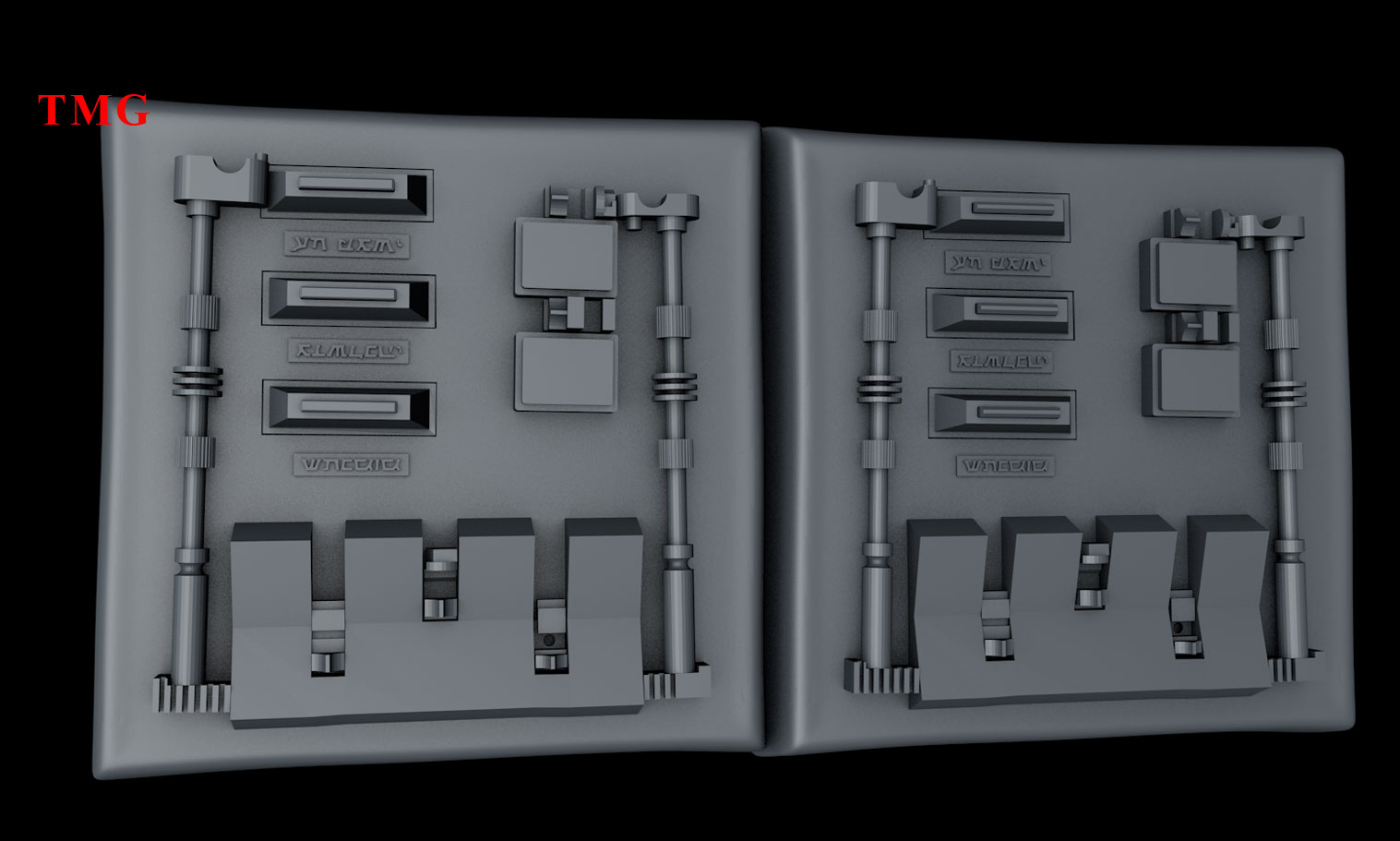

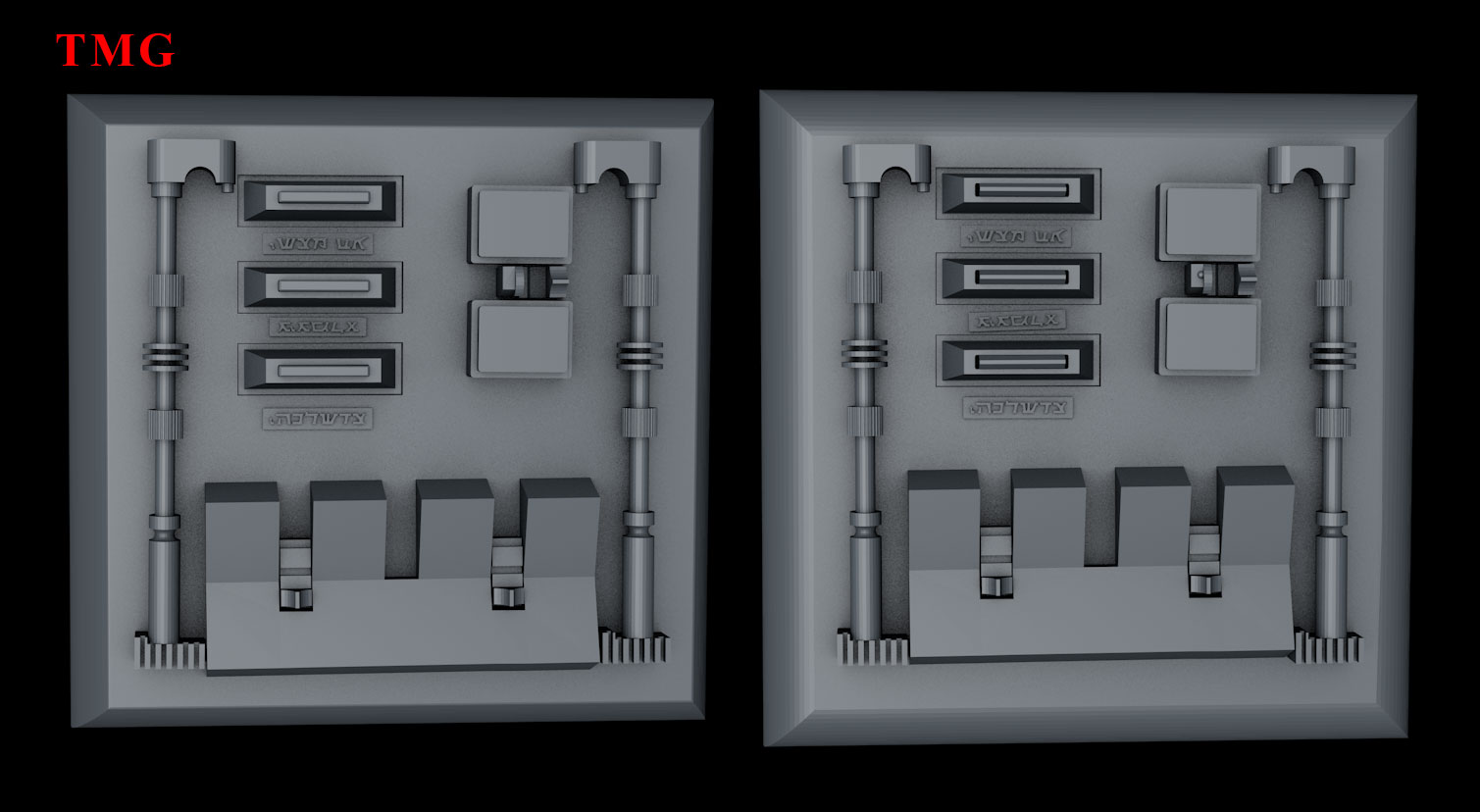

Well, found some things that weren't accurate to the reference, so started fixing it on the RotJ Box.

There is apparently a small sphere detail I had missed on the top silver greeblie between the two colored lenses, + the red lenses at the coin slots appeared a lot more tapered, yet with sharper corners and cut straight down at the same length at the sides - no taper there, so I tried to recreate that.

When I was done with that I decided to go back and check whether it was the same on the ESB. From the reference I could find it appeared so. Much more tapered at the front and with sharper corners, however, this one also had a taper at the sides, unlike the RotJ, so I incorporated that. When working on it I found some bad geometry behind the coin slots that may have been the reason why the 3D print slicer reported errors with the model. These errors are not visible from the outside and the other 3D software didn't pick it up. But, I fixed it and from what I can tell the red lenses were the only difference between my model and the reference that I could find.

If anyone can spot any other differences I would love to hear it.

There is apparently a small sphere detail I had missed on the top silver greeblie between the two colored lenses, + the red lenses at the coin slots appeared a lot more tapered, yet with sharper corners and cut straight down at the same length at the sides - no taper there, so I tried to recreate that.

When I was done with that I decided to go back and check whether it was the same on the ESB. From the reference I could find it appeared so. Much more tapered at the front and with sharper corners, however, this one also had a taper at the sides, unlike the RotJ, so I incorporated that. When working on it I found some bad geometry behind the coin slots that may have been the reason why the 3D print slicer reported errors with the model. These errors are not visible from the outside and the other 3D software didn't pick it up. But, I fixed it and from what I can tell the red lenses were the only difference between my model and the reference that I could find.

If anyone can spot any other differences I would love to hear it.

Too Much Garlic

Master Member

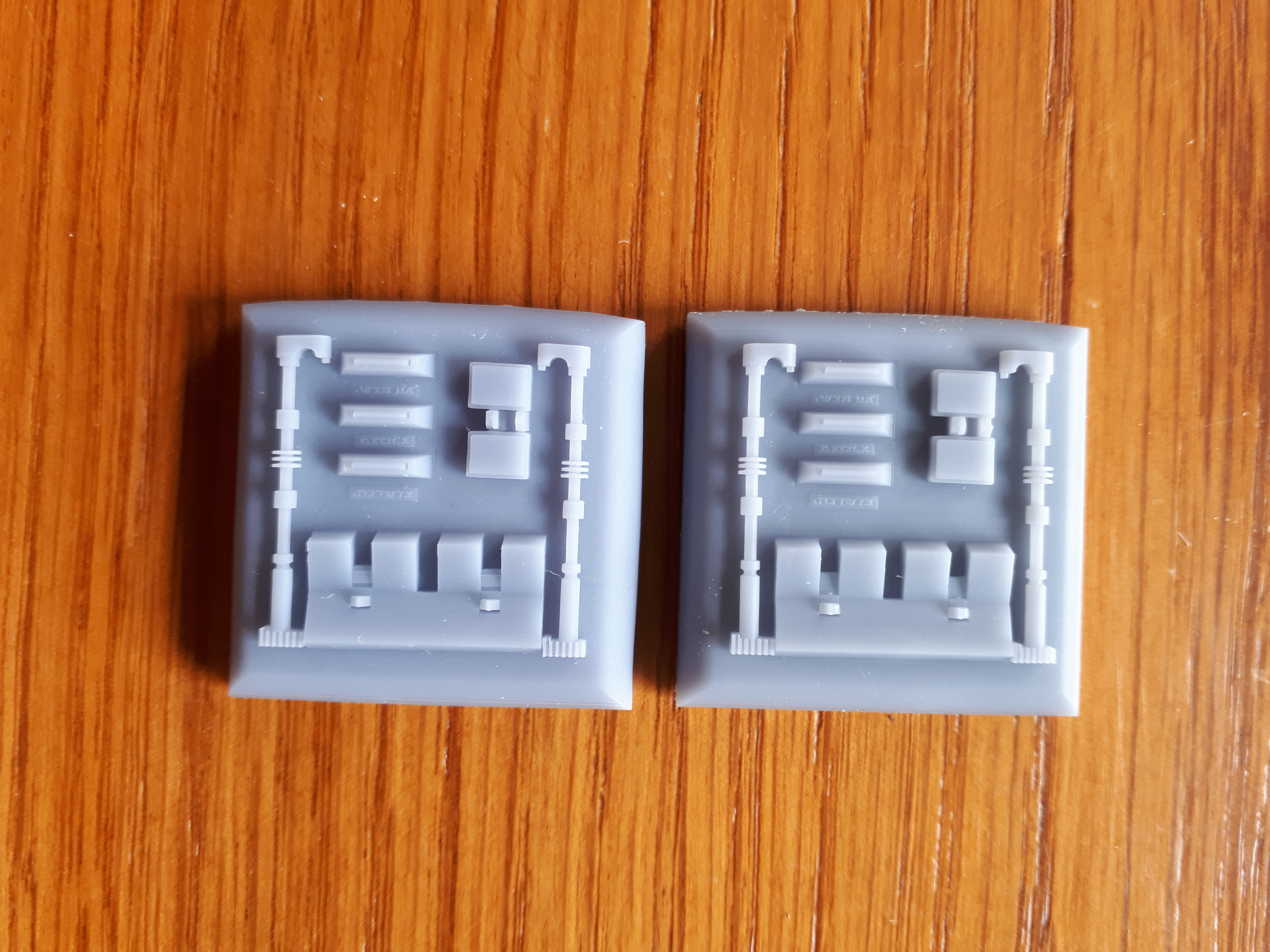

Was shown some better reference for the RotJ box and did a whole lot of reworking.

Old one on the left and new one on the right.

Old one on the left and new one on the right.

Too Much Garlic

Master Member

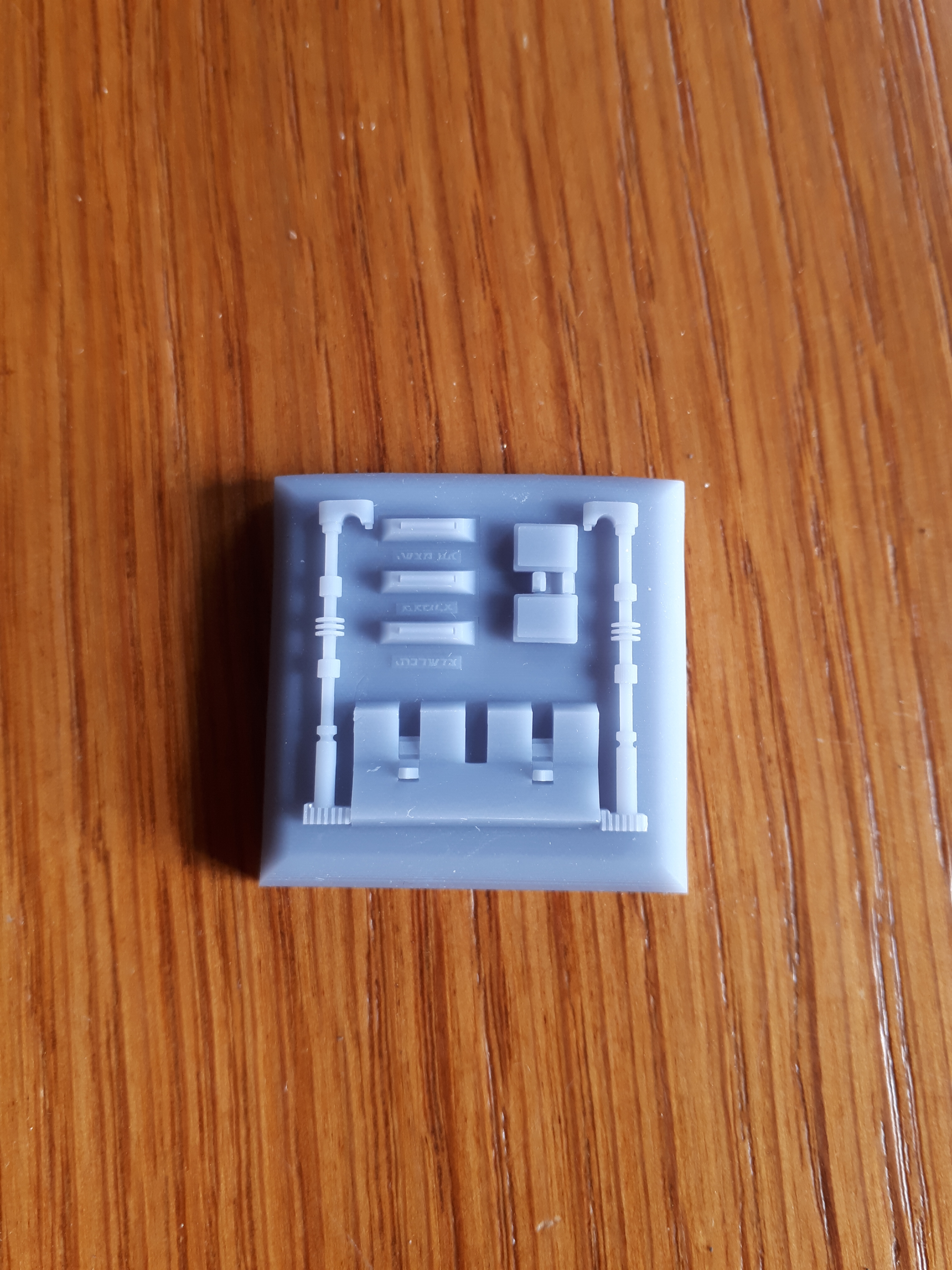

Tried the same settings with a RotJ box. The wonkiness at the top is due to me hollowing out the back and didn't account for potential warpage. However, the print is great and heating it with an air dryer softens it and I can push it back into position. I'll try a 0.02mm layer height hopefully tomorrow - this will take 4+ hours with the 0.05mm layer height only taking a little less than 2 - to check out if there is a difference in quality that will be worth the added time.

Also caught some errors in the model that I fixed.

Also caught some errors in the model that I fixed.

Too Much Garlic

Master Member

The 0.05mm layer height less than 2 hour print vs the 0.02mm layer height 5 and a half hour print.

I'll let you be the judge. Do you feel the extra time and slightly sharper detail is worth it? I know how I feel after seeing the comparison.

I'll let you be the judge. Do you feel the extra time and slightly sharper detail is worth it? I know how I feel after seeing the comparison.

Too Much Garlic

Master Member

Doing some more tests with the 0.05mm setting. Dennys Wang on Youtube suggests anti-aliasing to get rid of voxel lines, so I'm testing 2 types of that - one sharp and one blurred, as Dennys Wang suggests the latter with anti-aliasing 2, blur 2, but he's using another slicer than me, as Lychee doesn't have the exact same kinds of settings. I may try it in Chitubox with his exact recommendations later to see if I can get even better results.

Got the Anti-Aliasing Soft 2 back and that is NOT better.

Currently printing Anti-Aliasing Sharp 2 to see how that fares.

Got the Anti-Aliasing Soft 2 back and that is NOT better.

Currently printing Anti-Aliasing Sharp 2 to see how that fares.

Too Much Garlic

Master Member

Got it done. It is about on par with the version without anti-aliasing. There are some smoother areas, but it has some issues with edges, so the benefit is lost.

I'll stick with normal without anti-aliasing. At least when using Lychee slicer.

I'll stick with normal without anti-aliasing. At least when using Lychee slicer.

Too Much Garlic

Master Member

Sadly, I had just gotten started, but it was halted by health issues. Not related to 3D printing, so I'll get back to that as soon as I'm over this current issue. Though... with what the doctor said... I'd need to undergo a lot more tests... so things may take a while. Sorry guys. But at least I no longer hate resin 3D printing like I did before. Now I just want to get back to working with it because I finally got it working.

Hopefully I can get back to it in about 2-3 weeks. Maybe earlier, but no promises.

Hopefully I can get back to it in about 2-3 weeks. Maybe earlier, but no promises.

Sorry to hear that: hopes for a speedy recovery for ya!Sadly, I had just gotten started, but it was halted by health issues. Not related to 3D printing, so I'll get back to that as soon as I'm over this current issue. Though... with what the doctor said... I'd need to undergo a lot more tests... so things may take a while. Sorry guys. But at least I no longer hate resin 3D printing like I did before. Now I just want to get back to working with it because I finally got it working.

Hopefully I can get back to it in about 2-3 weeks. Maybe earlier, but no promises.

Too Much Garlic

Master Member

Thanks. I'll take things easy and hope it'll be over soon.

Too Much Garlic

Master Member

Well, we may now know what has caused the health issues. Not the best news, though... but at least now I know what the cause may be.

Will see if I can get things up and running again sometime next week. No promises though

Will see if I can get things up and running again sometime next week. No promises though

Too Much Garlic

Master Member

Am currently printing the main chest armor to see if the supports I added and orientation is good enough. I'll let you know once I get it out of the machine in about 1-2 hours from now... have already printed for a few hours.

Also went through all the models I could prep for printing and made print ready models with supports. The remaining will need to have some test prints done to see which orientation is best, as well as finishing out the face mask models so they don't trap resin inside. I've hollowed them out, but need to add drain holes or openings. I may just trim away the whole closed back, but that may make it too flimsy when printing, so I'll probably leave some areas running across the back connecting each side for support, which people can then trim away.

Have also considered how I could do the dome position so it sits perfect every time... though... I really don't feel up to doing that right now. Now I just want to make sure things print properly and start getting things in motion.

Also went through all the models I could prep for printing and made print ready models with supports. The remaining will need to have some test prints done to see which orientation is best, as well as finishing out the face mask models so they don't trap resin inside. I've hollowed them out, but need to add drain holes or openings. I may just trim away the whole closed back, but that may make it too flimsy when printing, so I'll probably leave some areas running across the back connecting each side for support, which people can then trim away.

Have also considered how I could do the dome position so it sits perfect every time... though... I really don't feel up to doing that right now. Now I just want to make sure things print properly and start getting things in motion.

Too Much Garlic

Master Member

Failure. I guess the angle was too steep, as there are displacement lines horizontally across the front of the armor in several places. Will try to angle it down more, so it isn't so vertical. Will try another print another day, as I'm test printing something else tonight and may print some endoskeleton parts tomorrow.

Too Much Garlic

Master Member

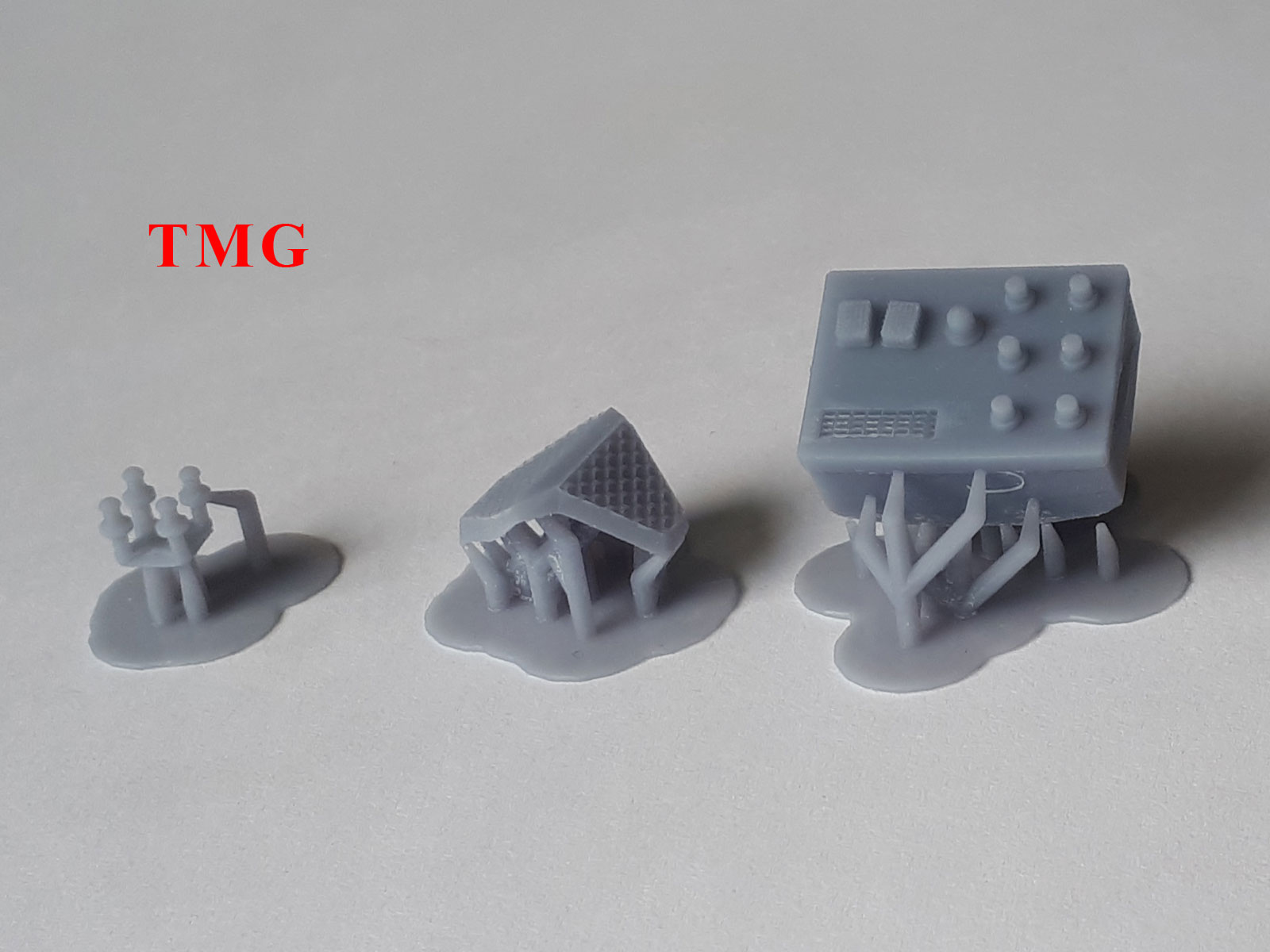

At least these test prints came out okay. The orientation on these work without issues, though, the grills are prone to capturing and keeping water and excess resin in the spaces, so I need to invest in a better connector between my compressor and airbrush, as for some reason, just screwing the airbrush directly onto it doesn't give a tight enough fit, so the air can't keep the pressure up. I'll try with one of my other airbrushes to see if one of those work for now.

You can actually see the knurling pattern on the six metal studs on the belt box in pictures. Hard to tell just by looking at it, as it's just too small.

You can actually see the knurling pattern on the six metal studs on the belt box in pictures. Hard to tell just by looking at it, as it's just too small.

Last edited:

Looking great! Love the attention to detail you’re putting in!

You mentioned (via PM) that any tips for printing would be great to share. So here are a few of mine, not sure if you already do some of them and I hope none of this sounds the least but know-it-all or condescending!

Looks like you’re trying to print with as few supports as possible, but for maintaining straight edges I tend to use a LOT of very small contact supports running along the entire edge/perimeter (if that makes sense) I use Lychee’s inline supports with .3mm touch points at a .8mm spacing. They basically peel off at the edge especially using heat. For reference I use .6mm as a support on the main starting points of a print and a lot of .3mm all over. Almost never anything larger, except for large prints.

Ideally also angle your prints in 2 axis to minimize both the internal stresses of the layers but also reduce the strain of the layers on supports. A good tool for helping identify the ideal angle for your specific printer is the link below. It’ll help minimize the effects of the stepping on flat surfaces. From the resolution of the screen.

www.rc87.blog

www.rc87.blog

You mentioned (via PM) that any tips for printing would be great to share. So here are a few of mine, not sure if you already do some of them and I hope none of this sounds the least but know-it-all or condescending!

Looks like you’re trying to print with as few supports as possible, but for maintaining straight edges I tend to use a LOT of very small contact supports running along the entire edge/perimeter (if that makes sense) I use Lychee’s inline supports with .3mm touch points at a .8mm spacing. They basically peel off at the edge especially using heat. For reference I use .6mm as a support on the main starting points of a print and a lot of .3mm all over. Almost never anything larger, except for large prints.

Ideally also angle your prints in 2 axis to minimize both the internal stresses of the layers but also reduce the strain of the layers on supports. A good tool for helping identify the ideal angle for your specific printer is the link below. It’ll help minimize the effects of the stepping on flat surfaces. From the resolution of the screen.

Angle calculator for smooth surfaces in resin printing – RC87

Angle calculator for smooth surfaces in resin 3d printing. This angle is computed for the planes that are to be printed best, but cannot be printed flat. Useful for resin printers like eg. Elegoo, Anycubic, Phrozen, Creality, Prusa etc

www.rc87.blog

www.rc87.blog

Too Much Garlic

Master Member

Cool. Thanks for the info. I'll check the site tomorrow. I did hear the tip about angling the print in two directions - I'll try that next time with the belt box.

Gotta clean out the resin first to give it a good shake, as it's been sitting in the vat for too long and it didn't help just lightly stirring it so it was a uniform color.

Really appreciate the input.

Gotta clean out the resin first to give it a good shake, as it's been sitting in the vat for too long and it didn't help just lightly stirring it so it was a uniform color.

Really appreciate the input.

If any of it helps I’m glad! Great to see how this is shaping up!

Too Much Garlic

Master Member

I'll try reprinting the chest boxes. Tusks and grills came out perfect with the current supports, so no need to redo those. I use automatic supports, so I let the program figure it out, and add extra where I think they are needed. I'll see if I can tweak the connection points sizes and add more at the bottom edge to make sure it doesn't snap at the corners. I can post pictures of the supported tests here before printing to get feedback on whether they look good or where something could be done better.

For the belt boxes I really can't print them at a second rotation because of the tree rings on the rods. Doing it straight on means I don't need to support them, as they are naturally supported by the main body of the box at the straight angle I print them in, but if I angle it onto one of the corners, those rings will become a problem and will need supports. So doing the angle I'm forced to use, I just need to strengthen the supports at the bottom edge.

Hope that makes sense.

Currently down with a fever... but will try and print some more tests next week... hopefully.

For the belt boxes I really can't print them at a second rotation because of the tree rings on the rods. Doing it straight on means I don't need to support them, as they are naturally supported by the main body of the box at the straight angle I print them in, but if I angle it onto one of the corners, those rings will become a problem and will need supports. So doing the angle I'm forced to use, I just need to strengthen the supports at the bottom edge.

Hope that makes sense.

Currently down with a fever... but will try and print some more tests next week... hopefully.

Similar threads

- Replies

- 13

- Views

- 2,085