genZOD

Sr Member

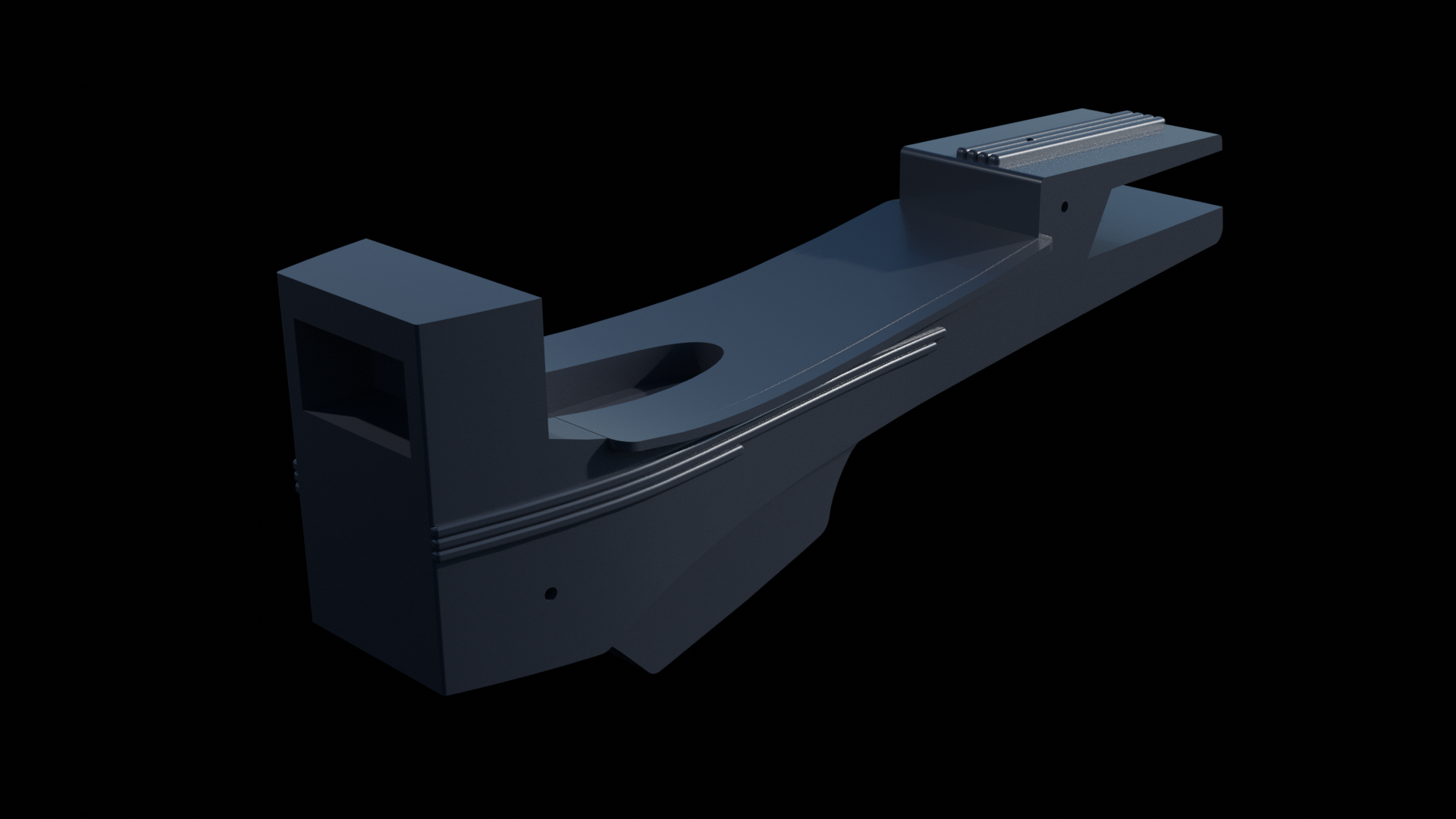

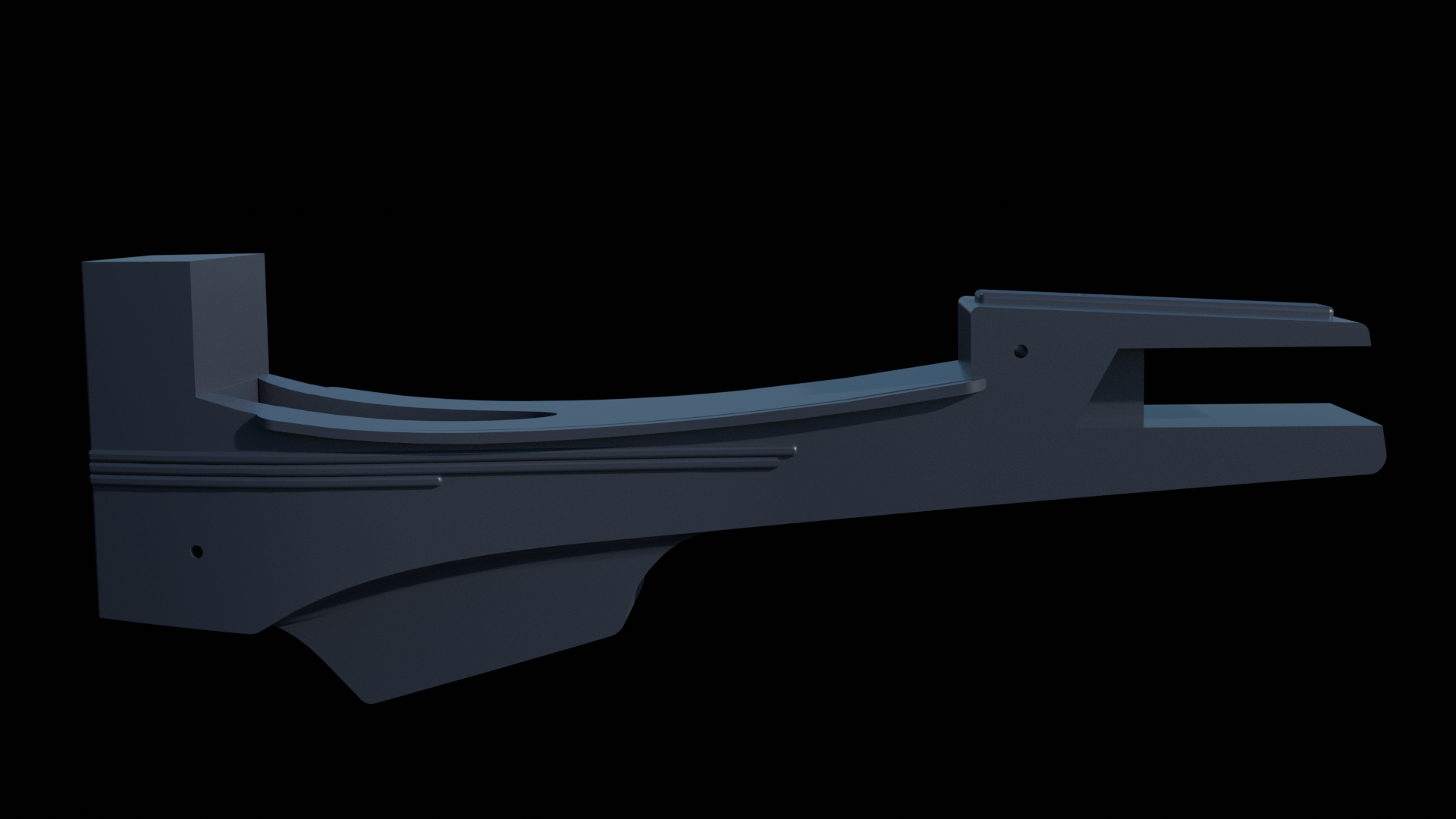

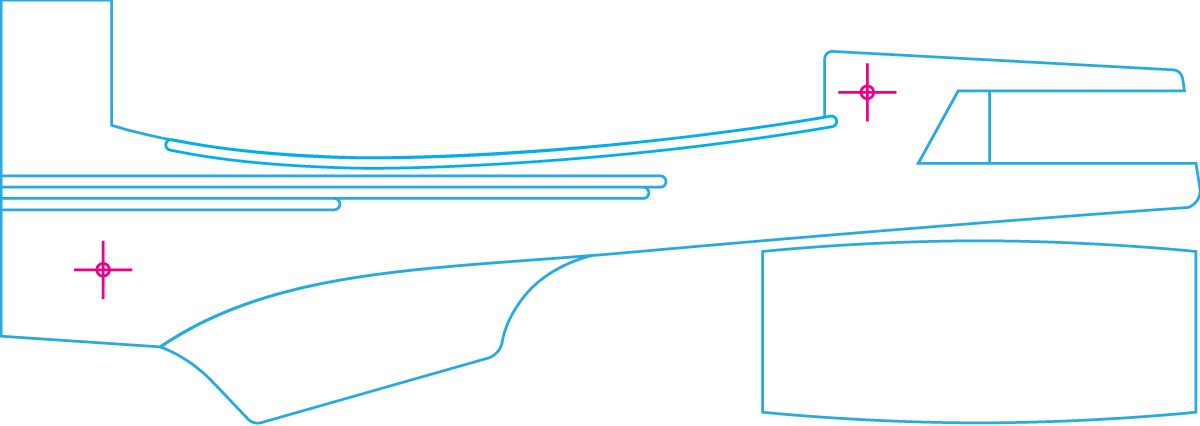

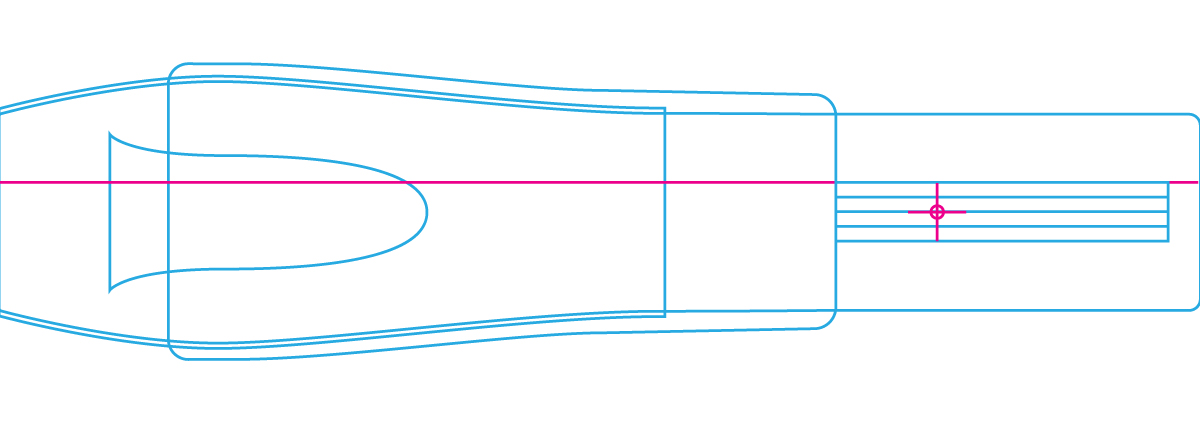

Hello All. I'm working on the P2 shell right now. I'm trying to get the basic shape right--so that I can 3D print it. After that, I'll do a bunch of sanding/filler to get all of the rounded off corners & bevels right. Then I'll make moulds for my fiberglass shell.

Anyway, to my eye the back half of my phaser is WAY to wide. I've matched the blueprints that I found online, but it looks off to me. To be fair, I've only ever seen the Diamond Select version in person.

TBH, I thought that I'd find better plans online. Anyway, help is always appreciated.

Anyway, to my eye the back half of my phaser is WAY to wide. I've matched the blueprints that I found online, but it looks off to me. To be fair, I've only ever seen the Diamond Select version in person.

TBH, I thought that I'd find better plans online. Anyway, help is always appreciated.

Last edited: