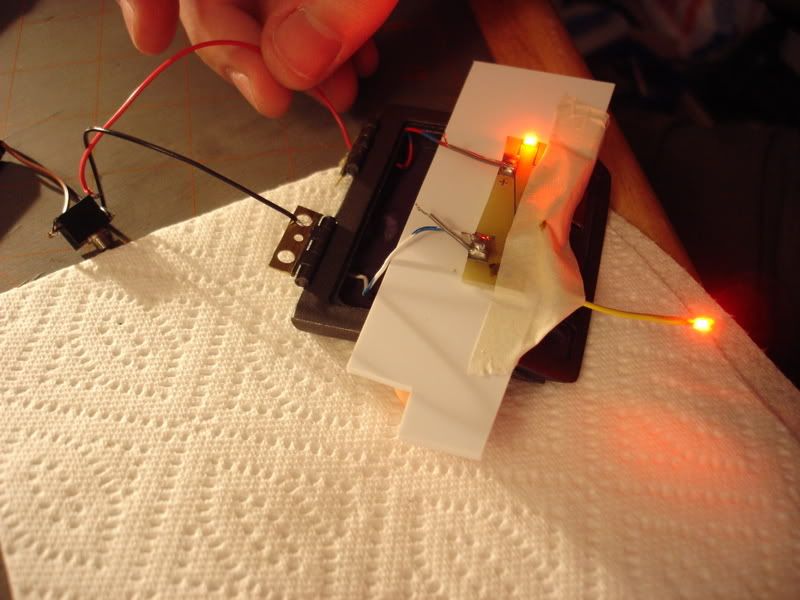

Well, This is the second tricorder I have put together. This time around I am of course going more slowly, implementing the lessons I learned the first time around, and was so happy with my progress.

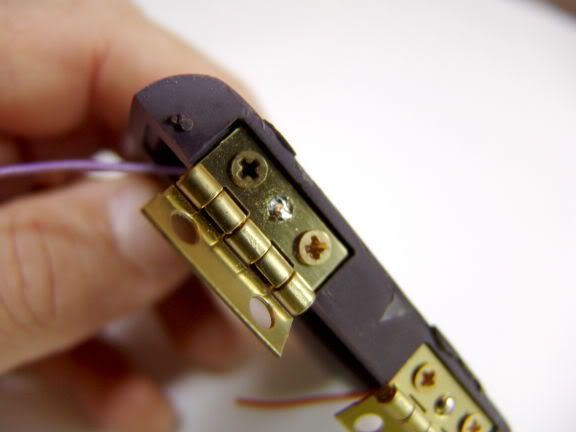

I got all my painting and assembly of the body done and was just beginning the fit of the door to the body today, and while filing the hinge leaves, I felt something fall out of my hand and into my lap. It was one of the door wires!

The wire was soldered to the leaf that got screwed and puttied into the door. Is there any way I can re-attach the wire without drilling out the putty and paint, and re-soldering it through that drilled hole? It took me weeks to putty/sand and putty/paint and sand/paint this thing.

I got all my painting and assembly of the body done and was just beginning the fit of the door to the body today, and while filing the hinge leaves, I felt something fall out of my hand and into my lap. It was one of the door wires!

The wire was soldered to the leaf that got screwed and puttied into the door. Is there any way I can re-attach the wire without drilling out the putty and paint, and re-soldering it through that drilled hole? It took me weeks to putty/sand and putty/paint and sand/paint this thing.