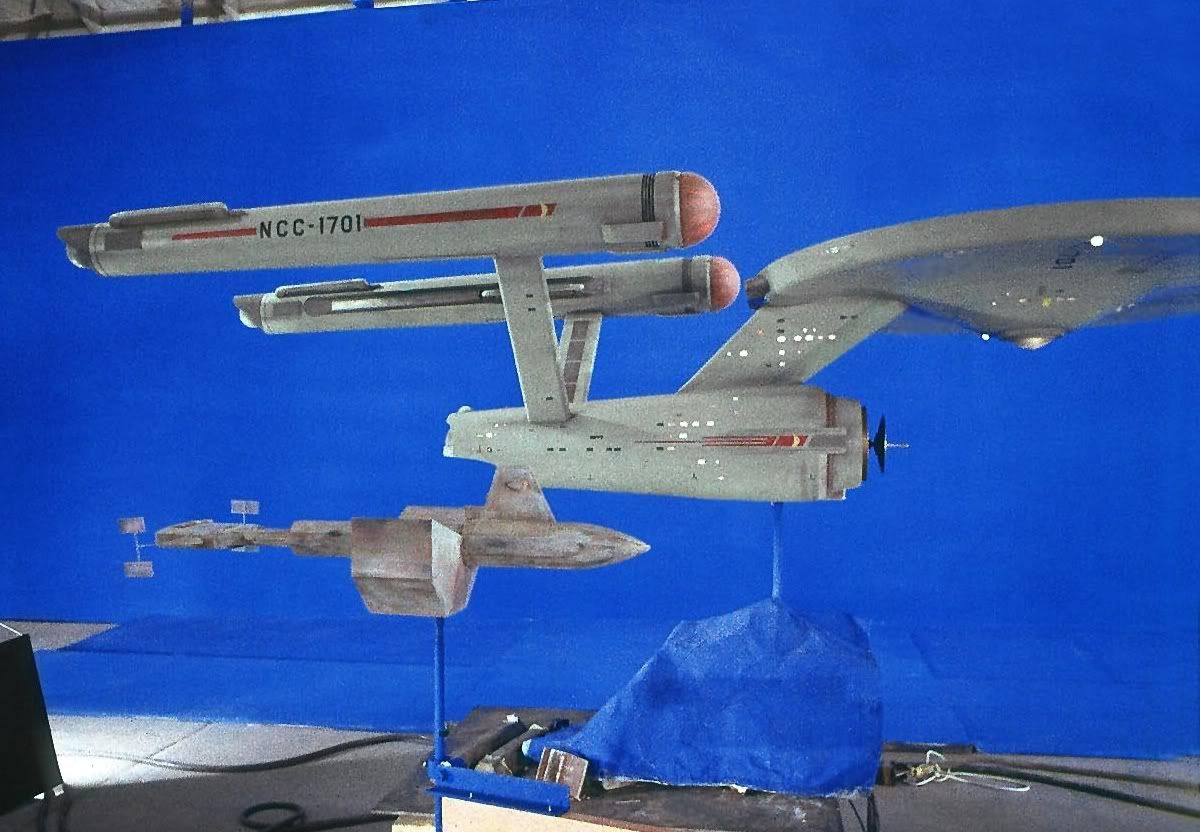

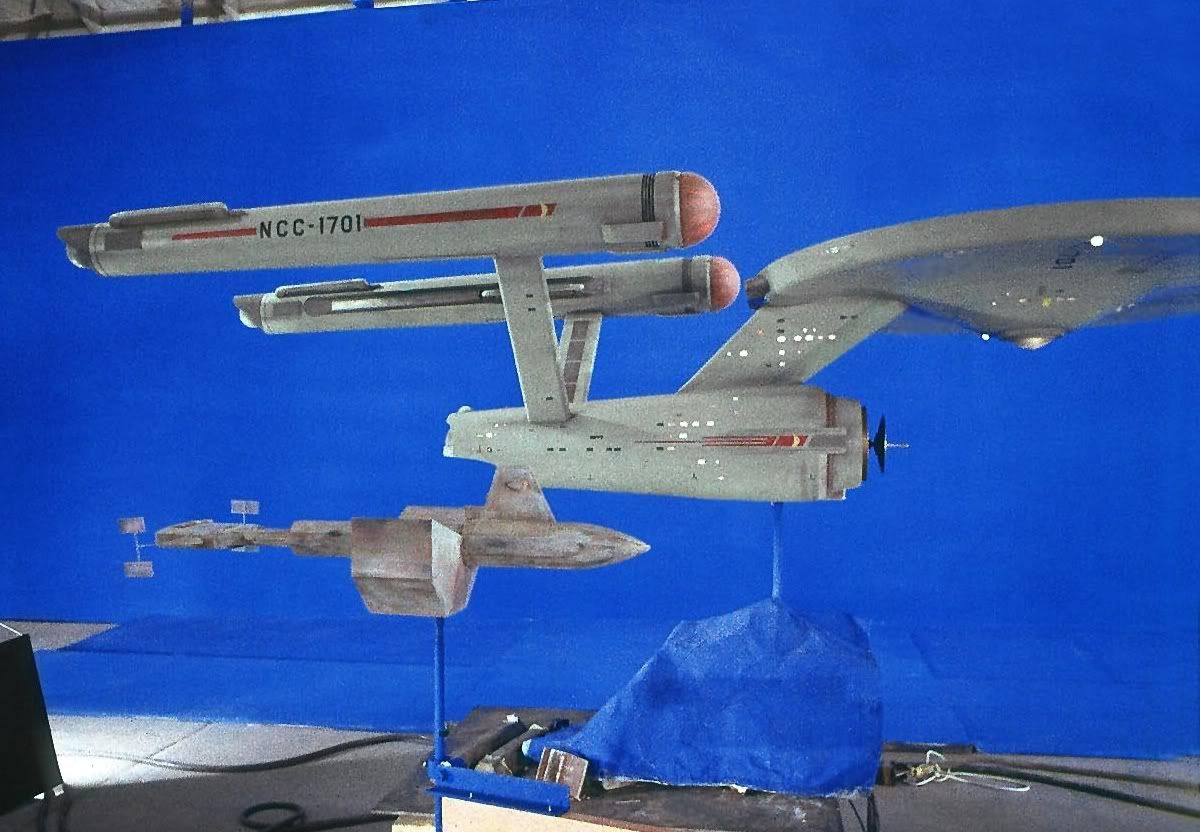

Funny how there isn't any sign of panel lines on the nacelles, 2nd hull, lower saucer. Thanks Spockboy, I always thought the same thing. The ST exibition that came to Phoenix was very very(I asked for my money back) disappointing.

I see this is your first post Spockboy, welcome to the RPF.

Now another update.

You guys remember me showing you this.

If you remember those slots in the middle.

I routed those out today, and put the nacelle together.

Here is how I did it-

I cut a 1" steel bar to fit each of the slots(they are 12" long). I use steel because of its strength, and hopefully it will not flex(it won't at that length, and the application isn't strong enough to be any problem).

But I do need to drill holes for screws.

So I use my trusty milling machine.

Pardon the mess, this is a manual milling machine. To some it will look like a drill press on steroids. It does do a whole lot more than drilling holes. It weighs over 2000 pounds, and is precise enough to put my initials on Lincoln's eyeball(on a penny, I'll never do it. I can't see that well:lol).

It's main job is to use a cutter to shape any material(looks like a drill bit, but it can cut on the side of the bit. They are called endmills, and they come in a variety of shapes and sizes. I use them in router as well. I'll show more about that as the project progresses). It is an indispensable tool in any machine shop.

For this post I will be using it to drill some holes.

Now in this pic you see a vise(blue thing to the left), a drill chuck w/drill bit(top). Below the drill bit there is a steel bar with holes in it. Now I needed to drill six holes in four bars. Some will think that could take all day. Nope it's whole lot easier than you think. The first thing I do is mark where I want the holes, I'm not showing that because the holes only need to be close to where I want them. Once I figure where I want them. I put the bar in the vise(tighten down).

Before I drill the hole I do something else.

See that little red box with the shaft on the left side of the vise. It has many uses(I use it hold measuring devices, at times), it has a magnetic base so it can be moved around. In this application I'm using it for a stop. It's placed at the end of the bar so I can drill holes in the same place on each bar. And since I need holes the same distance from each end of the bar, I just flip the bar over and both sides are taken care of. It really is that easy, and you can do the same trick with a drill press.

Next I place the bars in the slots. The fit is excellent.

Here is one side of the nacelle with the template removed, and the bars screwed into place. The nacelle is now one piece.

Next-

I place a pin at each end. So I can put the nacelle together for sanding/matching.

I placed an end cap on each end of the nacelle. So I can keep things together. It's notched so the cap is centered.

Here is the Nacelle in one piece. I have started to sand and it will take some work to get everything right. It's fit is much better than some mainstream kits I have. :lol

That's it for now, any questions comments?

Spockboy

Spockboy