mung

Sr Member

With a dozen or so of unfinished projects lying around I started a new one I call the Space Barge.

Over a year ago I purchased a couple of Trumpeter submarine kits that had begun to be assembled from a guy who decided for one reason or another not to continue his build.

I thought they might provide the basis for a spaceship one day and the fact that there was two of them made the deal all the more appealing.

Occasionally I would look at the hulls wondering what to do with them but inspiration never struck.

Often while waiting for a part to finish on the CNC machine at work, I doodle design thumbnails on scraps of paper and recently one of those thumbnails solidified into an idea of how to use those sub hulls in a model spaceship.

I have always been a fan of the spaceships in the Rag Tag Fleet of Battlestar Galactica the original series.

I was particularly fond of the Prison barge with its two sub halves and Leopold Gun Trusses top and bottom.

As it happened at the same model show that I acquired the two sub hulls I also purchased a couple of Hasegawa 1/72 Leopold kits.

I thought it would be a bit of a nod to the Prison Barge to combine my two Submarine hulls with the two Leopold trusses all be it in a somewhat different format.

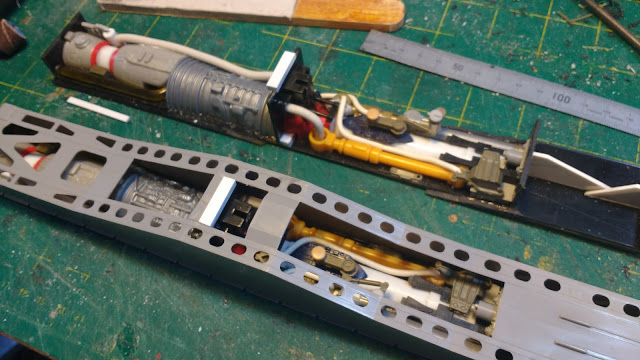

I started with a slab of 10mm thick foamed PVC to which I had to attach the submarine hulls.

The hulls came to me already glued together and the seams had been sanded and primered on one and just rough filler applied to the other.

I had to split them apart in order to securely fit them.

They are a pretty flimsy construction with no internal bracing of any kind. I managed to split them apart by gently squeezing resulting in only a few breaks to the seams which could easily be repaired later.

I traced around the edge of the hull onto the 100mm PVC to get a matching edge profile and used the cut off part to superglue to the inside of the hull half as reinforcement.

For a secure super glue bond to styrene it is best to roughen it up with 60 grit abrasive first.

I made a series of reinforcing circular bulkheads from 2mm styrene and cemented them into each of a half hull with some scraps of styrene keeping them perpendicular. The half hulls were then superglued to the slab and screws driven into pre-drilled holes. That hull is not going to come off.

The other halves of the hulls were then cemented into position with a lot of masking tape strips holding the edges in position till set the next morning.

One of the trusses from the Leopold kits I acquired was squashed out of shape.

It looks like somebody sat on it, something I was not made aware of when I purchased it.

Lucky for me this is a spaceship and the remedial work required would not detract from the finished article.

I decided to add some detail behind the trusses with added bulkheads to help force the bent one back into shape.

Also there is not a continuous straight edge on the truss so a made up a styrene base to compensate for the changes in level.

This meant I would have a flat base to glue to the flat slab underneath the model.

I sprayed the detail inserts with some dark grey primer before gluing them in place inside the truss, as I wont have much access later.

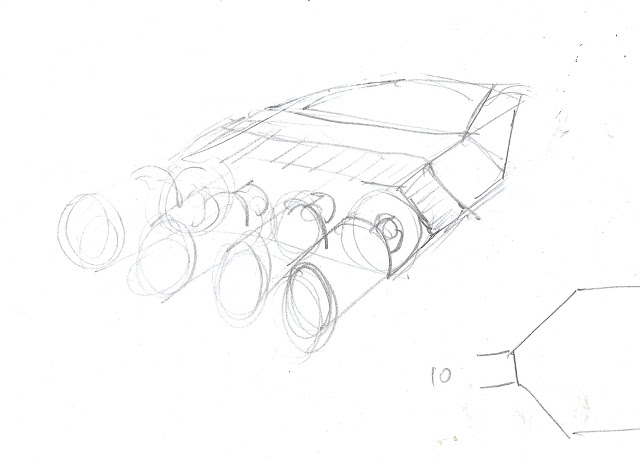

The next section tackled was the engine section. I had 4 old pop up sprinkler bodies that were made of the right sort of plastic and I thought might fit the bill so I did another rough scribble before launching into cutting styrene.

You can see that there isn't much to these scribbles but it is enough to get a concept clear in my own head in order to proceed.

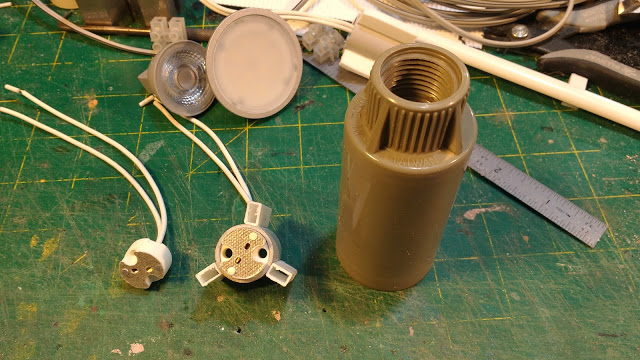

As is my usual practice I used LED downlights in the engines but this time the smaller MR11 type downlights.

The more common MR16 is 50mm in diameter with the MR11 only 35mm in diameter.

Notice that the pins are smaller and slightly closer together on the MR11 but they still fit the same connectors and both are 12 volt.

The MR11 I have put out 184 lumens of light and all four pull one amp at 12 volts.

I made up a locating device to fit the connector inside the pop up sprinkler body from some PVC electrical conduit and three bits of evergreen rectangular tube.

The pvc conduit was slightly bored out in the lathe to get the ceramic connectors to push fit in.

The evergreen rod was sanded at the bottom end to fit in the slightly tapered interior of the sprinkler head.

As there is no way to line up the pins when trying to put the lamps in I put the bulbs in and then pressed the whole assembly into the sprinkler.

The lamps have a life of 20,000 hours so I don't imagine ever having to replace them.

The sprinkler received some textured evergreen sheet and will get some further detailing later.

A 2mm styrene structure to house the engine section was constructed.

I am not going to put in an access hatch here so the wiring was sorted out and soldered up.

I also added a switch so I can turn the engine lights off separately from any control bridge lighting still to be determined.

The switch is buried in a recess in what was a wall mount for a dustbuster, The dust buster itself was used on the Escape Pod MK2 project.

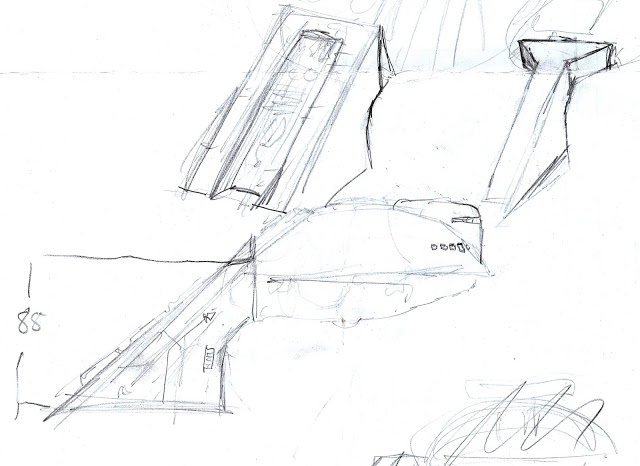

The next scribble was to sort out the command section.

I thought I could employ the original command section from an old spaceship which had been hacked some years ago.

I toyed with putting it in front like the BSG Prison Barge but preferred the original concept scribble with it sitting raised at the rear like the bridge of a container ship.

Over a year ago I purchased a couple of Trumpeter submarine kits that had begun to be assembled from a guy who decided for one reason or another not to continue his build.

I thought they might provide the basis for a spaceship one day and the fact that there was two of them made the deal all the more appealing.

Occasionally I would look at the hulls wondering what to do with them but inspiration never struck.

Often while waiting for a part to finish on the CNC machine at work, I doodle design thumbnails on scraps of paper and recently one of those thumbnails solidified into an idea of how to use those sub hulls in a model spaceship.

I have always been a fan of the spaceships in the Rag Tag Fleet of Battlestar Galactica the original series.

I was particularly fond of the Prison barge with its two sub halves and Leopold Gun Trusses top and bottom.

As it happened at the same model show that I acquired the two sub hulls I also purchased a couple of Hasegawa 1/72 Leopold kits.

I thought it would be a bit of a nod to the Prison Barge to combine my two Submarine hulls with the two Leopold trusses all be it in a somewhat different format.

| Leopold, a Battlestar Galactica staple. |

| Prison Barge from Galactica TOS. You can see the Leopold trusses peeking out top and bottom. |

| The rough scribble that got me enthusiastic enough to start the project. |

I started with a slab of 10mm thick foamed PVC to which I had to attach the submarine hulls.

The hulls came to me already glued together and the seams had been sanded and primered on one and just rough filler applied to the other.

I had to split them apart in order to securely fit them.

They are a pretty flimsy construction with no internal bracing of any kind. I managed to split them apart by gently squeezing resulting in only a few breaks to the seams which could easily be repaired later.

I traced around the edge of the hull onto the 100mm PVC to get a matching edge profile and used the cut off part to superglue to the inside of the hull half as reinforcement.

For a secure super glue bond to styrene it is best to roughen it up with 60 grit abrasive first.

I made a series of reinforcing circular bulkheads from 2mm styrene and cemented them into each of a half hull with some scraps of styrene keeping them perpendicular. The half hulls were then superglued to the slab and screws driven into pre-drilled holes. That hull is not going to come off.

The other halves of the hulls were then cemented into position with a lot of masking tape strips holding the edges in position till set the next morning.

One of the trusses from the Leopold kits I acquired was squashed out of shape.

It looks like somebody sat on it, something I was not made aware of when I purchased it.

Lucky for me this is a spaceship and the remedial work required would not detract from the finished article.

I decided to add some detail behind the trusses with added bulkheads to help force the bent one back into shape.

Also there is not a continuous straight edge on the truss so a made up a styrene base to compensate for the changes in level.

This meant I would have a flat base to glue to the flat slab underneath the model.

I sprayed the detail inserts with some dark grey primer before gluing them in place inside the truss, as I wont have much access later.

The next section tackled was the engine section. I had 4 old pop up sprinkler bodies that were made of the right sort of plastic and I thought might fit the bill so I did another rough scribble before launching into cutting styrene.

You can see that there isn't much to these scribbles but it is enough to get a concept clear in my own head in order to proceed.

As is my usual practice I used LED downlights in the engines but this time the smaller MR11 type downlights.

The more common MR16 is 50mm in diameter with the MR11 only 35mm in diameter.

Notice that the pins are smaller and slightly closer together on the MR11 but they still fit the same connectors and both are 12 volt.

The MR11 I have put out 184 lumens of light and all four pull one amp at 12 volts.

| From Left to right, Ceramic bi-pin connector, MR11, MR16. |

I made up a locating device to fit the connector inside the pop up sprinkler body from some PVC electrical conduit and three bits of evergreen rectangular tube.

The pvc conduit was slightly bored out in the lathe to get the ceramic connectors to push fit in.

The evergreen rod was sanded at the bottom end to fit in the slightly tapered interior of the sprinkler head.

As there is no way to line up the pins when trying to put the lamps in I put the bulbs in and then pressed the whole assembly into the sprinkler.

The lamps have a life of 20,000 hours so I don't imagine ever having to replace them.

The sprinkler received some textured evergreen sheet and will get some further detailing later.

A 2mm styrene structure to house the engine section was constructed.

I am not going to put in an access hatch here so the wiring was sorted out and soldered up.

I also added a switch so I can turn the engine lights off separately from any control bridge lighting still to be determined.

The switch is buried in a recess in what was a wall mount for a dustbuster, The dust buster itself was used on the Escape Pod MK2 project.

| Engine lighting switch. |

The next scribble was to sort out the command section.

I thought I could employ the original command section from an old spaceship which had been hacked some years ago.

I toyed with putting it in front like the BSG Prison Barge but preferred the original concept scribble with it sitting raised at the rear like the bridge of a container ship.