3d-builder

Sr Member

Well onto the lower hull.............

Ah ya the lower hull is one of those

things i go into expecting to get wrong......

at least a few times! But using some damage control

and taking notes helps, so does making the corrections

with cheap media.......like paper(if your a tree you

are probably not laughing right now.....sorry:angel)

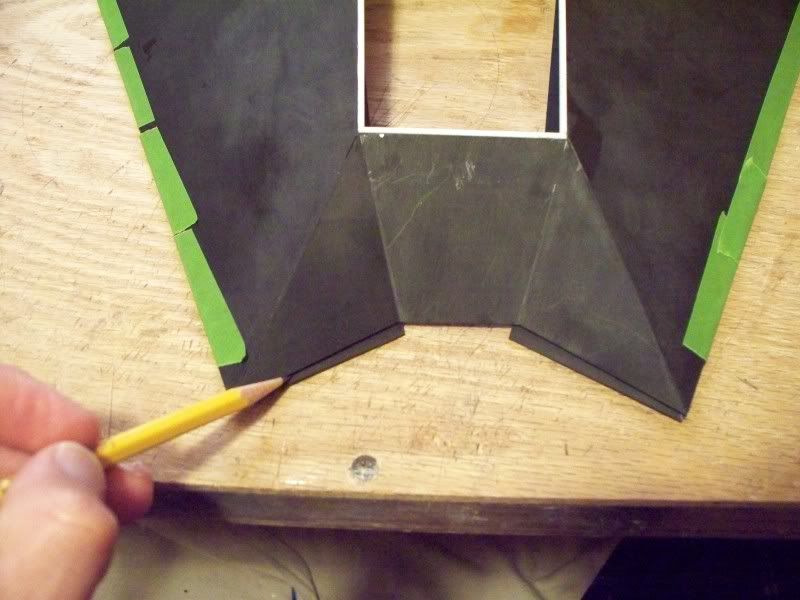

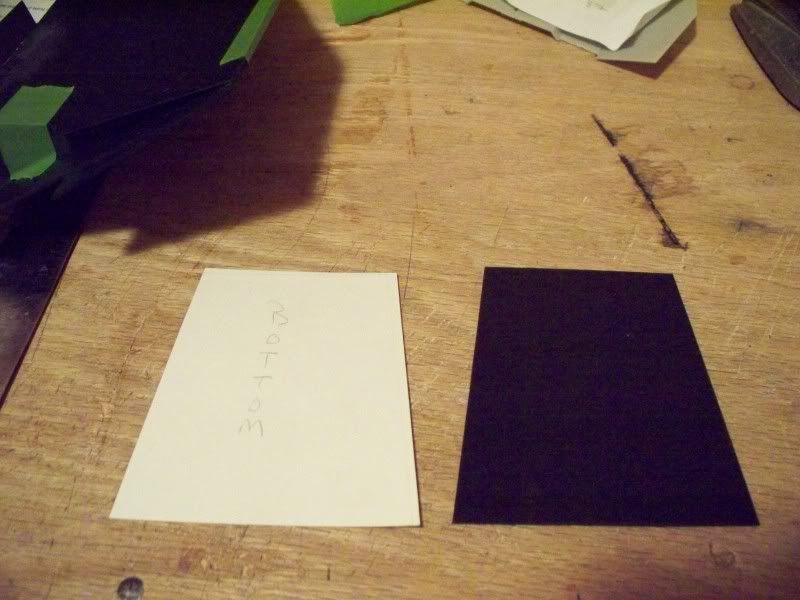

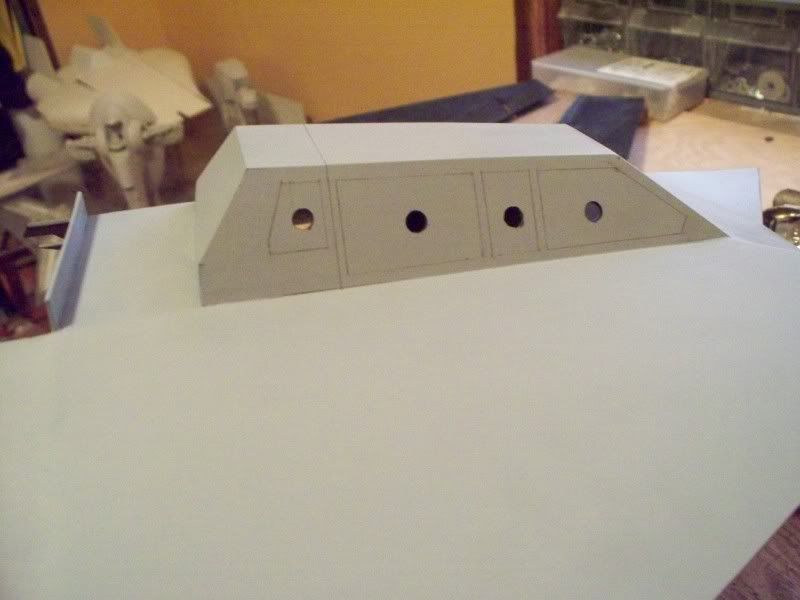

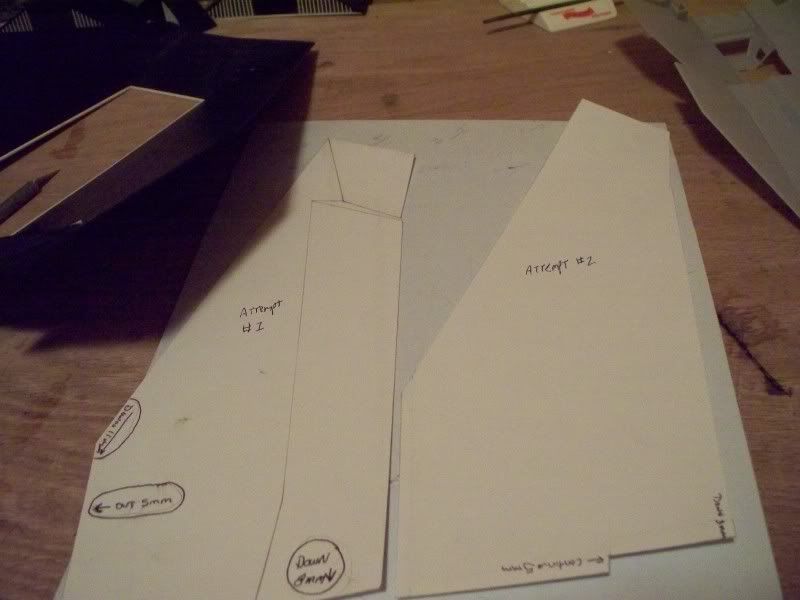

Any way first pic is not the lower hull but the

last pic of the canopy build.

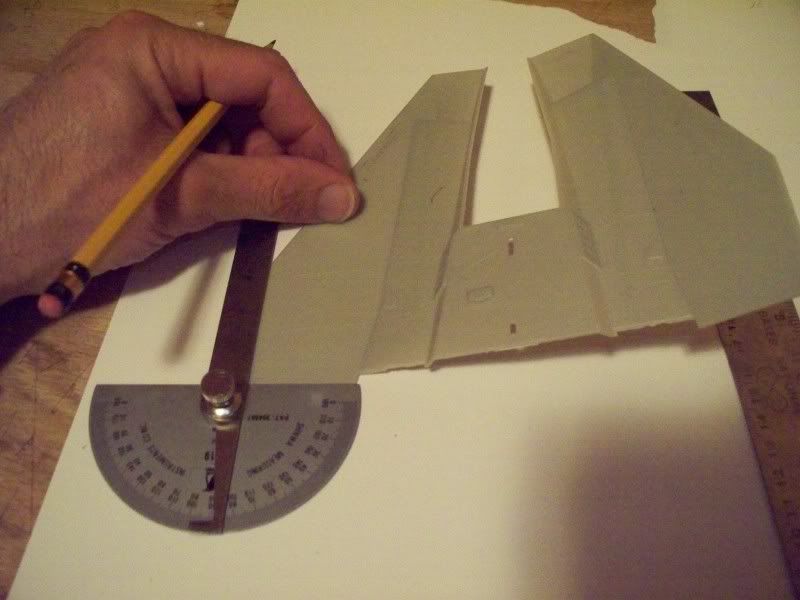

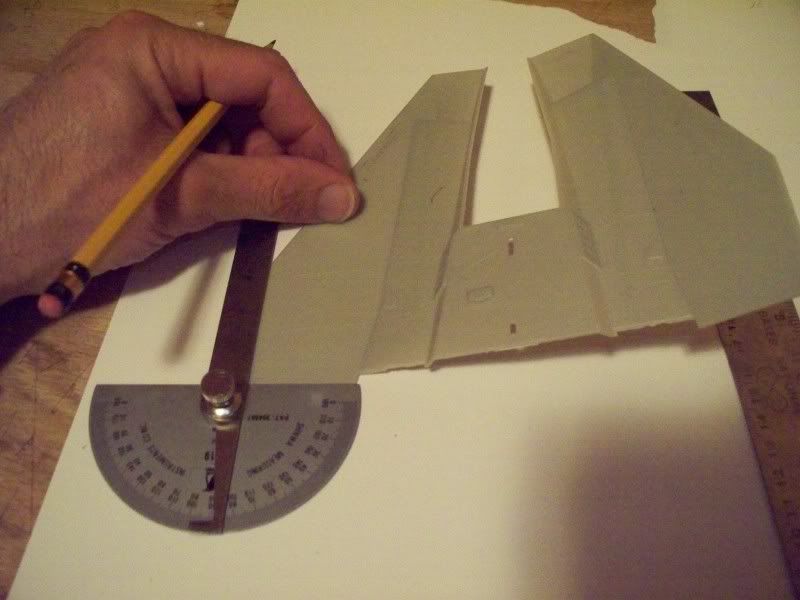

if you dont have one of these tools get one,

and use it to cheat as much as you can, as

you see me doing here to help figure out the

angles on the lower hull. Ah ya Micro Mark

has them if your considering.:thumbsup

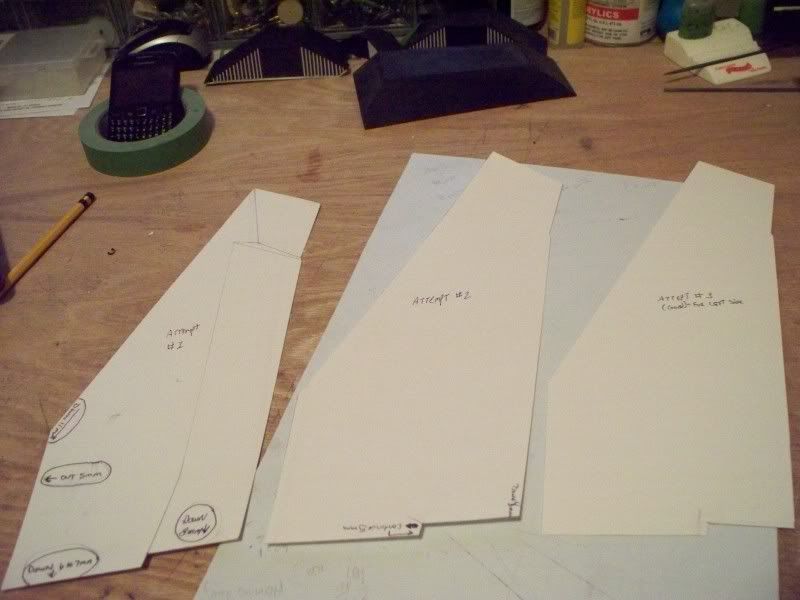

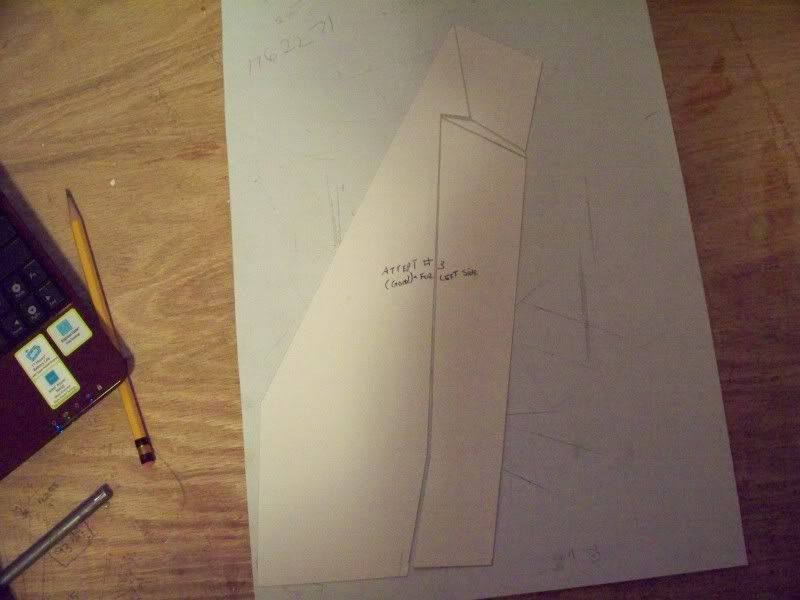

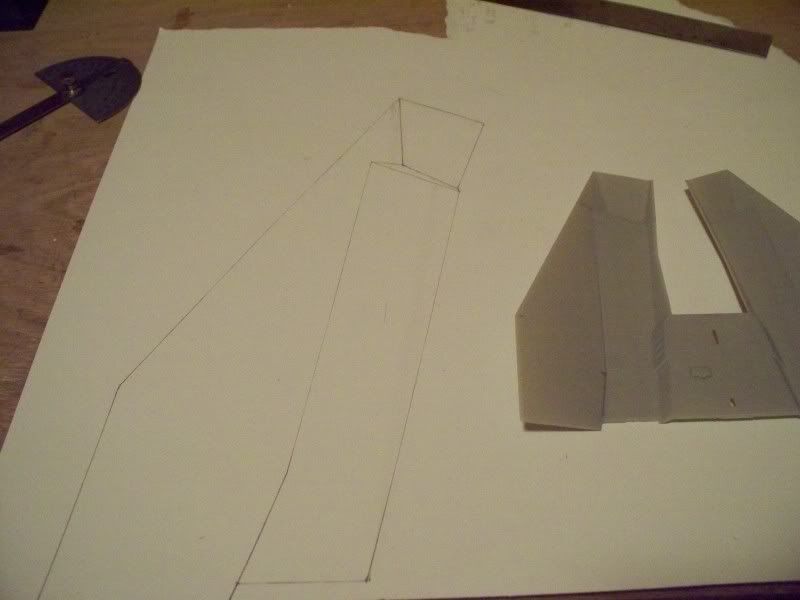

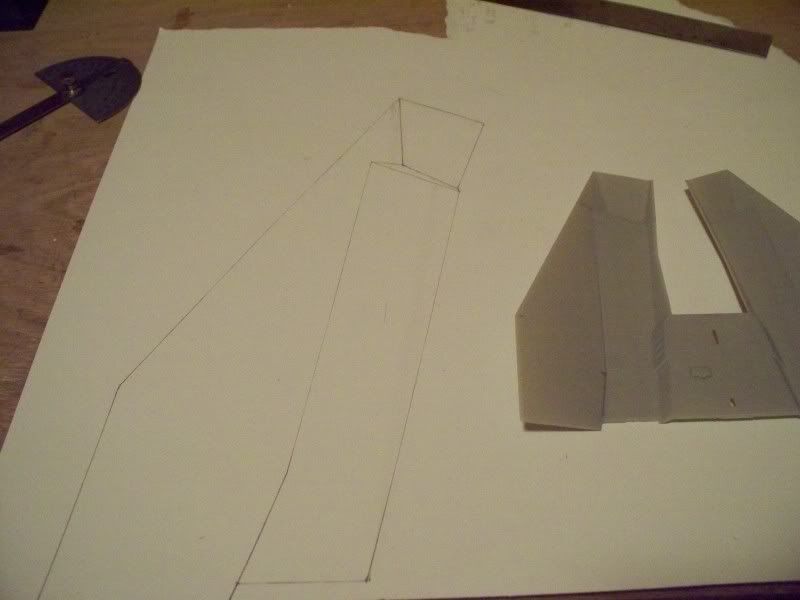

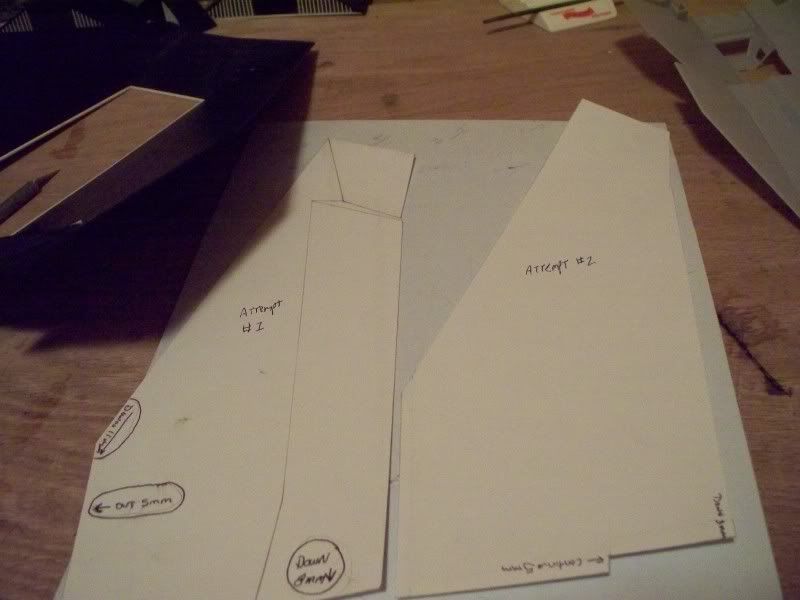

Moving along taking measurements and scaling them up

to have a decent looking template....

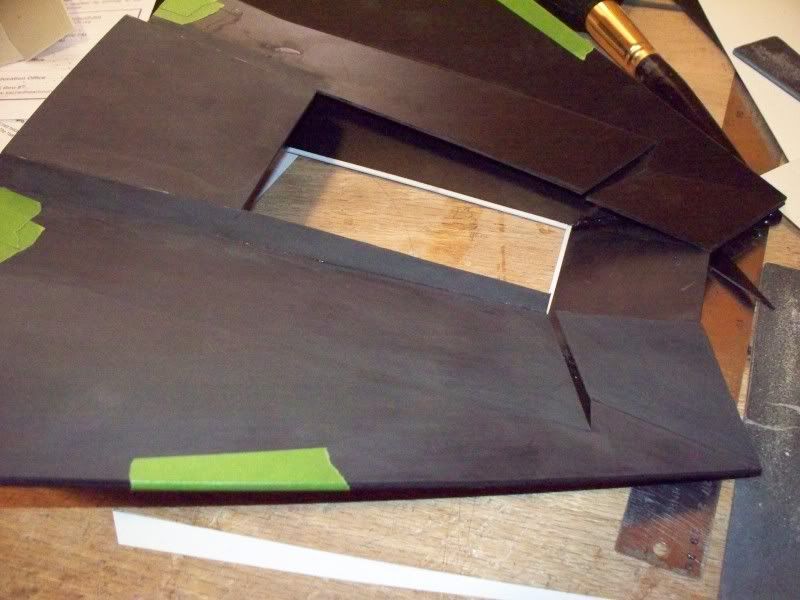

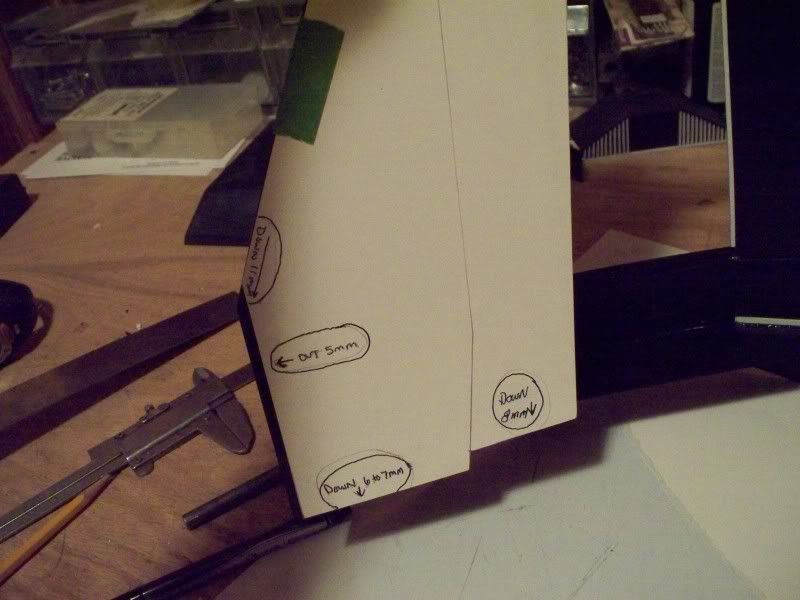

Did the above templete fit......NO and i knoew it

wasnt going to!LOL But as you can see i took some

corrective measurements and left the notes on the 1st

attempt.

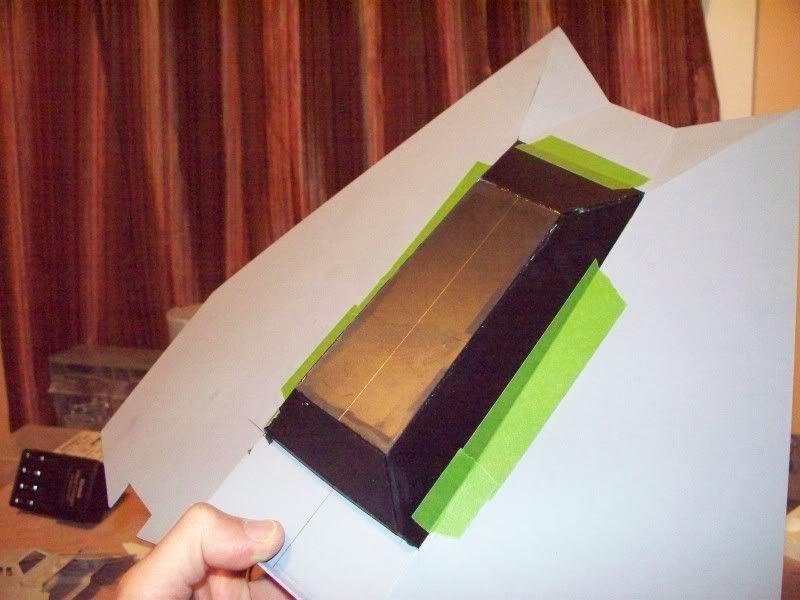

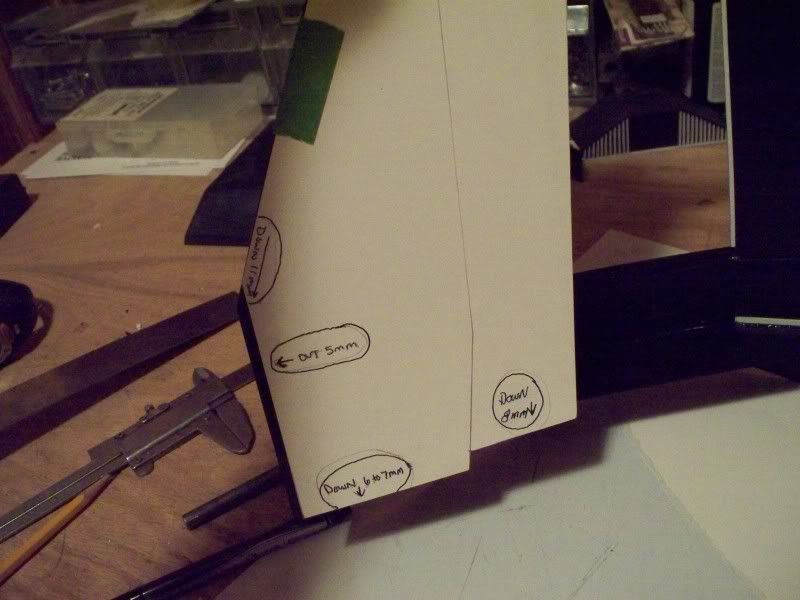

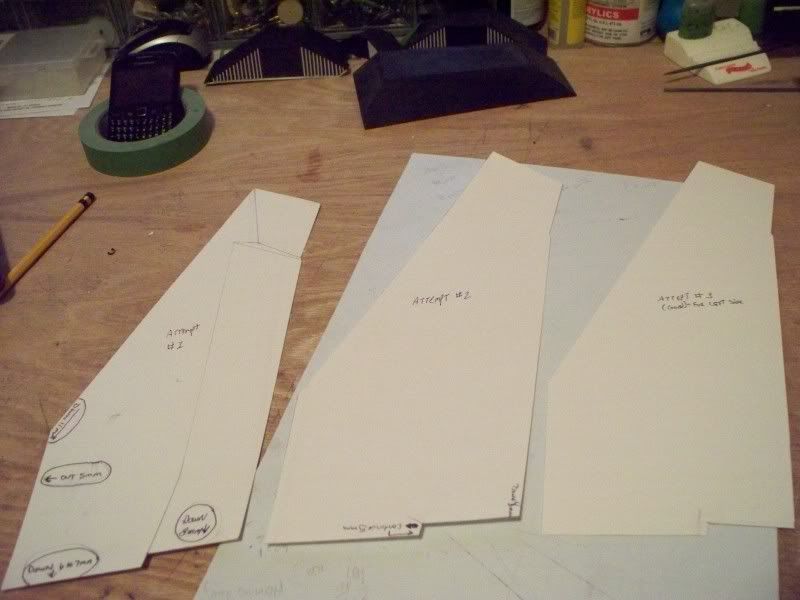

Ok 2nd attempt did that work.........ah No but again

dialing it in, again you can see the notes for change

only 2 this time!!!LOL

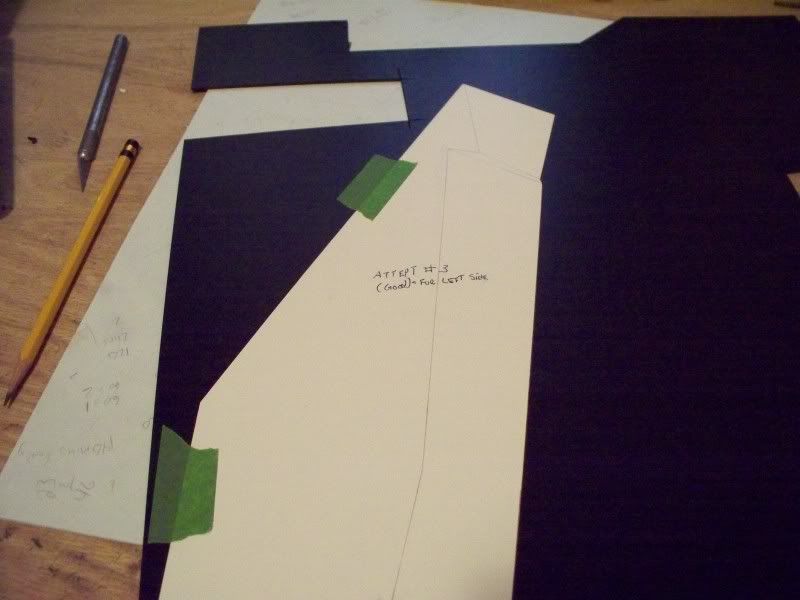

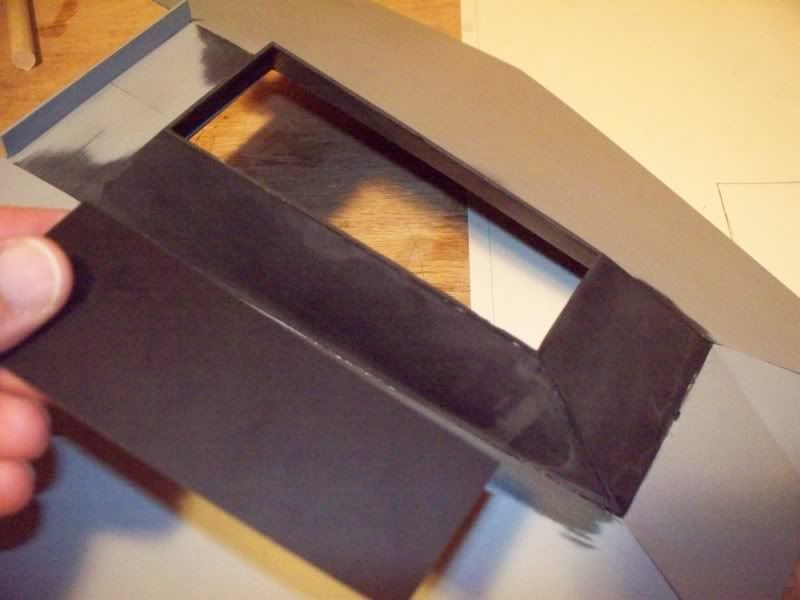

The 3rd attempt is good 3x's a charm must be something

to that saying eh?:lol Personally i think 1st time is a charm

but ......hey!

Ah ya the lower hull is one of those

things i go into expecting to get wrong......

at least a few times! But using some damage control

and taking notes helps, so does making the corrections

with cheap media.......like paper(if your a tree you

are probably not laughing right now.....sorry:angel)

Any way first pic is not the lower hull but the

last pic of the canopy build.

if you dont have one of these tools get one,

and use it to cheat as much as you can, as

you see me doing here to help figure out the

angles on the lower hull. Ah ya Micro Mark

has them if your considering.:thumbsup

Moving along taking measurements and scaling them up

to have a decent looking template....

Did the above templete fit......NO and i knoew it

wasnt going to!LOL But as you can see i took some

corrective measurements and left the notes on the 1st

attempt.

Ok 2nd attempt did that work.........ah No but again

dialing it in, again you can see the notes for change

only 2 this time!!!LOL

The 3rd attempt is good 3x's a charm must be something

to that saying eh?:lol Personally i think 1st time is a charm

but ......hey!