Thanks guys small update.

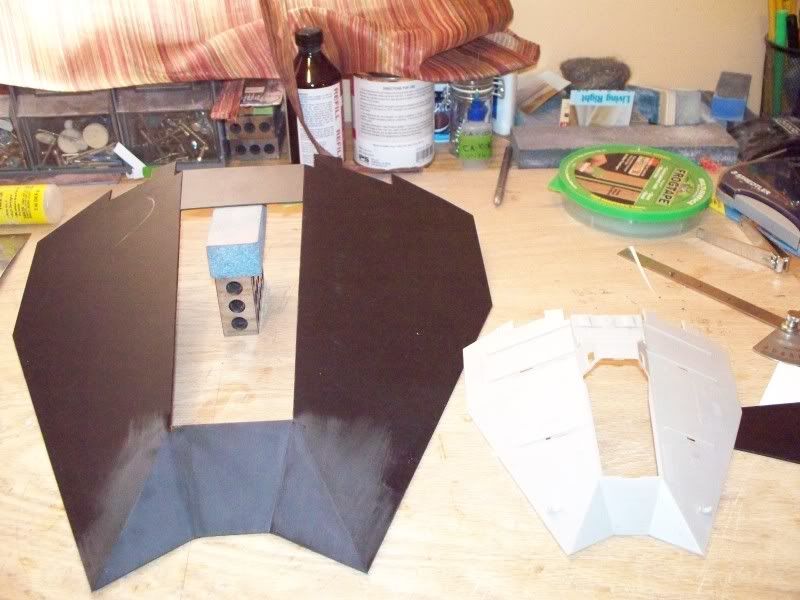

I want to start using some solvents

to weld projects, in a way it makes

or forces you to be a little cleaner

with seams.Where the CA glues

will fill gaps they dry fast and

brittle, so for the speeder i am

really going to try to get away

from this. I pickrd up a can of

"Weld On 3" works great, i

dispense it out of a 27 gage

needle applicator.With this

size applicator there is basicaly

no odor.....that works for me!:thumbsup

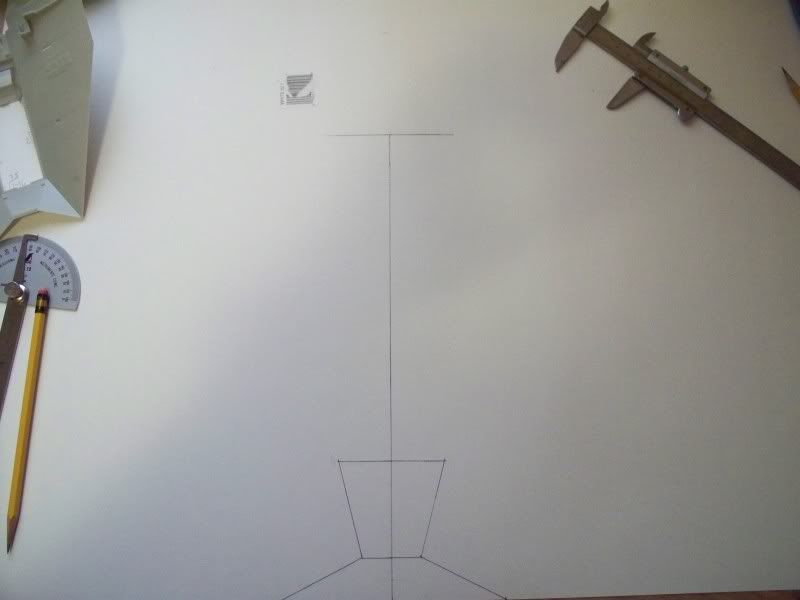

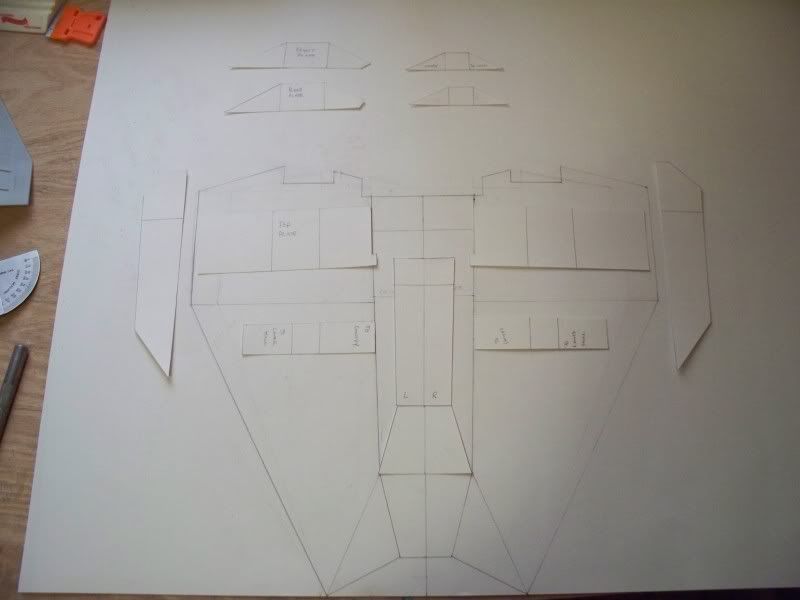

I took the hull plan template and just

fillet it up.

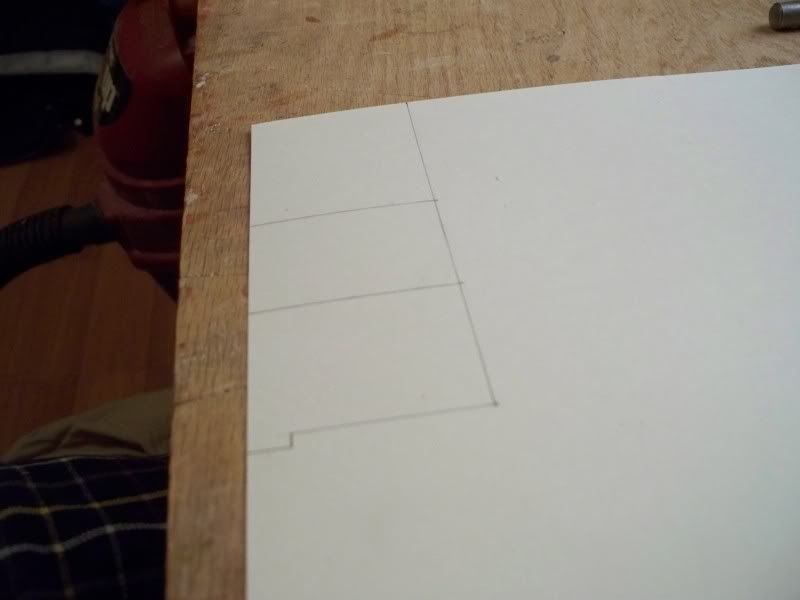

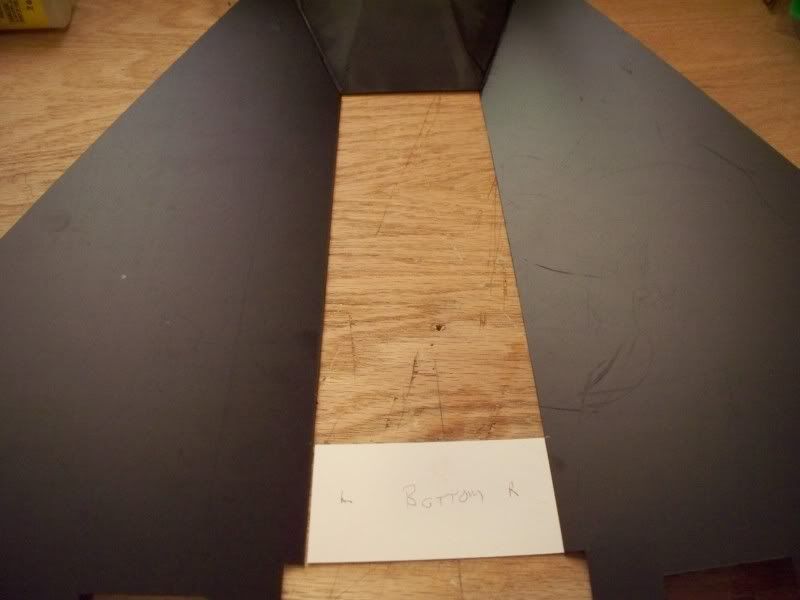

For the front clip piece in this photo

i just scored the reference lines

on the back side, and carefully

worked it until they split open,

but not enough to break it into

sections. The "opened" reference lines

on the back side are then filled with

the thick CA glue, this makes for a

100% seamless seems on the front.

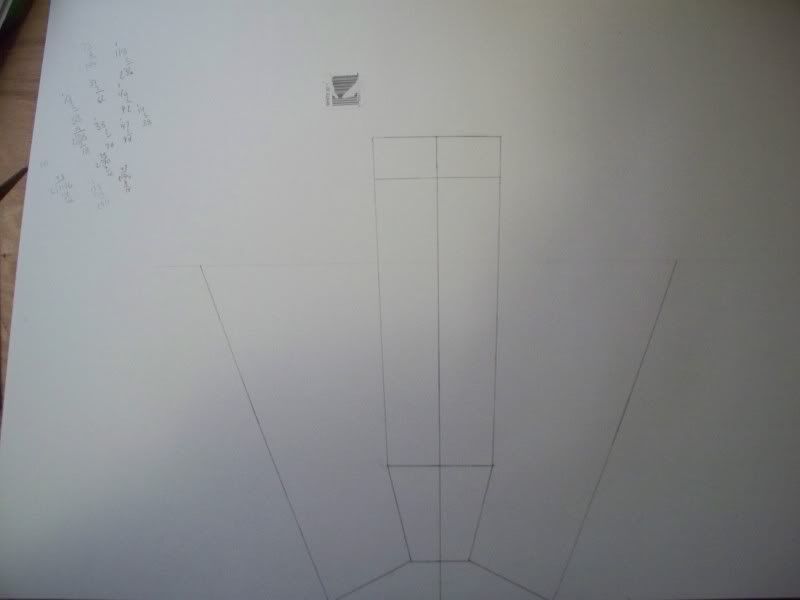

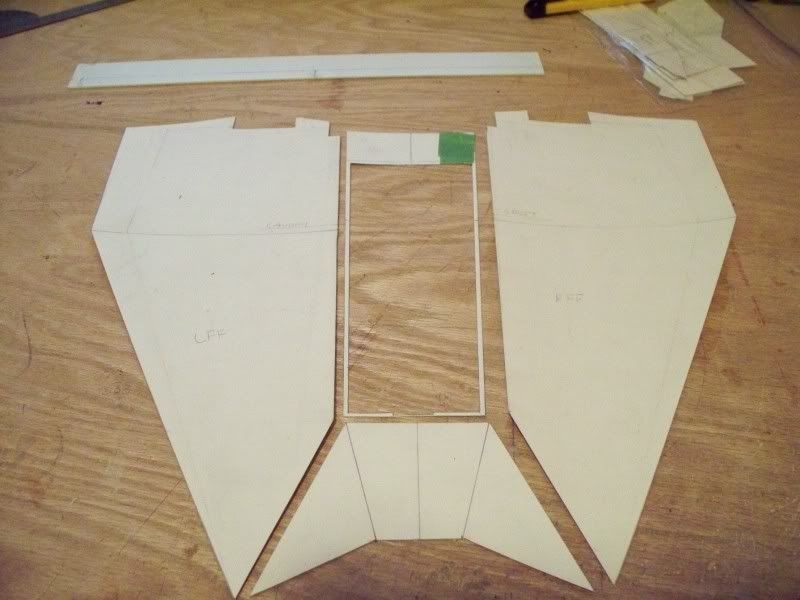

To get tight seems where the hull halves

meet the front clip, i sanded the leading

edges at angles then i was abke to use'the solvent

to join the plastic. I will get a litle cleaner with the

solvent, but as you can see on the left after it evaporates

it is easily sanded away.

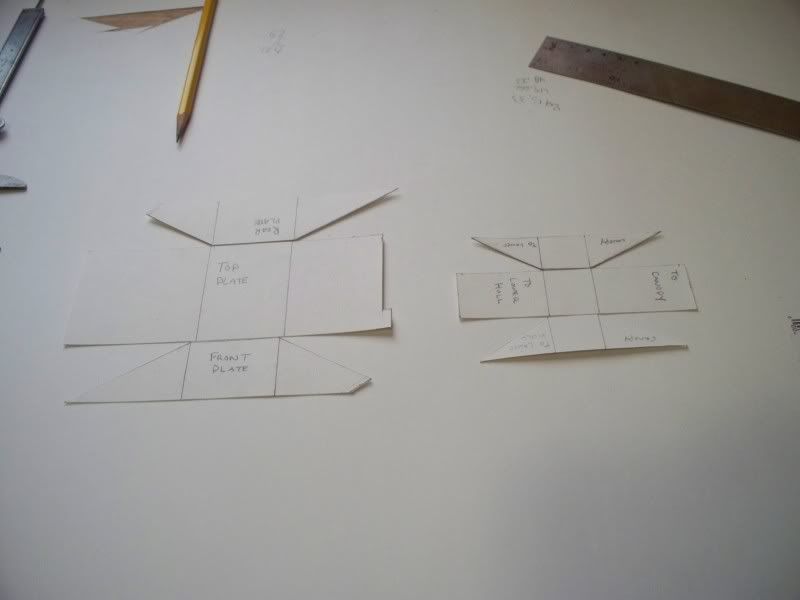

I wanted to knock out one of the rear boxes, I added

the small strip styrene to the bottom of the front plate

first.Then i cut the heat fins and trimmed them before

fitting the front plate to the top plate.

Small mock up ....

thumbsup

thumbsup