Not my first SS build but i am no pro. I enjoy building things and finished my Y-wing last year. I still do not have the guts to tackle my Pyro X-wing nor my Tie so how about another 3D print based build.

My plan was to find a SS 3D model to learn how to resin print with. I was given an Elegoo Mars and needed an excuse to use it. I also have good friends who build large format industrial 3D printers. Between the two of them why not tackle another Star Wars OT model. At first i was going to do the escape pod but settled on the Snowspeeder.

Large scale 3D printing is not free so after some horse trading i had a deal to 3D print all the parts that would not fit on my ultimaker.

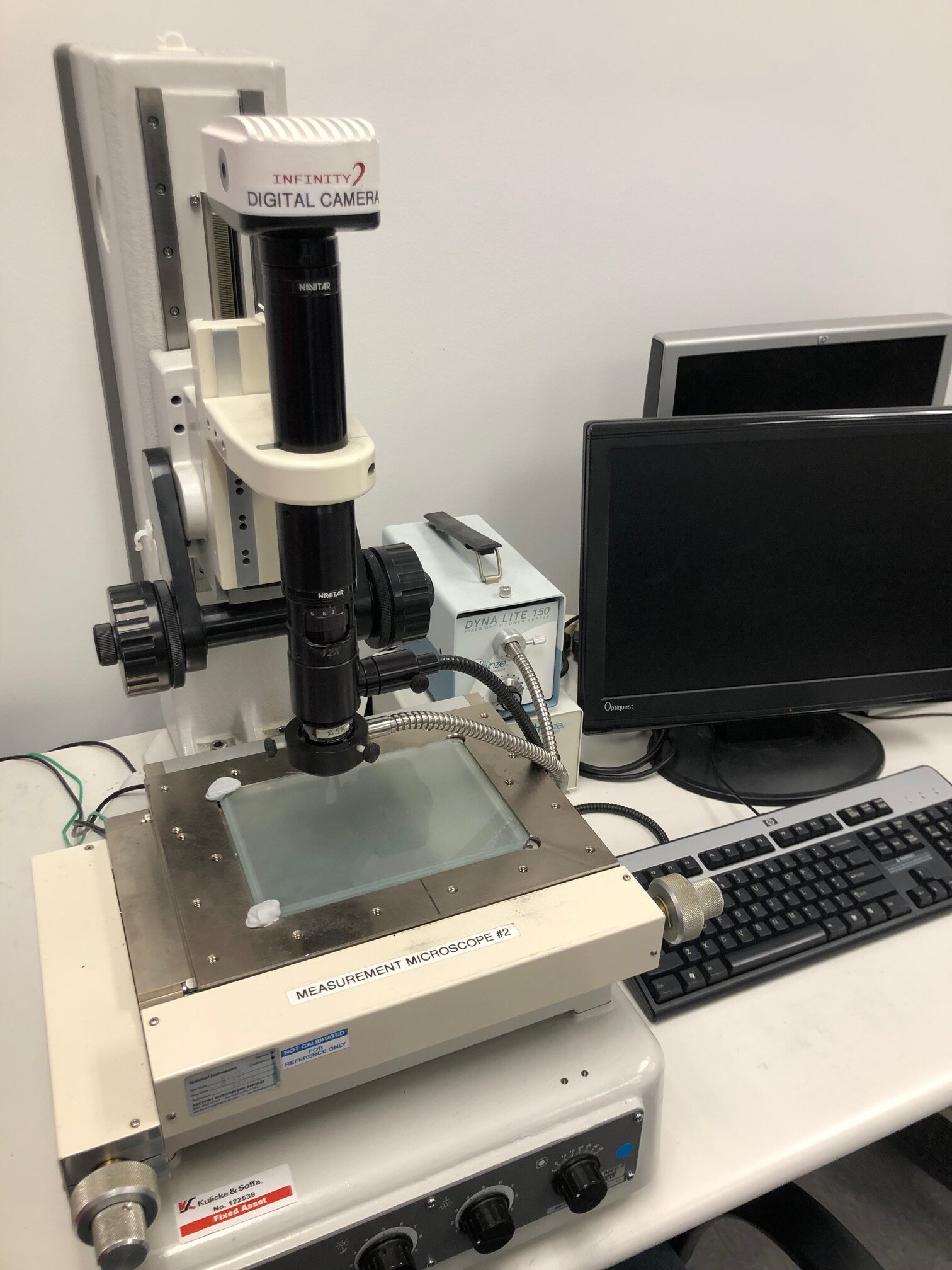

One surplus measuring microscope for a few large pieces of plastic. Good deal for both parties. sort of...

I did not realize how wonky the flat panels would be on the print. Great for what the market they are serving but not so great for a SS model. I will be thinking quite a bit about my next steps.

My plan was to find a SS 3D model to learn how to resin print with. I was given an Elegoo Mars and needed an excuse to use it. I also have good friends who build large format industrial 3D printers. Between the two of them why not tackle another Star Wars OT model. At first i was going to do the escape pod but settled on the Snowspeeder.

Large scale 3D printing is not free so after some horse trading i had a deal to 3D print all the parts that would not fit on my ultimaker.

One surplus measuring microscope for a few large pieces of plastic. Good deal for both parties. sort of...

I did not realize how wonky the flat panels would be on the print. Great for what the market they are serving but not so great for a SS model. I will be thinking quite a bit about my next steps.