-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Limited Run RUN CLOSED * DL-44 ESB Blaster Machined Parts Set * RUN CLOSED

- Thread starter Boba Debt

- Start date

Lichtbringer

Master Member

Scott,if i may chime in, parting with a live center is not the best idea.

Let them drop (maybe on some soft material if it can be done safe) - or if the part has a hole, use a suiting rod in a drillchuck to keep them from falling.

Let them drop (maybe on some soft material if it can be done safe) - or if the part has a hole, use a suiting rod in a drillchuck to keep them from falling.

JLinNY

Sr Member

Boba,

I ordered a Hoth hider with the two rows of knurling, would it be possible to change that to either a single row or no knurling? It has nothing to do with the workmanship, but after seeing it in person I am not crazy about the look of the two rows of knurling.

The other hiders look sweet.

As far as the knobs go, unfortunately I don't have anything to add photo wise. I don't think they look terrible, but not perfect either. I could live with it though. All I can say is get it as best as you can. I will go with what the group decides.

I ordered a Hoth hider with the two rows of knurling, would it be possible to change that to either a single row or no knurling? It has nothing to do with the workmanship, but after seeing it in person I am not crazy about the look of the two rows of knurling.

The other hiders look sweet.

As far as the knobs go, unfortunately I don't have anything to add photo wise. I don't think they look terrible, but not perfect either. I could live with it though. All I can say is get it as best as you can. I will go with what the group decides.

Thanks. I don't do that anymore, but at the time (2 years ago or more), this was my very old lathe, and the gibs were SO loose and terrible it was the only way to part material. It had too much play and would bind if I didn't. It was scary.

Now with my new lathe I don't have that problem and aluminum parts like butter very easily.

Now with my new lathe I don't have that problem and aluminum parts like butter very easily.

Boba Debt

Master Member

That hole in the knob the shop made is definitely countersunk, to aid in the threading. I don't think it needs to be as deep as it is, but it's most certainly countersunk. Clear as day.

Scottjua posted those photos way back in December of 2014, showing the difference in height between the angled section and the straight section.

I think we all understand how much one little detail can throw off the look of a part, which is why we're all here, discussing all these little details on tiny parts, trying to get it right.

This is the first I've heard that you had correspondence with someone involved with LFL, but it makes no real difference to me. Unless they have the parts in hand, the fact that they are closely involved with LFL doesn't add any more weight to their claims, as far as I can tell. Saying something is virtually identical isn't the same as saying something is completely 100% identical, just as "close enough" isn't the same as totally accurate. That's like saying an MGC broomhandle Mauser is virtually identical to a C96 from 1930. Or the newer Armitage Shanks handwheel is "virtually identical" to the older handwheel that was used on the original lightsaber prop. They're close, but they're simply not the same

I'm not the only one who believes they see something very different when comparing the fundamental shapes of the Bespin and Hoth flash hiders. I think the one Lichtbringer made is the closest anyone has come.

All that said, I'm gonna let the flash hider issue go, and chalk it up to simple lack of communication and specificity on all our parts.

There isn't a counter sink on the drawing of the scope bracket disk so I doubt they would include one in the code but I'll double check with the shop.

I just went through both threads and I didn't see this picture posted in either

If I had seen that picture it would have made my job easier

I'm a bit put off by how easily you dismiss my source. he is a very valuable member of this forum and is a terrific resource.

He has access to more info then we will ever know about and he has produced licensed products for LFL. He spent a lot of time reverse engineering the blue prints I sent to him, comparing them to crystal clear photos that he had access to. And he did it without asking for any compensation.

I have never seen Lichtbringer's version but if you post a link I'll check it out.

I think they tried to replicate my prototype knob's knurl. But I used a straight knurl and then hit the edges with a file to soften them up, which is why they look like ()

I discussed this with you via telephone before I bought the sample from you and you seemed ok with me using it for the project, I hope I didn't misunderstand???

Boba,

I ordered a Hoth hider with the two rows of knurling, would it be possible to change that to either a single row or no knurling? It has nothing to do with the workmanship, but after seeing it in person I am not crazy about the look of the two rows of knurling.

The other hiders look sweet.

As far as the knobs go, unfortunately I don't have anything to add photo wise. I don't think they look terrible, but not perfect either. I could live with it though. All I can say is get it as best as you can. I will go with what the group decides.

I am sorry to say but all of the flash hiders are machined.

I ordered 10 extra units but 5 are Bespin and the other 5 are the 2 Row Hoth variant.

The knurl on these should be super light and it will be possible to get rid of most of it with a light sanding. I think you will be very happy with it once it is sanded and weathered.

It looks like the photos have since been removed, but they were definitely there.

He had waited to get prints of them in the mail IIRC, then he posted them after Xmas.

If you go back through the thread, you'll see the photo of Lichtbringer's hider.

It concerns me that all these photos were/are in the thread that you yourself keep referring us to, and you claim you've never seen them.

I'm sorry you're put off. It's not my intention to offend. I'm speaking plainly. We all see things a little differently, and I believe it's entirely possible that your source sees something different when he/she looks at the crystal clear photos he/she has access to, compared to what I and a few others see when we compare the shapes of the different flash hiders.

He had waited to get prints of them in the mail IIRC, then he posted them after Xmas.

If you go back through the thread, you'll see the photo of Lichtbringer's hider.

It concerns me that all these photos were/are in the thread that you yourself keep referring us to, and you claim you've never seen them.

I'm sorry you're put off. It's not my intention to offend. I'm speaking plainly. We all see things a little differently, and I believe it's entirely possible that your source sees something different when he/she looks at the crystal clear photos he/she has access to, compared to what I and a few others see when we compare the shapes of the different flash hiders.

Last edited:

I discussed this with you via telephone before I bought the sample from you and you seemed ok with me using it for the project, I hope I didn't misunderstand???

oh no not at all. I know that. I was just trying to articulate why I thought they went with that cut rather than a traditional knurl

Boba Debt

Master Member

I just spent 50 minutes looking through both threads.

I did not see any post that showed Lichtbringer's hider.

I finally found Scott's original post in which he posted the very clear image of the Bespin Scope Bracket disk. It was at the bottom of page 7 of the old discussion thread. I must have missed it at that time because he posted it on Jan 10th and I didn't post until Jan 13th.

If he posted it in December I can't find it and by the time he posted it in January we had already decided on the 50/50 split for the disk.

You say "It's not my intention to offend" right after you post this comment - "It concerns me that all these photos were/are in the thread that you yourself keep referring us to, and you claim you've never seen them"

That is a very offensive comment. What is your concern? Why do you think I am juts "claiming" to not see the images?

At this time this was happening I was working 12 hours a day, 7 days a week on the F-35 program yet I still managed to keep this project on track.

I can't help it if everyone does not read every post or every email.

There are very clear drawings of the current parts in the first and second post of this thread and there are very clear pictures of the parts from my original run in the same posts.

I try to keep everyone in the loop and I know I informed everyone via email of every finalized drawing so I don't understand why the shape of the Hoth Flash Hider and the 50/50 split are issues now.

I'm going to do an email blast for the Bespin Scope Bracket Disk because I need a majority consensus before I ask the shop to change their drawing and code.

Hopefully I will receive enough replies to know what the group wants.

- - - Updated - - -

To be honest I am at a total loss as to why they machined each slot instead of doing a knurl.

I discuss these parts at great length with the shop but something must have gotten lost in the translation.

I did not see any post that showed Lichtbringer's hider.

I finally found Scott's original post in which he posted the very clear image of the Bespin Scope Bracket disk. It was at the bottom of page 7 of the old discussion thread. I must have missed it at that time because he posted it on Jan 10th and I didn't post until Jan 13th.

If he posted it in December I can't find it and by the time he posted it in January we had already decided on the 50/50 split for the disk.

You say "It's not my intention to offend" right after you post this comment - "It concerns me that all these photos were/are in the thread that you yourself keep referring us to, and you claim you've never seen them"

That is a very offensive comment. What is your concern? Why do you think I am juts "claiming" to not see the images?

At this time this was happening I was working 12 hours a day, 7 days a week on the F-35 program yet I still managed to keep this project on track.

I can't help it if everyone does not read every post or every email.

There are very clear drawings of the current parts in the first and second post of this thread and there are very clear pictures of the parts from my original run in the same posts.

I try to keep everyone in the loop and I know I informed everyone via email of every finalized drawing so I don't understand why the shape of the Hoth Flash Hider and the 50/50 split are issues now.

I'm going to do an email blast for the Bespin Scope Bracket Disk because I need a majority consensus before I ask the shop to change their drawing and code.

Hopefully I will receive enough replies to know what the group wants.

- - - Updated - - -

oh no not at all. I know that. I was just trying to articulate why I thought they went with that cut rather than a traditional knurl

To be honest I am at a total loss as to why they machined each slot instead of doing a knurl.

I discuss these parts at great length with the shop but something must have gotten lost in the translation.

Last edited by a moderator:

Last edited:

Boba Debt

Master Member

I saw that and to be honest I thought that was an incomplete attempt at a flash hider.

I don't know what his general dimensions are but they do not look to far off from mine.

I also do not understand why there is a large concave transition from the body to the cone.

This picture also doesn't show if the front and back are counter bored or if it has the barrel through design that I came up with

As far as I know, it has not been done by anyone else.

I don't know what his general dimensions are but they do not look to far off from mine.

I also do not understand why there is a large concave transition from the body to the cone.

This picture also doesn't show if the front and back are counter bored or if it has the barrel through design that I came up with

As far as I know, it has not been done by anyone else.

Boba Debt

Master Member

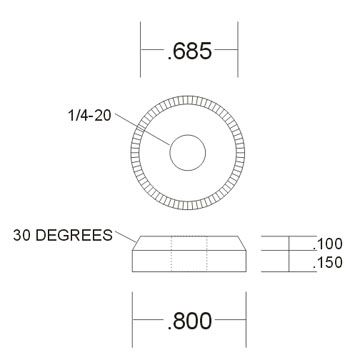

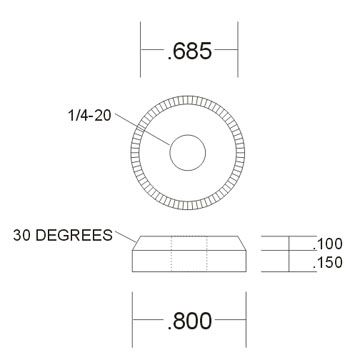

THE SHOP HALTED PRODUCTION ON THIS PART UNTIL WE FIGURE OUT THE KNURL/SLOTS ON THE RIM

But looking at this picture Scott Posted the 50/50 height split does not look right

View attachment 530421

I think this drawing is more accurate:

We are lucky that this production was halted on this part.

I don't mind changing this but I need a group consensus before I ask the shop to change their drawings and code. They know they have to fix the slots but they are not expecting me to change the dimensions.

But looking at this picture Scott Posted the 50/50 height split does not look right

View attachment 530421

I think this drawing is more accurate:

We are lucky that this production was halted on this part.

I don't mind changing this but I need a group consensus before I ask the shop to change their drawings and code. They know they have to fix the slots but they are not expecting me to change the dimensions.

I like 006 as well but will go with group consensus

Mara Jade's Father

Master Member

I like the new drawing.

I like 006 as well but will go with group consensus

I Like Ike.

The 006 drawing looks closer to me.

Jason

Jason

Solos blaster

Sr Member

I agree with 006 looking better as well.

Curmudgeon

Well-Known Member

I prefer accuracy but I'll trust the blaster experts with this choice

I like the new design better, but would be fine with either. My preference leans towards it because it happens to look right in that picture. But until I saw that, I was convinced it was 50/50. Sigh.. Such a pain not having better reference!

Also, I'd just like to thank BobaDebt for working so hard on all of this. I know it's a complex and daunting project.

I also think a certain member should perhaps be a little less condescending and rude.. Because it's getting on my nerves and it's not even directed at me.

Also, I'd just like to thank BobaDebt for working so hard on all of this. I know it's a complex and daunting project.

I also think a certain member should perhaps be a little less condescending and rude.. Because it's getting on my nerves and it's not even directed at me.

Similar threads

- Replies

- 4

- Views

- 394

- Replies

- 0

- Views

- 478

- Replies

- 9

- Views

- 1,388

- Replies

- 53

- Views

- 7,907

- Replies

- 10

- Views

- 2,101