Has anyone here attempted it?

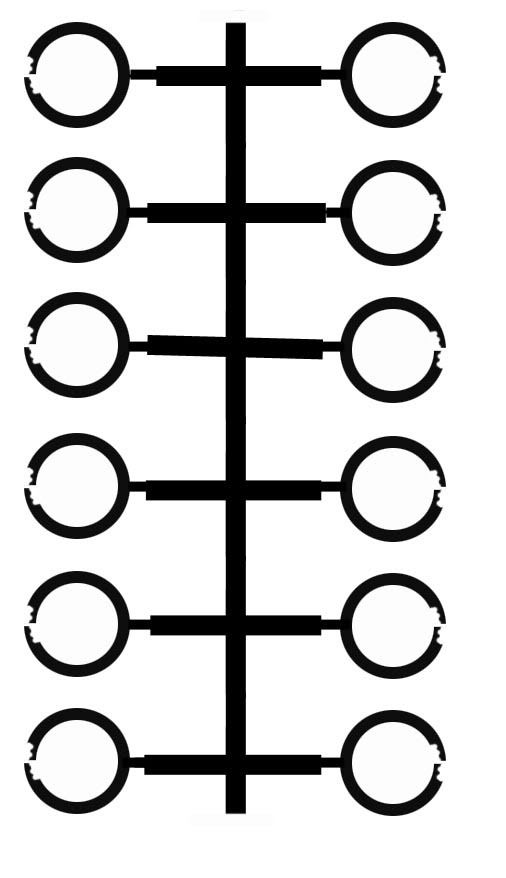

I've been considering making my own chain-mail type armor for some time now for various fantasy/medieval related projects, and have been unsatisfied with the results that I've seen with the hackneyed method of cutting PVC pipe down.

However...

In my search...I was browsing the WETA website and I found a link for their WETA/TENZAN mail group. Apparently, it would seem that they used a specialized injection molding process to form their rings.

There were no further details about production.

Although: there was a small blip about the promise of providing their products to organizations beyond film, such as theatre and REENACTMENT GROUPS. Though they say it is planned for the future, I am not particularly optimistic about the timeliness of these plans.

So here is my question to all you experienced film-prop-costume-maker-officionados... Could it be done in the SAME way? OUTSIDE of WETA?? HAS it been done, to the same standard? HOW would it be done, and WHO would be capable if the task was assigned?

Link to WETA/TENZAN here... http://www.wetanz.com/armour-chainmaille

Feel free to discuss and share your thoughts.

P.S. PLEASE DO NOT re-link me to alleyscratch or any website that uses the same technique unless it's for the sake of technique comparison and discussion. Although I commend them for their efforts and their ability (as well as their persistence in the technique), it simply does not look the same. Until PVC mail can be indistinguishable from the real metal thing (Or likewise, WETA's product), I will never be satisfied. The technique of making rings from PVC pipe just wont' cut it for me.

I've been considering making my own chain-mail type armor for some time now for various fantasy/medieval related projects, and have been unsatisfied with the results that I've seen with the hackneyed method of cutting PVC pipe down.

However...

In my search...I was browsing the WETA website and I found a link for their WETA/TENZAN mail group. Apparently, it would seem that they used a specialized injection molding process to form their rings.

There were no further details about production.

Although: there was a small blip about the promise of providing their products to organizations beyond film, such as theatre and REENACTMENT GROUPS. Though they say it is planned for the future, I am not particularly optimistic about the timeliness of these plans.

So here is my question to all you experienced film-prop-costume-maker-officionados... Could it be done in the SAME way? OUTSIDE of WETA?? HAS it been done, to the same standard? HOW would it be done, and WHO would be capable if the task was assigned?

Link to WETA/TENZAN here... http://www.wetanz.com/armour-chainmaille

Feel free to discuss and share your thoughts.

P.S. PLEASE DO NOT re-link me to alleyscratch or any website that uses the same technique unless it's for the sake of technique comparison and discussion. Although I commend them for their efforts and their ability (as well as their persistence in the technique), it simply does not look the same. Until PVC mail can be indistinguishable from the real metal thing (Or likewise, WETA's product), I will never be satisfied. The technique of making rings from PVC pipe just wont' cut it for me.

Last edited: