You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OdiWan72´s prop family

- Thread starter OdiWan72

- Start date

What printer did u use to print this if you don’t mind me asking? MJF?

Yeah, I just noticed the real scope on that one. Damn scope costs twice as much as the rest of the kit I bet! So cool.

Yeah...these damn OO scopes go for quite a bit of money. I had the chance to buy one without the mount (used for Lee Harvey Oswald´s Kennedy assasination rifle) for a decent price some years ago.

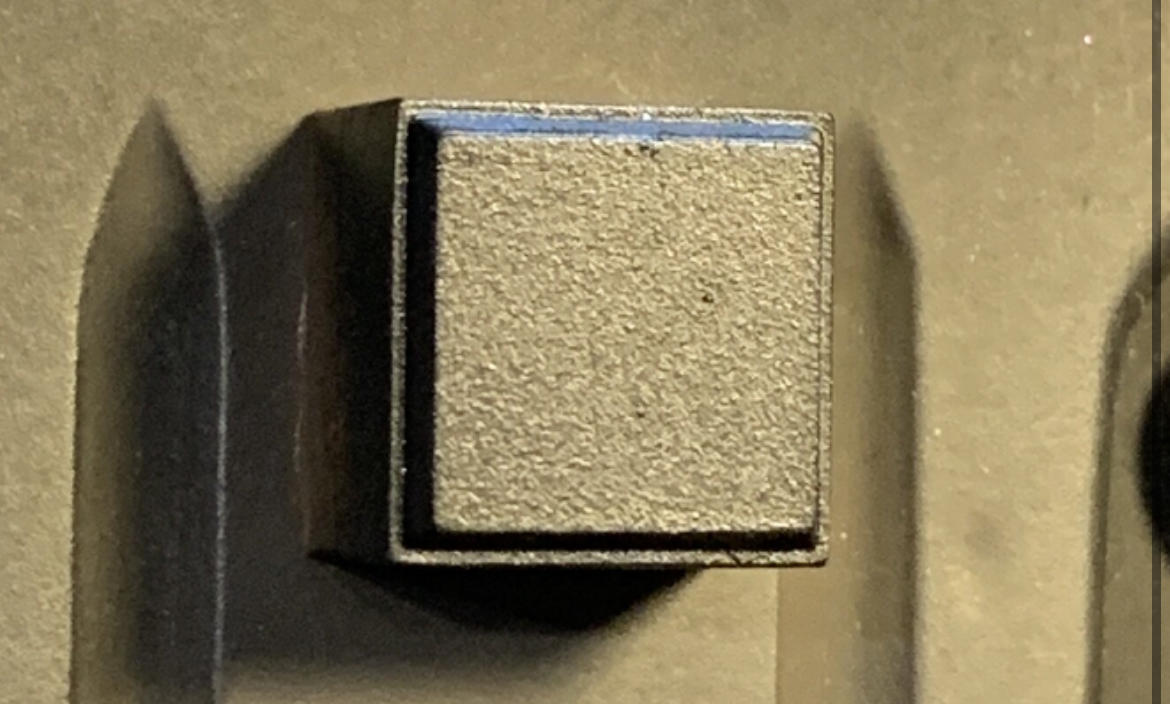

What printer did u use to print this if you don’t mind me asking? MJF?View attachment 1534792

These are resin printed Field Mashall knobs, based on measurements taken from an actual vintage RS button

The texture is a result of the painting process, the prints itself are smooth

Gorgeous, especially the SE-14! I was excited when they were in R1, but it’s lame that they’re so ubiquitous now. Is that a Sean Morgan kit? What's the scoop with the rectangular marks on the right side of the SE-14, do those show up in some pics of the original?

The buttons look good on the Merr Sonn, nearly impossible to find real ones (my personal quest lol). Plus the damn DIN plug, which you have also got correct (of course!)

Thanks Pedro

The marks on the blasters right sight are probably from the mounts, that were attached on the Evazan blaster.

I think they made some resin casts of the Rexim and dressed it up as -reserve- Evazan blasters. When they needed a "pistol" for the TK photoshoot, they painted one of these casts black, but decided to remove the mounts/ double scope and added the Ohio Ordinance scope instead.

Just like the ANH DH17, the TK SE14 is poorly cast and undersized compared to the actual Rexim FV4...

I liked the idea of building a more idealized "hero" SE14, that the prop dept. molded (as I did with my ANH DH17 and the ESB E11).

The correct DIN plug pops up on ebay.co.uk from time to time

jkno

Legendary Member

The blasters look fantastic!!Small update...

Had a bit of time to spend today and decided to tweak some blasters.

First is my interpretation of the MS Power 5, that I added 3D prints of the impossible to find vintage RS pushbuttons to. In addition to that, I modified the original Transcriptor knobs on the blasters left side to look more like what was used on the actual prop.

View attachment 1533840View attachment 1533841View attachment 1533842View attachment 1533843View attachment 1533844

Next in line was my idealized SE14 Stormtrooper blaster.

I chose NOT to paint it in that boring satin black, but to give it a more realistic paintjob.

Also added the wires and the RS button to the magwell.

View attachment 1533845View attachment 1533846View attachment 1533847View attachment 1533848

Will see what smaller tasks I can get done in the near future.

Thx for looking!

These are resin printed Field Mashall knobs, based on measurements taken from an actual vintage RS button

The texture is a result of the painting process, the prints itself are smooth

Thanks Obi! Why the added texture.. aren’t the buttons smooth?

Also are you sure it’s not nylon? FM unless he’s changed his process uses SLS shapeways prints.

I am sure…had a special agreement with Chris, so mine are resinThanks Obi! Why the added texture.. aren’t the buttons smooth?

Also are you sure it’s not nylon? FM unless he’s changed his process uses SLS shapeways prints.

The standard ones in his shop are probably different?!…

Texture was result of the painting process…not necessarily intentional, but since most props have crude rattlecan paintjobs, it suits the build imho

Was it originally white or black in color?

Black plastic with colored semi-transparent covers (since they were meant to be illuminated).Was it originally white or black in color?

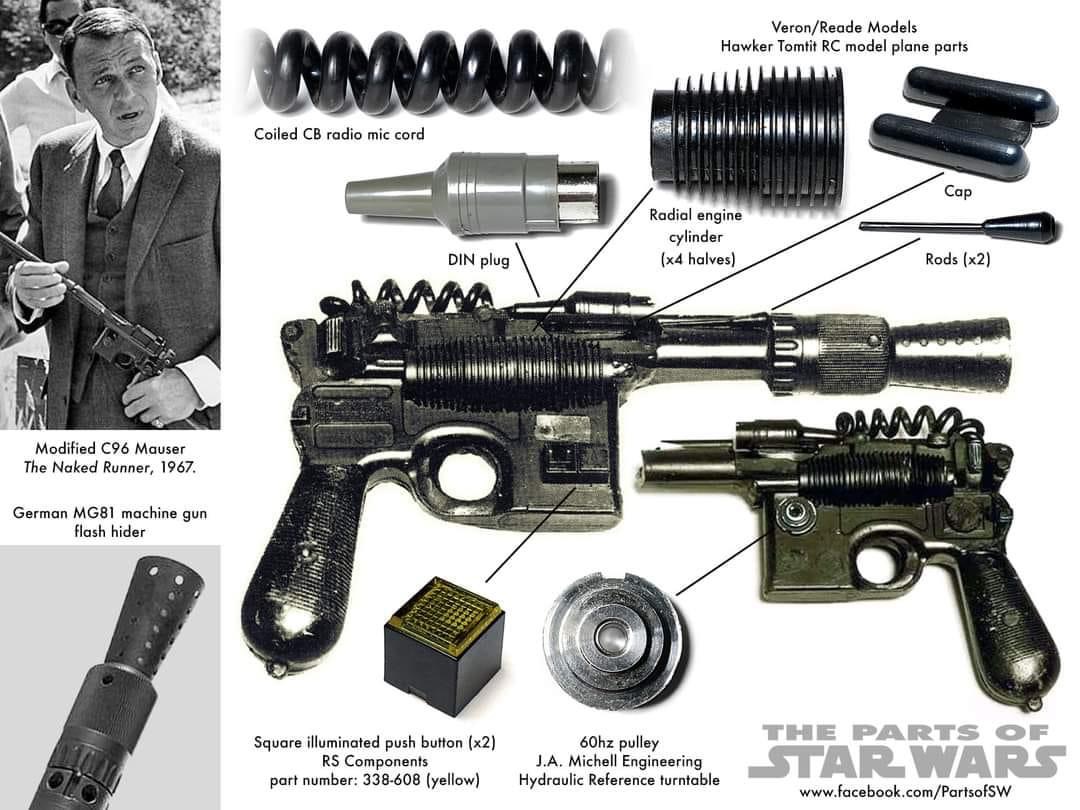

POSW has a pic of these on their diagramm for the Merr-Sonn and the SE14

Gotchya! This pic from POSW u mean ya?

Check ‘em, my Crown Jewels! I wish I could get more, didn’t get enough for my own builds. I’ll probably work up an accurate 3d model one of these days, though Chris seems to have the printed replica thing covered.

Don’t touch these. Actually, don’t even look at them.

Don’t touch these. Actually, don’t even look at them.

Attachments

You found them????? WOW…details pleaseCheck ‘em, my Crown Jewels! I wish I could get more, didn’t get enough for my own builds. I’ll probably work up an accurate 3d model one of these days, though Chris seems to have the printed replica thing covered.

Don’t touch these. Actually, don’t even look at them.

There’s not much to tell I’m afraid, I wish there was! I scoured the Internet for hours and hours over about 2 years looking for them. I lucked out found 6 via eBay, the UK seller’s father used to work at RS apparently, and had these and a variety of little components of use to us. Nice fellow, and he knows we need them should more turn up (not counting on it alas).

I did get a green rectangular button cap, like the original Imperial officers wore…but green. It does have an interesting fresnel pattern behind the colored piece, on the white diffuser. Been trying to decipher that for a while too…

I did get a green rectangular button cap, like the original Imperial officers wore…but green. It does have an interesting fresnel pattern behind the colored piece, on the white diffuser. Been trying to decipher that for a while too…

A new addition to the collection…

Special thanks to CWOODREPLICAS for helping me to get this item over to Germany!

The original large bulb was destroyed during shipping, but the rest made it through ok.

I see a restauration project on the horizon

Special thanks to CWOODREPLICAS for helping me to get this item over to Germany!

The original large bulb was destroyed during shipping, but the rest made it through ok.

I see a restauration project on the horizon

Need some input from you guys please...

Like I already wrote, I intend to restore the lamp.

The round base is missing (just like on the lamps used in the ANH Tatooine hangar) and there are several rusted areas. The outer paint is bleached out from decades of being exposed to the elements.

Restoring would involve to completely strip it, have all metal parts bead-blasted, repaint it and convert the lamp for use with 220V voltage.

NOW the question is: Restoration YES or NO?

Shall I rework it to its former glory or keep it the way it is and simply clean it/ convert the electrical components and add a new base???

What´d you guys recommend?

Like I already wrote, I intend to restore the lamp.

The round base is missing (just like on the lamps used in the ANH Tatooine hangar) and there are several rusted areas. The outer paint is bleached out from decades of being exposed to the elements.

Restoring would involve to completely strip it, have all metal parts bead-blasted, repaint it and convert the lamp for use with 220V voltage.

NOW the question is: Restoration YES or NO?

Shall I rework it to its former glory or keep it the way it is and simply clean it/ convert the electrical components and add a new base???

What´d you guys recommend?

Disassembly begun, during which I came across something cool

It‘s the copper mounting plate for the bulb holder…look what I found in its backside! Looks like a printing plate (it‘s mirrored) from „Broadbent and Company“, a UK company which was founded in 1864

Look at all these awesome engravings!!!

Were these lamps built in the UK after all?

lonepigeon need your expertise please

It‘s the copper mounting plate for the bulb holder…look what I found in its backside! Looks like a printing plate (it‘s mirrored) from „Broadbent and Company“, a UK company which was founded in 1864

Look at all these awesome engravings!!!

Were these lamps built in the UK after all?

lonepigeon need your expertise please

Attachments

hey Markus  I would probably restore it. If it's a carefull restauration intending to give it back its full glory with modern eletric components, I wouldn't see the harm. Now that is just a personnal point of view and you'll probably get 50% people saying that and the other half being against doing anything to that vintage lamp. It all comes down to what you prefer in the end I think

I would probably restore it. If it's a carefull restauration intending to give it back its full glory with modern eletric components, I wouldn't see the harm. Now that is just a personnal point of view and you'll probably get 50% people saying that and the other half being against doing anything to that vintage lamp. It all comes down to what you prefer in the end I think

Thanks for your opinion my friend...hey MarkusI would probably restore it. If it's a carefull restauration intending to give it back its full glory with modern eletric components, I wouldn't see the harm. Now that is just a personnal point of view and you'll probably get 50% people saying that and the other half being against doing anything to that vintage lamp. It all comes down to what you prefer in the end I think

I know asking about someones personal, subjective POV is probably not bringing me one step further ... my bad LOL

While disassembly is proceeding, I find more and more areas, which are nearly impossible to simply "clean" while keeping the original finish. Besides of that, there seems to be a lighter layer of paint brushed (!) over the original bright yellow color. Some areas are very rusty, so bead blasting might be my best choice to prepare the lamp parts for a fresh coat of paint.

Maybe I´ll try my hands at (re-)weathering it as part of the restoration

Here´s some more information about the company, which I found engravings of on the copper mounting plate:

1914 - 1945

Broadbent manufactured centrifuges for the production of explosives and chemicals. With a skilled workforce of 500, the company was also commissioned to support the WWII effort by manufacturing ammunition hoists and midget submarines.

No mentions about them being involved in the construction of the BARTOW lamps (which were produced in the USA)

Similar threads

- Replies

- 18

- Views

- 4,401

- Replies

- 130

- Views

- 20,242

- Replies

- 13

- Views

- 3,207