You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NIKE MAG Knockoffs

- Thread starter lint

- Start date

LeExpiredMilk

New Member

I too, had a problem with the flickering lights when they came out of the box, but only on the bubble on one shoe. I resolve it temporarily time to time, by either widening the shoe with my hand and/or pushing in the bubble. However, this may not work for you, depending on the extent of your issue.

I do that from time to time, but it gets frustrating when you just want the damn thing to stay on.

cavx

Master Member

I do that from time to time, but it gets frustrating when you just want the damn thing to stay on.

My EL in my left shoe is doing that now. So soon I will have to open the shoe yet again to repair this.

LeExpiredMilk

New Member

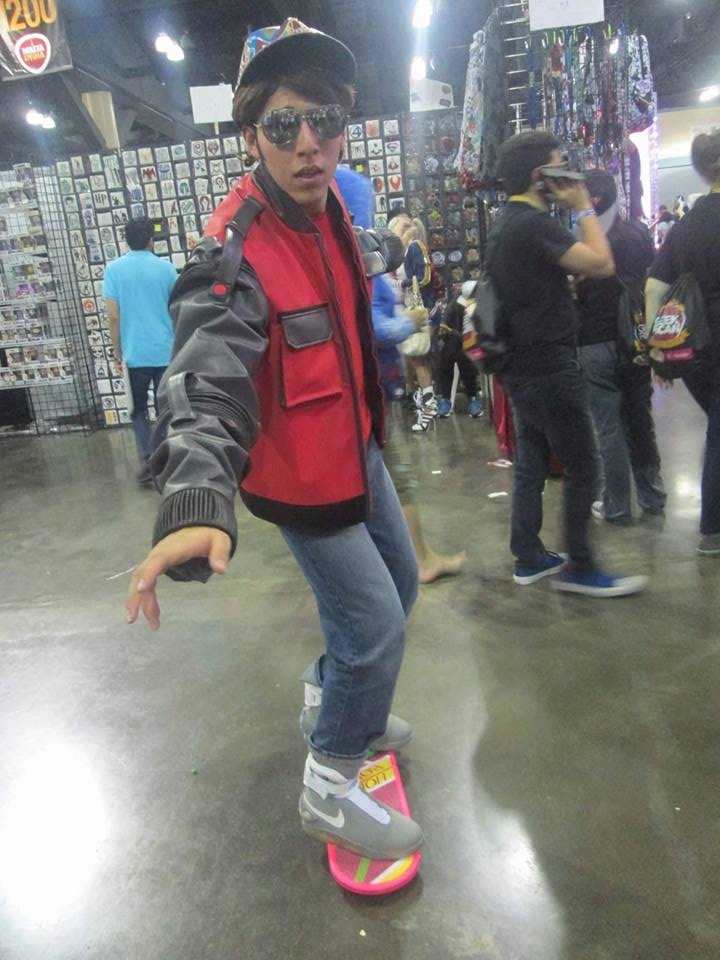

So I cosplayed Marty on Sunday at Puerto Rico Comic Con and it was a hit! I'll post a picture here somewhere. My right shoe had a light that just refused to turn on, but people didn't care. They loved it. I was still pretty bothered by it, and I thought it couldn't get worse. HOOO BOY. I checked the shoes like 5 minutes ago just to find out that the ******** cables on my right shoe broke off and I have no idea where they are. Ain't that swell. Now I have a half functioning pair of Mags. Yippeeee!

LeExpiredMilk

New Member

MrSouthpaw

Sr Member

I have all that same gear. And look almost exactly the same costume-wise when in outfit.

Except, no sunglasses since he doesn't wear them in part 2. And I tight-roll my jeans like the movie.

Except, no sunglasses since he doesn't wear them in part 2. And I tight-roll my jeans like the movie.

cavx

Master Member

There you can see the light that wouldn't turn on. Now the cables are gone. WAT DO?

Time to decide do you want to wear them as a costume shoe or mod them?

So this is the HC jacket?

Since my last attempt was looking, just was like XXXL instead of XL and given the bellows on these sleeves would actually work if they were stiff, I am thinking of buying this jacket and going over all the parts in grey silicone. Silicone bites into cloth, so it won't ever come out. It also forms a skin, so will hide all the stitch lines. I already have the vest part sorted, just need to mold those belt and cuff parts again.

It is also good that you can put the board on the ground. No way would I be doing that with my Matty Collector.

LeExpiredMilk

New Member

That isn't a HC jacket. I got that one off eBay for about $100 plus shipping. And I am gonna end up modding the shoes, I just have no idea where to start, I'm new at this. Any suggestions?

MrSouthpaw

Sr Member

So this is the HC jacket?

Since my last attempt was looking, just was like XXXL instead of XL and given the bellows on these sleeves would actually work if they were stiff, I am thinking of buying this jacket and going over all the parts in grey silicone. Silicone bites into cloth, so it won't ever come out. It also forms a skin, so will hide all the stitch lines. I already have the vest part sorted, just need to mold those belt and cuff parts again.

It's an ebay/amazon jacket from the factories.

The sleeves on this model are vinyl, not cloth. Thick, heavy vinyl. In fact all the grey detail is vinyl.

The cuff is not pleated so it's a large hole. And they still put a snap button on it for basically no good reason.

Overall though, the sleeves are still way better than the cloth sleeves on the other models. The bellows have that well-organized look, whereas the cloth sleeves end up looking a bit frumpy. The straps for the bellows attach via snap-button. Way more secure then the velcro on the cloth-sleeved jackets.

If you can get it on ebay, you can probably get it customized for a small fee. I would ask them to pleat the cuff, get rid of the wrist snap. And instead of the ribbed cuff/belt material, just make it smooth so you can attach your own hardware.

cavx

Master Member

It's an ebay/amazon jacket from the factories.

Is there a link for this? Given 2015 is well and truly over, this might be hard to find now.

If you can get it on ebay, you can probably get it customized for a small fee. I would ask them to pleat the cuff, get rid of the wrist snap. And instead of the ribbed cuff/belt material, just make it smooth so you can attach your own hardware.

I have the proper seat back/upright covers for the belt and cuffs. Every time we have a curb side collection, I drive around the local streets taking these office chairs, remove the part I need and throw the rest back on the street. I think I have at least 6 sections now. Each one is then split in half to make two. I did make a mold long enough for a one part belt, but it needs to be redone because I made from silicone and I need it made from flexible polyurethane so I can cast silicone belts from it. I have even found a special glue that glues silicone!

The reason I want to use silicone instead of polyurethane is the poly belt cracked when bent too far. The silicone will fold over onto itself without issue.

Besides, the textured surface of the vest is silicone, so if the belt is silicone, just makes it easier to pour all the parts. I could probably make the mold so the belt is actually part of the vest. It just means I pour that part in black first, let it cure, then pour the red for the texture.

MrSouthpaw

Sr Member

Is there a link for this? Given 2015 is well and truly over, this might be hard to find now.

I have the proper seat back/upright covers for the belt and cuffs. Every time we have a curb side collection, I drive around the local streets taking these office chairs, remove the part I need and throw the rest back on the street. I think I have at least 6 sections now. Each one is then split in half to make two. I did make a mold long enough for a one part belt, but it needs to be redone because I made from silicone and I need it made from flexible polyurethane so I can cast silicone belts from it. I have even found a special glue that glues silicone!

The reason I want to use silicone instead of polyurethane is the poly belt cracked when bent too far. The silicone will fold over onto itself without issue.

Besides, the textured surface of the vest is silicone, so if the belt is silicone, just makes it easier to pour all the parts. I could probably make the mold so the belt is actually part of the vest. It just means I pour that part in black first, let it cure, then pour the red for the texture.

I got mine from Amazon. I do remember seeing the same model on ebay, but I can't seem to find it now. Anyways, here's the Amazon link.

http://www.amazon.com/Back-Future-J...817&sr=8-1&keywords=back+to+the+future+jacket

There isn't much in the way of used office chairs where I live. I do have a 10 foot section of ribbed tubing from a local hardware store. The same stuff I think Jedifyfe used in his build.

cavx

Master Member

I got mine from Amazon. I do remember seeing the same model on ebay, but I can't seem to find it now. Anyways, here's the Amazon link.

http://www.amazon.com/Back-Future-J...817&sr=8-1&keywords=back+to+the+future+jacket

There isn't much in the way of used office chairs where I live. I do have a 10 foot section of ribbed tubing from a local hardware store. The same stuff I think Jedifyfe used in his build.

That is not a bad jacket for "off the rack" and for the price (1/10th of the MP). I would not mind spending a few hundred on this modding it up.

I didn't know you can buy ribbed tubing apart from the round stuff for agriculture. I have the real deal here and will make it properly for mine.

Same for the textured surface. I bought a full sheet of light diffuser for the mold.

I would have to test the adhesion of the silicone to that vinyl. It should stick and it would look neat to cover the stitching.

MrSouthpaw

Sr Member

That is not a bad jacket for "off the rack" and for the price (1/10th of the MP). I would not mind spending a few hundred on this modding it up.

I didn't know you can buy ribbed tubing apart from the round stuff for agriculture. I have the real deal here and will make it properly for mine.

Same for the textured surface. I bought a full sheet of light diffuser for the mold.

I would have to test the adhesion of the silicone to that vinyl. It should stick and it would look neat to cover the stitching.

I agree. It's the best of the bunch for the price. Very visually effective. And really only people around here and hardcore BTTF fans would know the difference.

I'm pretty sure it is for agriculture. It's about 6 inches diameter or so. It's good enough for now. If I zip-tie it on, I can just replace later.

As for the body I just don't have room or resources to get into that. And I'm mostly satisfied with the sleeves as-is, except the cuff-size and the weight.

G35fastcoupe

New Member

Similar threads

- Replies

- 4

- Views

- 1,414

- Replies

- 52

- Views

- 5,582