Only problem with watching people demo the QiDi tech S-Box is so far there are only unboxing videos. There aren't even any actual review videos on it, just opening the box and saying a few things that don't help a beginner in the least.It's like cooking in that you can watch people demo it for you, but until you do it you can't fully understand it. Once you learn it you have a new skill that is highly valuable for many different aspects of your life outside of the original purpose you learned it for. And you can get high off the fumes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Adventures in 3D Printing

- Thread starter masterjedi322

- Start date

have you tried the facebook group? I hate social media sites but I created a burner account just for reading 3d printing groups.

qidi fb group

qidi fb group

I'll do that now. Thanks for the recommendation.have you tried the facebook group? I hate social media sites but I created a burner account just for reading 3d printing groups.

qidi fb group

add a bunch of groups, like 3d resin printing for beginners, 3d printing pro the list goes on.I'll do that now. Thanks for the recommendation.

Great conversation, all!

Had better luck with the second attempt. Got 2 out of 4 parts that were usable.

The barrel got stuck to the FEP again, so I will try the silicon trick and reprint today.

The cylinder finished printing, but again, the bottom surface was warped, similar to the prior attempt. I’m guessing the chambers being hollow make it difficult for the piece to support it’s own weight causing the warping. I will reorient and reprint along with the cylinder.

Sean

Had better luck with the second attempt. Got 2 out of 4 parts that were usable.

The barrel got stuck to the FEP again, so I will try the silicon trick and reprint today.

The cylinder finished printing, but again, the bottom surface was warped, similar to the prior attempt. I’m guessing the chambers being hollow make it difficult for the piece to support it’s own weight causing the warping. I will reorient and reprint along with the cylinder.

Sean

TazMan2000

Master Member

Great conversation, all!

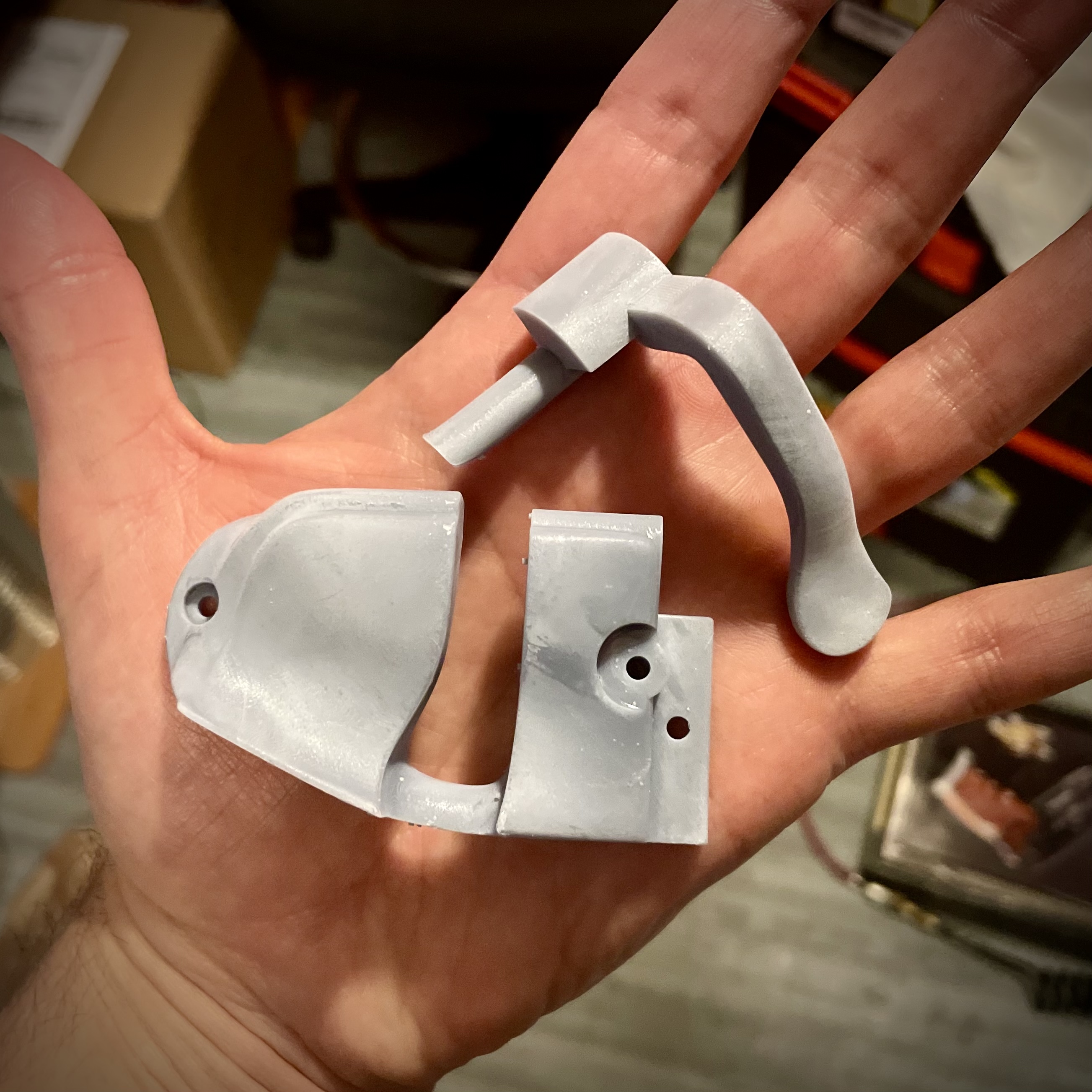

Had better luck with the second attempt. Got 2 out of 4 parts that were usable.

View attachment 1451983

The barrel got stuck to the FEP again, so I will try the silicon trick and reprint today.

The cylinder finished printing, but again, the bottom surface was warped, similar to the prior attempt. I’m guessing the chambers being hollow make it difficult for the piece to support it’s own weight causing the warping. I will reorient and reprint along with the cylinder.

Sean

Were all the supports still good? No disbonding? Try levelling with a slightly thicker piece of paper. Follow all the directions of levelling and don't forget to zero the bed and save the value.

TazMan2000

The barrel not got off the FEP, so hard to tell on the supports.Were all the supports still good? No disbonding? Try levelling with a slightly thicker piece of paper. Follow all the directions of levelling and don't forget to zero the bed and save the value.

TazMan2000

The cylinder supports look good. I think the chamber walls are just too thin to support the weight of the piece on its side.

Thanks for the tip on leveling with a thicker sheet of paper. Will give that a shot!

Question - the instructions say to level without the vat installed (i.e. with the build plate directly on the LCD). Seems to me the vat should be in place when leveling, no?

Sean

TazMan2000

Master Member

The barrel not got off the FEP, so hard to tell on the supports.

The cylinder supports look good. I think the chamber walls are just too thin to support the weight of the piece on its side.

Thanks for the tip on leveling with a thicker sheet of paper. Will give that a shot!

Question - the instructions say to level without the vat installed (i.e. with the build plate directly on the LCD). Seems to me the vat should be in place when leveling, no?

Sean

No. The piece of paper will simulate the thickness of the vat and give room for the first layer. I've heard some people do that with the Mars, but the FEP is, or at least should be a constant thickness and doing it with the FEP installed, means you have to empty the vat out and clean it perfectly every single time you level.

If you don't have one, get a micrometer and measure the thickness of the paper you are using in thousandths of a mm. Different papers have different thicknesses and you can't always go by paper weight.

Check the build plate on all angles against a known good straight edge like a machinist ruler. I've heard that the Mono X had some build plates make it out of the factory a bit warped.

If you have good adhesion on one side, try moving the problematic part onto that area (that is, if you think the build plate is level).

When you level the build plate, do the X pattern of tightening the screws. A little tightness at a time until they are all at about the same amount of torque.

Oh, and the supports tool for the Photon Workshop is crap...at least for outside supports. Inside supports on hollow parts is actually pretty good.

Photon Workshop by default does a infill. If you don't want that go to the icon on the header that looks like a chain link fence. When you slice the model, look at the layers and see what the software is telling the screen to do.

TazMan2000

Last edited:

Thanks for all the great tips!

Had another failed print yesterday, so I did the following:

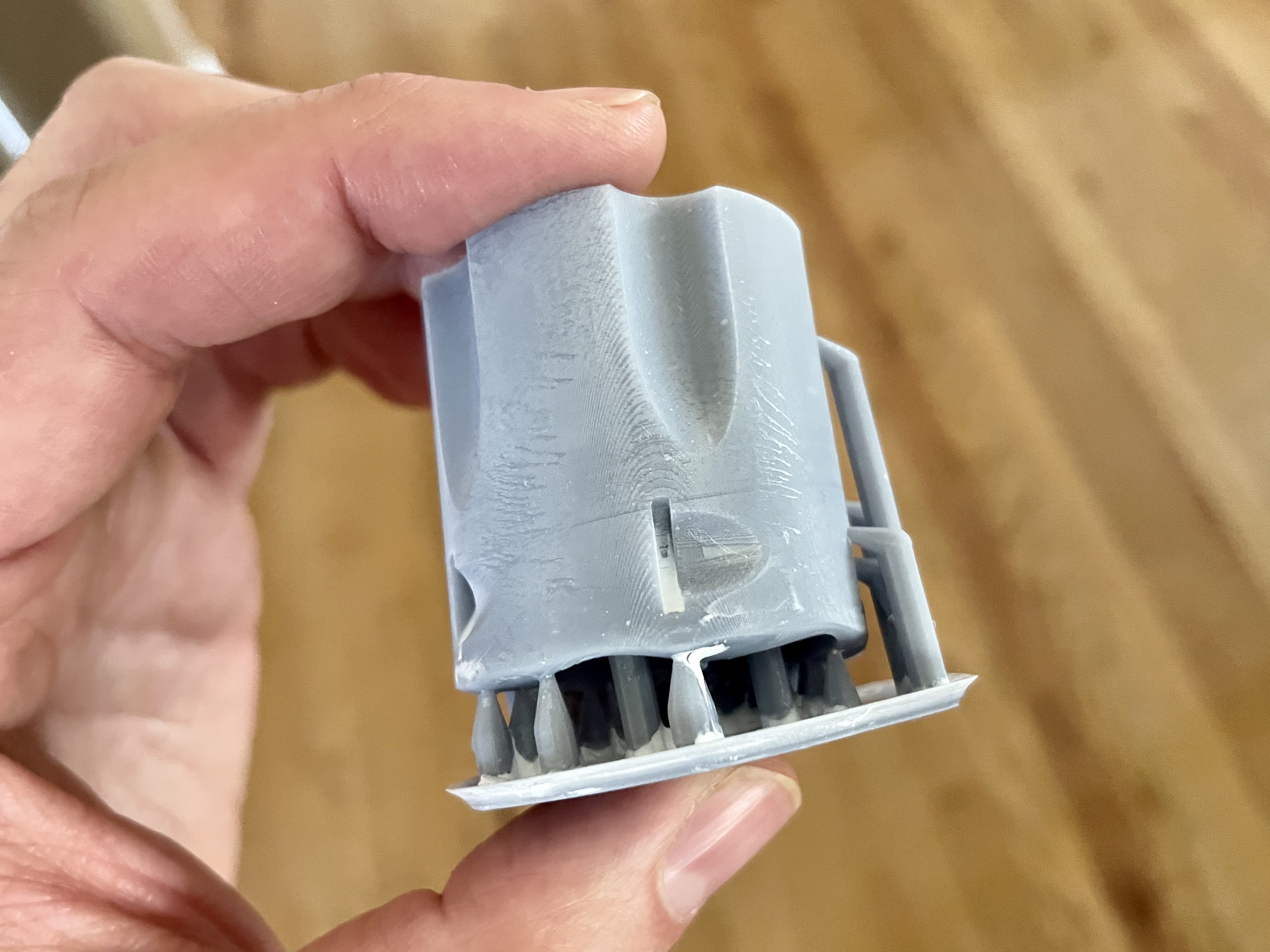

I finally got the barrel to print - looking good!

The cylinder also printed, but upon closer inspection, it’s warped, similar to the previous prints. I didn‘t notice it when the print finished - I suppose it could have been there, but I’m thinking this may be the result of cleaning/curing.

When the parts finish printing, I drop them into some IPA and run them through the AnyCubic cleaning station for ~5 min. I then take them out, and put them under the Cure station for another ~5 min. Could that cause warping?

Sean

Had another failed print yesterday, so I did the following:

- Leveled the printer. When pushing down on the printer, I noticed it had a slight wobble to it. Looking at the base, I noticed there are four adjustable feet. I used those to level the printer left to right and then front and back.

- Re-leveled the build plate. Followed Tazman’s instructions above.

- Applied some PTFE 3 in 1 lubricant to the FEP. This will, hopefully, prevent the resin from sticking to the bottom of the vat.

I finally got the barrel to print - looking good!

The cylinder also printed, but upon closer inspection, it’s warped, similar to the previous prints. I didn‘t notice it when the print finished - I suppose it could have been there, but I’m thinking this may be the result of cleaning/curing.

When the parts finish printing, I drop them into some IPA and run them through the AnyCubic cleaning station for ~5 min. I then take them out, and put them under the Cure station for another ~5 min. Could that cause warping?

Sean

TazMan2000

Master Member

Post curing definitely can cause some warping issues, but I don't think that is your problem on the cylinder.

In my opinion, you should either put the flat side (if there is one) directly on the build plate, or use light supports all across the bottom.

I'm assuming you're using 0.05 layer height. From each support that you currently have on the cylinder, there is a large area that is unsupported. Pretend that you're building a brick bridge. You can't lay bricks end to end without supports over long spans.

TazMan2000

In my opinion, you should either put the flat side (if there is one) directly on the build plate, or use light supports all across the bottom.

I'm assuming you're using 0.05 layer height. From each support that you currently have on the cylinder, there is a large area that is unsupported. Pretend that you're building a brick bridge. You can't lay bricks end to end without supports over long spans.

TazMan2000

I’ve printed the cylinder 3 times now in different orientations, and the warping seems to occur on the same surface as the supports.

As an experiment, I am currently printing four cylinders in different orientations. I also switched from medium and heavy supports to light.

Assuming the prints finish, I will be sure to let the parts fully dry after cleaning before curing to see if I can isolate where in my workflow the warping is occurring.

Thanks so much for the help! Really appreciate it!

Sean

As an experiment, I am currently printing four cylinders in different orientations. I also switched from medium and heavy supports to light.

Assuming the prints finish, I will be sure to let the parts fully dry after cleaning before curing to see if I can isolate where in my workflow the warping is occurring.

Thanks so much for the help! Really appreciate it!

Sean

Frustrating day today…

Tried orienting the cylinders in four different configurations, all with light supports. The supports printed fine, but all four cylinders failed…TWICE!

Was going to try upping to medium supports, but before I do, any thoughts on what’s going on here…?

Sean

Tried orienting the cylinders in four different configurations, all with light supports. The supports printed fine, but all four cylinders failed…TWICE!

Was going to try upping to medium supports, but before I do, any thoughts on what’s going on here…?

Sean

TazMan2000

Master Member

It could mean that the resin is too cold. If your room is warm that you're printing in, disregard that.

If the part is solid, it may be the peel force to unbond the resin from the FEP is too great so it breaks it off of the supports.

The print bed may be too close to the screen, so you could re-level with a slightly thicker piece of paper. It could be the resin is getting smashed into the screen and squishing the supports, eventually breaking them off.

Another thing is that it could be is that you may need to hollow your prints to reduce the area and thusly the peel force.

One good thing is that it appears your have good adhesion to the print surface.

TazMan2000

If the part is solid, it may be the peel force to unbond the resin from the FEP is too great so it breaks it off of the supports.

The print bed may be too close to the screen, so you could re-level with a slightly thicker piece of paper. It could be the resin is getting smashed into the screen and squishing the supports, eventually breaking them off.

Another thing is that it could be is that you may need to hollow your prints to reduce the area and thusly the peel force.

One good thing is that it appears your have good adhesion to the print surface.

TazMan2000

This may help with understanding peel force.

It could mean that the resin is too cold. If your room is warm that you're printing in, disregard that.

If the part is solid, it may be the peel force to unbond the resin from the FEP is too great so it breaks it off of the supports.

The print bed may be too close to the screen, so you could re-level with a slightly thicker piece of paper. It could be the resin is getting smashed into the screen and squishing the supports, eventually breaking them off.

Another thing is that it could be is that you may need to hollow your prints to reduce the area and thusly the peel force.

One good thing is that it appears your have good adhesion to the print surface.

TazMan2000

Thanks again!

I’m printing indoors at room temp, so don’t think it’s that…

I’ll continue to tweak things to see if I can get them dialed in.

Sean

TazMan2000

Master Member

Just as an experiment, try warming the resin bottle in a container of warm water.Thanks again!

I’m printing indoors at room temp, so don’t think it’s that…

I’ll continue to tweak things to see if I can get them dialed in.

Sean

I had nothing but trouble when my resin was cold. 25 -30 degrees Celsius is generally an OK temperature.

TazMan2000

I thought I posted this here, but your going to need to understand this video combined with the power of the peel force video.

Thanks! That video is very helpful!I thought I posted this here, but your going to need to understand this video combined with the power of the peel force video.

As for today’s experiment, I got good news and I got bad news…and then maybe some more good news.

The good news is I went back to a previous file I printed and retried it with success. That gives me confidence that I have the build plate leveled, resin is at a good temp, and the printer is generally configured properly.

Bad news is I’m still having the same warping issues. This is before washing and curing.

So the good news is I at least have a better idea where my issue is - in supporting the parts.

Has anyone done an Anders BR blaster that would care to share some tips?

Sean

you should also try this with every resin you get on each printer to help dial it in. Also something I don't hear people talking about as much is try printing the part at around 40% of the original size as a test print so you don't waste as much resin and time seeing how it prints.

Another great tip! Thanks! Will try this tomorrow!you should also try this with every resin you get on each printer to help dial it in. Also something I don't hear people talking about as much is try printing the part at around 40% of the original size as a test print so you don't waste as much resin and time seeing how it prints.

Sean

Similar threads

- Replies

- 1

- Views

- 187

- Replies

- 2

- Views

- 248