You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Millennium Falcon parts for 3d Printing

- Thread starter maruska

- Start date

maruska

Sr Member

I'm following all this with interest, maruska. Thanks for what info you have offered. I apologize if my inquiries were bothersome. Just curious. And really just trying to get some parts for a model.

No worries. Not a bother at all. I'm glad you're curious. Curiosity keeps us young. : )

I'll keep plugging along and posting parts when I can. It's slow going, but we'll get there... eventually.

maruska

Sr Member

Those Quad cannons are gorgeous!

C

Thank you! Credit also goes to vfxsup64 for the brilliant photo-matched underlay work.

I said I didn't know anything about 3D files not computers. That was quickly followed by "I suppose maybe I need to learn". "Maybe... I can get someone to help me out a little" is part of the learning process and in that most of your second paragraph was quite helpful and I appreciate that. The rest of your post is knee-jerk, presumptuous, speculative, judgmental, ranting drivel. Unnecessary and not helpful. My time and money is limited. Who can fault anyone for looking to save time and money? Thanks but whatever, dude.

Again, maybe I should look further into 3D printing. I was actually looking at a book at the library just last week because I have been following some of this tech lately. Honestly it did not look very helpful and I'm certainly not looking for a degree in CAD. What I saw in that book actually, in a way, prompted me to approach this thread as I did. The choice is mine to look to pay others for their hard earned time, experience and knowledge or to look into it further myself, hopefully with a little positive help from others. But I don't need someone to tell me who they think I am or how they think I should or should not approach a given situation. I'm a round adult peg. Please don't jam me into your square hole. Please don't do that to anyone. It doesn't move anything forward. The most valid points can be easily invalidated by mere poor presentation.

I'm following all this with interest, maruska. Thanks for what info you have offered. I apologize if my inquiries were bothersome. Just curious. And really just trying to get some parts for a model.

I didn't mean to direct that at you personally bro... I've been hearing it alot lately (not just from you) and basically it had to come out generally. I didn't direct it at you personally I promise. There's alot of really good information out there. There's a new service out that allows people with 3D printers to sign up for it and offer their printing services for you. I think that's a great idea. You contact one of these guys and they print up whatever you need for an agreed upon price and since it's just a guy in his workshop with a printer with nothing better to do, they work with ya to get it just the way you want.

As far as learning 3D on your own, Google has their own 3D program out there called Sketchup and it's not hard at all to learn... best of all it's free! After viewing a few tutorials online one weekend I found myself being able to make some pretty good models with it in a short amount of time. (I too don't have much time these days so I know how you feel about that). Not to mention they have a HUGE online database of free downloadable models that you can print right away if you want.

These days you can actually buy your own 3D printer for under $500... I've seen some go for as little as $350... but then again, you get what you pay for and the cheaper it is, the lower the quality of the print itself. But it gives you something that you can experiment with and learn on.

Again, I didn't direct any of my last rant personally at you bro... just there are alot of people as of late that feel as if they can just come into the forums and say oh whoa is me and get something for nothing without doing anything for themselves. That's who it was directed at. I apologize if you took it that way and am more then willing to help and teach ya anything you want about this area!

SGluedMyFingers

Well-Known Member

It's all good. A few crossed wires. It happens. We are all just trying to build the best models we can and we are passionate about our hobby. I think everyone here can appreciate that. :thumbsup

bwayne64

Master Member

Sure! Once (or if) I ever get this working on just a standalone microprocessor, I'll share the code. It's kind of a convoluted set-up at the moment - but it was a quick way to visualize what's going on with the two motions of the servos.

I'll also need to hunt down some smaller servos - this is them placed in a ANH 5' scale gun. The mini in the barrel mount is pretty hidden (in blue), but the main yoke servo would stick out of the turret deck pretty bad...

View attachment 535209

Man this is awesome ! As for the servos, if you used small gears and /or chains and sprockets you could put the servos lower in the gun well. I think they make miniature chains for stuff like this. I just can't remember where I've seen them. Great stuff as usual. Cheers,

Joe

PS. Found some

http://sdp-si.com/eStore/CoverPg/Drive_Components.htm

Last edited:

Vacformedhero

Sr Member

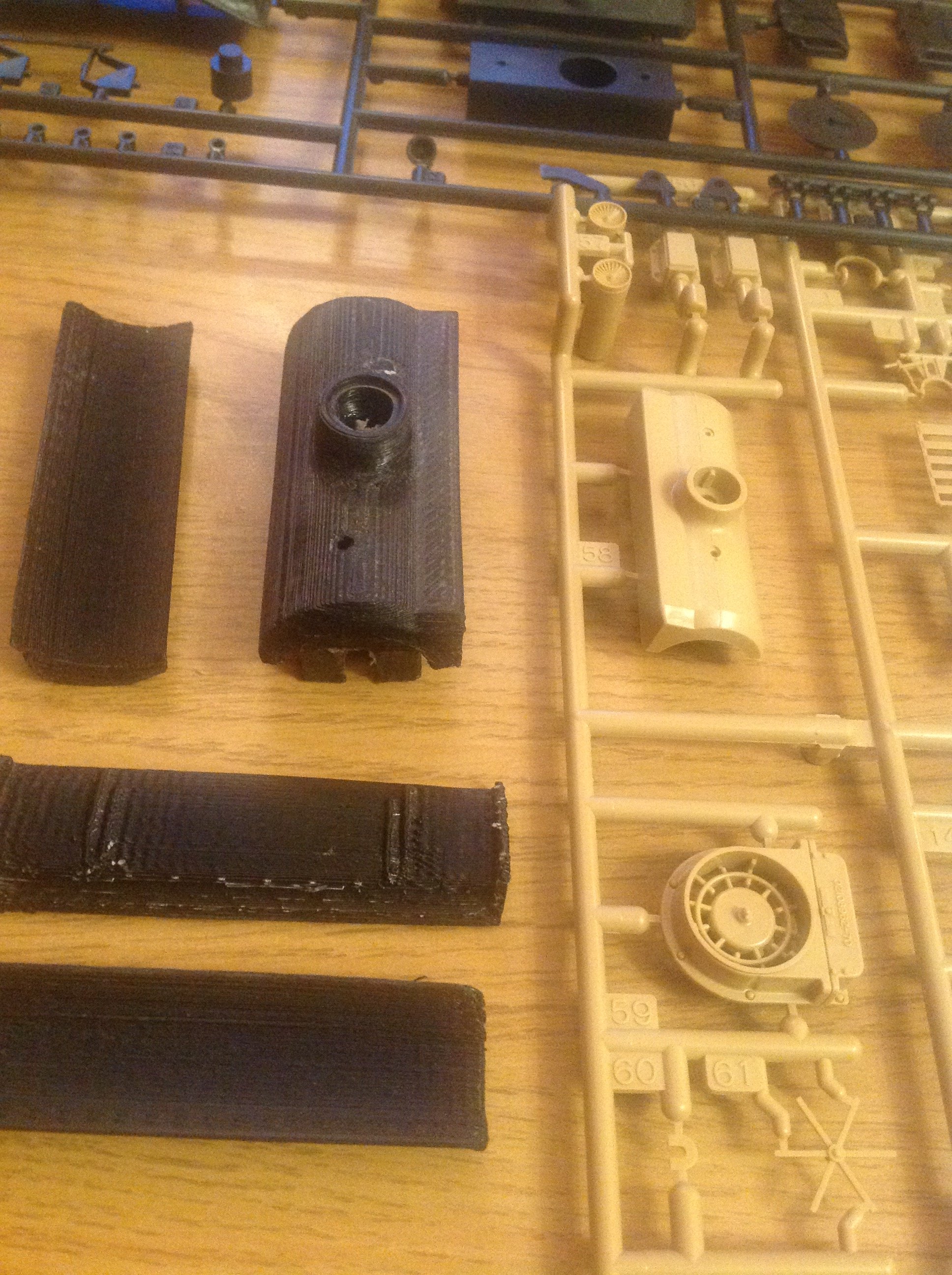

Small update I just wanted to show the raw 3D printed parts maruska supplies the 3D models of, which I picked up today

Here they are next to the 1/35 scale Panther g for shape comparison , and 1/25 scale centurion for size comparison .

the aurora plough blades are quite rough, I have never cleaned up 3D printed parts before so I need to research it

thanks again maruska

Here they are next to the 1/35 scale Panther g for shape comparison , and 1/25 scale centurion for size comparison .

the aurora plough blades are quite rough, I have never cleaned up 3D printed parts before so I need to research it

thanks again maruska

SGluedMyFingers

Well-Known Member

Well I cut the crap out of my finger this week and regular scratch building is out of the question. So I followed through on the interest I had already developed and figured that I would delve into this 3D software and see what happened.

I spent this morning learning a little about 123D Design, midday scrounging through reference photos trying to figure some measurements and drawing a few plans and all afternoon and evening fumbling around doing trial and error type stuff until I came up with this:

View attachment 1850_SWI_9361.jpg

View attachment 1850_SWI_9361.jpg

It's the start of a McLaren wheel hub for the Falcon engine deck. It's a little wonky - didn't quite get the curvature right. But it's a start.

And yeah, I've got questions now. Is 123D Design really decent software or should I be looking for something else? Preferably free. The main problem I had was being able to measure specific areas of the individual parts once grouped. Or any part for that matter. Am I missing something in 123D or does it just not do that kind of stuff? If someone can recommend better freeware that would be awesome. I just went with what Shapeways said would be a good start. I haven't figured out how I'm going to do the spokes. There are a lot of concave cuts that's going to take a little more know-how than I picked up in every instructional video I could find. And I'm really not sure how I'm going to get the spokes into the hub. Trying to mesh parts with parts in 123D has been cutting voids instead of meshing. Maybe I'm missing something.

If there is another thread where questions like these are more appropriate, please let me know and I'll gladly take them there. Any positive or helpful feedback appreciated.

I don't see, at the moment, how some of you guys do the insanely cool things you do without smashing your keyboard with your face, but I hoping this will get easier with a little work. I can certainly see being able to do things that I just can't do with stock styrene, a hobby knife, files and superglue. This could turn into an invaluable skill set for some parts. But I'm not sure I'm using software that's going to get me where I really want to go. If I really want to go there. The frustration to fun cost benefit analysis didn't weigh out very well today. But when I first started scratching very small parts in styrene, I sorta felt the same way. I'll get there. But I'm sure hoping to be able to find a resource to ask some specific questions. I'll play around with the spokes some more tonight and tomorrow. We'll see how it goes. Hopefully I won't end up with a concussion.:wacko

I spent this morning learning a little about 123D Design, midday scrounging through reference photos trying to figure some measurements and drawing a few plans and all afternoon and evening fumbling around doing trial and error type stuff until I came up with this:

View attachment 1850_SWI_9361.jpg

View attachment 1850_SWI_9361.jpgIt's the start of a McLaren wheel hub for the Falcon engine deck. It's a little wonky - didn't quite get the curvature right. But it's a start.

And yeah, I've got questions now. Is 123D Design really decent software or should I be looking for something else? Preferably free. The main problem I had was being able to measure specific areas of the individual parts once grouped. Or any part for that matter. Am I missing something in 123D or does it just not do that kind of stuff? If someone can recommend better freeware that would be awesome. I just went with what Shapeways said would be a good start. I haven't figured out how I'm going to do the spokes. There are a lot of concave cuts that's going to take a little more know-how than I picked up in every instructional video I could find. And I'm really not sure how I'm going to get the spokes into the hub. Trying to mesh parts with parts in 123D has been cutting voids instead of meshing. Maybe I'm missing something.

If there is another thread where questions like these are more appropriate, please let me know and I'll gladly take them there. Any positive or helpful feedback appreciated.

I don't see, at the moment, how some of you guys do the insanely cool things you do without smashing your keyboard with your face, but I hoping this will get easier with a little work. I can certainly see being able to do things that I just can't do with stock styrene, a hobby knife, files and superglue. This could turn into an invaluable skill set for some parts. But I'm not sure I'm using software that's going to get me where I really want to go. If I really want to go there. The frustration to fun cost benefit analysis didn't weigh out very well today. But when I first started scratching very small parts in styrene, I sorta felt the same way. I'll get there. But I'm sure hoping to be able to find a resource to ask some specific questions. I'll play around with the spokes some more tonight and tomorrow. We'll see how it goes. Hopefully I won't end up with a concussion.:wacko

Last edited:

SGluedMyFingers

Well-Known Member

Stayed up until 6 in the morning. Came really close to having something I was happy with. Tried to break all the pieces into two saves. Got confused. Saved the simple parts over the complicated parts. All gone. Luckily I was too exhausted to smash my computer. Played around a little with Fusion 360 but it keeps saying my graphics capability is too crappy.

Still learned some cool stuff. Again, any recommendations on freeware that won't wreck my PC is appreciated.

Still learned some cool stuff. Again, any recommendations on freeware that won't wreck my PC is appreciated.

maruska

Sr Member

Small update I just wanted to show the raw 3D printed parts maruska supplies the 3D models of, which I picked up today

http://www.therpf.com/attachment.php?attachmentid=537613&d=1444163187&thumb=1http://www.therpf.com/attachment.php?attachmentid=537614&d=1444163187&thumb=1http://www.therpf.com/attachment.php?attachmentid=537615&d=1444163187&thumb=1

Here they are next to the 1/35 scale Panther g for shape comparison , and 1/25 scale centurion for size comparison .

the aurora plough blades are quite rough, I have never cleaned up 3D printed parts before so I need to research it

thanks again maruska

Oh! So glad to see you're getting some use out of the files!

Looks like you got FDM prints - which are sturdy, but not super high fidelity. I've been using FDM prints for basic placement and proportioning, but I'll do final prints in PolyJet (Eden/Objet) or SLA (stereolithography). Check out some different processes if you do another round. I think you'll be surprised by the results.

Cheers,

J.

maruska

Sr Member

Stayed up until 6 in the morning. Came really close to having something I was happy with. Tried to break all the pieces into two saves. Got confused. Saved the simple parts over the complicated parts. All gone. Luckily I was too exhausted to smash my computer. Played around a little with Fusion 360 but it keeps saying my graphics capability is too crappy.

Still learned some cool stuff. Again, any recommendations on freeware that won't wreck my PC is appreciated.

Oh - bummer Fusion is beyond your PC's GPU - it has been my goto CAD software for the past year or more. I think it is by far the best tool out there for the type of work that goes on here at the RPF. All the kit parts I've posted here have bee done in Fusion. (The cockpit interior and seats were done in Solidworks, as was the 5' master model). I've just been really impressed with what the Fusion Team has been doing. I think you'll find 123D a bit limiting eventually..

J.

SGluedMyFingers

Well-Known Member

Yes that is a bit of a bummer. But I think I'm going to try to use it some anyway. It may gum up a little but I don't see myself doing parts as complex as what you are doing. Maybe i can still get some use from it. I'm also experimenting with some of the other software you've mentioned previously. I'll just have to find what works best for my needs and my system.

I think I've just about figured out how I can work out decent looking McLaren Wheels. I'm still looking at that Tamiya Leopard Vent (part 6) with determination and a little fear. I'm eyeballing all this and holding up a ruler to reference pics knowing full well that perspective is kicking my butt.

Thanks for the new addiction... I think. There's only so much you can do with Plastruct, Evergreen and Aves.

I think I've just about figured out how I can work out decent looking McLaren Wheels. I'm still looking at that Tamiya Leopard Vent (part 6) with determination and a little fear. I'm eyeballing all this and holding up a ruler to reference pics knowing full well that perspective is kicking my butt.

Thanks for the new addiction... I think. There's only so much you can do with Plastruct, Evergreen and Aves.

Vacformedhero

Sr Member

Thanks , yeah proportion wise they are spot on, as Tox suggested I've sourced another local printer and going to walk in an discuss what I'm after , hopefully the next test should be an improvement quality wise ,Oh! So glad to see you're getting some use out of the files!

Looks like you got FDM prints - which are sturdy, but not super high fidelity. I've been using FDM prints for basic placement and proportioning, but I'll do final prints in PolyJet (Eden/Objet) or SLA (stereolithography). Check out some different processes if you do another round. I think you'll be surprised by the results.

Cheers,

J.

maruska

Sr Member

Just got these polyjet printed and added a single coat of white primer. No sanding yet.

This is the ANH 5' gun printed at half scale. It was printed in six pieces and includes hollows for 1/16" steel rods inside the barrels and the articulation points.

I did this as a test print to figure out my tolerances for snap fits and such.

This is the ANH 5' gun printed at half scale. It was printed in six pieces and includes hollows for 1/16" steel rods inside the barrels and the articulation points.

I did this as a test print to figure out my tolerances for snap fits and such.

SteveStarkiller

Sr Member

whoa, very nice!

Similar threads

- Replies

- 2

- Views

- 911

- Replies

- 11

- Views

- 1,012

- Replies

- 2

- Views

- 870