You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

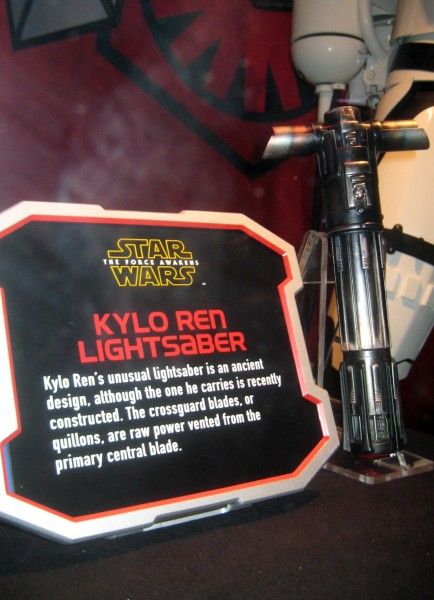

Kylo Ren Saber hollow hilt for electronics

- Thread starter guabe

- Start date

Ok so I printed a full hilt using the most recent files and all printed great. I still believe that you have some parameter not setup correctly and you are getting hollow parts. I want to show how I print my parts using simplify3d.

Printing the parts vertically gives them an overall better look, because the layering effect is reduced. Notice that I scaled the body section to 102% this is to compensate for the thread tightness you get in home printers versus Shapeways. At 102% you will be able to screw the parts easier.

Here are some pics of my print.

Thanks.

Printing the parts vertically gives them an overall better look, because the layering effect is reduced. Notice that I scaled the body section to 102% this is to compensate for the thread tightness you get in home printers versus Shapeways. At 102% you will be able to screw the parts easier.

Here are some pics of my print.

Thanks.

Chicagovader

Sr Member

Very impressive Gustavo!!

Noob to 3D print finishing here, so I have a question. I had someone generous enough to to a print of one of these for me, & it should be pretty much identical to the one guabe posted in 262.

I've heard the sanding with progressively finer sandpaper is the way to go on smoothing out a 3D print, but I've also heard of a brush on product that pretty much levels evrything out with no visible print lines. What would be recommended with a print like this? I don't want to lose any details be sanding them away, or by filling them in with a leveling product.

What's the expert's consensus?

I've heard the sanding with progressively finer sandpaper is the way to go on smoothing out a 3D print, but I've also heard of a brush on product that pretty much levels evrything out with no visible print lines. What would be recommended with a print like this? I don't want to lose any details be sanding them away, or by filling them in with a leveling product.

What's the expert's consensus?

Noob to 3D print finishing here, so I have a question. I had someone generous enough to to a print of one of these for me, & it should be pretty much identical to the one guabe posted in 262.

I've heard the sanding with progressively finer sandpaper is the way to go on smoothing out a 3D print, but I've also heard of a brush on product that pretty much levels evrything out with no visible print lines. What would be recommended with a print like this? I don't want to lose any details be sanding them away, or by filling them in with a leveling product.

What's the expert's consensus?

With the small details on this you'd be better off alternating sanding and heavy coats of filler primer. The Smooth-on epoxy coating tends to fill in interior corners and round exterior corners - it's not great for things with fine sharp edged detail. Filler primer does as well to a lesser extent but it goes on a lot thinner and it's easier to control.

- - - Updated - - -

You did a good job with that, Lukyanov. What steps did you follow to achieve that finish?

lukyanov

Sr Member

With the small details on this you'd be better off alternating sanding and heavy coats of filler primer. The Smooth-on epoxy coating tends to fill in interior corners and round exterior corners - it's not great for things with fine sharp edged detail. Filler primer does as well to a lesser extent but it goes on a lot thinner and it's easier to control.

- - - Updated - - -

You did a good job with that, Lukyanov. What steps did you follow to achieve that finish?

Thanks.

Quality of lightsaber largely depends on the printer model and plastic I think.

This is my first experience in processing 3D-printed model.

In the beginning I had bad-quality detail with dropped out plastic threads (somewhere). Printer layer thickness is 0.2 mm.

First I use sandpaper #320, than #600. After roughing I treated with acetone on rag (with finger force pushing) to a smooth condition. Than finishing with sanpaper up to #2000.

Somewhere defects are seen, but I am satisfied (I hope looks like celebration prop).

After processing with wool, ABS-plastic gets shine like a metal (later I take a photo).

Waiting modified emitter from guabe (first printed part has super-****ty-quality, you can see it earlier).

Everyone understand me?

Here's another weaver-ABS-detail finishing by me using only sandpaper:

In the begining:

PLA-plastic much harder to handle with with abrasives, and it not treated with acetone. Here is my cap (I'll cover it later with matte varnish)

I have a question: what kind of paint should I use to color smooth parts? Acrylic does not hold on it...

Last edited:

Obiwanortega

New Member

Are this files aviable mate? good job

lukyanov

Sr Member

Hi! Only high part with side tubes or whole lightsaber? Do not want to recast all of itLukyanov, I'm working on the newer details.

Thanks for the pics.

dday

Sr Member

Has anyone wired one of these up?

I'm having trouble figuring out how to get all the stuff inside!

The LED with LED heatsink and the cup the heatsink screw into don't really fit into the emitter section. It will go in, but there is a gap of like 2CM between the LED and the divider/ledge where the blade sits.

Then the MHS board, battery and speaker holder don't really fit in either. I can modify the MHS unit to fit in, but then the speaker still is like 3CM up because of the shape of the pommel. I must be dumb, it just doens't feel like it will work nicely and that I'll have to just tape it all up and cram it in.

I'm having trouble figuring out how to get all the stuff inside!

The LED with LED heatsink and the cup the heatsink screw into don't really fit into the emitter section. It will go in, but there is a gap of like 2CM between the LED and the divider/ledge where the blade sits.

Then the MHS board, battery and speaker holder don't really fit in either. I can modify the MHS unit to fit in, but then the speaker still is like 3CM up because of the shape of the pommel. I must be dumb, it just doens't feel like it will work nicely and that I'll have to just tape it all up and cram it in.

Similar threads

- Replies

- 13

- Views

- 340

- Replies

- 4

- Views

- 465

- Replies

- 2

- Views

- 1,329

- Replies

- 14

- Views

- 2,863