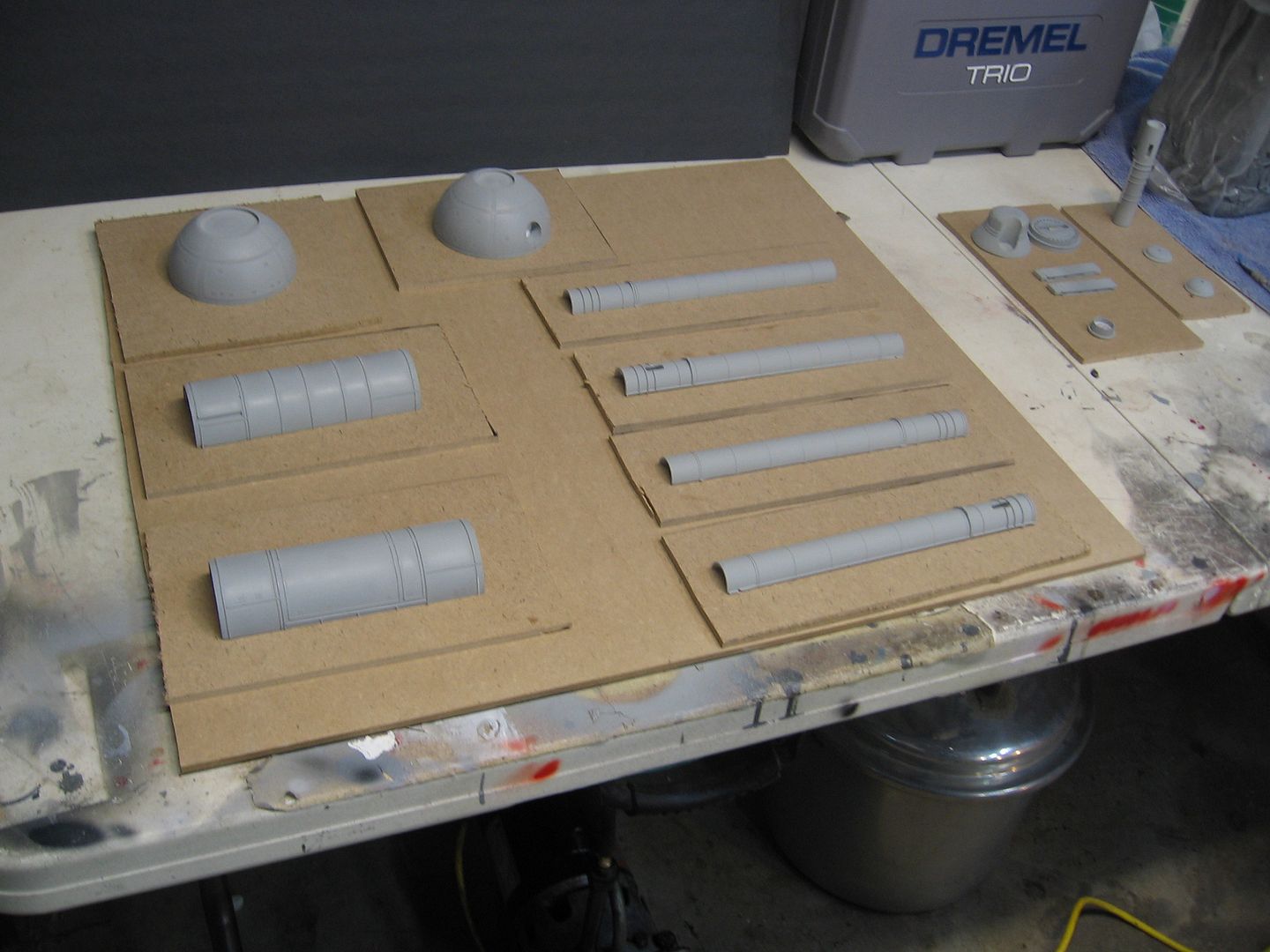

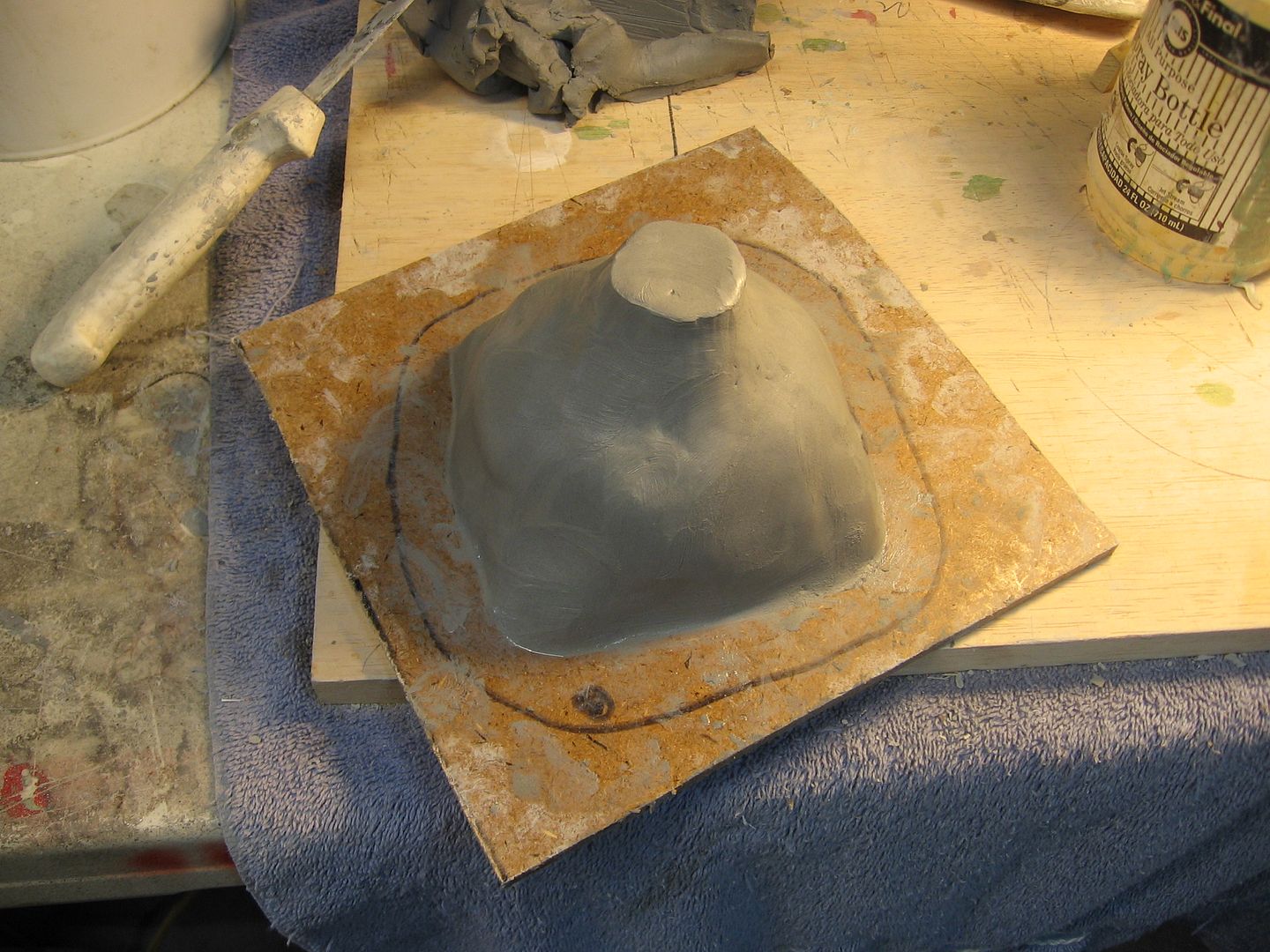

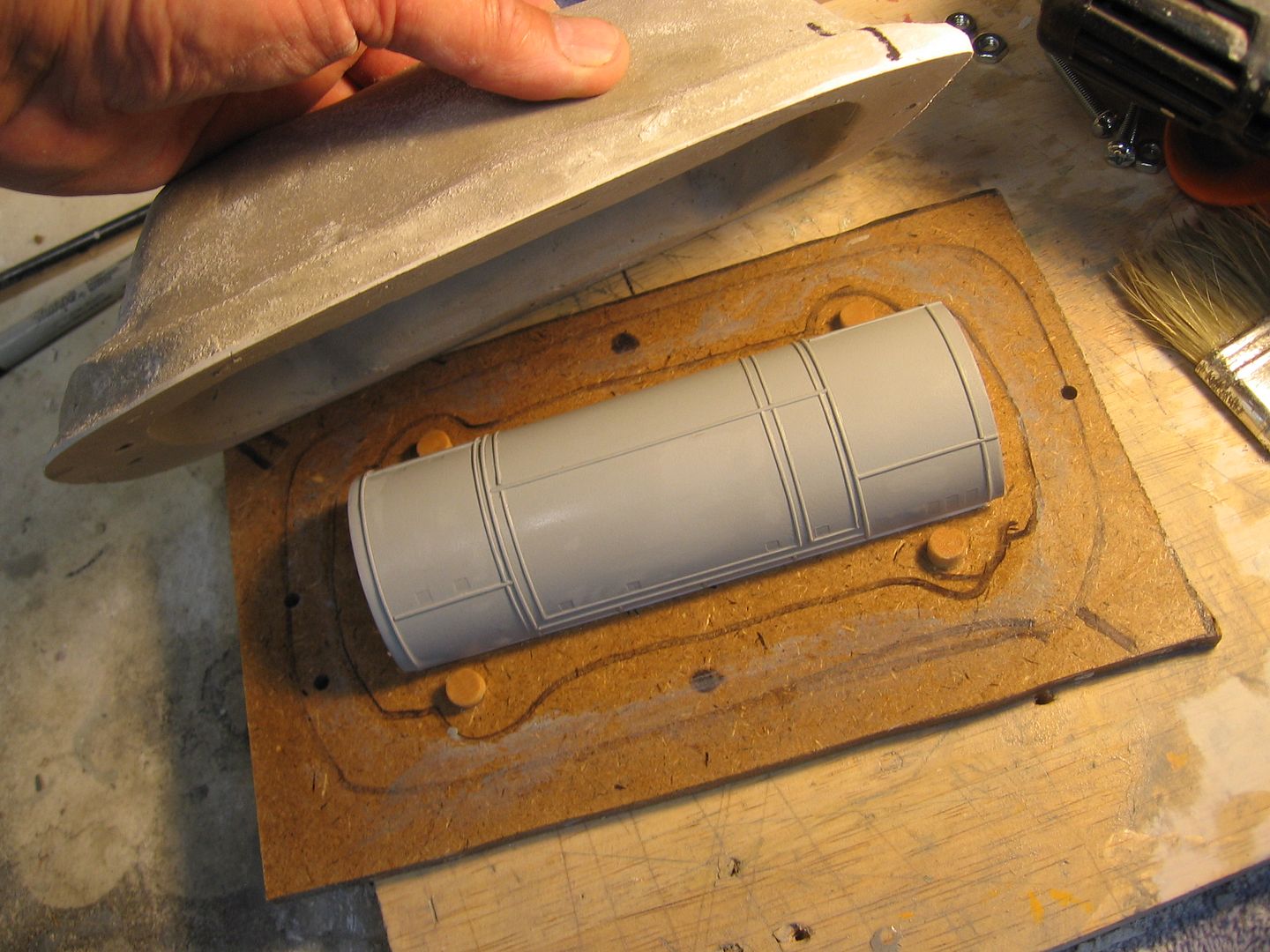

What you see here is EM 210 water based clay and I’m using it to form what will eventually be the silicone molds themselves. It’s backward but it will create the correct shaped mother mold made from Ultracal30. A very hard tool stone.

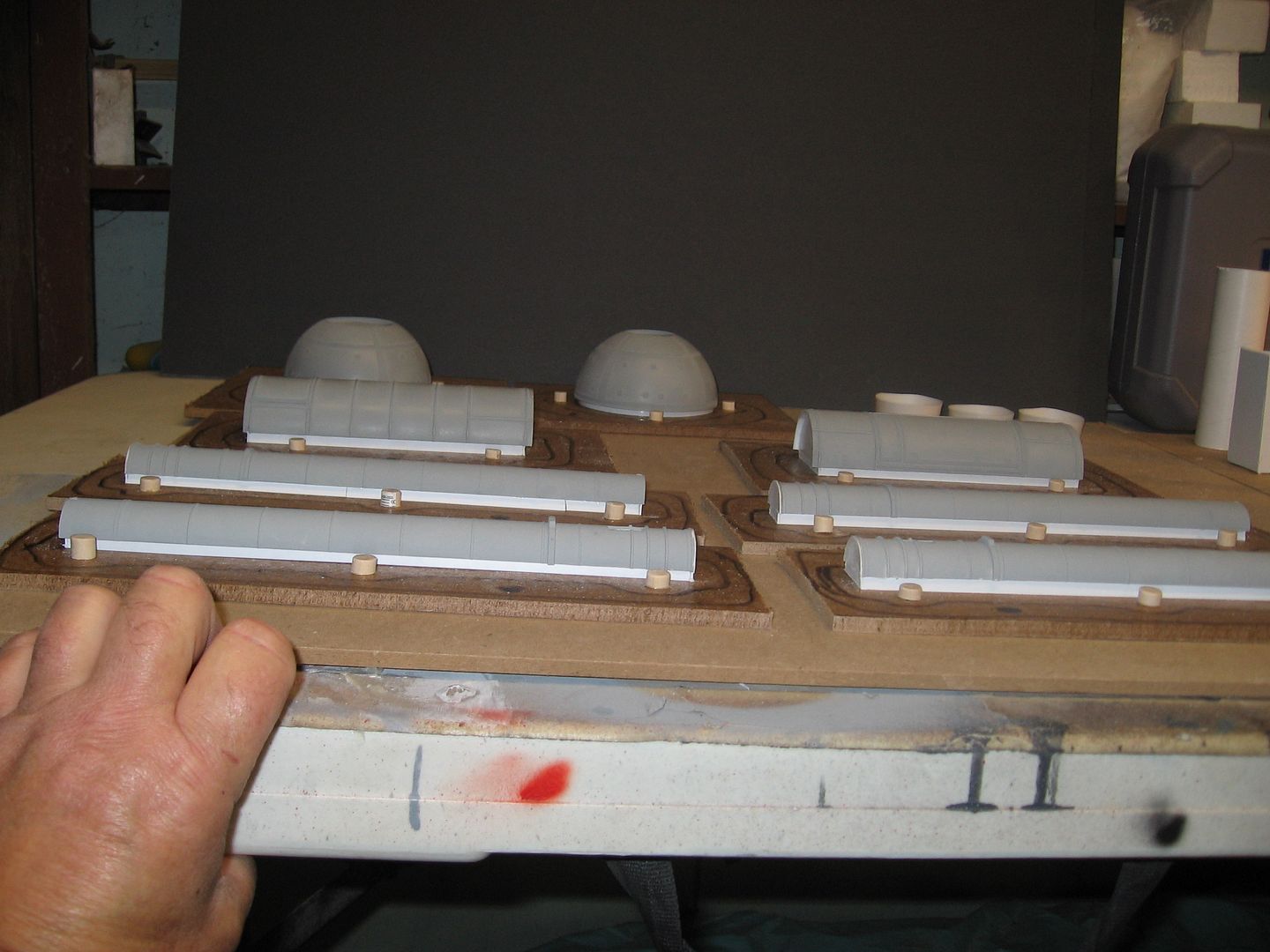

The clay is sliced up in thin sections and formed over the masters. You can smooth it out with a bit of water and your hands. The part sticking up is the pour hole.

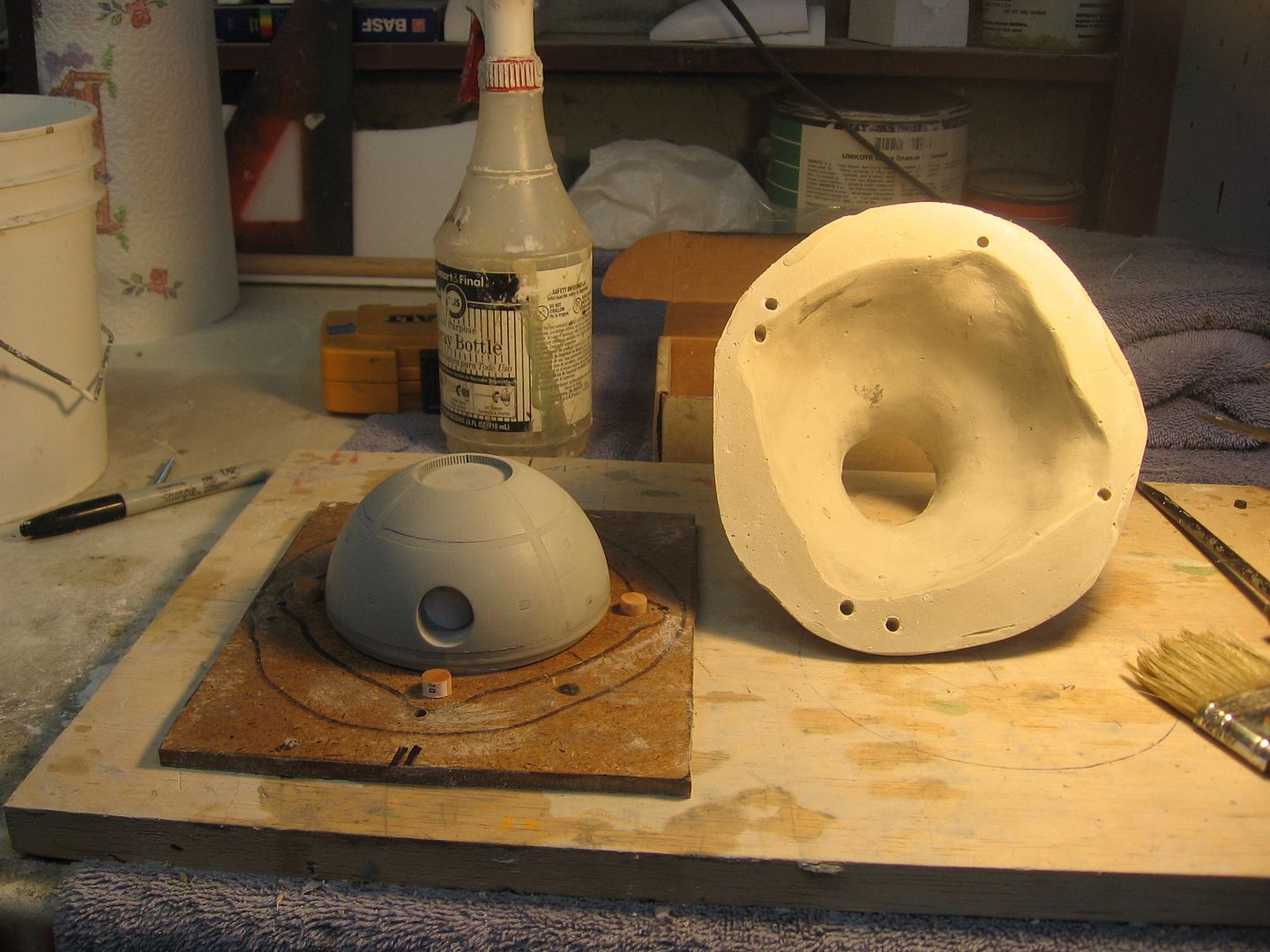

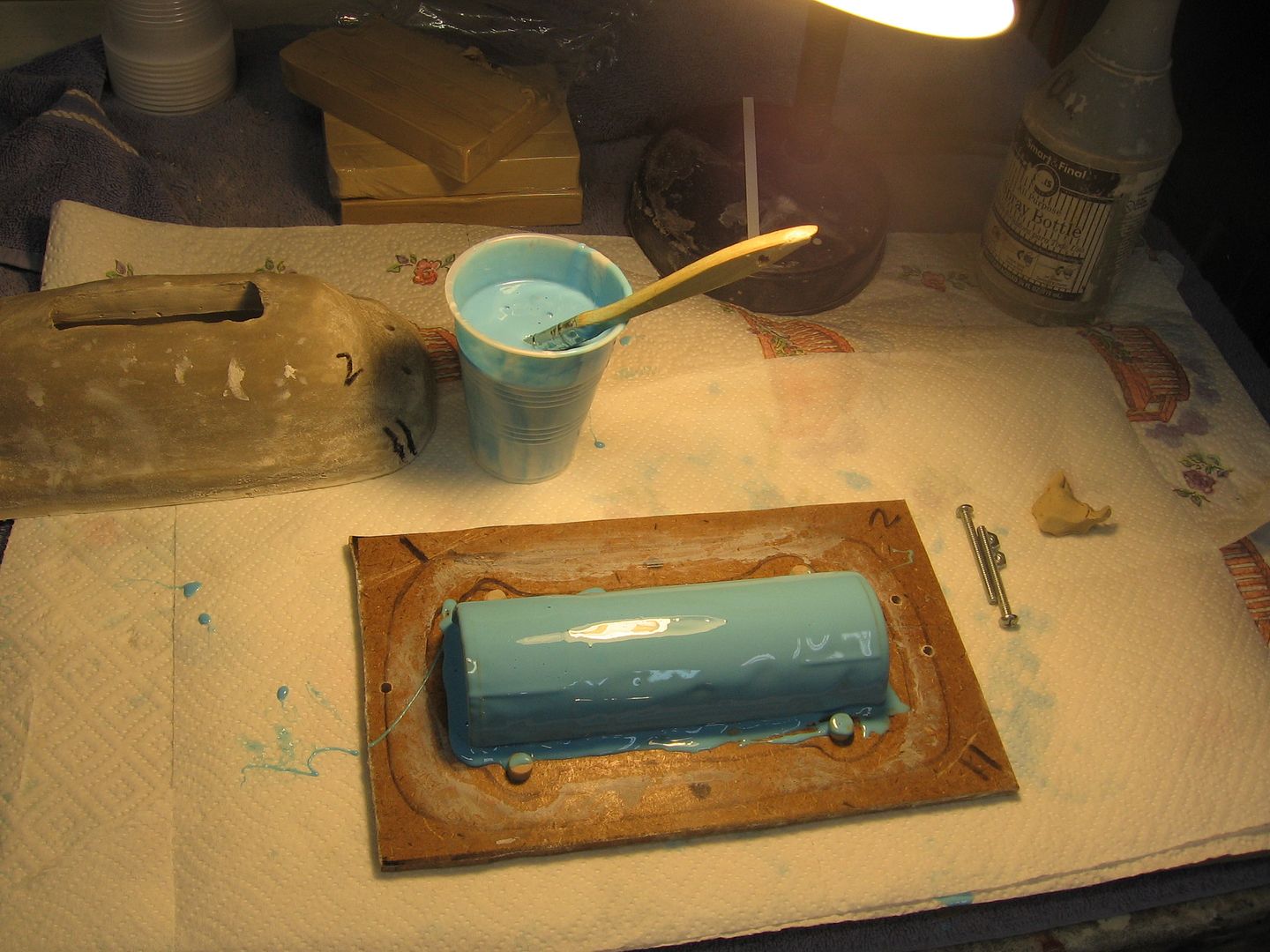

Once all the jackets are formed in water based clay I use some Crystal Clear over the clay. This forms a barrier that helps the clay pull away from the stone when opened. Additionally I use petroleum jelly based mold release on the surrounding wood mounting board to aid in release from the stone.

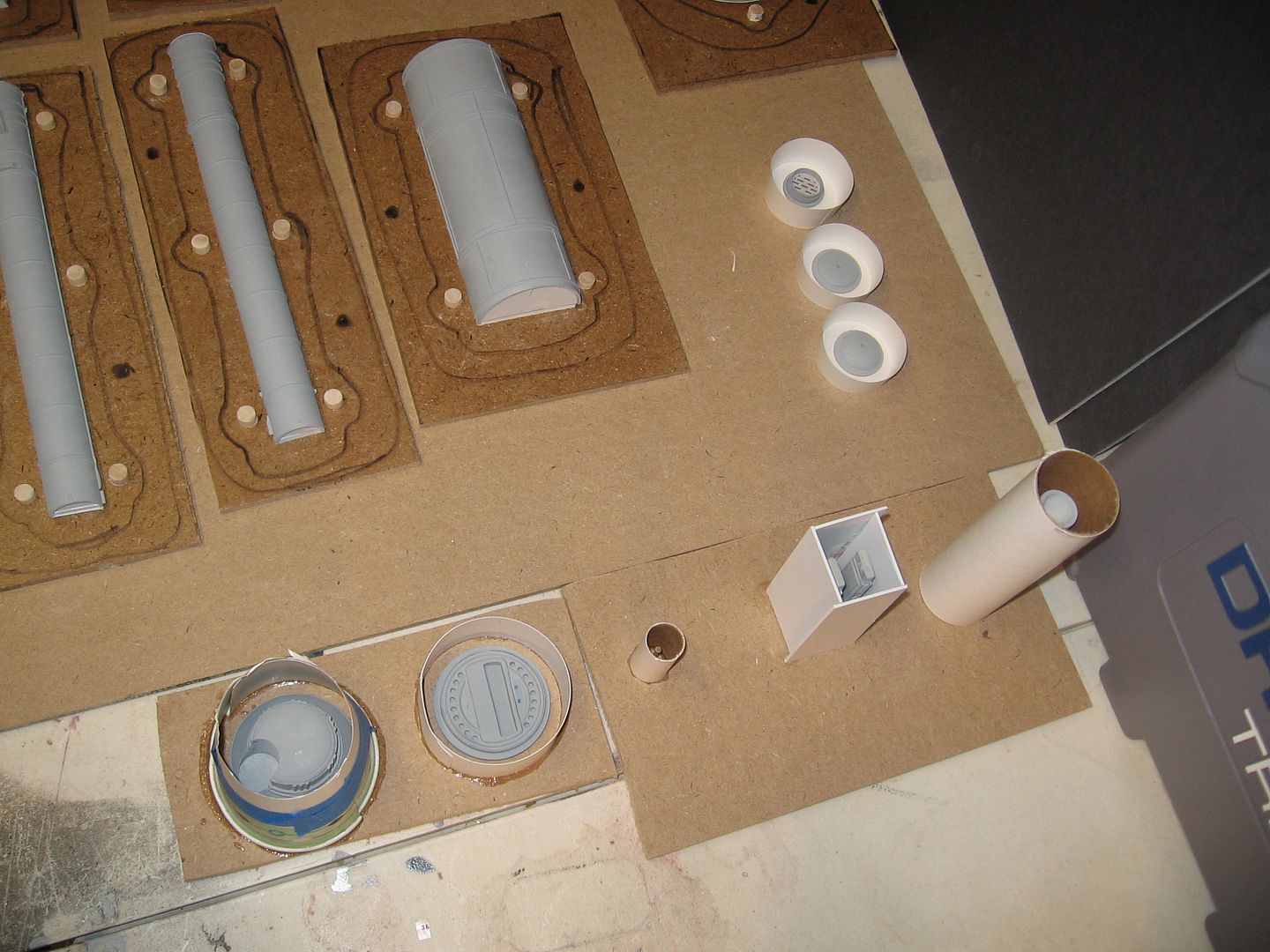

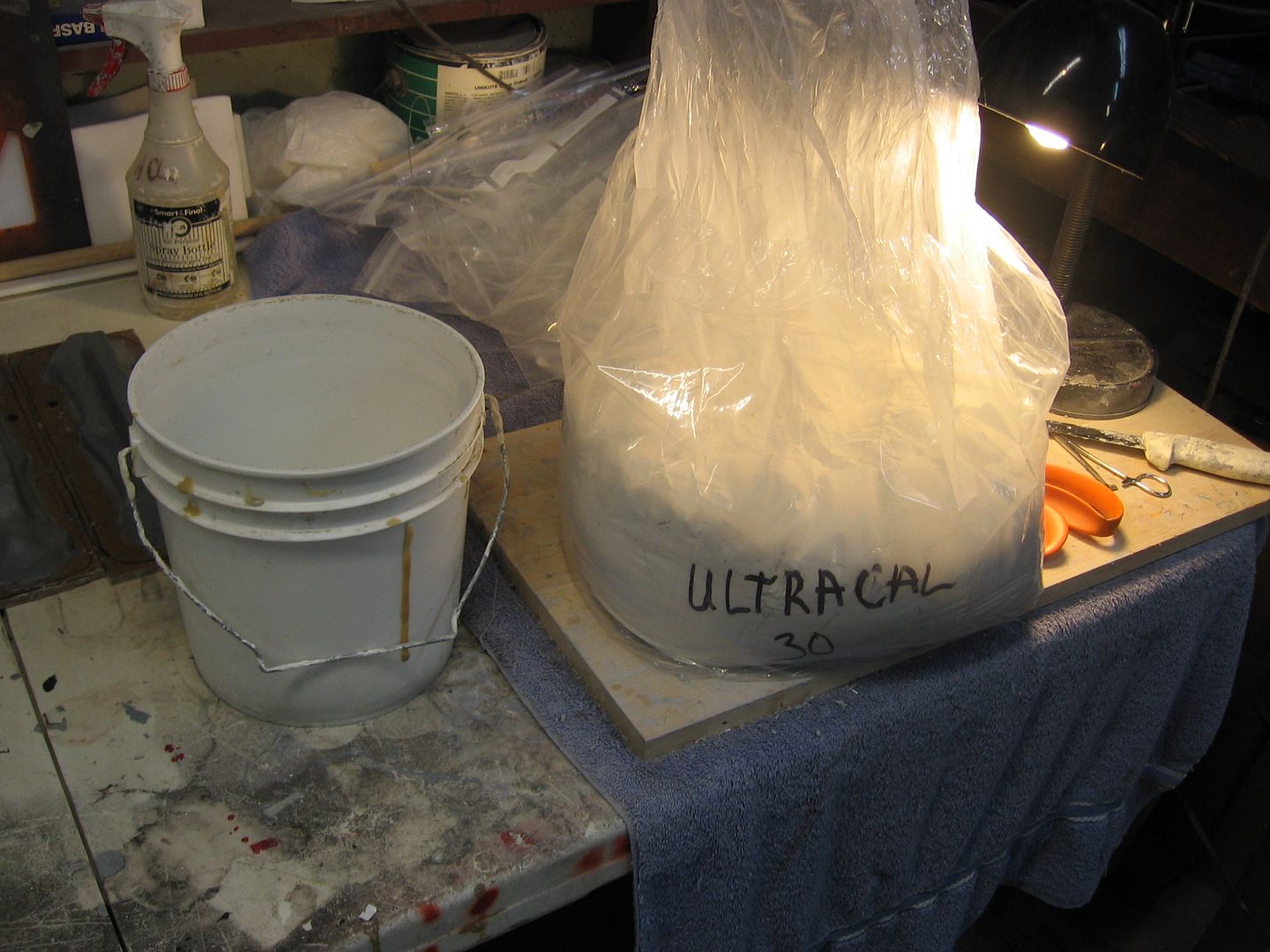

Ultracal 30 mixes just like plaster and takes longer to set up giving you plenty of working time to form it. It will gel up slowly and using water and your hands you can smooth it nicely.

I first use a splash coat and before that sets up all the way I apply a second coat. If you are doing large molds you’ll need to use some burlap or fiber to reinforce the stone. But these molds are small so I left that step out.

Once the stone sets up I like to leave it over night before opening . But before I do open them up tomorrow I have to drill a few alignment holes through the edges. These will later be used to bolt the case mold to the mounting surface. They have to go back in the same position over the master and this prevents them from floating under the hydraulic pressure of the silicone once poured into the mold.

Next I’ll open these up, clean out the clay and clean the masters off with water. The masters should stay mounted to the boards when opened as they are tack glued down. The water base clay in general doesn’t stick well to plastic and wood surfaces.

Once they are all cleaned out the case molds are put back over the masters. Bolted to the surface and the silicone poured into the openings up top of the cases or mother molds.

I will drill some relief holes in a few choice locations for trapped air. Once poured up you will see the silicone coming up through them you know the trapped air is evacuated. Simply stick some clay in the hole to close it.

Once you open the molds you have a nice even thickness silicone mold supported by the stone mother mold and little or no waste of silicone.

More tomorrow.

Steve