You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kit of the USS Daedalus NCC-129?

- Thread starter SteveNeill

- Start date

- Status

- Not open for further replies.

SteveNeill

Sr Member

Thanks Mark.

steve

steve

SteveNeill

Sr Member

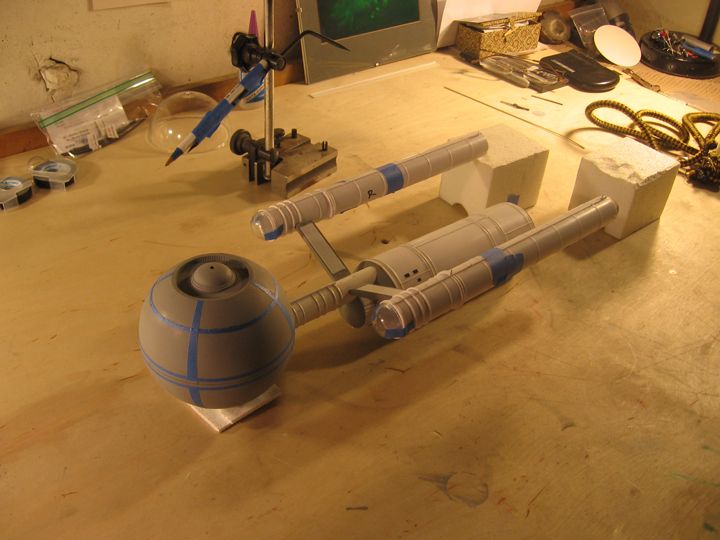

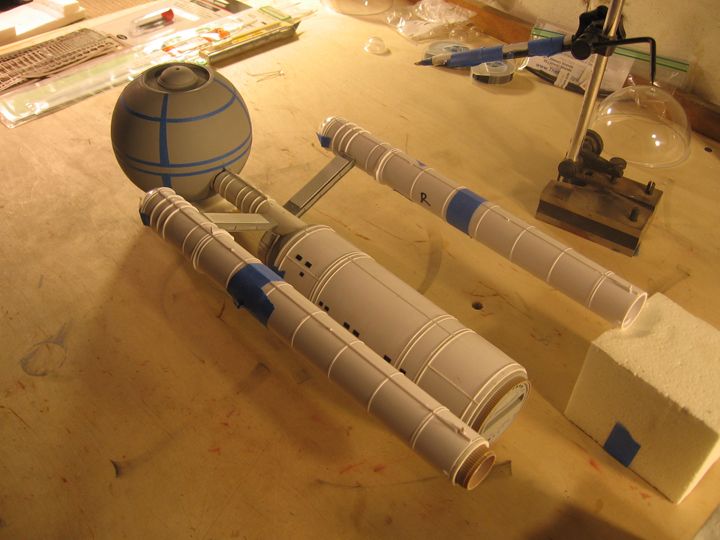

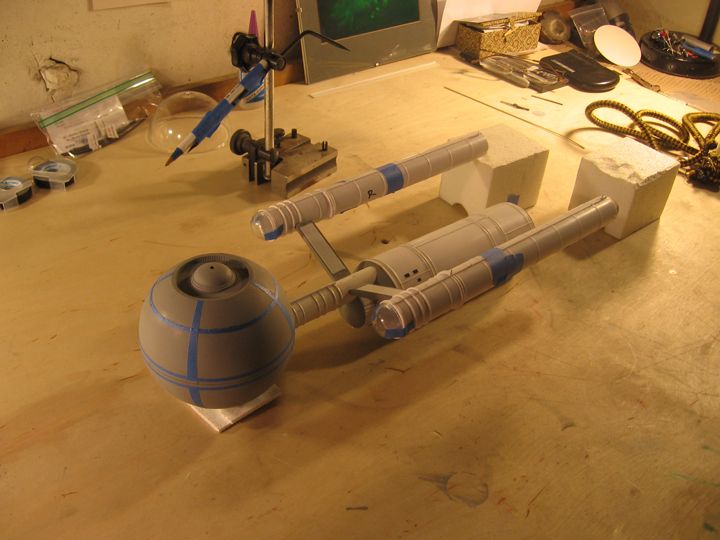

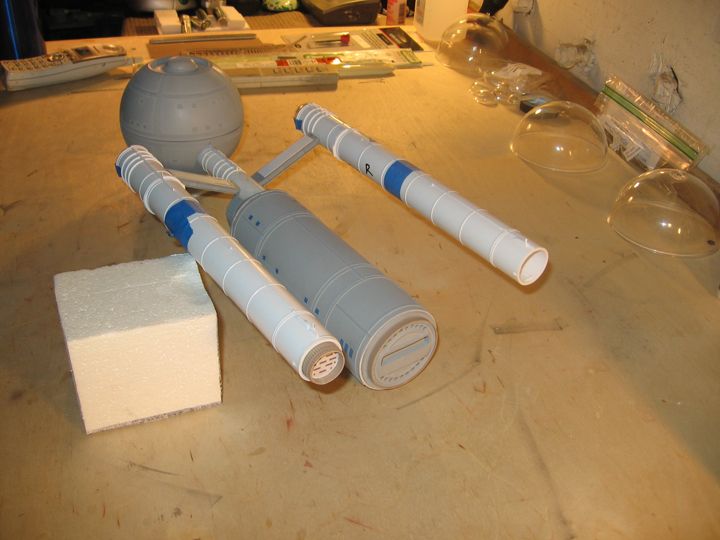

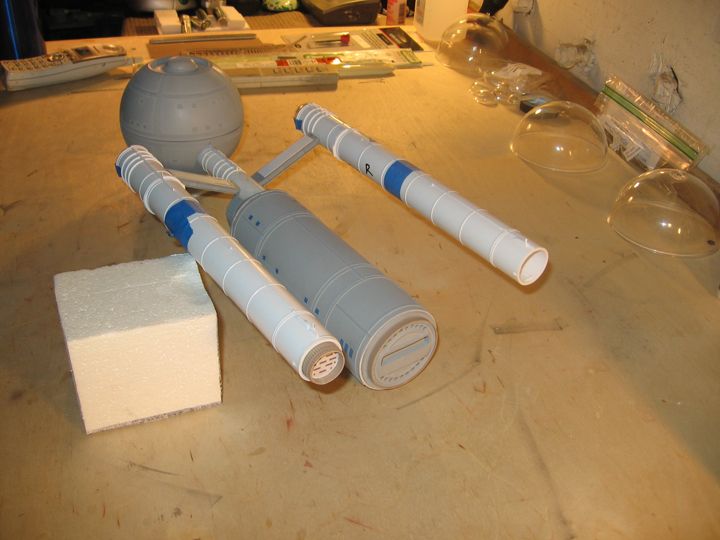

Getting this tape cut and on and parallel was a bit tough. The surface gage was used to create the circles to follow. Calibers and a soft tape measure to get the horizontal tapered panels.

Tomorrow tonight I'll get the window tape on and a few other details and start adding a few layers of primer. Once the tape is removed I'll have some nice deep panels and windows. Scribing wasn't an option as I wouldn't have got those recessed panels. I pretty sure Greg did this.

More tomorrow night. I put in about two hours a night after my 8 hour day with customer models.

Steve

P.S. I got the bridge turned on the lathe last night and the lower dome too.

Tomorrow tonight I'll get the window tape on and a few other details and start adding a few layers of primer. Once the tape is removed I'll have some nice deep panels and windows. Scribing wasn't an option as I wouldn't have got those recessed panels. I pretty sure Greg did this.

More tomorrow night. I put in about two hours a night after my 8 hour day with customer models.

Steve

P.S. I got the bridge turned on the lathe last night and the lower dome too.

Last edited:

SteveNeill

Sr Member

Got all the windows on the ball. Not to many because you the builder are going to have to drill them out and file. Fun huh?

Over all this kit will be easy to build but the windows are the only real hard thing.

So who carries small little files? These windows are 1/8th by 1/8th. Any smaller and it would nearly be impossible to drill them out.

Tomorrow I'll primer this all with a few coats and tomorrow night remove the tape. I'll scribe the 3mm NAV light locations and do the secondary hull windows and we are nearly ready to start the molds.

Steve

Over all this kit will be easy to build but the windows are the only real hard thing.

So who carries small little files? These windows are 1/8th by 1/8th. Any smaller and it would nearly be impossible to drill them out.

Tomorrow I'll primer this all with a few coats and tomorrow night remove the tape. I'll scribe the 3mm NAV light locations and do the secondary hull windows and we are nearly ready to start the molds.

Steve

trekriffic

Sr Member

1/8 x 1/8 on the windows eh? I have just the set of files from XACTO. They are really small. Unfortunately, they are discontinued now. Wish they were still available so I could get a new set as I have used and abused the hell out of them.

SteveNeill

Sr Member

Thanks guys. I'm going to contact my LHS and see what they have. they must have something.

Steve

Steve

SteveNeill

Sr Member

Rob that's a good thought but what clear resin would you suggest. The problem with clear resin is you can't see if the casting has bubbles or not. Once you primer it terrible flaws can show up. I don't want the builder to have to deal with that.

Thanks,

Steve

Thanks,

Steve

robn1

Master Member

...what clear resin would you suggest. The problem with clear resin is you can't see if the casting has bubbles or not...

Well I hoped you would know more about that than I do :lol

I haven't done much casting, but I've been researching in preparation for an upcoming project. Smooth-On and Polytek both make clear urethanes. I would think a tint or filler could be added to make it a milky translucent color, this would make it easier to see imperfections on the surface but still allow for lighting.

This thread has some good tips for powdering the molds to make the resin flow better, eliminating surface bubbles. The texture this creates would also help make the surface more visible.

This is just a suggestion of course, but I hope it helps to see other options. I'm sure it'll turn out great however you do it.

SteveNeill

Sr Member

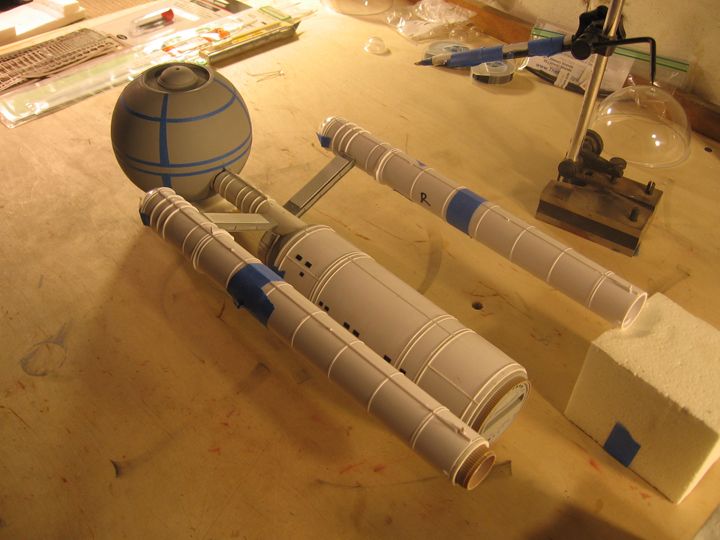

Nearly have the secondary hull completed. Array is pretty well cleaned up.

The ball came out pretty well. It would have been better if I had some to CNC cut vinyl tape for the windows but all and all it’s good.

Its mother’s day this weekend so I doubt I’ll get to the molds but the following week yes.

More tomorrow.

Steve

Primer over the tape

Pull it away and soft sand to clean up.

The ball came out pretty well. It would have been better if I had some to CNC cut vinyl tape for the windows but all and all it’s good.

Its mother’s day this weekend so I doubt I’ll get to the molds but the following week yes.

More tomorrow.

Steve

Primer over the tape

Pull it away and soft sand to clean up.

SteveNeill

Sr Member

Thanks Shizman.

And Rob thank you too! I don't know everything by a long shot. I'm always learning too.

Steve

And Rob thank you too! I don't know everything by a long shot. I'm always learning too.

Steve

SteveNeill

Sr Member

Well thanks. Rob it will be around until the molds break down.

Steve

Steve

Aztek Dummy

Well-Known Member

Steve,

I can cut you vinyl of any shape and size. what can you use?

Now that I think about it, it's probably a day late and a dollar short, but keep me in mind next time!

I can cut you vinyl of any shape and size. what can you use?

Now that I think about it, it's probably a day late and a dollar short, but keep me in mind next time!

SteveNeill

Sr Member

Thanks Aztek. doing these by hand was not the way but as you said.

Thanks again and I'll keep that in mind.

steve

Thanks again and I'll keep that in mind.

steve

- Status

- Not open for further replies.

Similar threads

- Replies

- 36

- Views

- 5,033

- Replies

- 251

- Views

- 40,374

- Replies

- 100

- Views

- 16,291

- Replies

- 2

- Views

- 1,805