You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

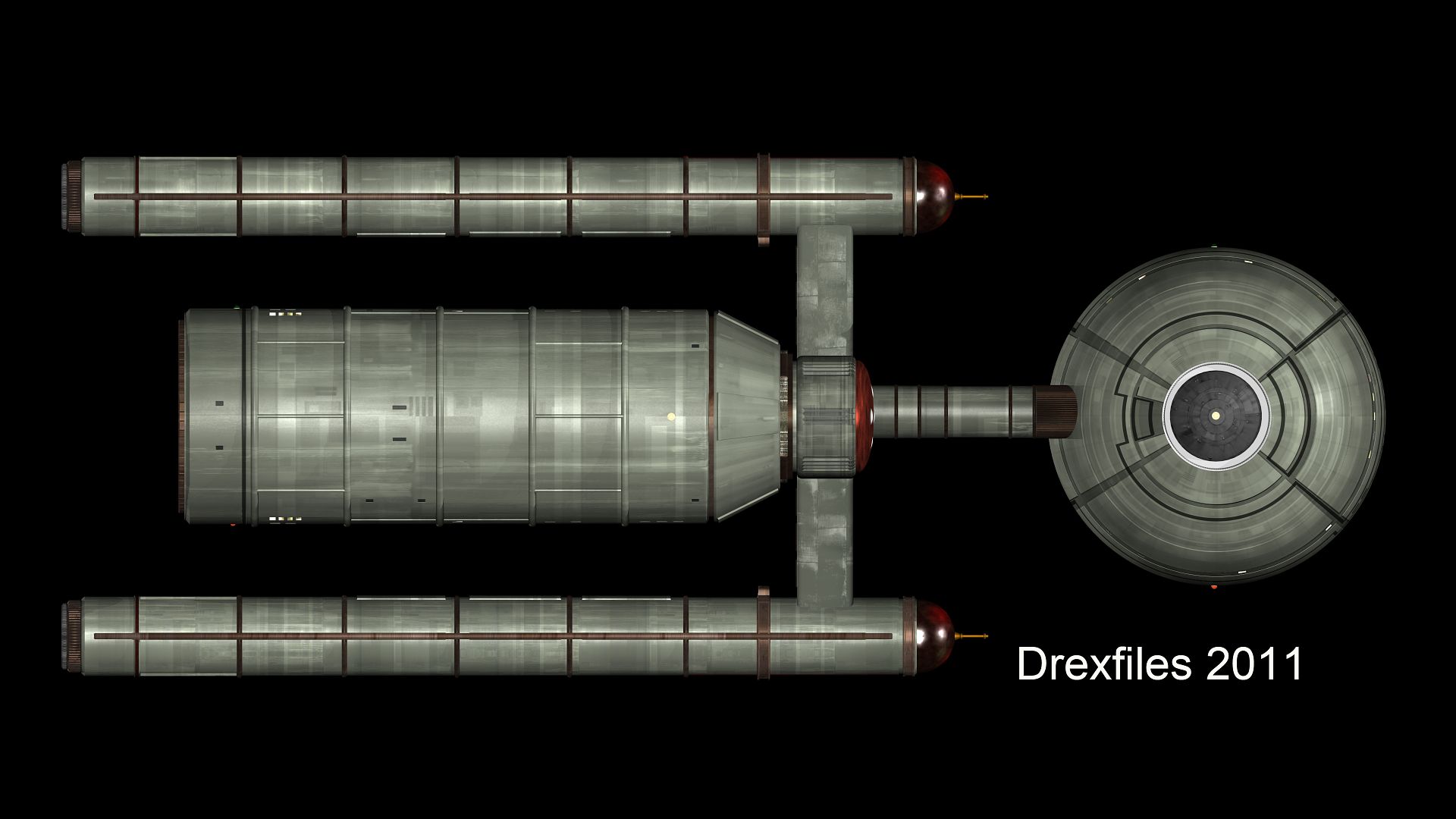

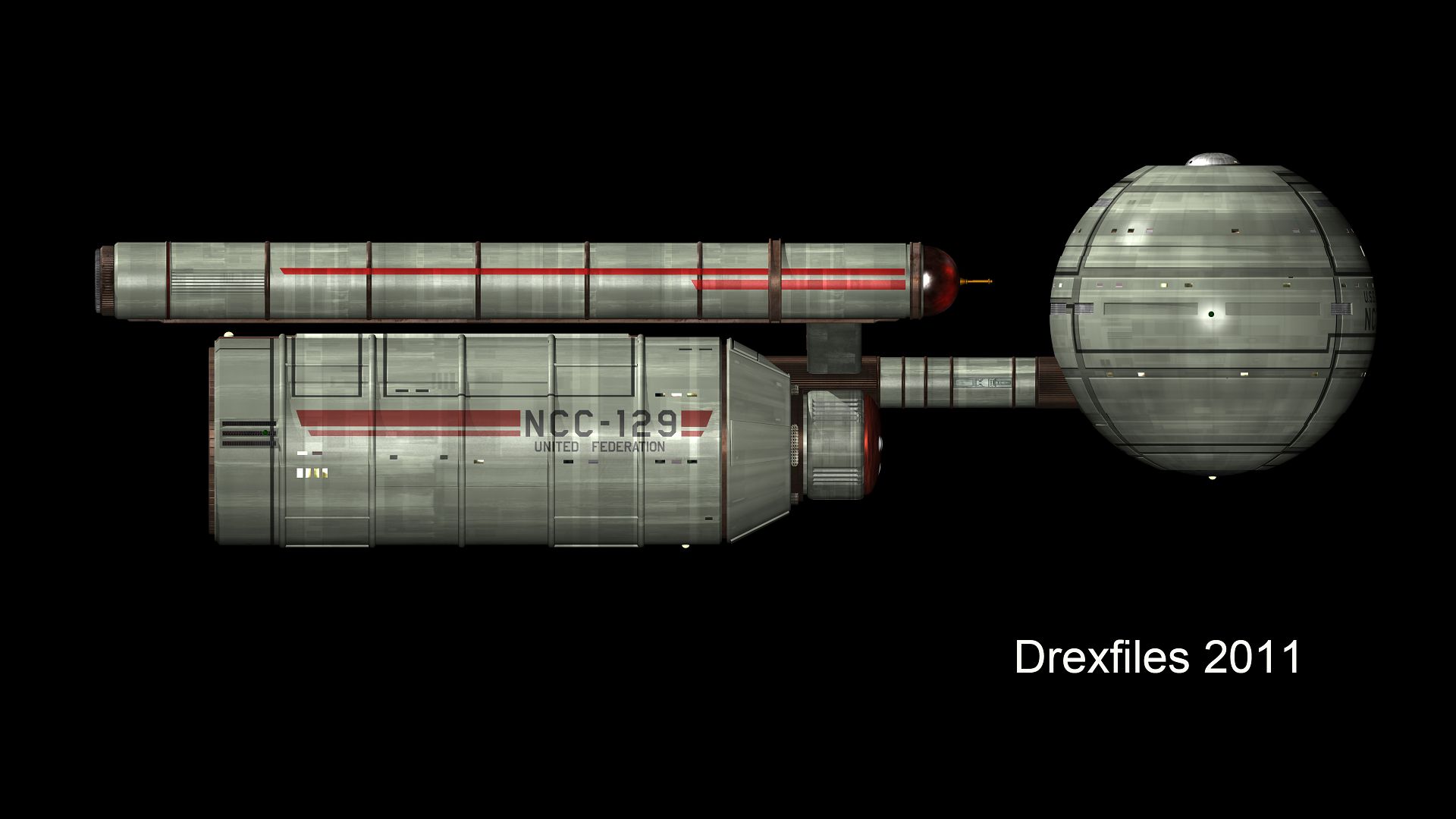

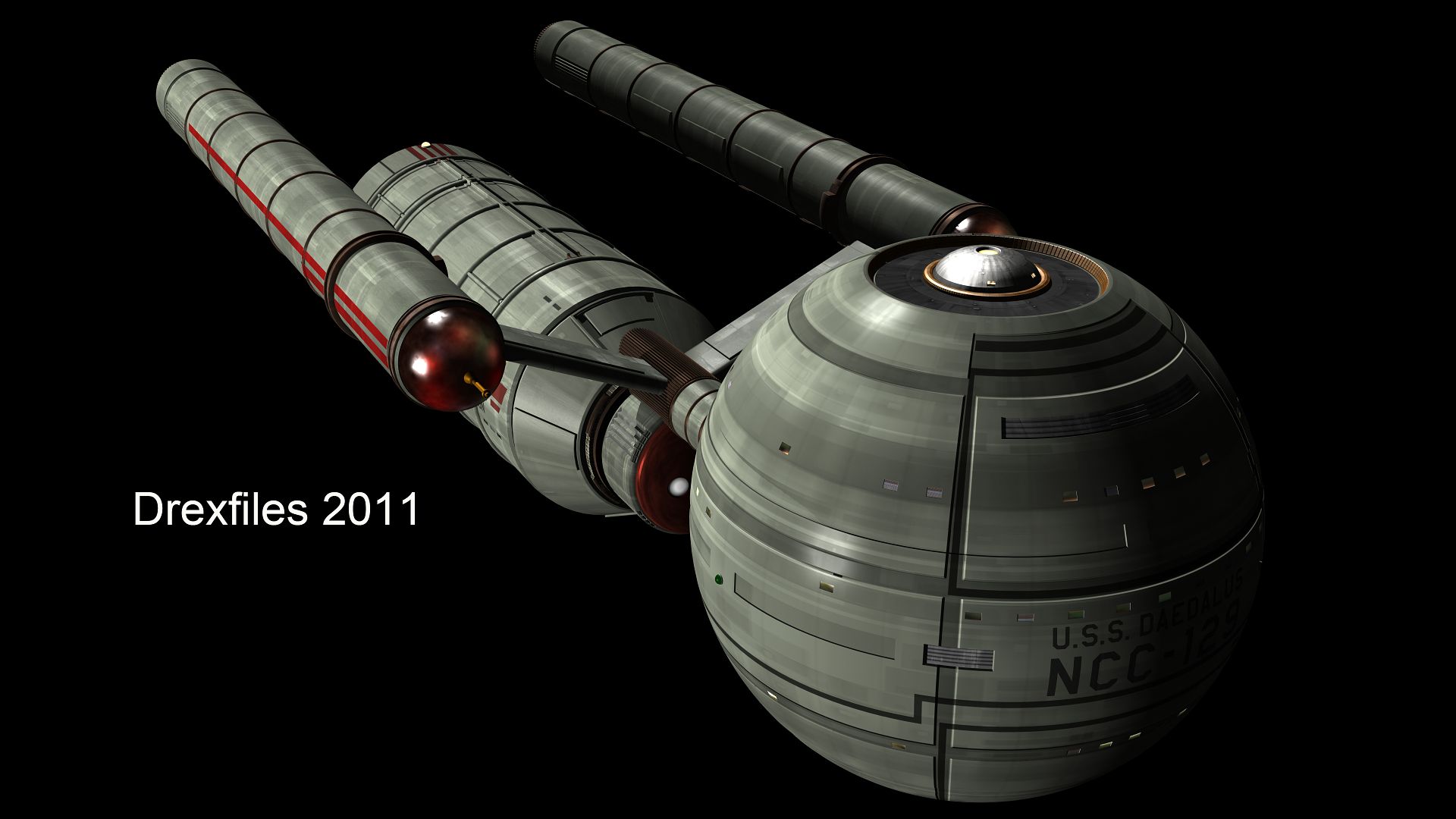

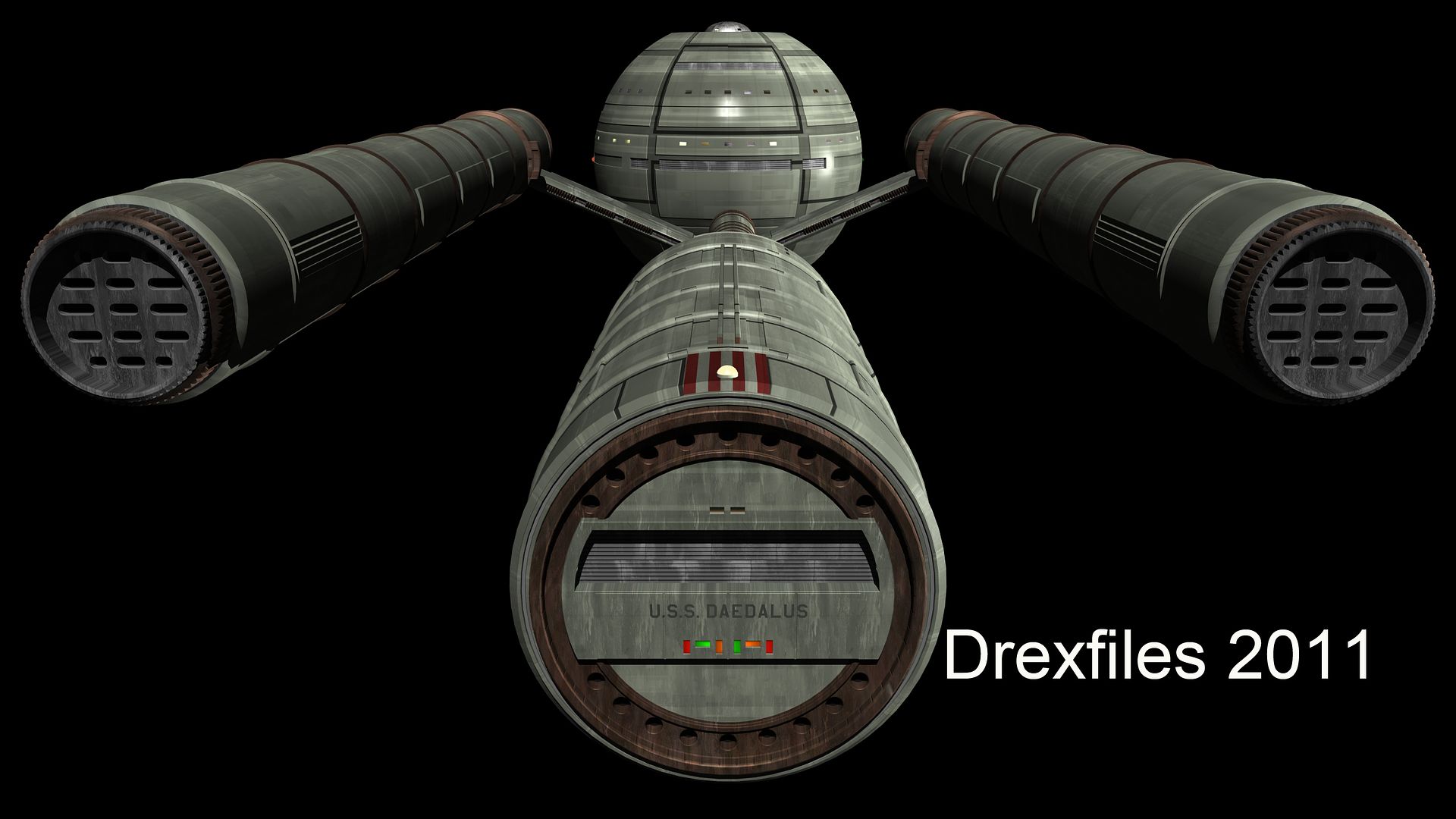

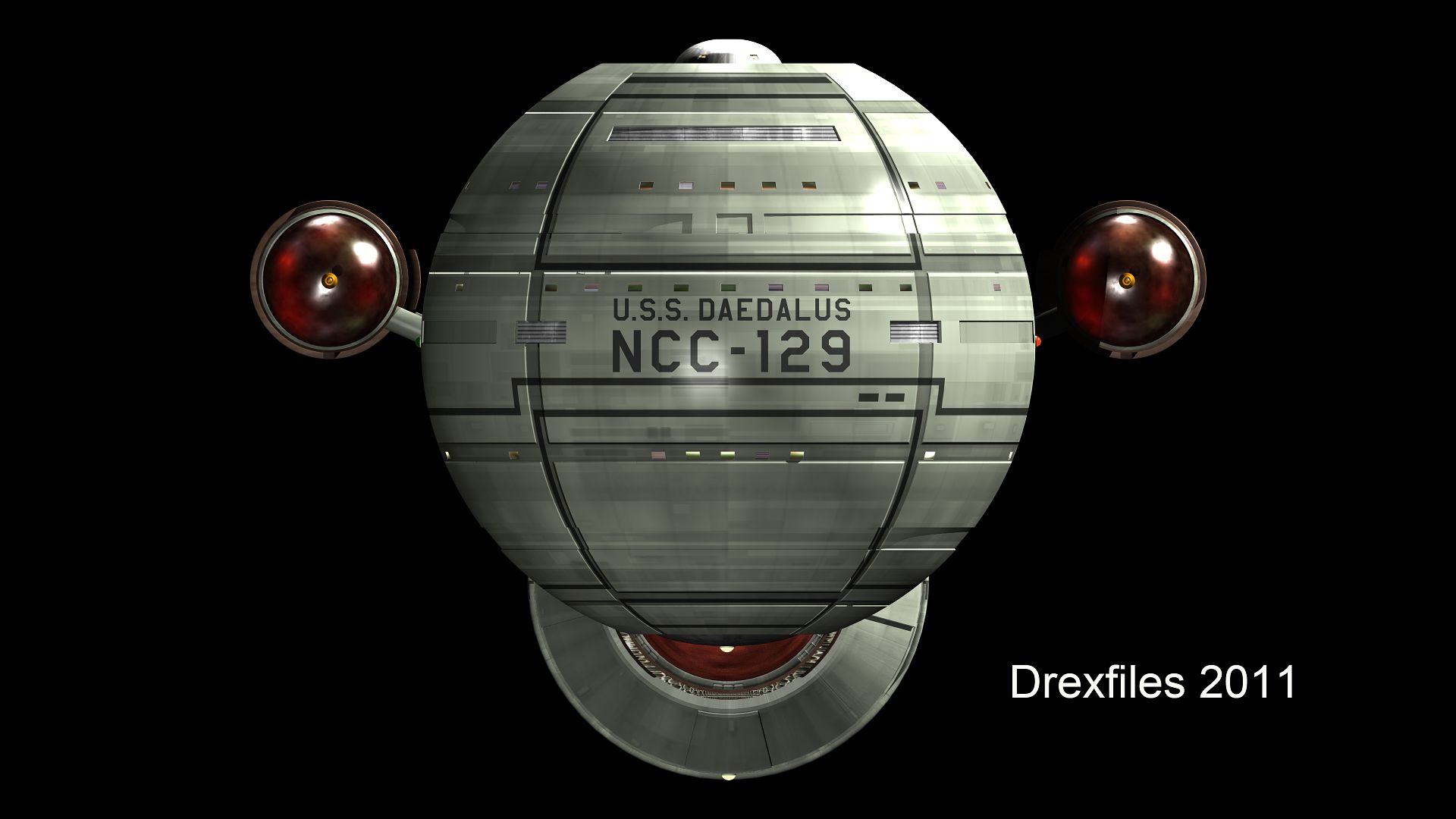

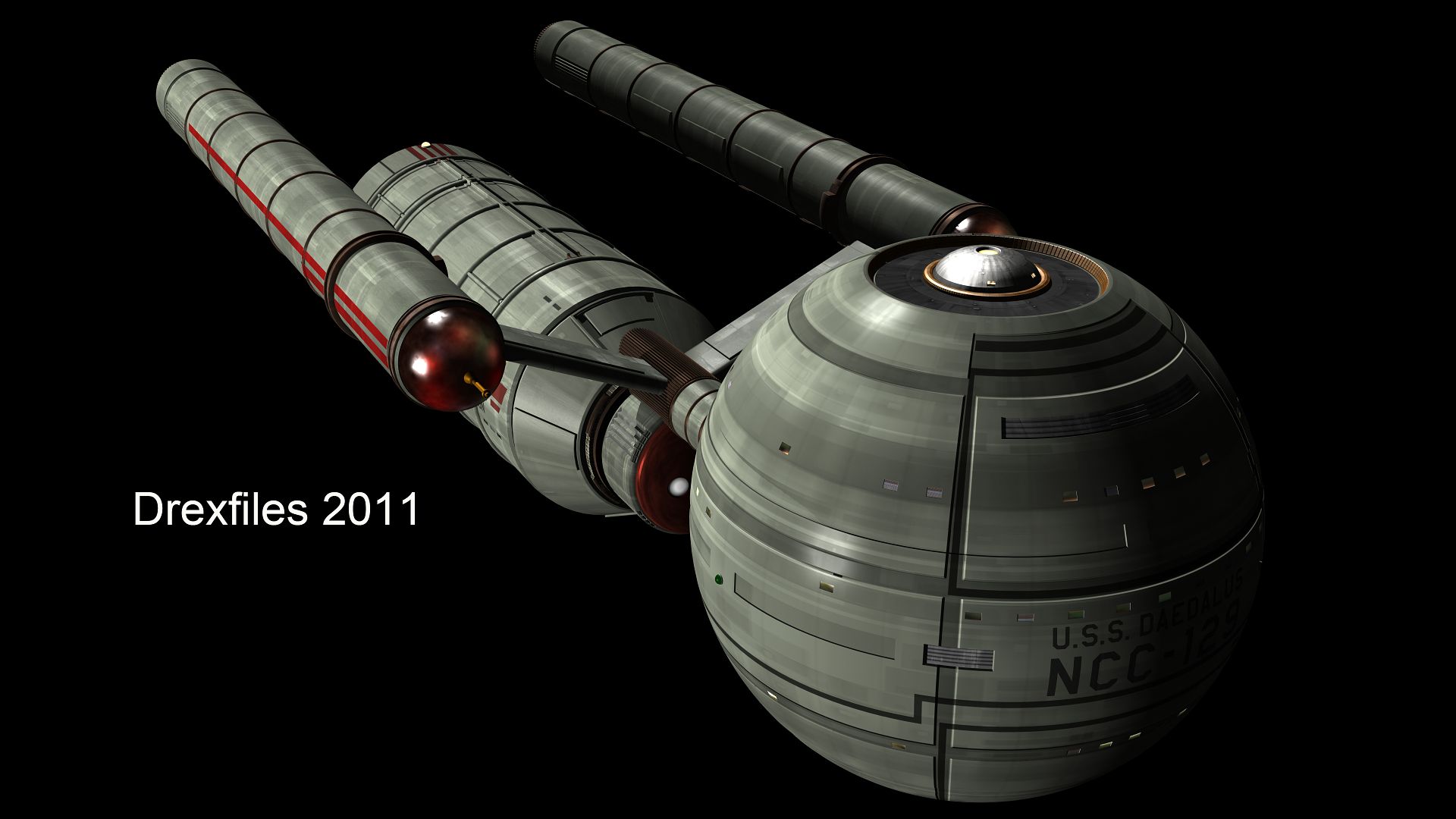

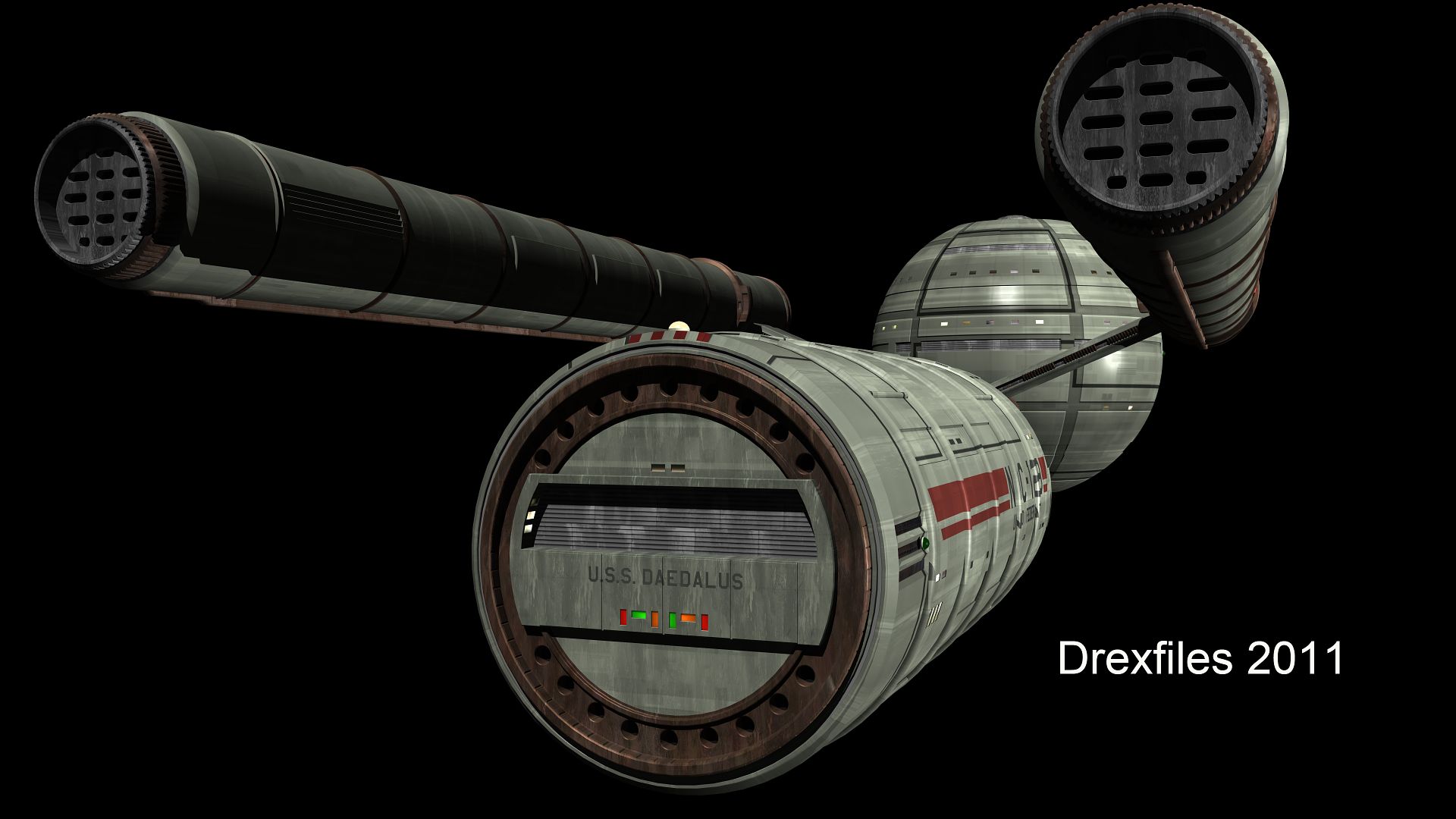

Kit of the USS Daedalus NCC-129?

- Thread starter SteveNeill

- Start date

- Status

- Not open for further replies.

Hi Steve. I'm very sorry to hear about your wife. I hope she feels better soon. You recommended the Fox lathe to me and I can't thank you enough. One of the things I discovered when I went to my local Woodcraft store was that the lathe will turn acrylic and other types of plastic. In fact they sell acrylic blanks for pens to turn on the wood lathes. The guy at the store said the key is to keep the tools sharp and take non aggressive layers off when turning. Anyway I thought I would pass that on figuring you could save hours of puttying and sanding to get a smoothe surface on the wood when you would'nt have grain to fill using the plastic. Any plastics store in your area (yellow pages) carries all kinds of plastic including scraps that can be purchased for a buck a pound. They have all sizes of tubes, solid rods and thick blocks that would turn nicely.

SteveNeill

Sr Member

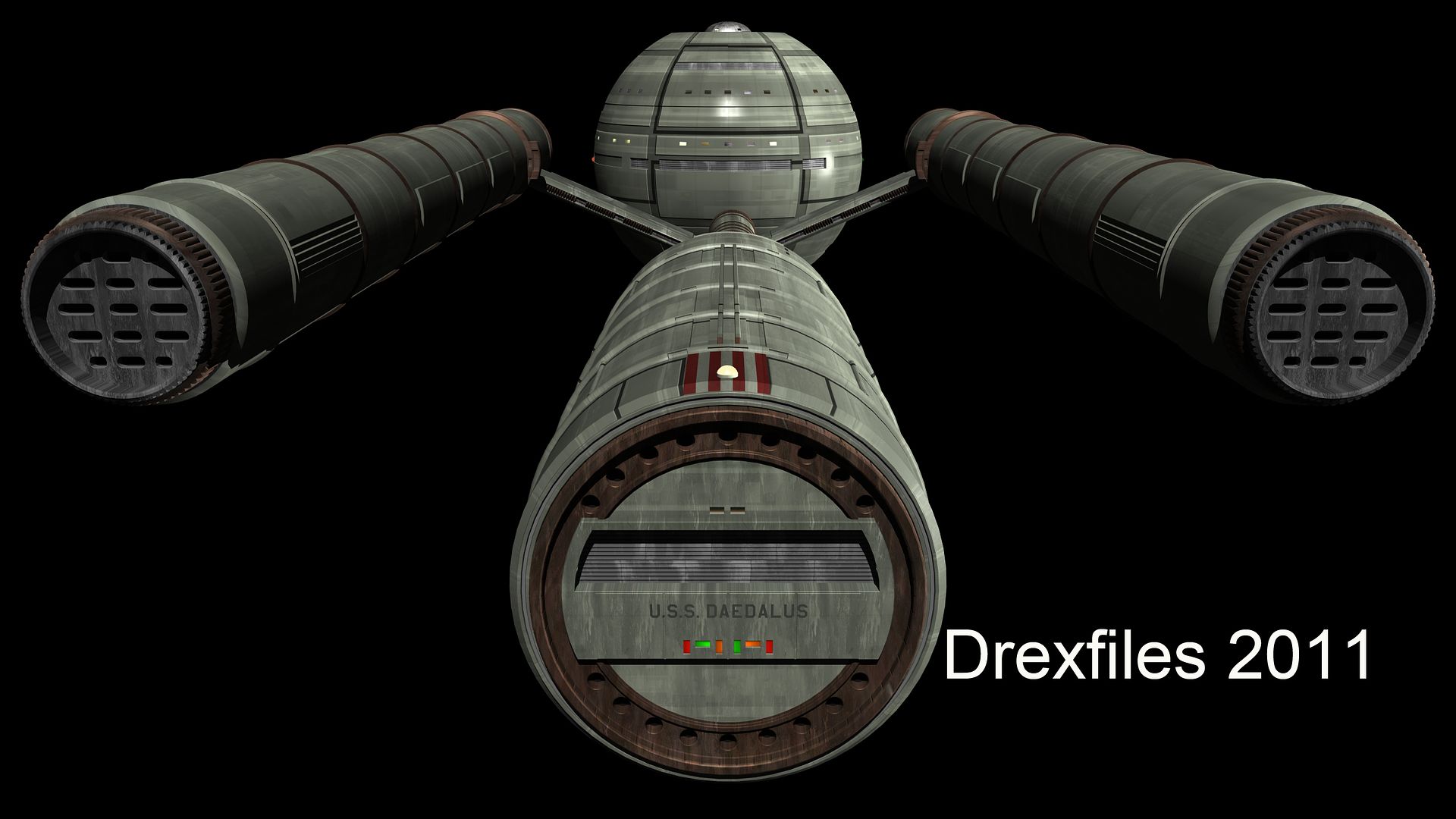

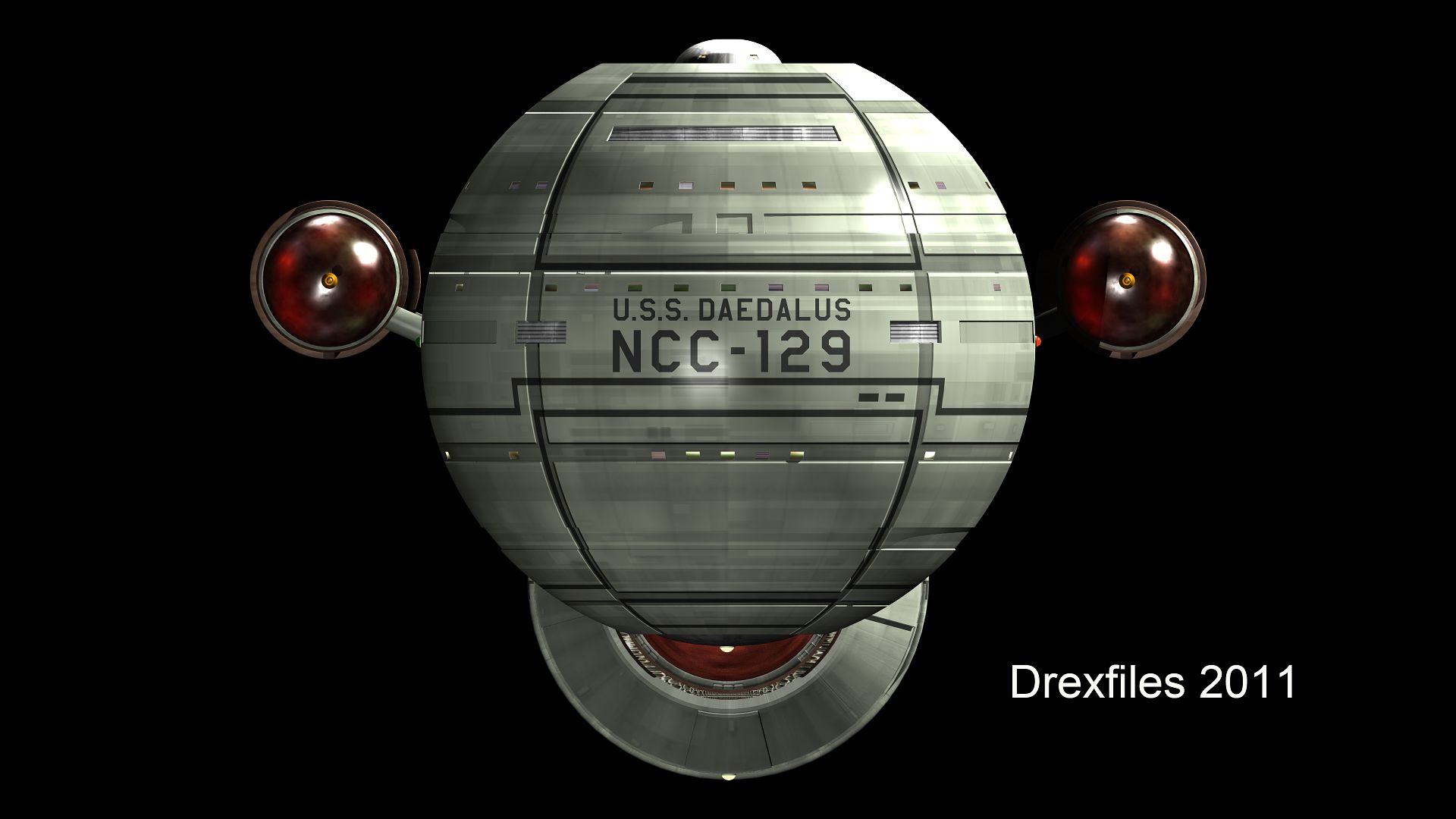

Doug worked on the model a bunch this weekend for me and added a lot of details not seen in Greg's old model. Including Aztecs.

Although I might include some of the new details and Aztecs are up to Rob at Acreations and you the builder. Personally I'll pass on the Aztecs but make it an option.

I think Doug did a great job of making this look like a real ship and not just a desk top model but then again he's damn good at it. It's what he does.

These have never been seen before! Thanks Doug for the re-work of the model!

Steve

These are just a few of the many images Doug sent me.

Although I might include some of the new details and Aztecs are up to Rob at Acreations and you the builder. Personally I'll pass on the Aztecs but make it an option.

I think Doug did a great job of making this look like a real ship and not just a desk top model but then again he's damn good at it. It's what he does.

These have never been seen before! Thanks Doug for the re-work of the model!

Steve

These are just a few of the many images Doug sent me.

trekman1017

Well-Known Member

got any good side or bottom shots?

SteveNeill

Sr Member

Hi Steve. I'm very sorry to hear about your wife. I hope she feels better soon. You recommended the Fox lathe to me and I can't thank you enough. One of the things I discovered when I went to my local Woodcraft store was that the lathe will turn acrylic and other types of plastic. In fact they sell acrylic blanks for pens to turn on the wood lathes. The guy at the store said the key is to keep the tools sharp and take non aggressive layers off when turning. Anyway I thought I would pass that on figuring you could save hours of puttying and sanding to get a smoothe surface on the wood when you would'nt have grain to fill using the plastic. Any plastics store in your area (yellow pages) carries all kinds of plastic including scraps that can be purchased for a buck a pound. They have all sizes of tubes, solid rods and thick blocks that would turn nicely.

Thanks so much I kinda figured but the nearest plastics store is an hour drive for me that carries such things. LHS carries thick Styrene though.

Thanks again very much.

steve

SteveNeill

Sr Member

trekman1017

Well-Known Member

I'm sorry I'm like a kid in a candy store, can we please see the rest? pretty please?

SteveNeill

Sr Member

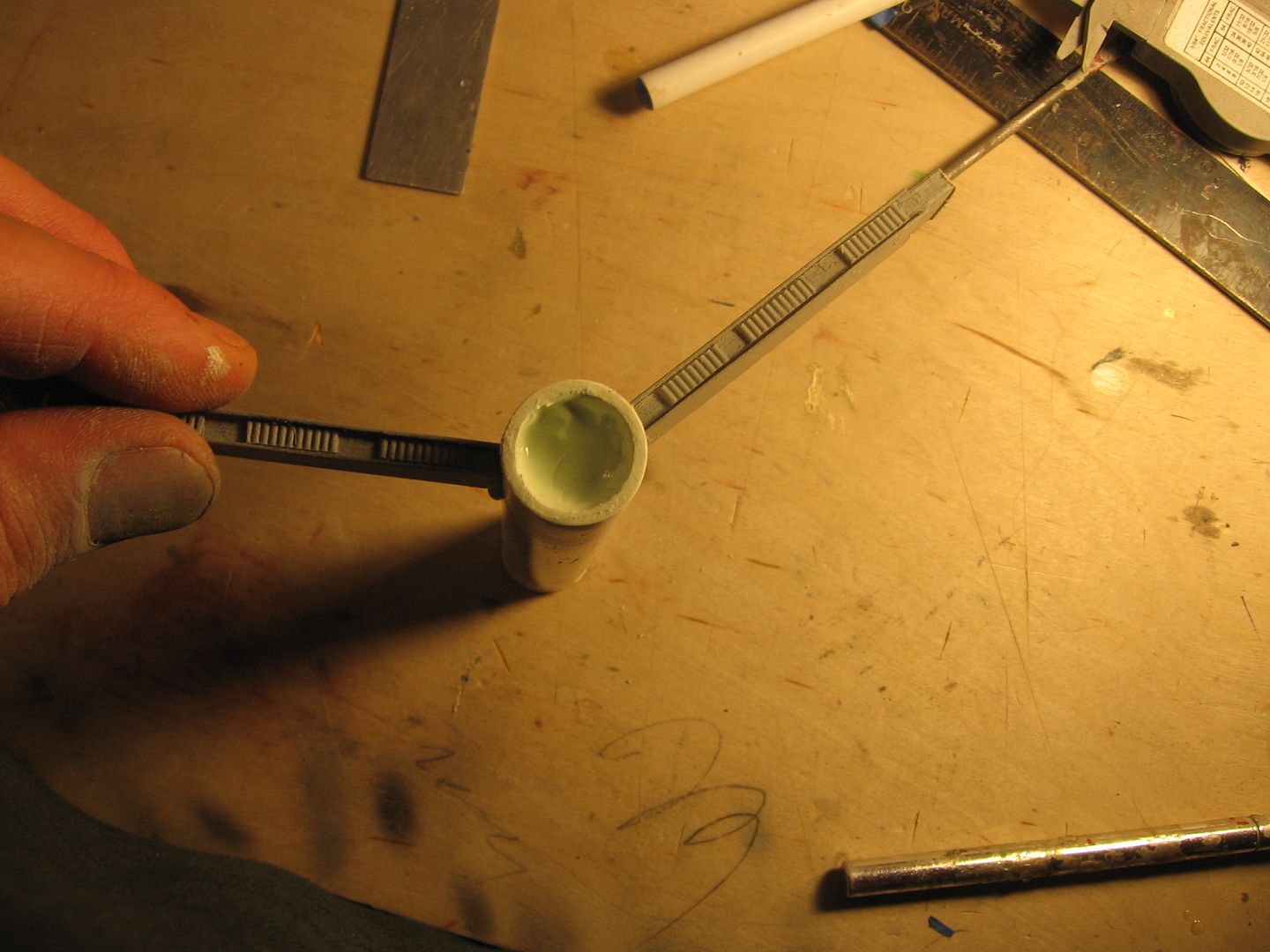

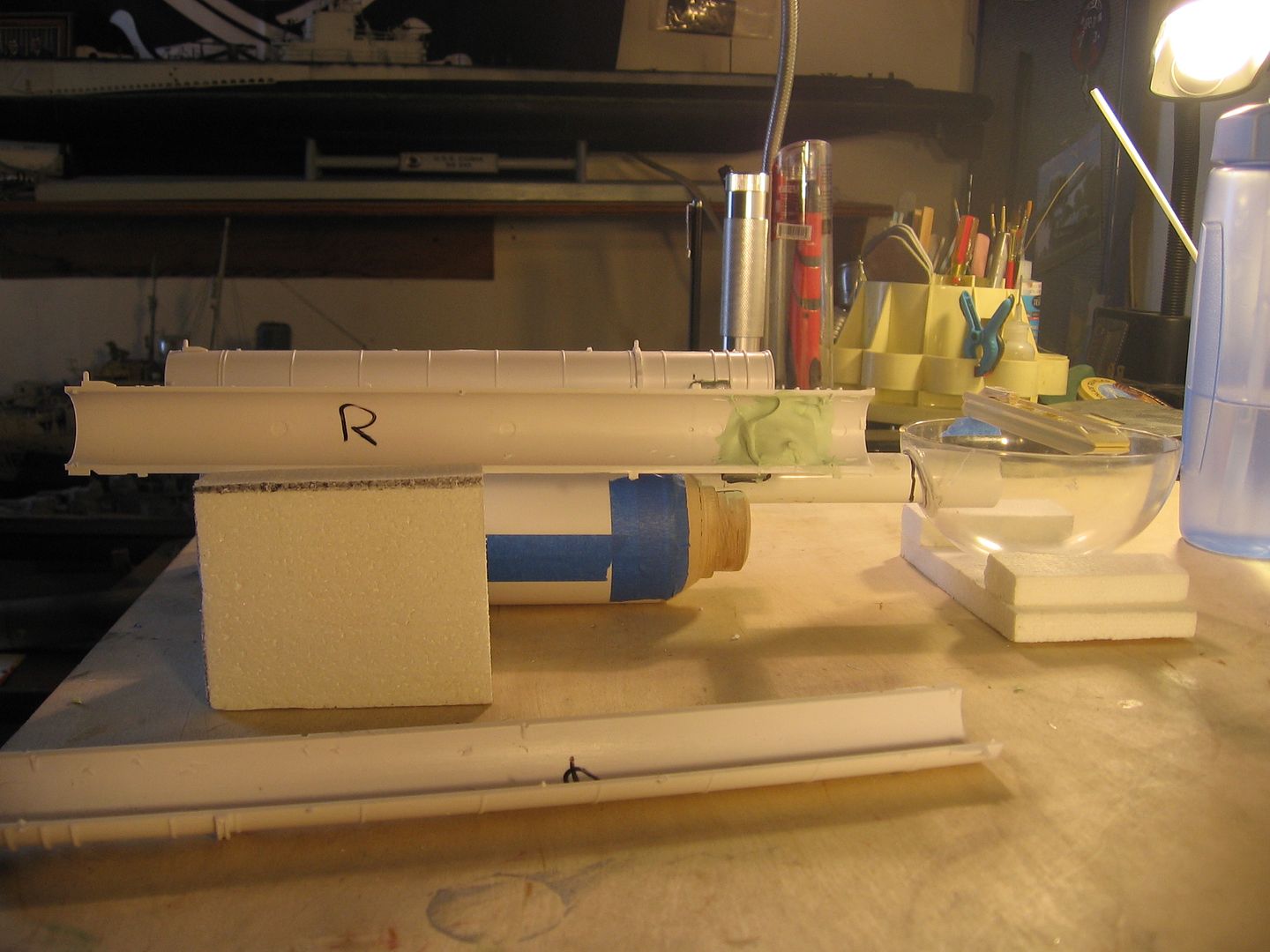

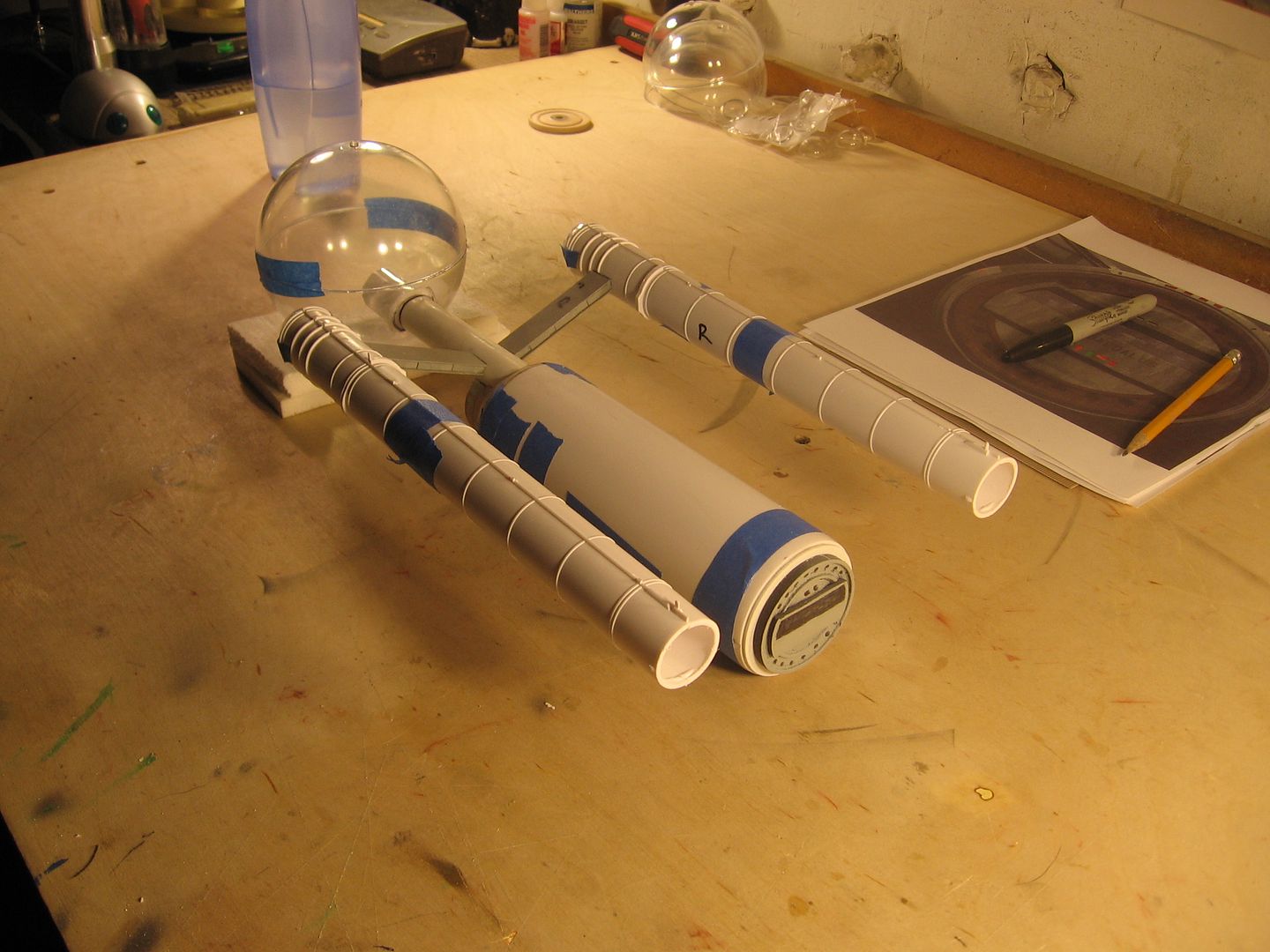

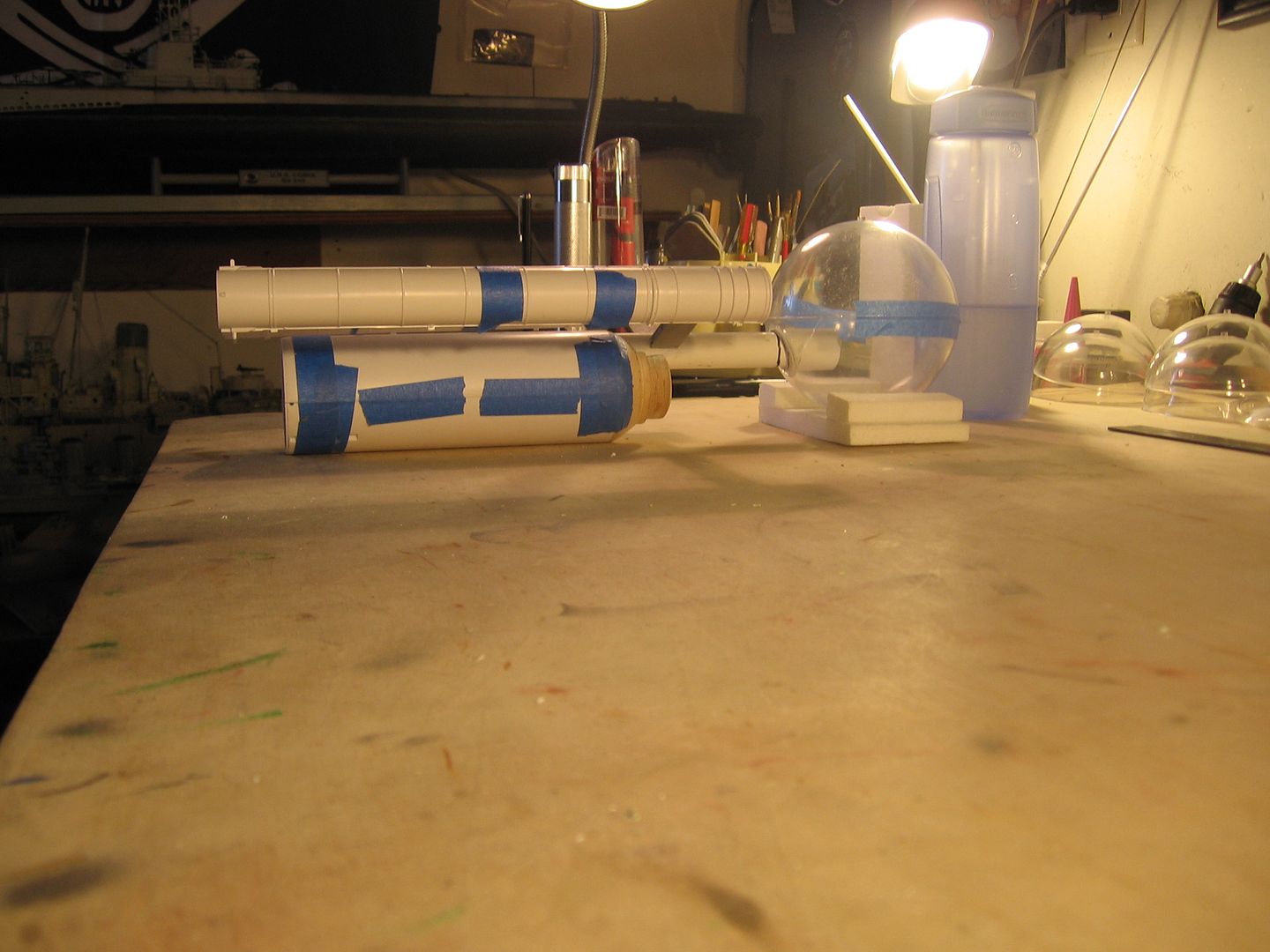

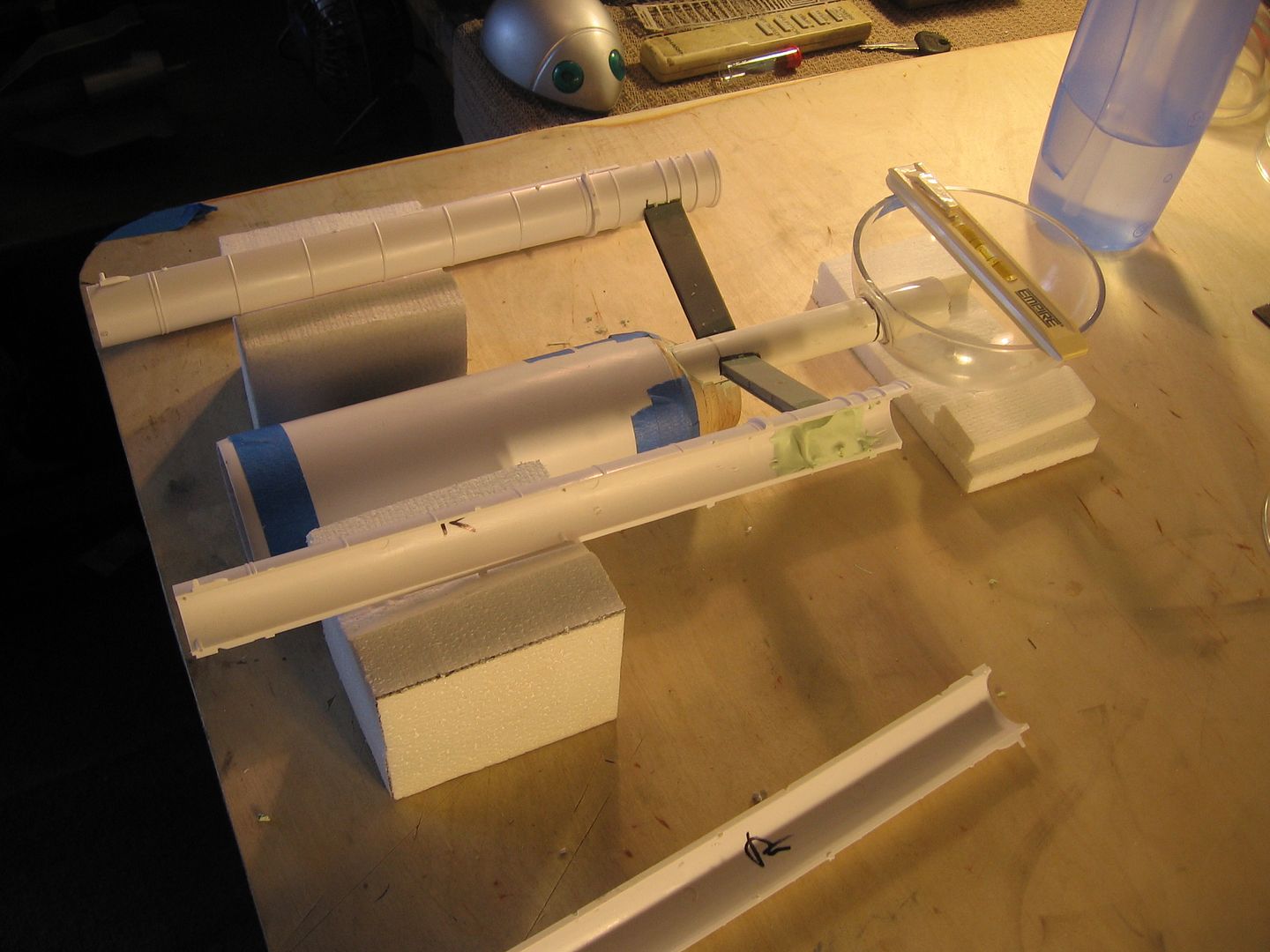

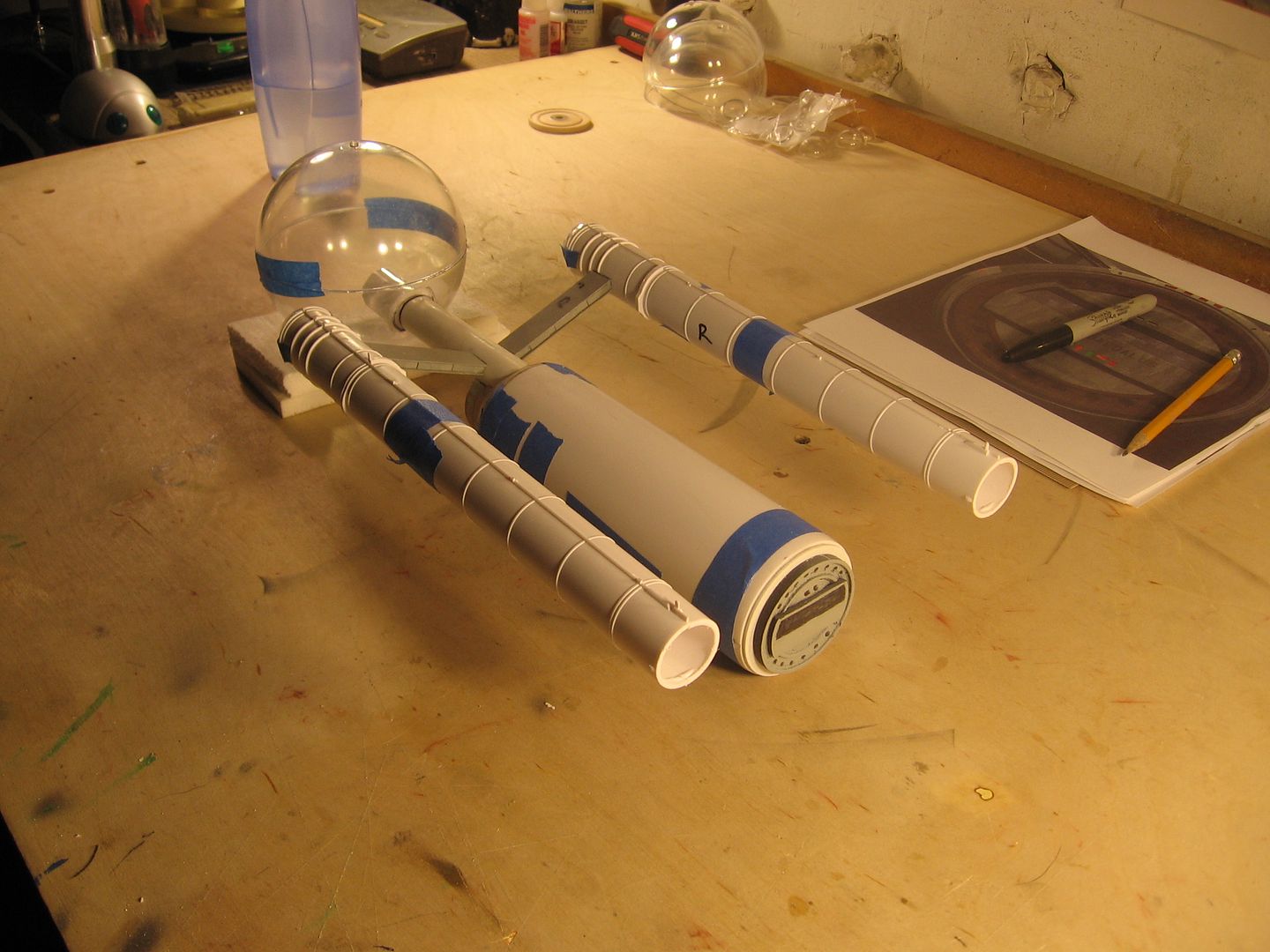

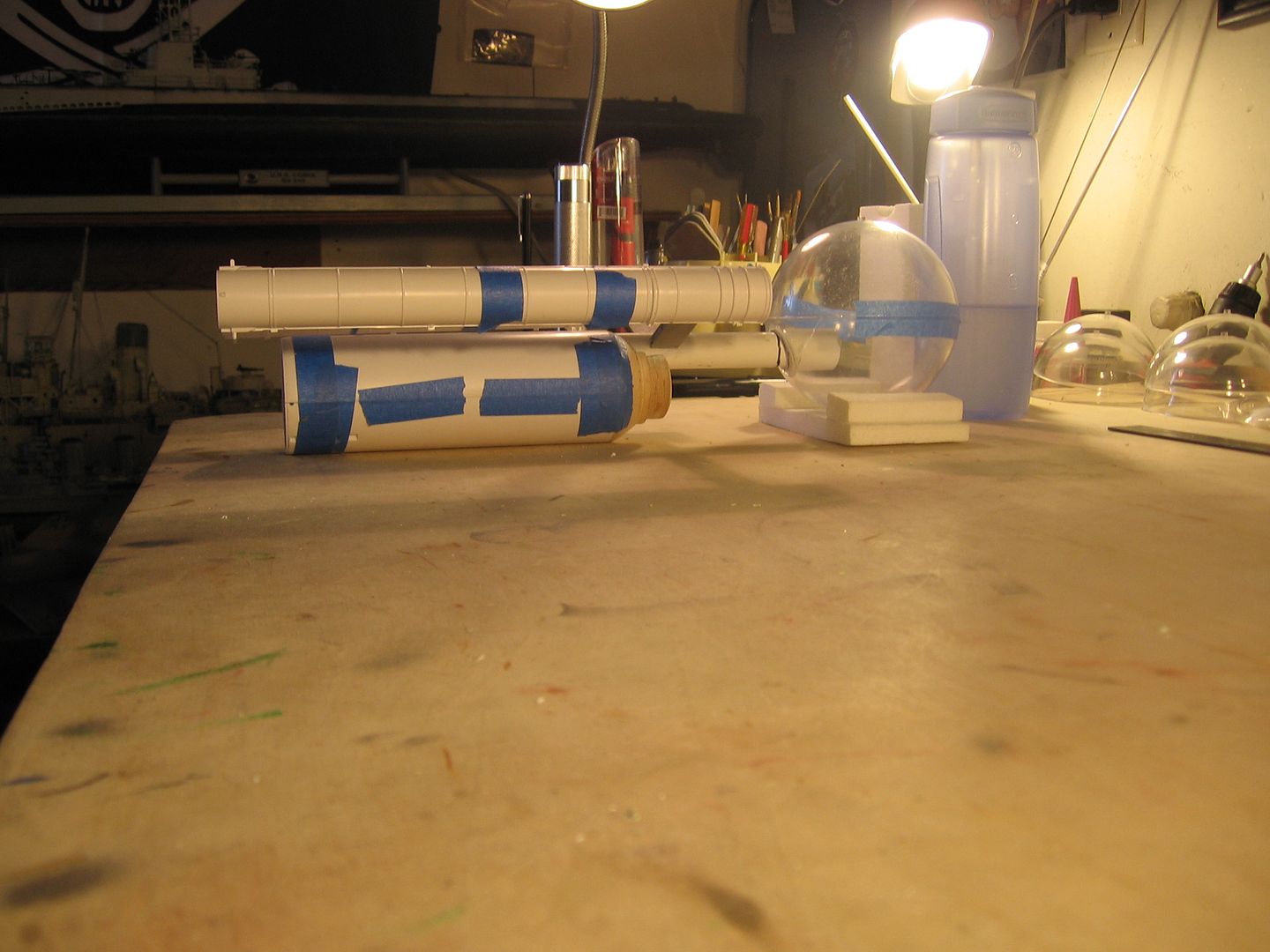

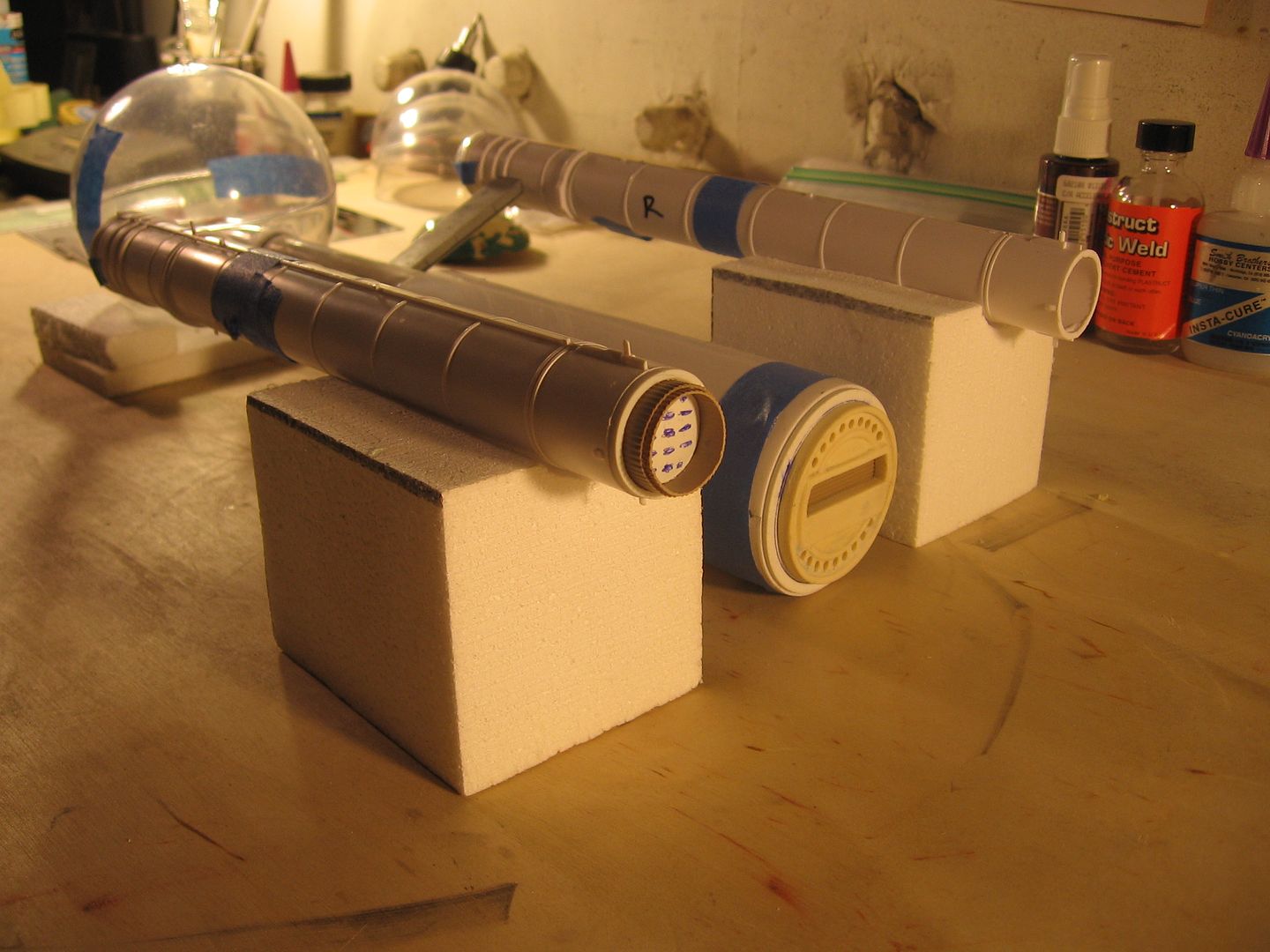

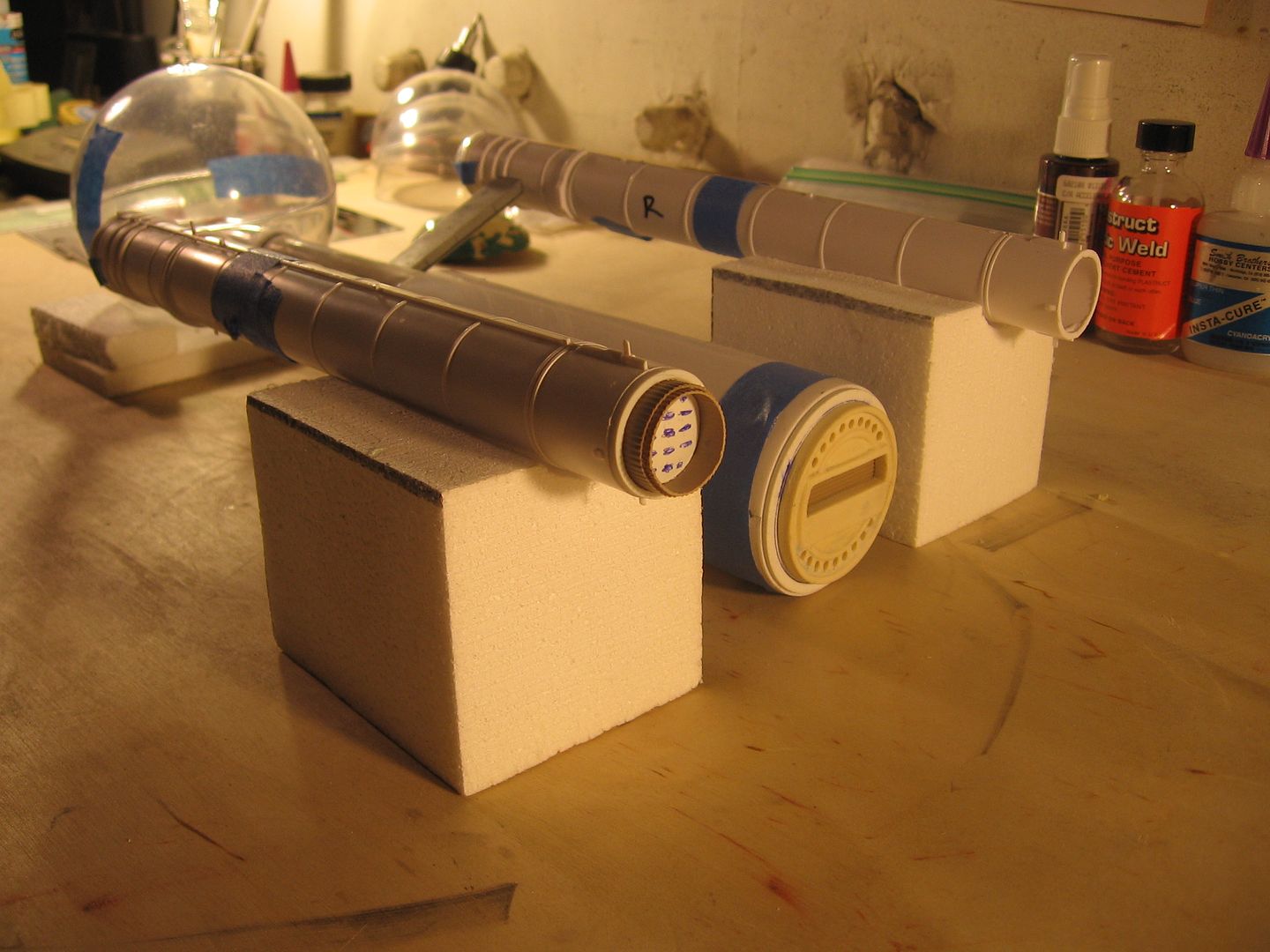

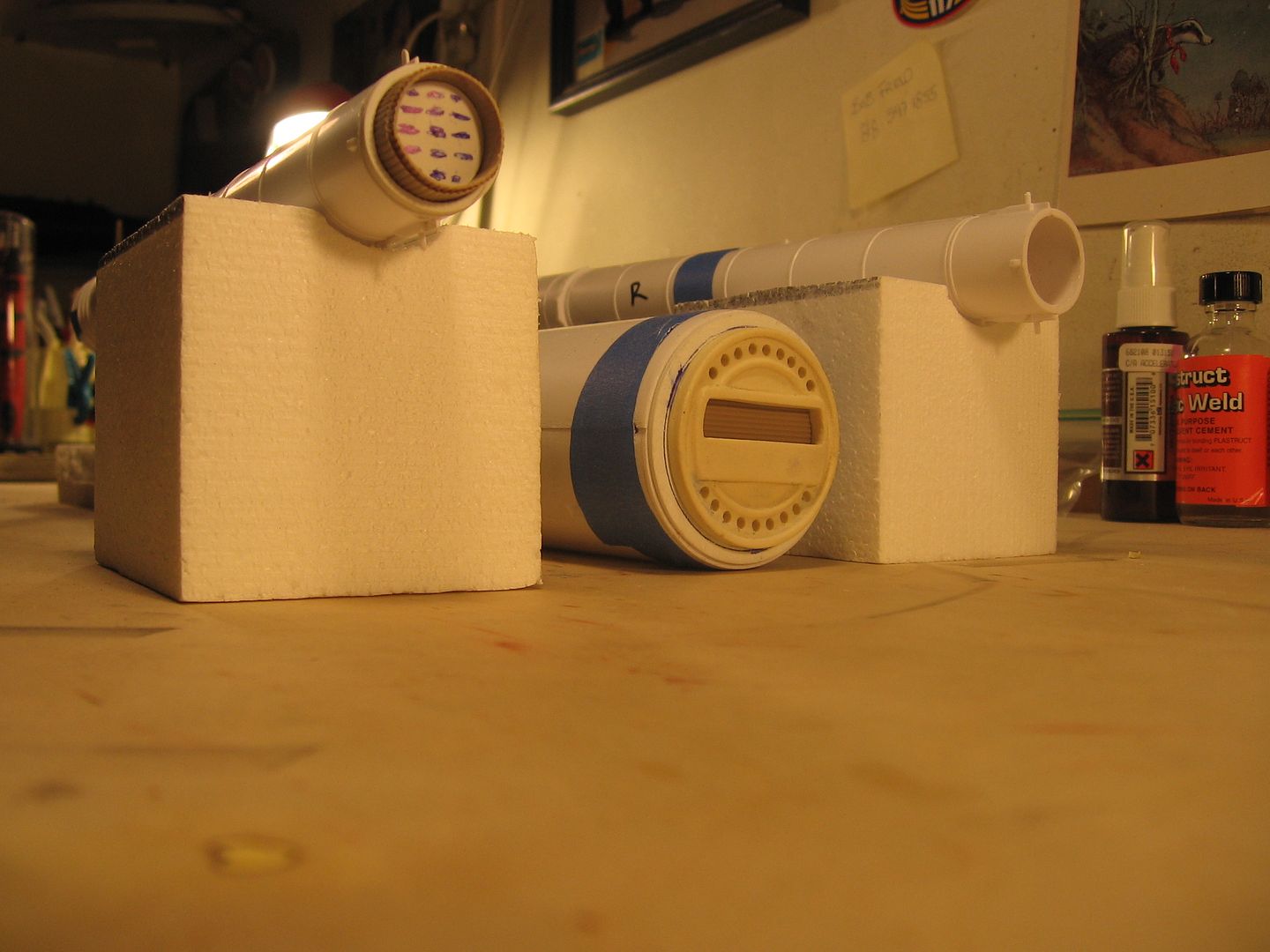

Lots more done today. I used finishing glaze to make exact negatives of the pylons into the neck and the nacelles. They fit exact no drooping. This should make the kit easy to assemble as they will be part of the castings.

Also started the end cap on the secondary hull. The holes aren’t drilled yet or the hanger bay cut out. Just marked loosely with a sharpie for looks.

Hopefully I’ll get to work a bit on her through the week in the evenings.

More to come,

Steve

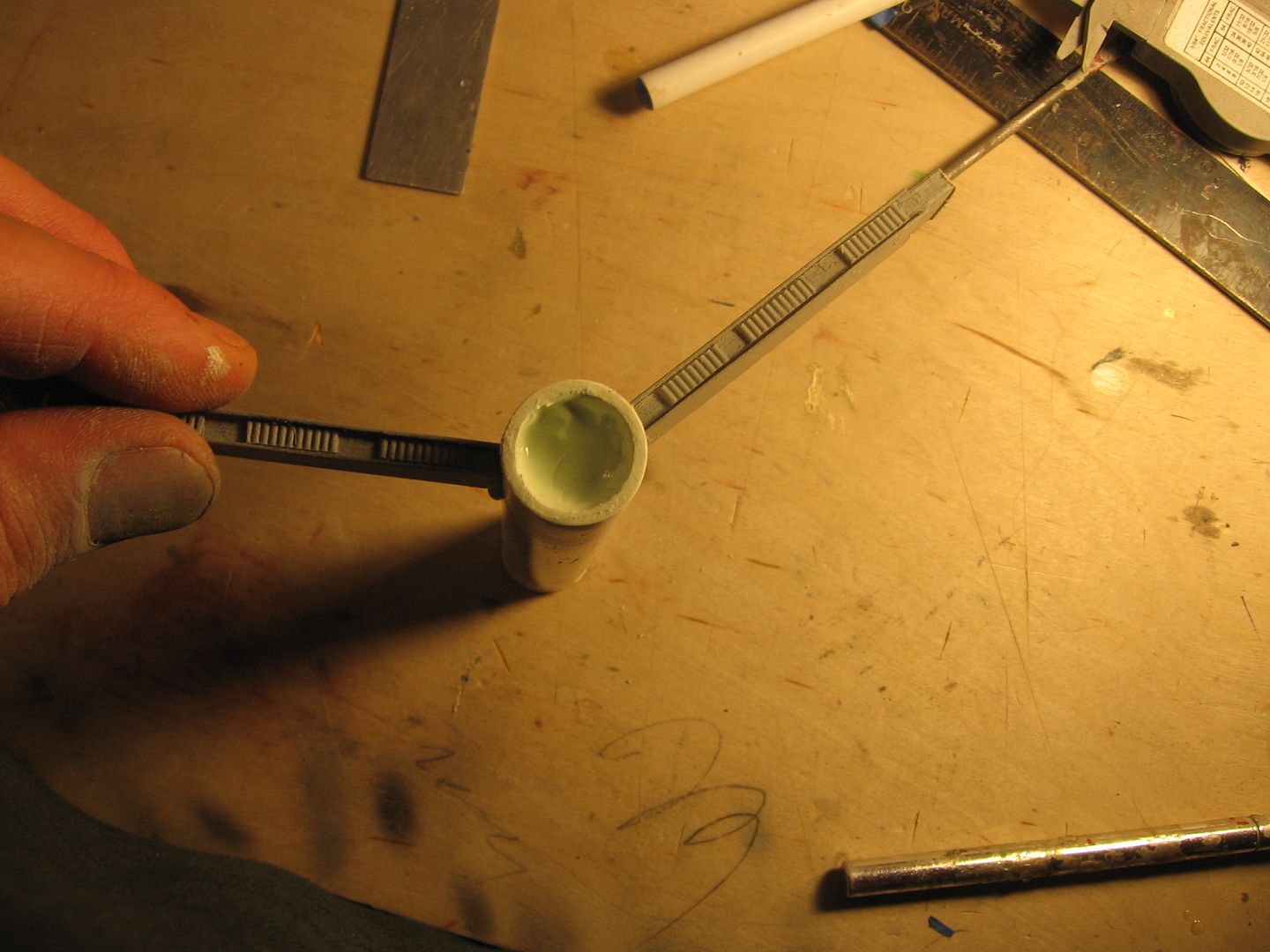

Here you can see the glazing putty inside the neck. The neck will be solid cast with a aluminium tube running through it fot wiring. Smae with the plylons.

Getting things nice and level. Glazing putty to create the sockets for the pylons.

Also started the end cap on the secondary hull. The holes aren’t drilled yet or the hanger bay cut out. Just marked loosely with a sharpie for looks.

Hopefully I’ll get to work a bit on her through the week in the evenings.

More to come,

Steve

Here you can see the glazing putty inside the neck. The neck will be solid cast with a aluminium tube running through it fot wiring. Smae with the plylons.

Getting things nice and level. Glazing putty to create the sockets for the pylons.

trekriffic

Sr Member

Those renderings by Doug Drexler are flat out beautiful! What a joy it must be to work with such talented people Steve. I'm amazed at how far along you've come on this in so short a time. Nice work so far.

P.S. I'm sorry for not saying something earlier but I'm saddened at the news of your wife's cancer returning. I hope and pray she beats it again.

I'm sure all your fellow modellers are with you in supporting her in this fight.

P.S. I'm sorry for not saying something earlier but I'm saddened at the news of your wife's cancer returning. I hope and pray she beats it again.

I'm sure all your fellow modellers are with you in supporting her in this fight.

Captain April

Sr Member

My friend Jeff built a nice model of this ship also, here's a link to pictures.Daedalus Class U.S.S. ESSEX by Jeff Pollizzotto Modelworks

Last edited:

SteveNeill

Sr Member

Thanks Steve! And she will.

Captain she's a beaut! Thanks for posting.

Steve

Captain she's a beaut! Thanks for posting.

Steve

SteveNeill

Sr Member

Thanks Nurturer

SteveNeill

Sr Member

Thanks tony. Thanks very much.

The model is started and will be available soon.

Steve

The model is started and will be available soon.

Steve

SteveNeill

Sr Member

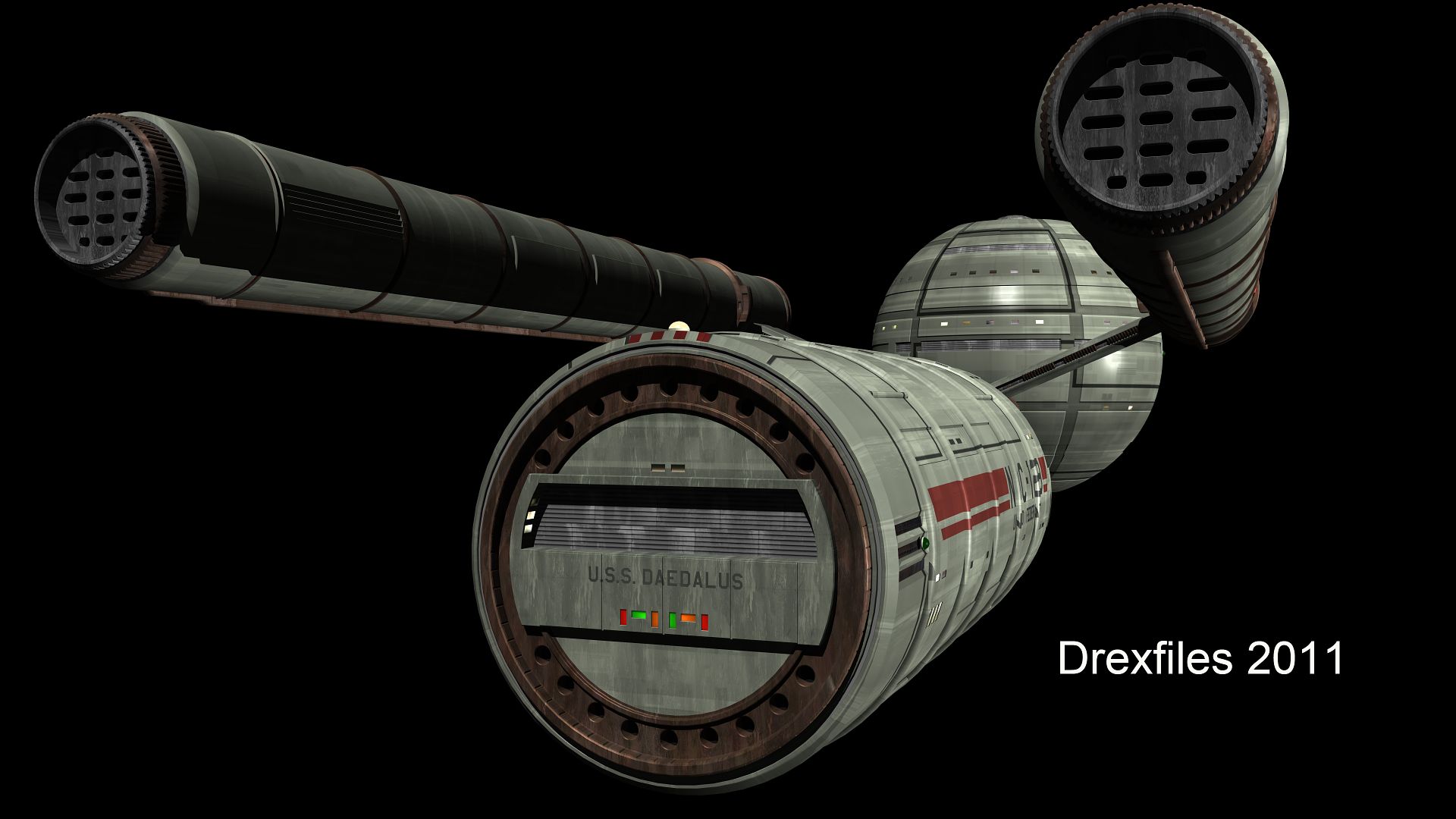

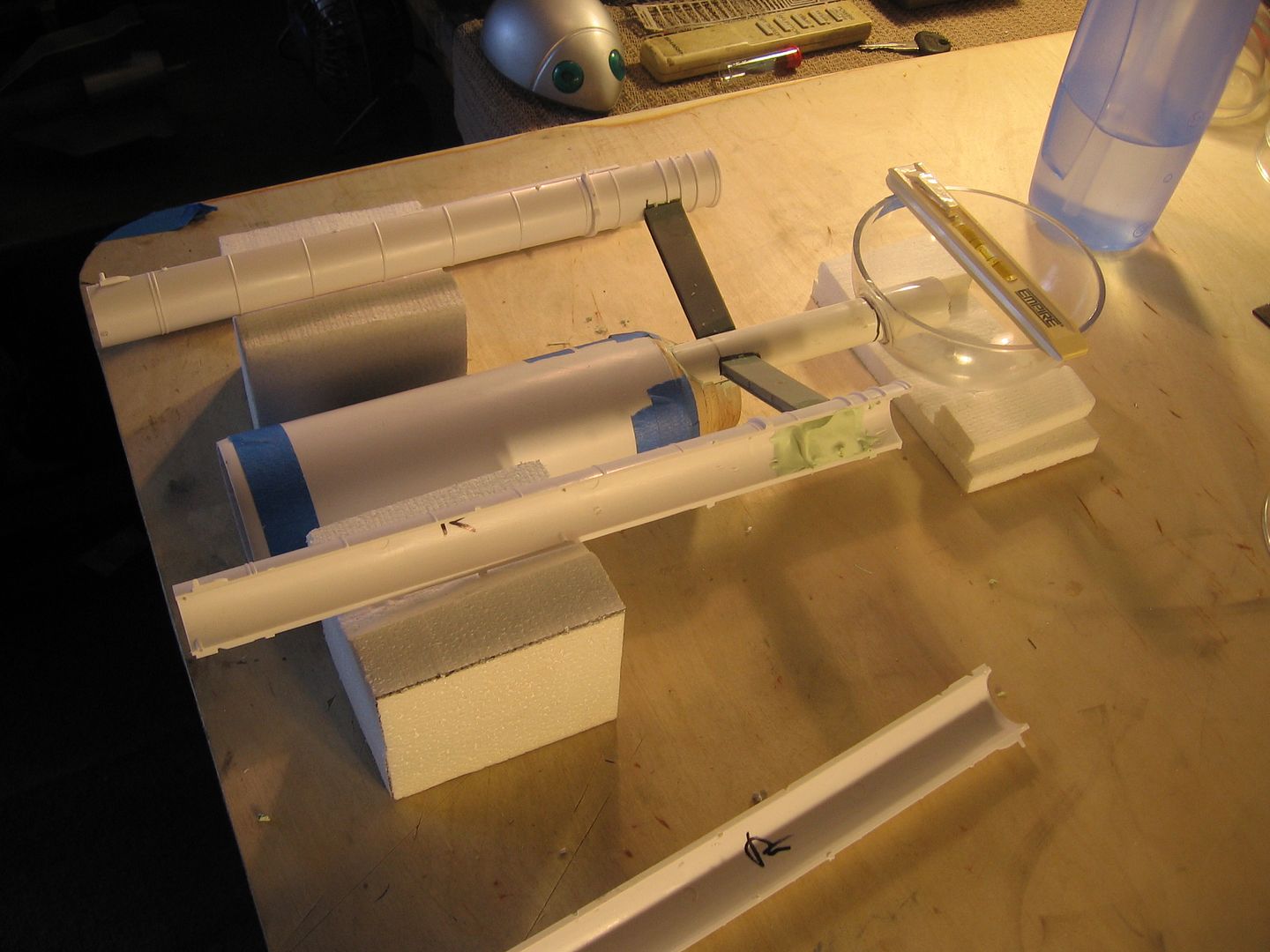

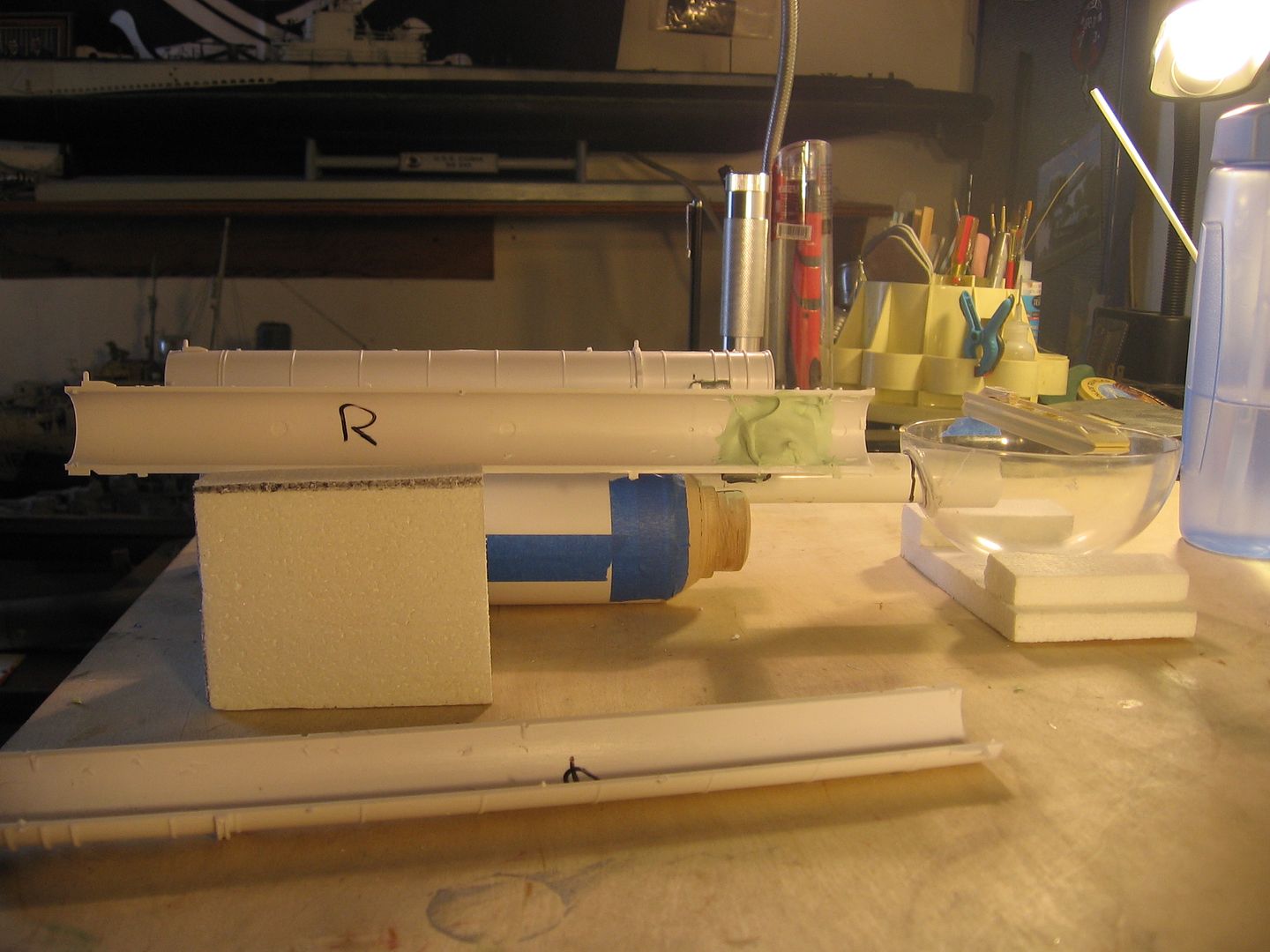

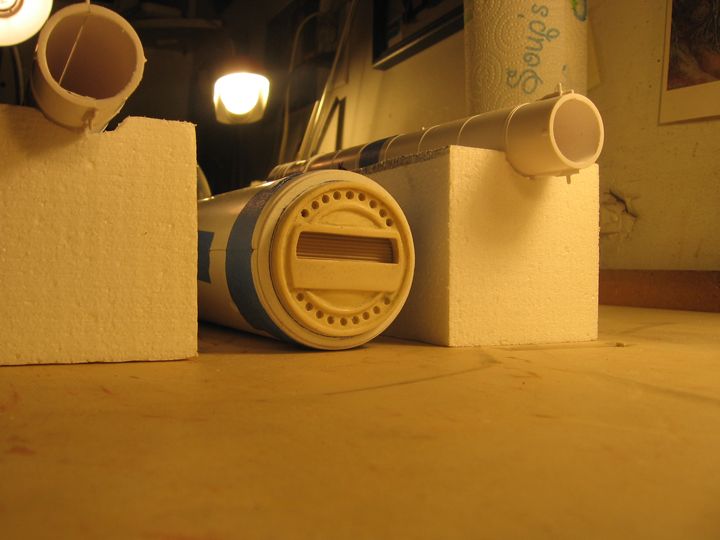

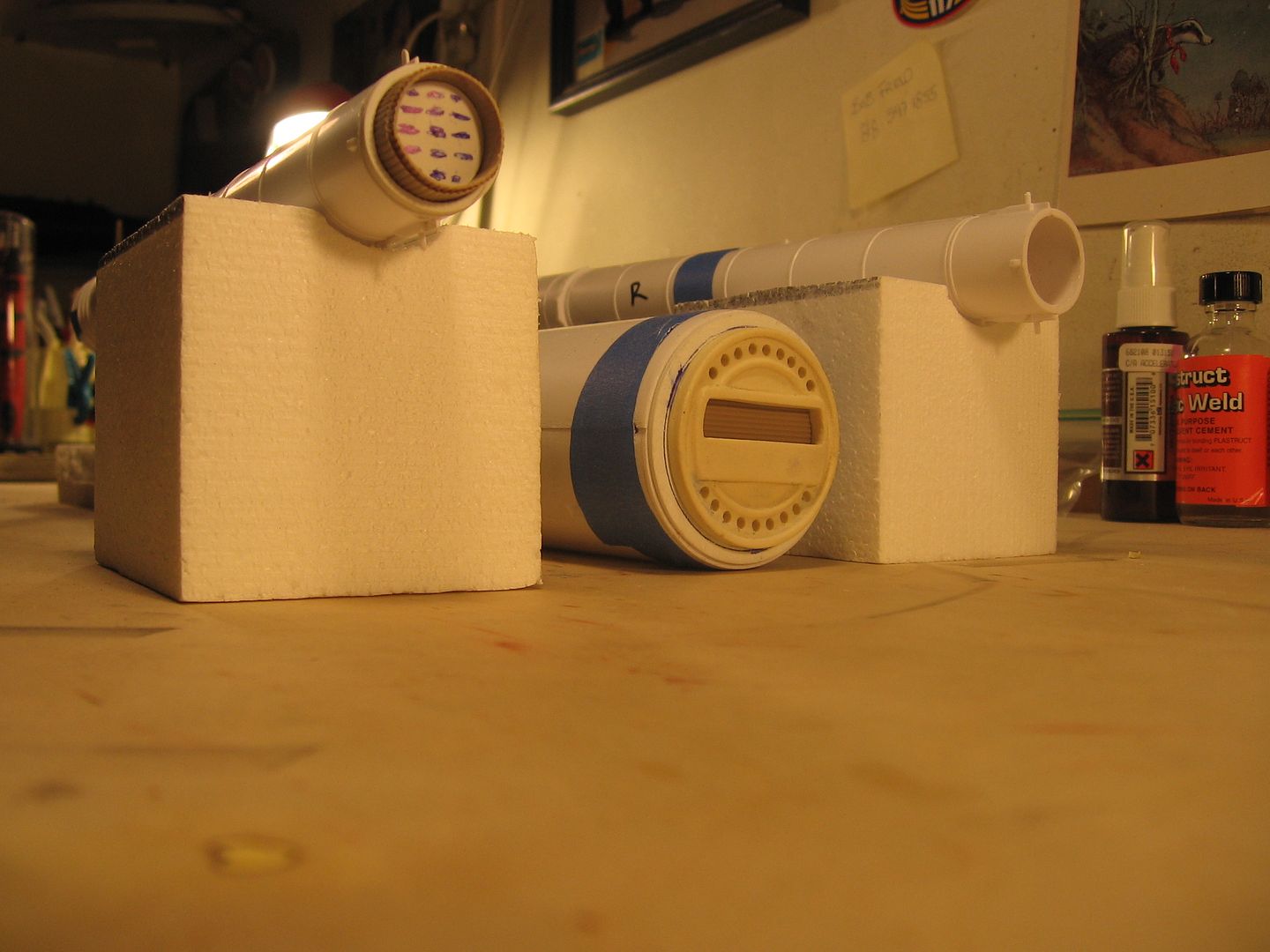

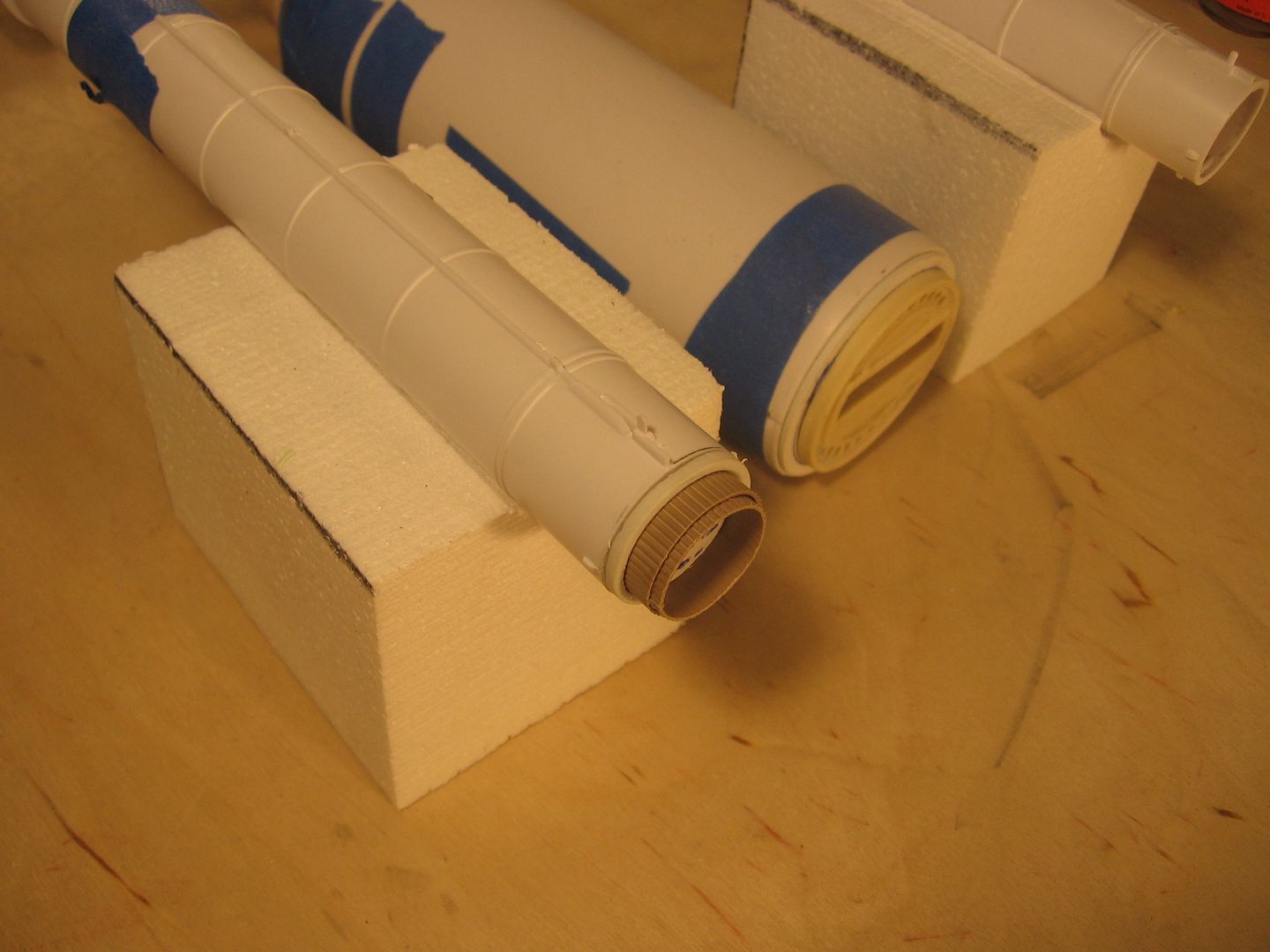

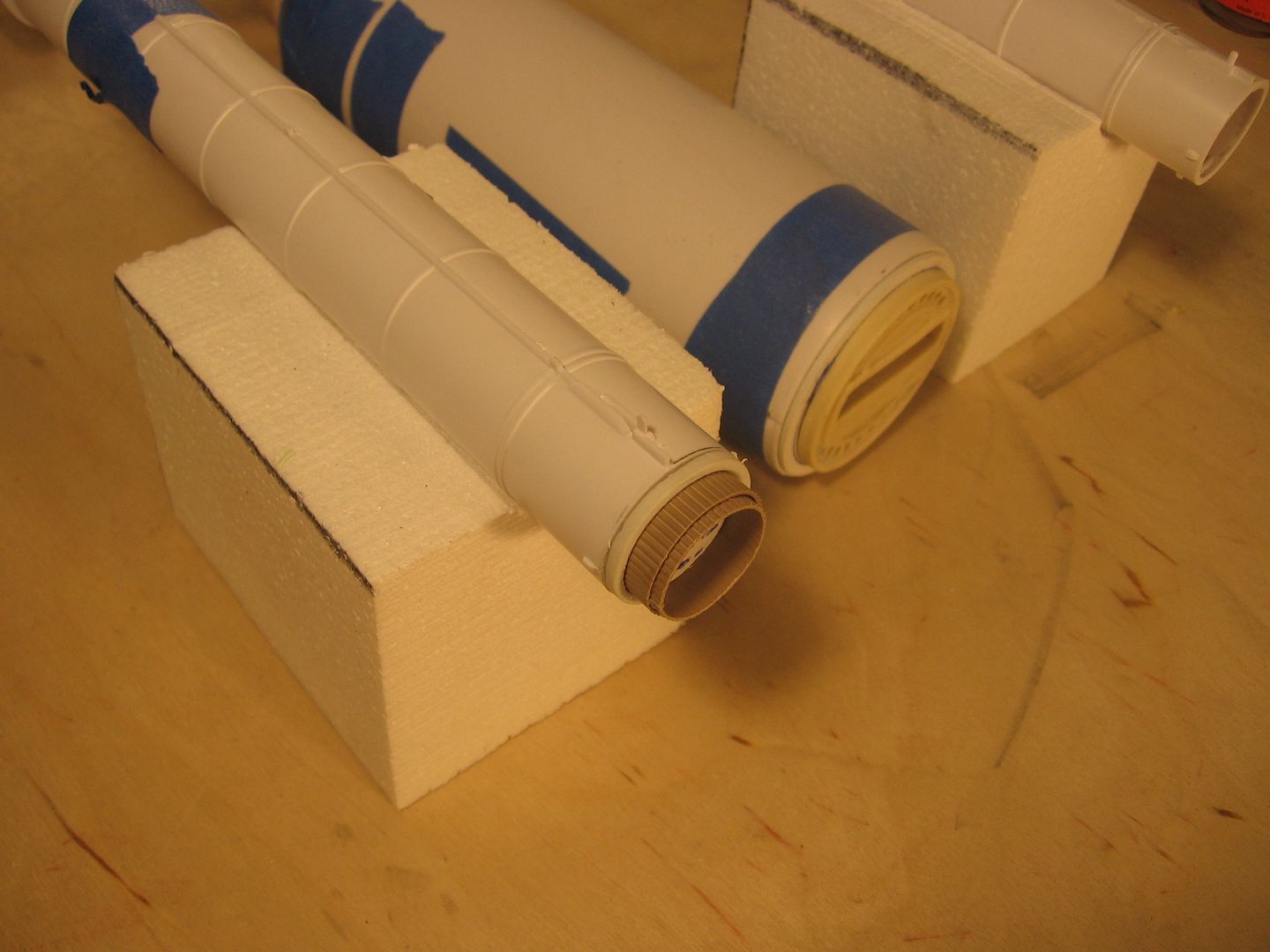

And a bit more on the Daedalus. Been working nights on the hanger bay end cap. Harder to do by hand than it looks. Some lathed and the rest by hand.

I made a rough part and then made a waste mold. This way I poured up a resin part and can clean is up, drill the holes, attach it to the end cap and make the final mold.

I did this one real quick tonight to see how it would look. Holes were drilled on the drill press and just eye balled for now. I'll do the real thing tomorrow night.

Beauty is with the waste mold if you screw it up, pour another.

Steve

I made a rough part and then made a waste mold. This way I poured up a resin part and can clean is up, drill the holes, attach it to the end cap and make the final mold.

I did this one real quick tonight to see how it would look. Holes were drilled on the drill press and just eye balled for now. I'll do the real thing tomorrow night.

Beauty is with the waste mold if you screw it up, pour another.

Steve

Last edited:

SteveNeill

Sr Member

Thanks you are very kind.

steve

steve

trekman1017

Well-Known Member

How did you make that? just layering plastic or what.

SteveNeill

Sr Member

No thick styrene and a lathe. The hanger area styrene. Made a rough one and then a waste mold and cleaned it up.

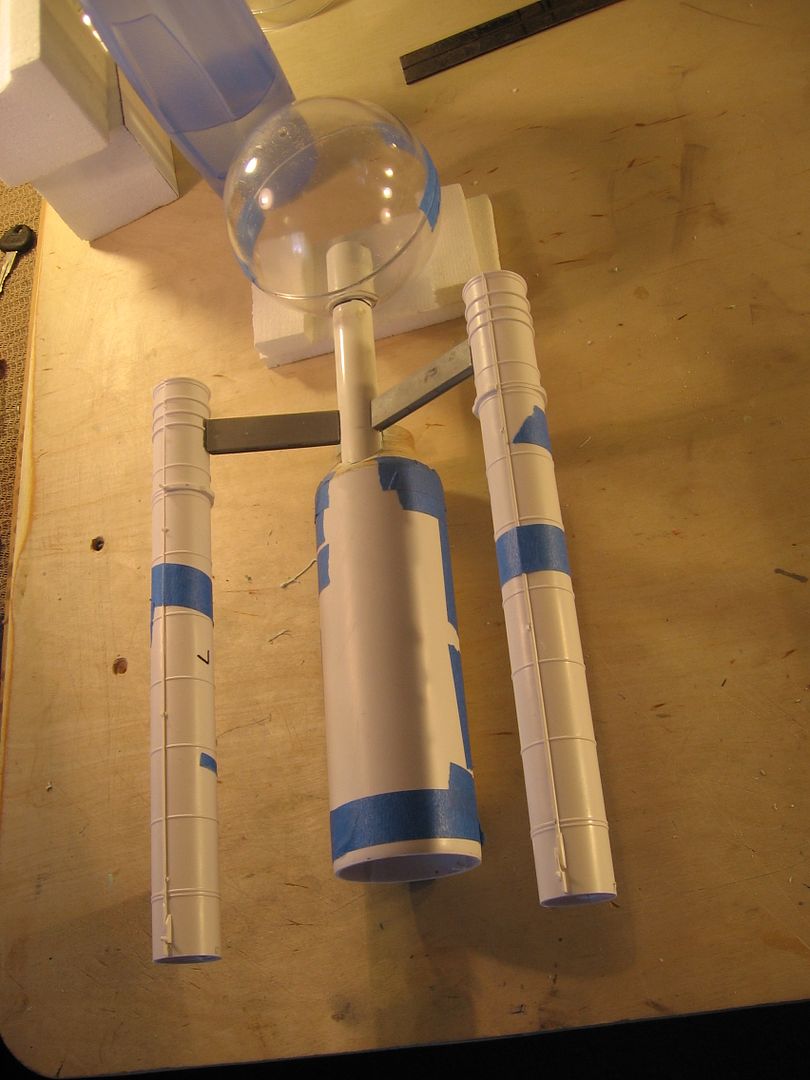

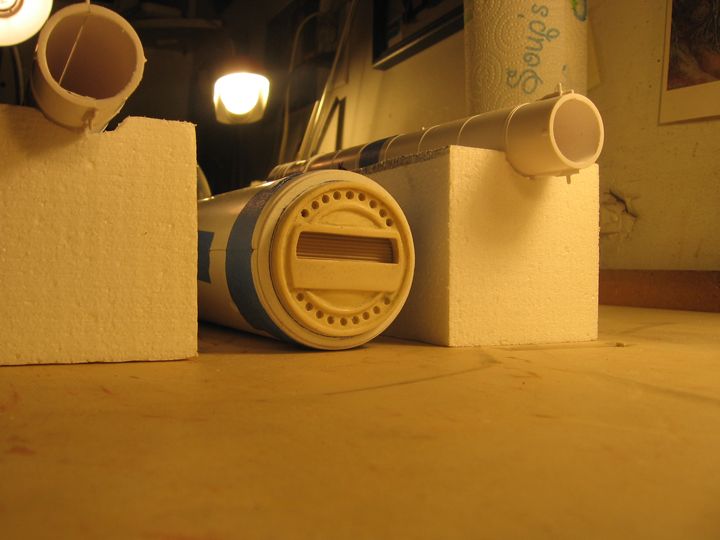

Here is the real part with the properly spaced and sized holes.

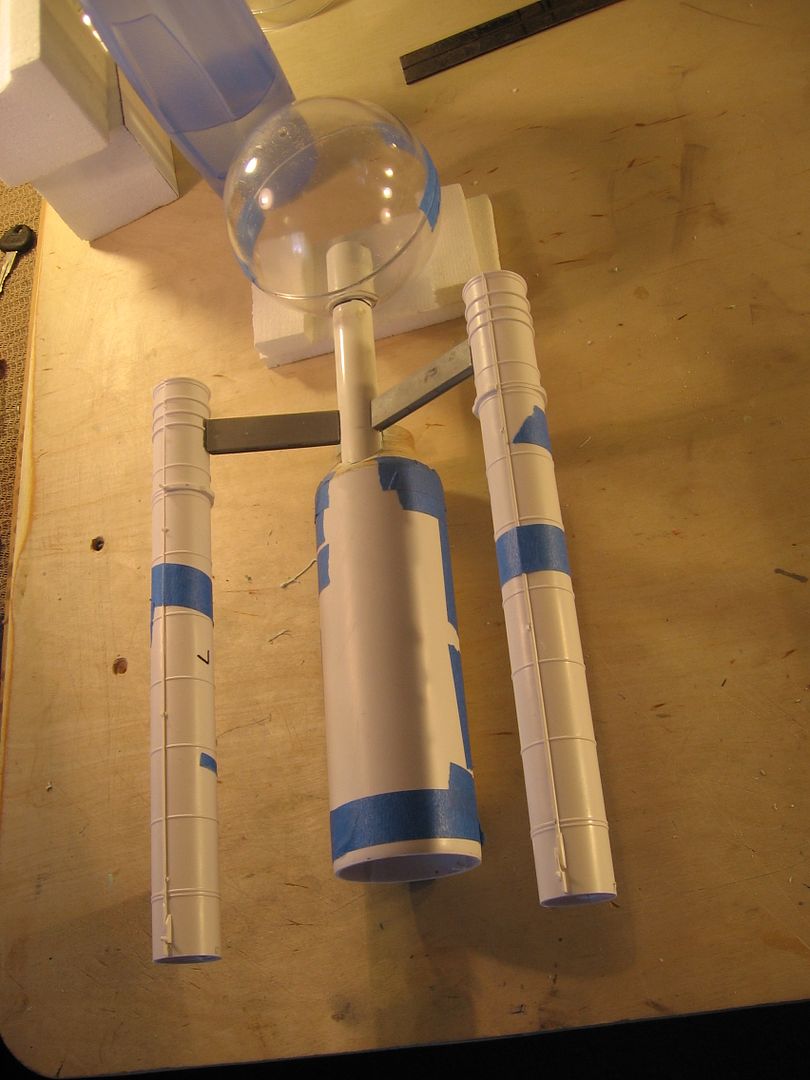

End cap on the nacelle was turned on a lathe and styrene ribbed sheeting used. The holes are just drawn in free hand for now. I'll have a PE part made for those. The holes are just two small. A decal would work too but the PE will be nicer I think.

Steve

Here is the real part with the properly spaced and sized holes.

End cap on the nacelle was turned on a lathe and styrene ribbed sheeting used. The holes are just drawn in free hand for now. I'll have a PE part made for those. The holes are just two small. A decal would work too but the PE will be nicer I think.

Steve

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 36

- Views

- 5,053

- Replies

- 251

- Views

- 40,443

- Replies

- 100

- Views

- 16,299

- Replies

- 2

- Views

- 1,805