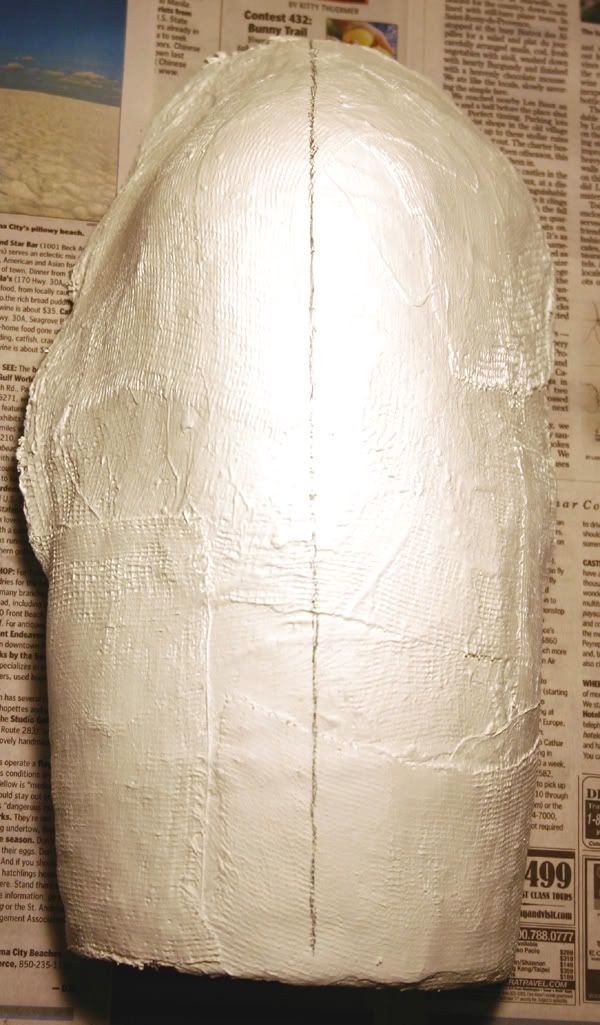

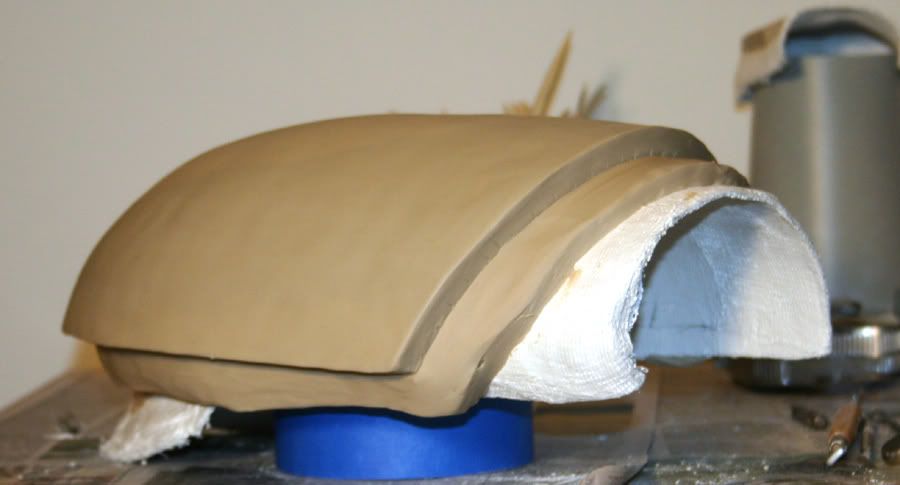

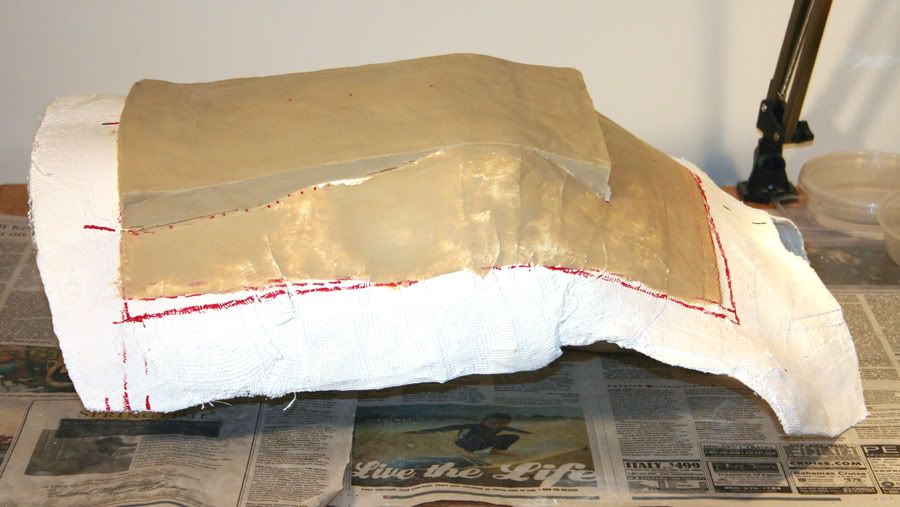

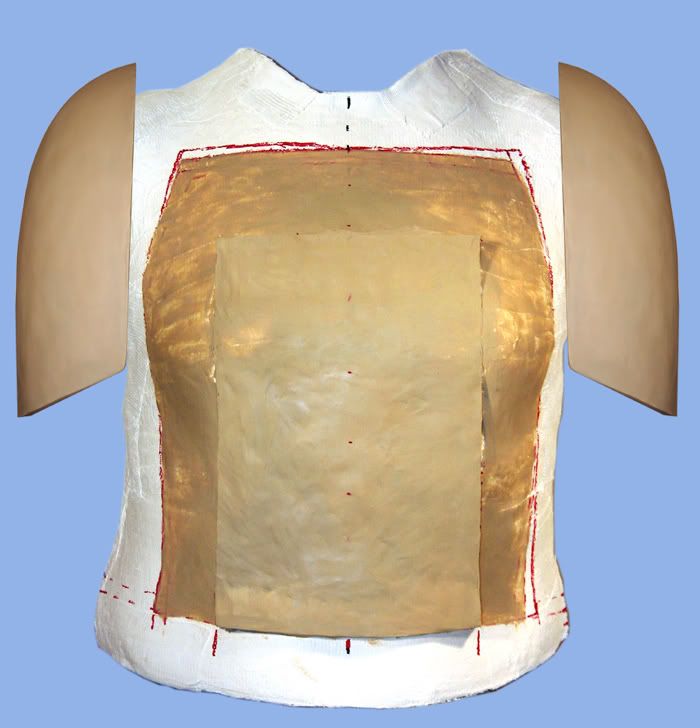

Here's the hard model for the shoulder bell...

I still have to shape the curvature better and smooth out the surface some more, but it turned out decent and workable. I will fill in the back side with clay to about half inch thick overall, then make a two part mold to cast the final pieces.

Lessons learned:

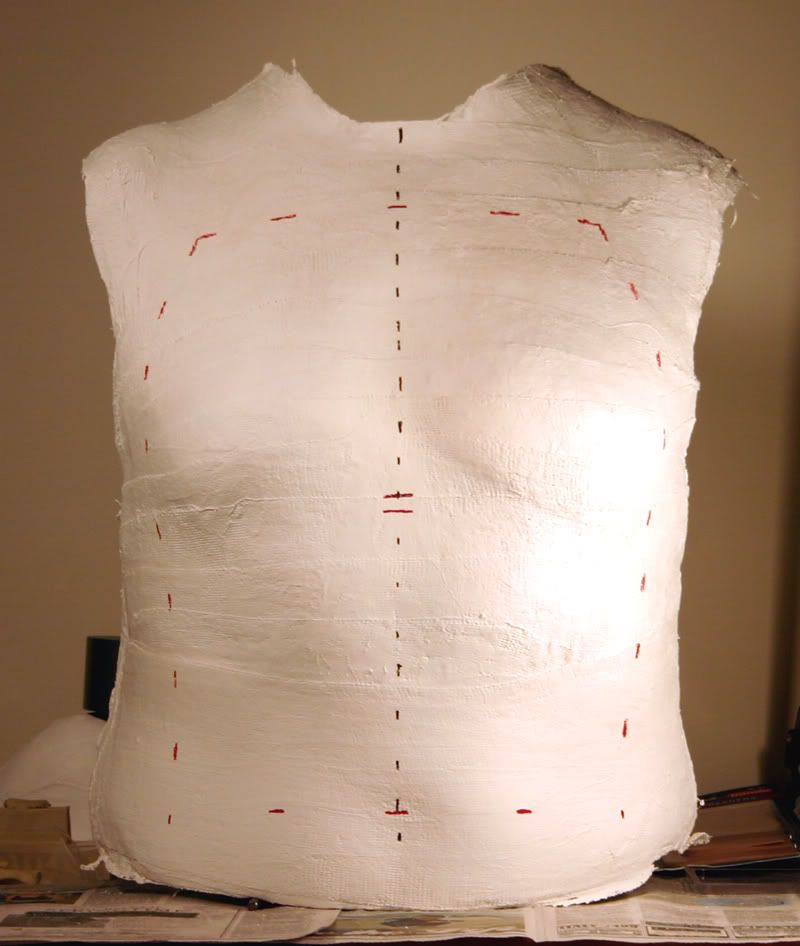

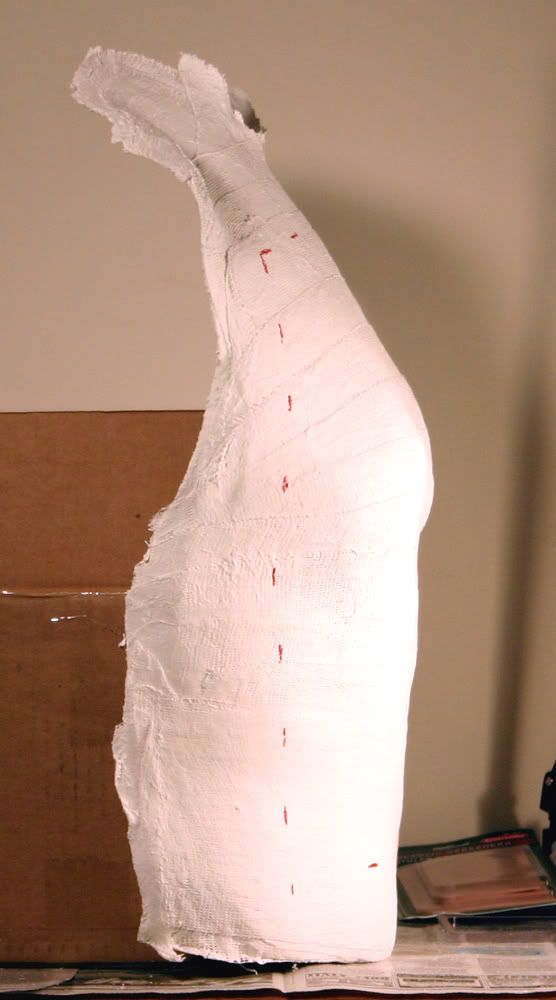

- You can see in the pix there are a couple dozen low spots, 5-6 of which were from pockets of un-cured resin. I know what I did wrong there, I mixed the bondo hardener and the resin catalyst in the same cup that I mixed the bondo and resin in for the gelcoat, then poured the whole mess into the mold. I should have poured the homemade gelcoat into another cup before adding the hardener. There was some unmixed resin on the sides of the cup that got into the mold as I poured. :confused

- I should have left the plastic harden overnight before breaking it out of the mold. When I did the handguards they shrunk a tiny bit as they cured, and popped right out of the mold with no problems. I only waited like three hours. When I demolded it there was a boatload of plaster totally stuck to the model. Also, just from jockying it around to try and break it free, I put several cracks in the bondo edges. Luckily, the plaster was pretty easy to scrape off and the cracks I can fill with epoxy.

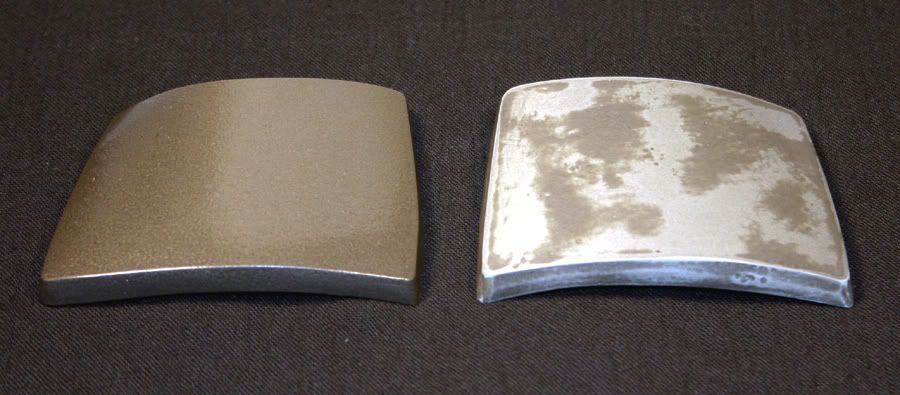

I'm sorely tempted to leave the low spots in the model. With a little creative weathering they could be blaster dings.

~ Koda