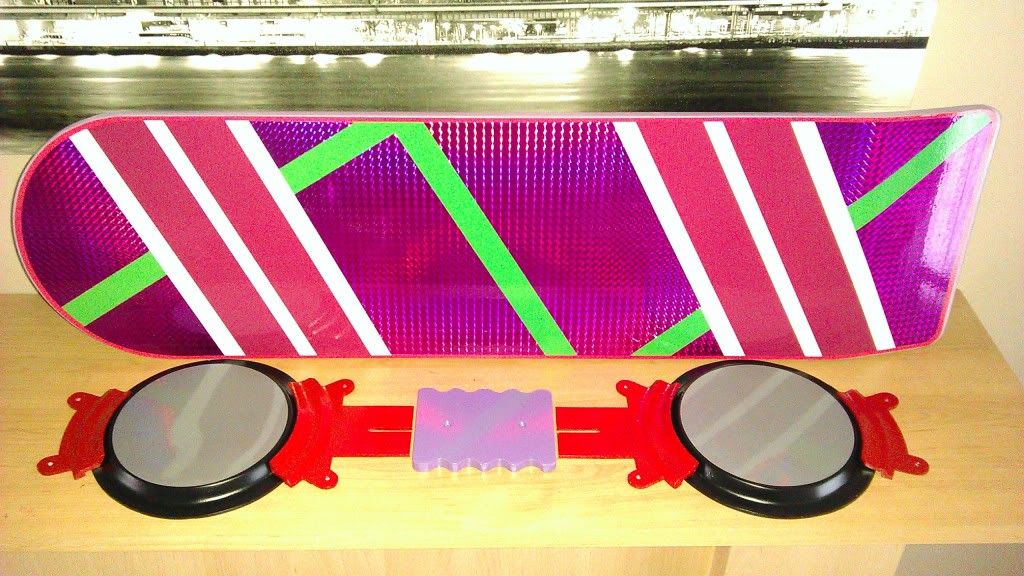

today was paint day: the task to paint up the 1st casts:

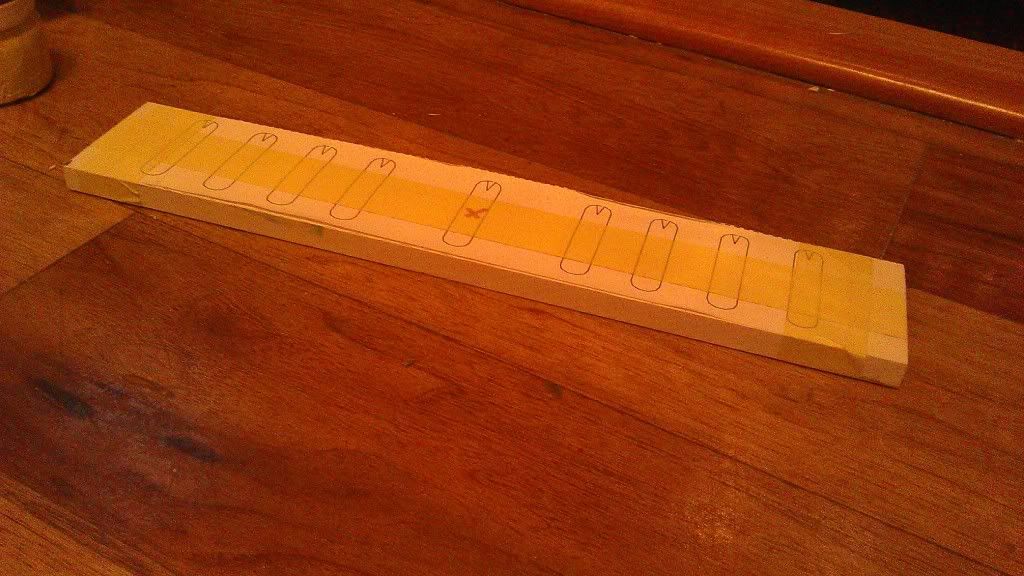

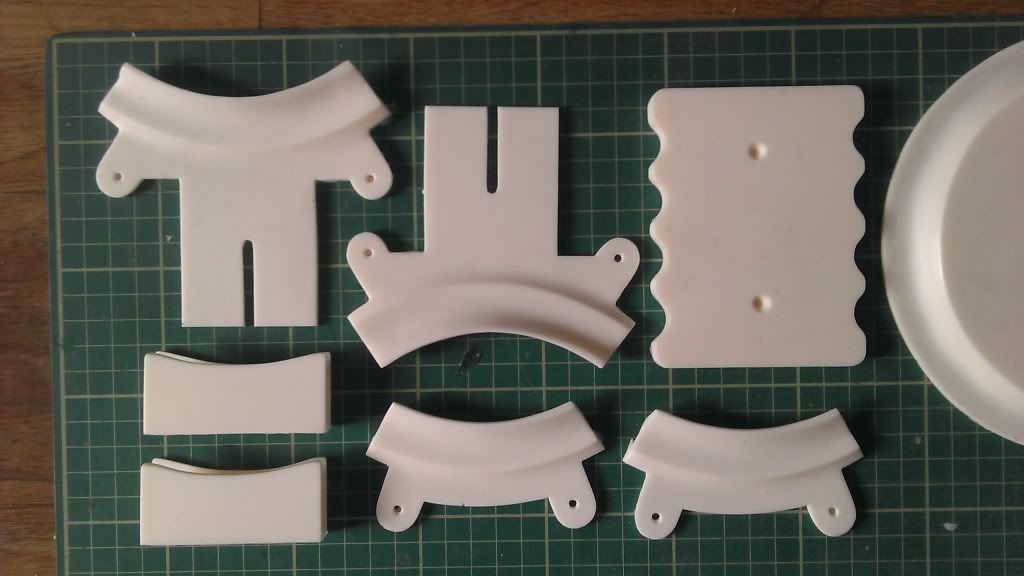

opted for the hi build primer in case of any minor flaws, seems i may as well just gone for the normal primer as there isnt anything on the surface causing a problem, so cleaned down the resin of its oils, gave it a little sand to the underside of the parts to keep it all flat:

so primered up:

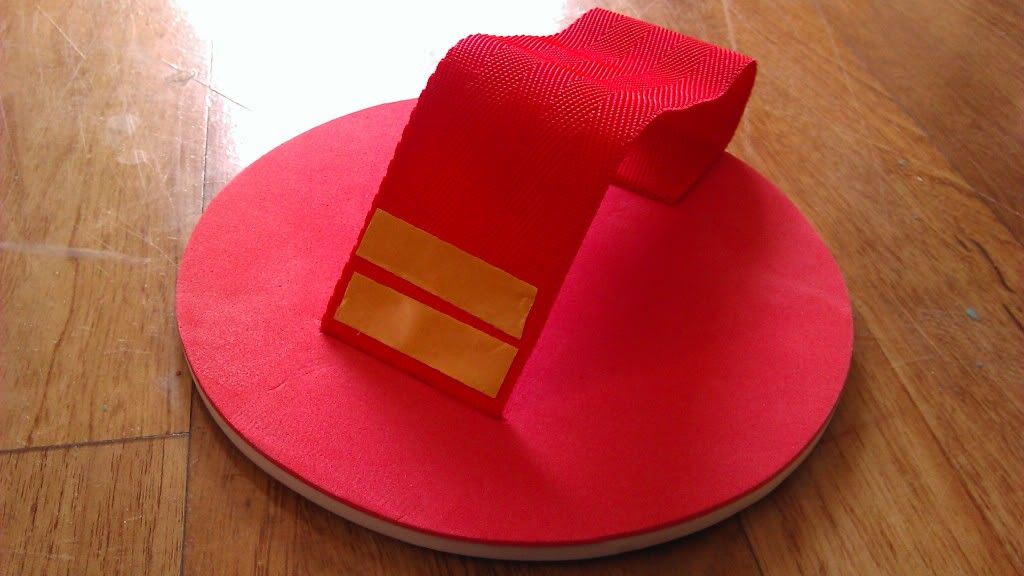

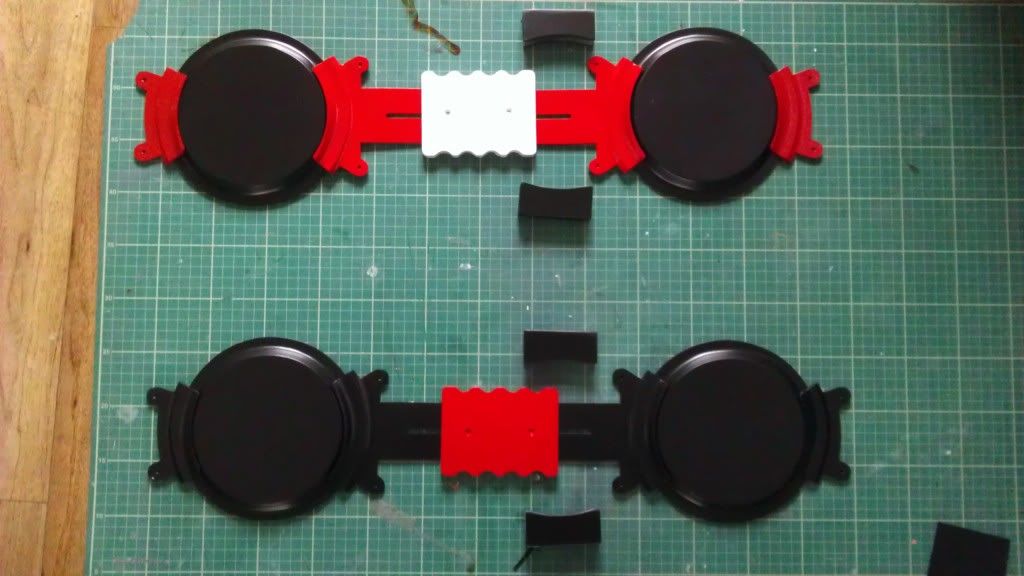

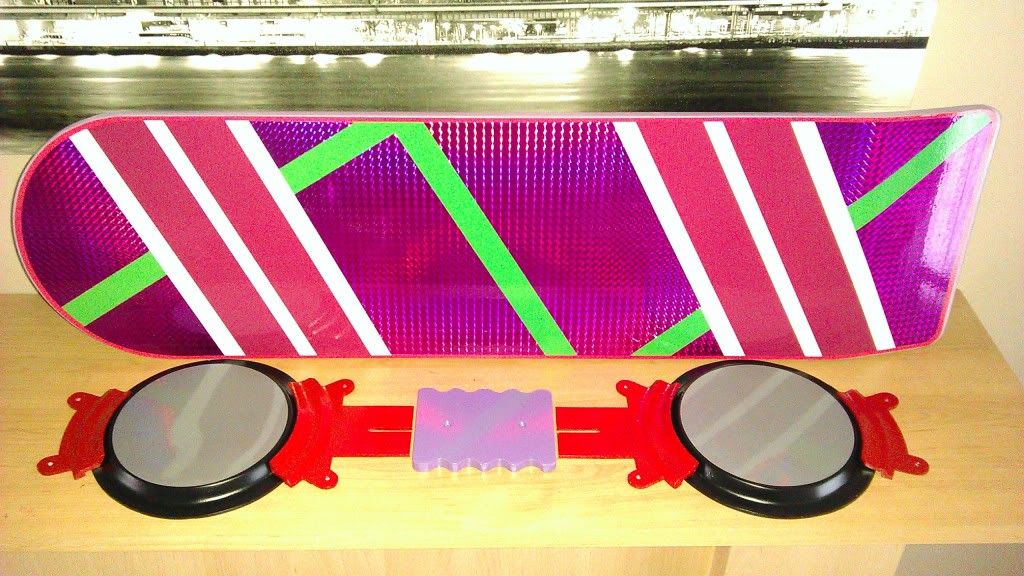

next step paint choice - i was seeking a red theat wasnt bright, yet had a brown tinge to it, hard ask so i opted for ford radient red: hard to see in the pics but there is more burgandy with the naked eye, satin black for the magnets, and lavender plasticote for the purple centre bit:

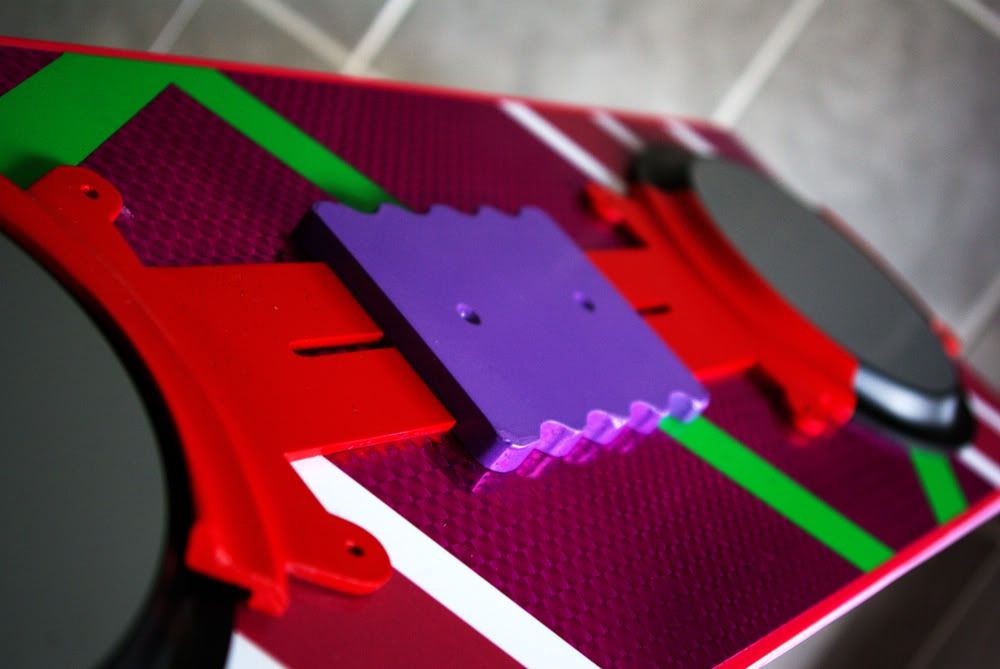

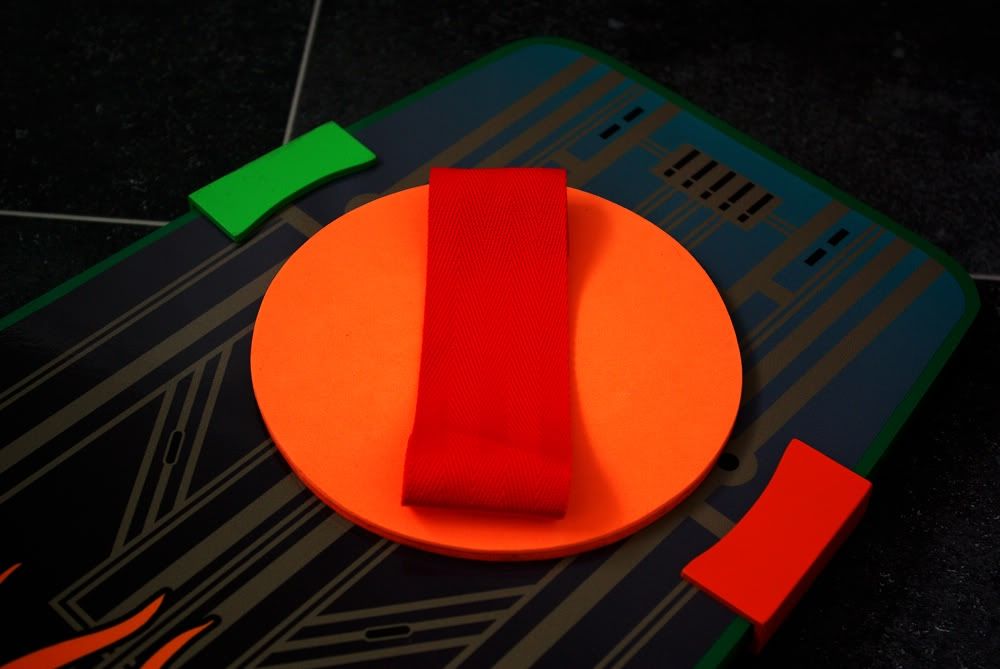

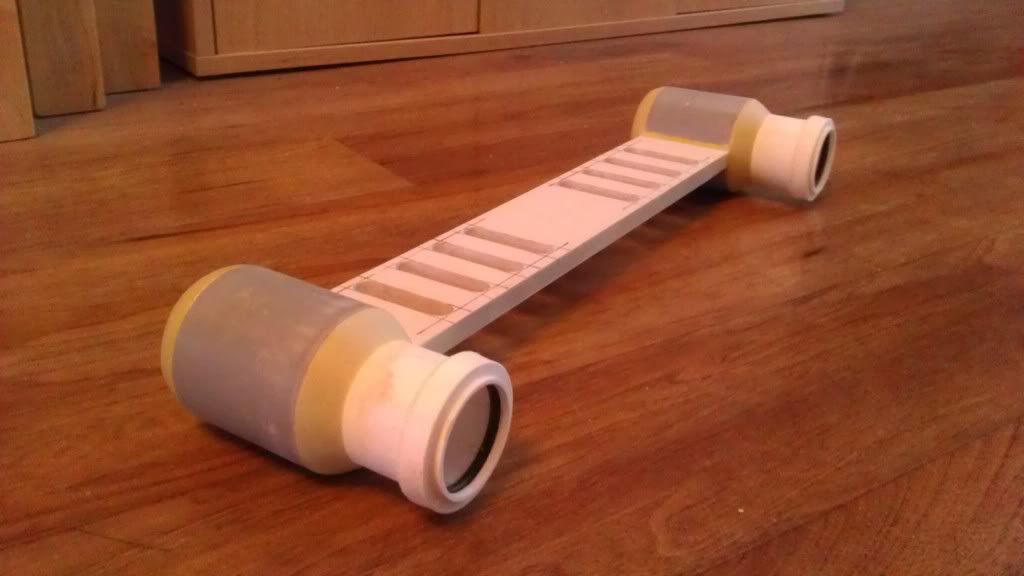

decided to roughly put the bits in order, added the adhesive silver circles, the vinyl im using is a silver with a metallic look to it so it gives off a nice reflection without lamination:

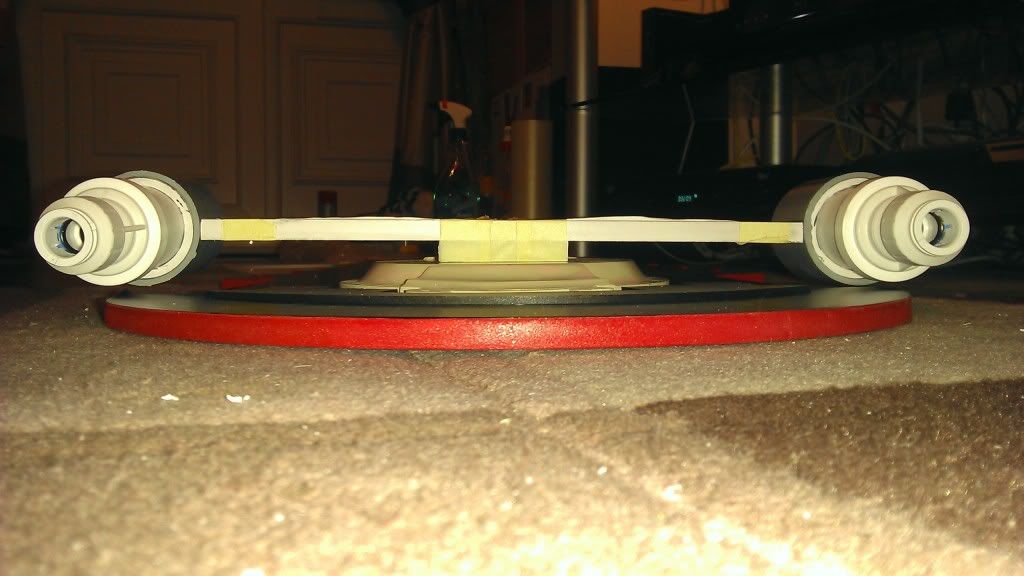

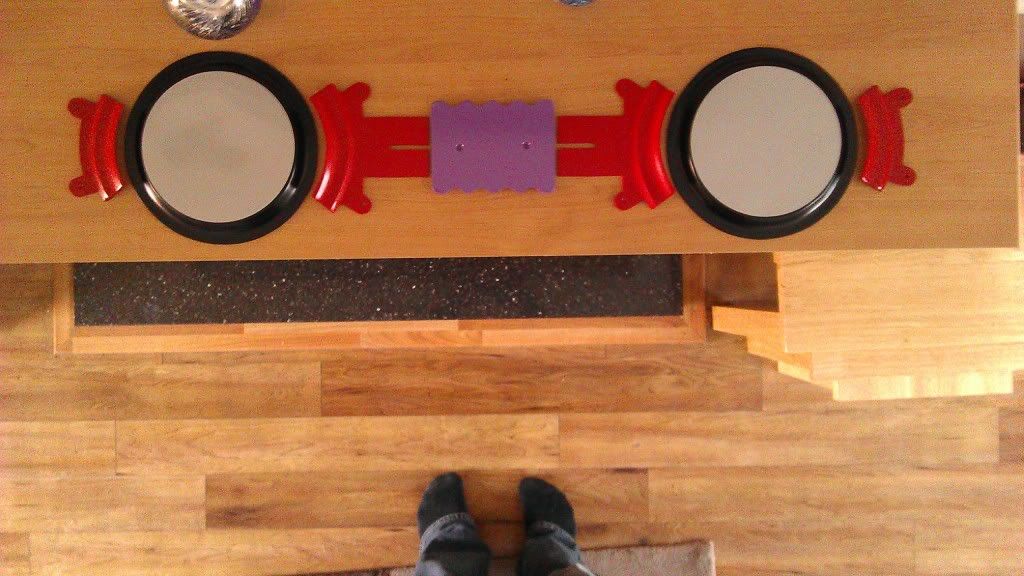

and when dryer i positioned all the bits butted up:

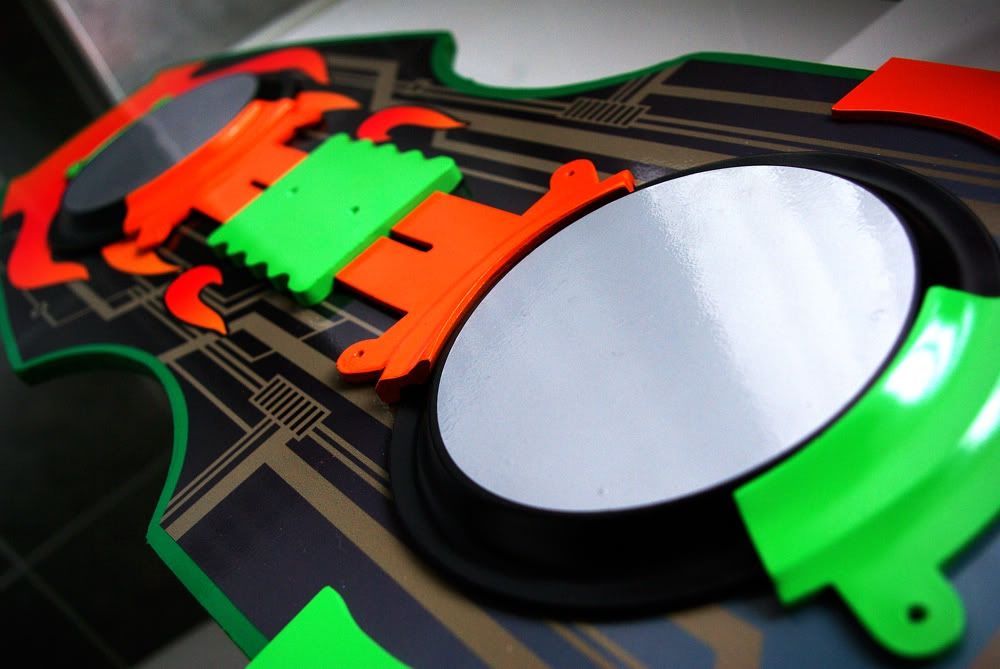

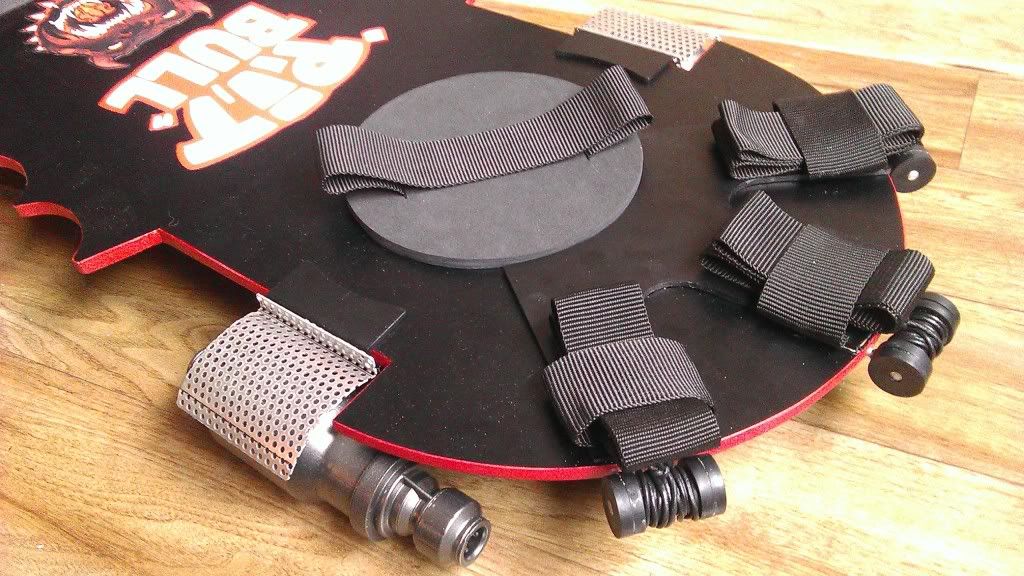

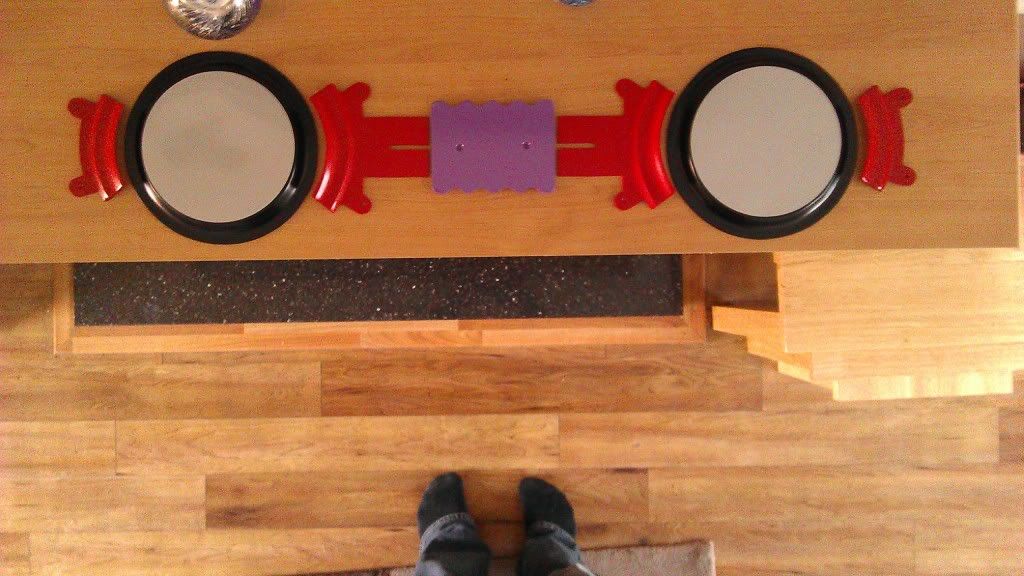

and showing the thicknesess of the parts:

casting will commence again tomorrow for some more parts, will need some more resin to do them all and more paint for the other boards.

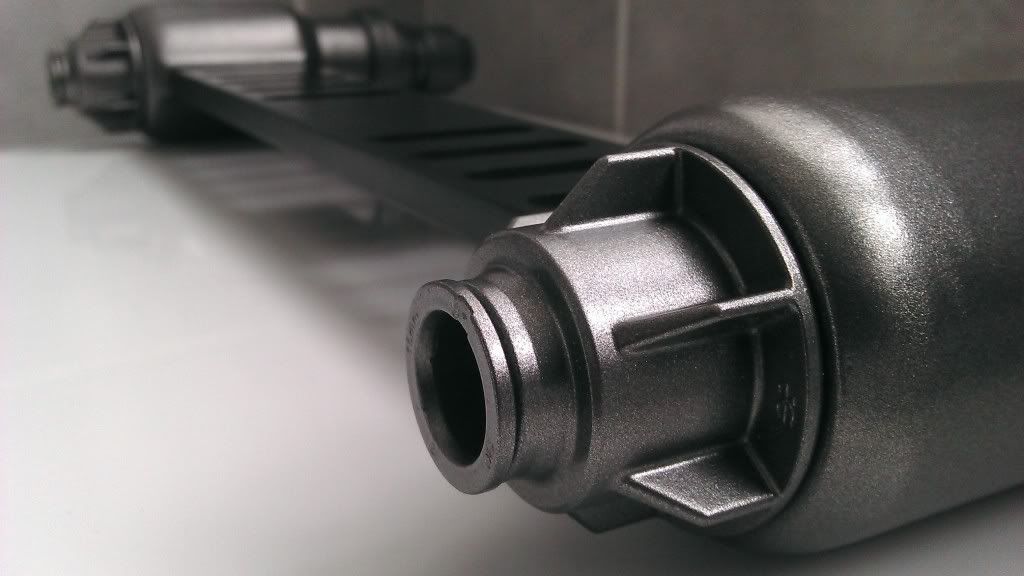

final pic of the current build status showing all the reflections:

opted for the hi build primer in case of any minor flaws, seems i may as well just gone for the normal primer as there isnt anything on the surface causing a problem, so cleaned down the resin of its oils, gave it a little sand to the underside of the parts to keep it all flat:

so primered up:

next step paint choice - i was seeking a red theat wasnt bright, yet had a brown tinge to it, hard ask so i opted for ford radient red: hard to see in the pics but there is more burgandy with the naked eye, satin black for the magnets, and lavender plasticote for the purple centre bit:

decided to roughly put the bits in order, added the adhesive silver circles, the vinyl im using is a silver with a metallic look to it so it gives off a nice reflection without lamination:

and when dryer i positioned all the bits butted up:

and showing the thicknesess of the parts:

casting will commence again tomorrow for some more parts, will need some more resin to do them all and more paint for the other boards.

final pic of the current build status showing all the reflections:

Last edited: