tubachris85x

Master Member

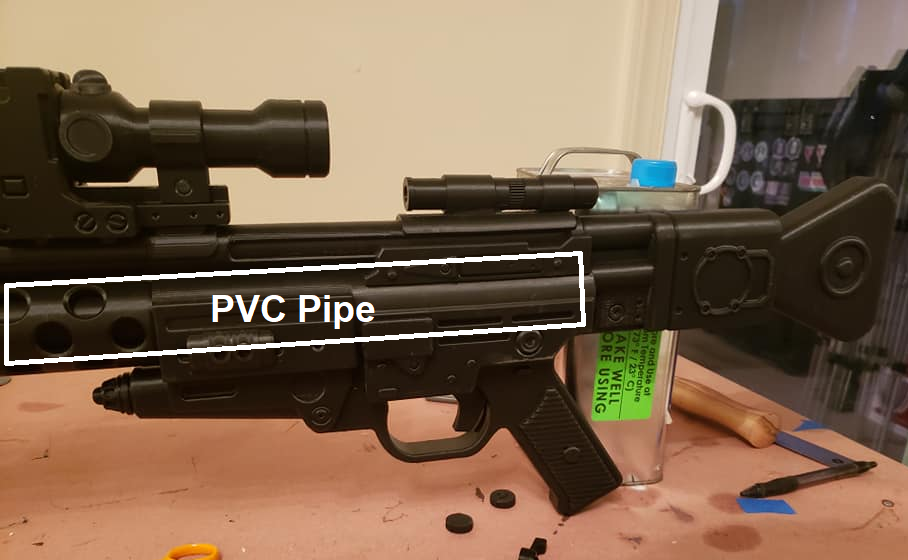

So I am working on a blaster, and need to make the barrel portion removable, but in such a way I won't lose structural support.

The basic idea is that I would bore a hole through the main body of the PLA print piece, and then embed a PVC pipe through the length of the body, leaving a section also exposed to slide the main barrel over top and secure it. The issue though, is that this means that I need to figure how to create a hole both deep enough and that doesn't damage the print. IIRC, this is 80% infill

I was thinking of looking into some machining shops in the area to do this as it requires precision, but those experienced, what do you think? This is a pretty big print, the overall length of the piece is 4'.

Thank you

The basic idea is that I would bore a hole through the main body of the PLA print piece, and then embed a PVC pipe through the length of the body, leaving a section also exposed to slide the main barrel over top and secure it. The issue though, is that this means that I need to figure how to create a hole both deep enough and that doesn't damage the print. IIRC, this is 80% infill

I was thinking of looking into some machining shops in the area to do this as it requires precision, but those experienced, what do you think? This is a pretty big print, the overall length of the piece is 4'.

Thank you