BobbyFromBUF

Well-Known Member

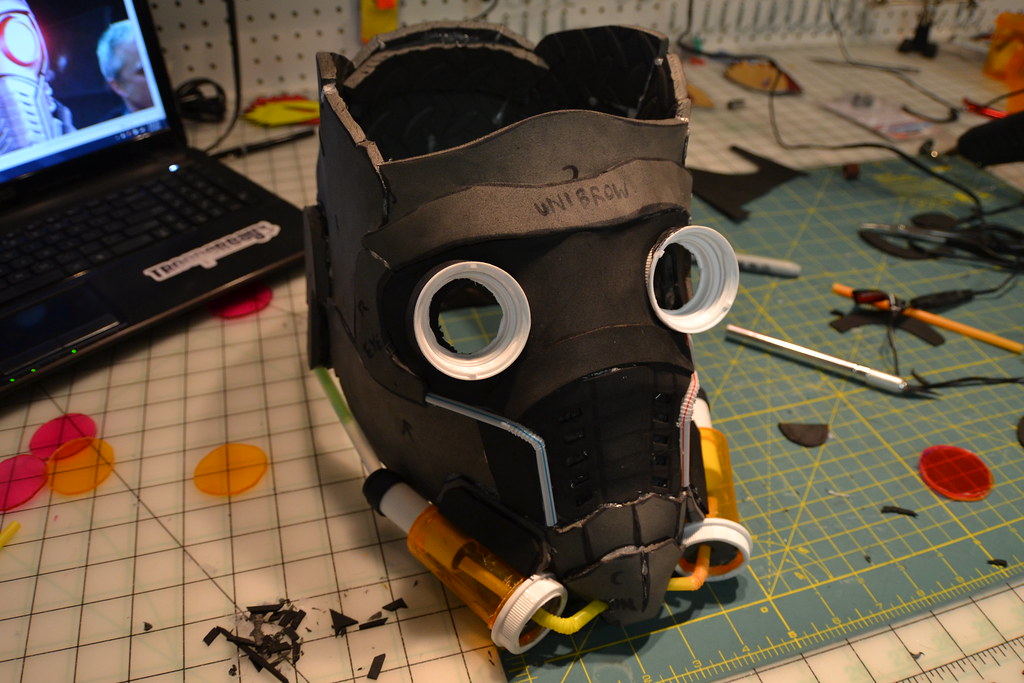

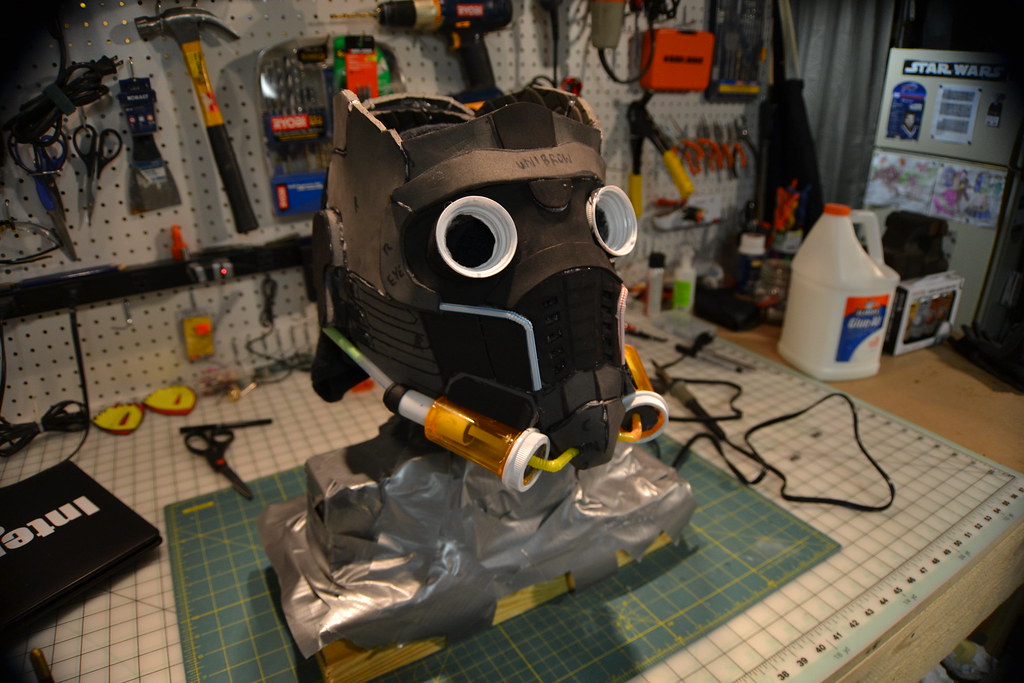

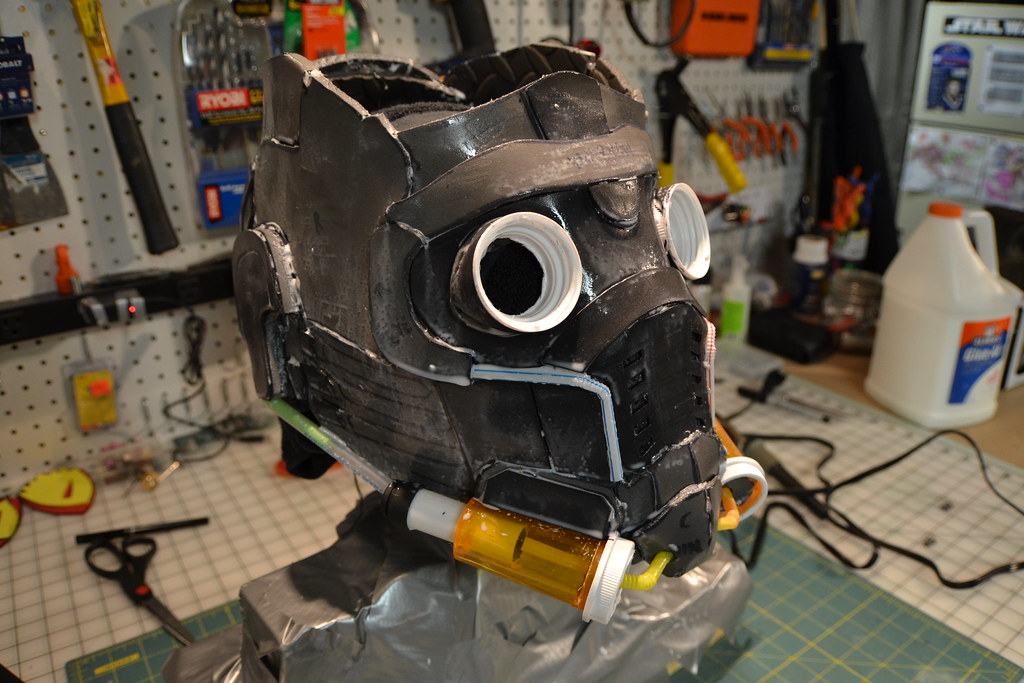

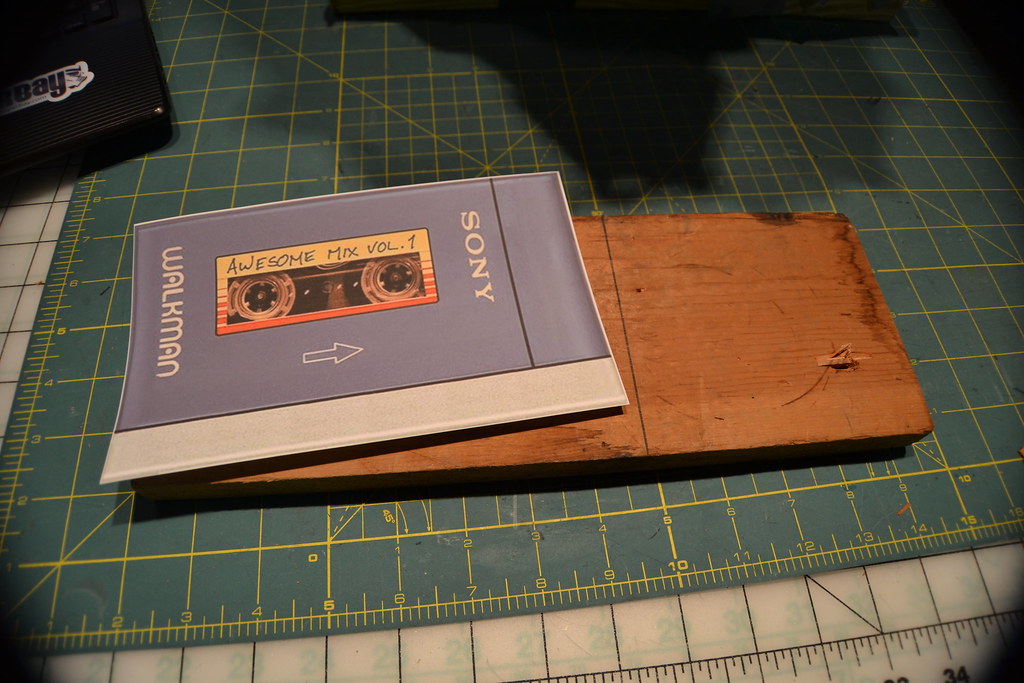

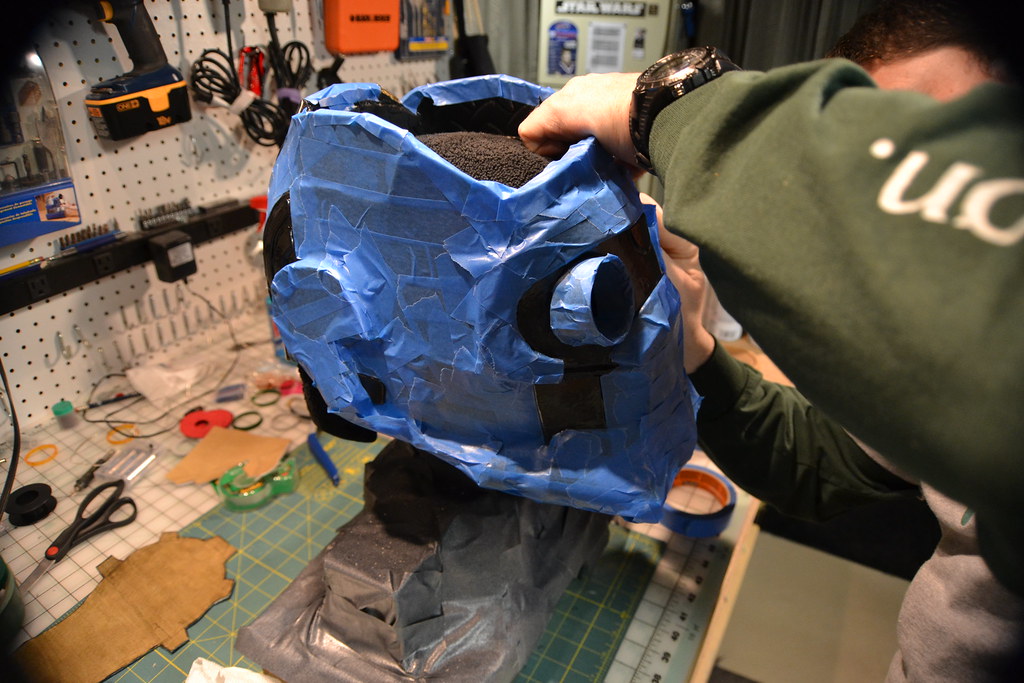

My friend, Kevin has decided that he would like to build a Guardians of the Galaxy, Star-Lord cosplay. I am assisting him with this endeavor. So, I have decided to created a build thread to document our process.

Here goes:

First of all, gotta thank JFCustom for the pdo file! Great job. This is the version of the pepakura file we started with. Here's a link: http://www.therpf.com/f24/jfcustoms-foam-files-148889/

As with all foam peps we started by printing the file on card-stock paper, and cutting out the pieces.

DSC_0101 by bobby_whalen, on Flickr

DSC_0101 by bobby_whalen, on Flickr

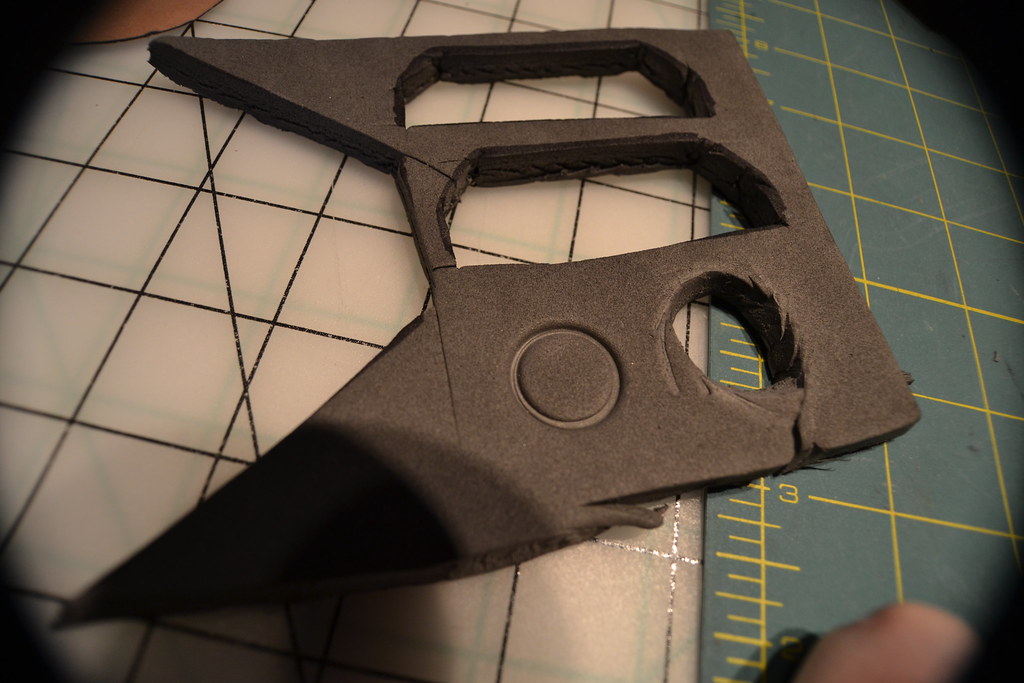

Once we had the paper parts, we traced them onto the back of an anti-fatigue mat. The mat comes on a 4'x8' roll at Ollie's Bargain Outlet for $17.99. We ended up using about 1/3 of a roll.

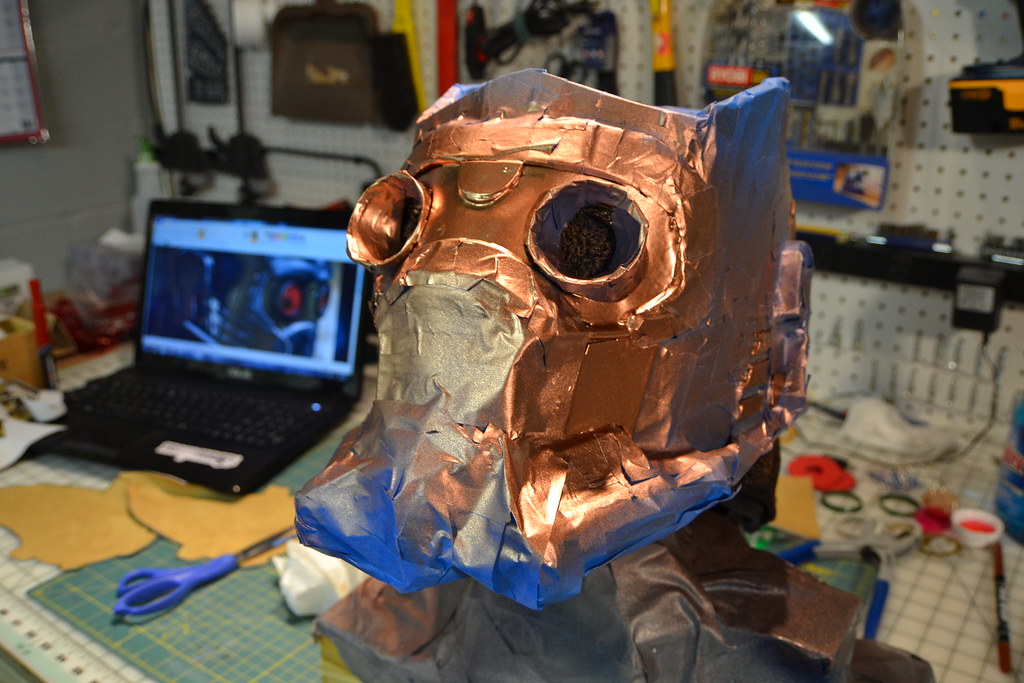

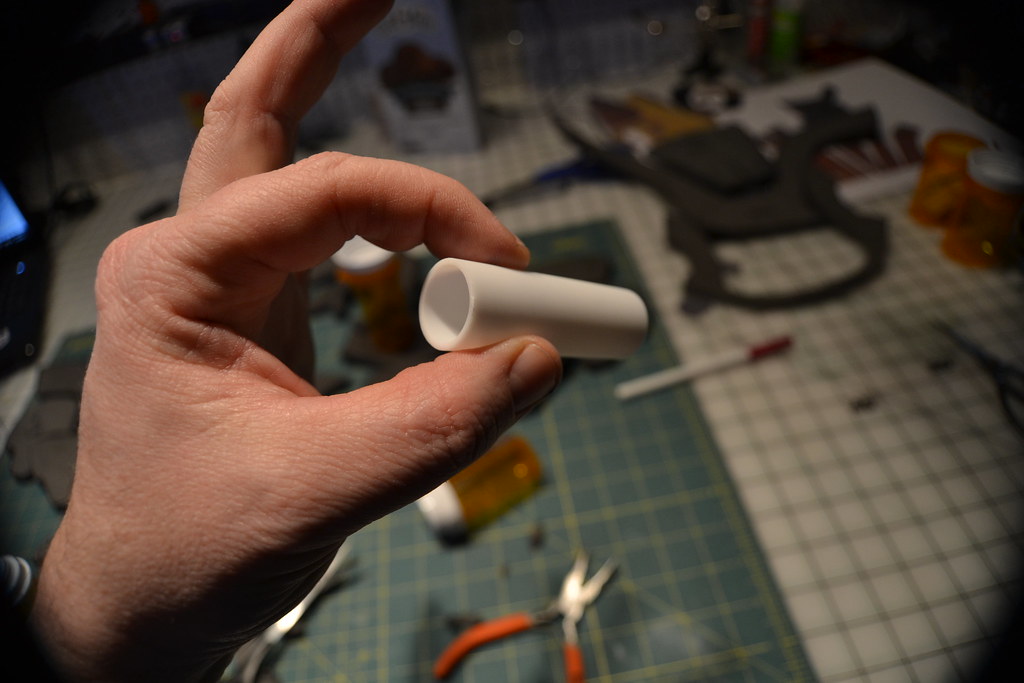

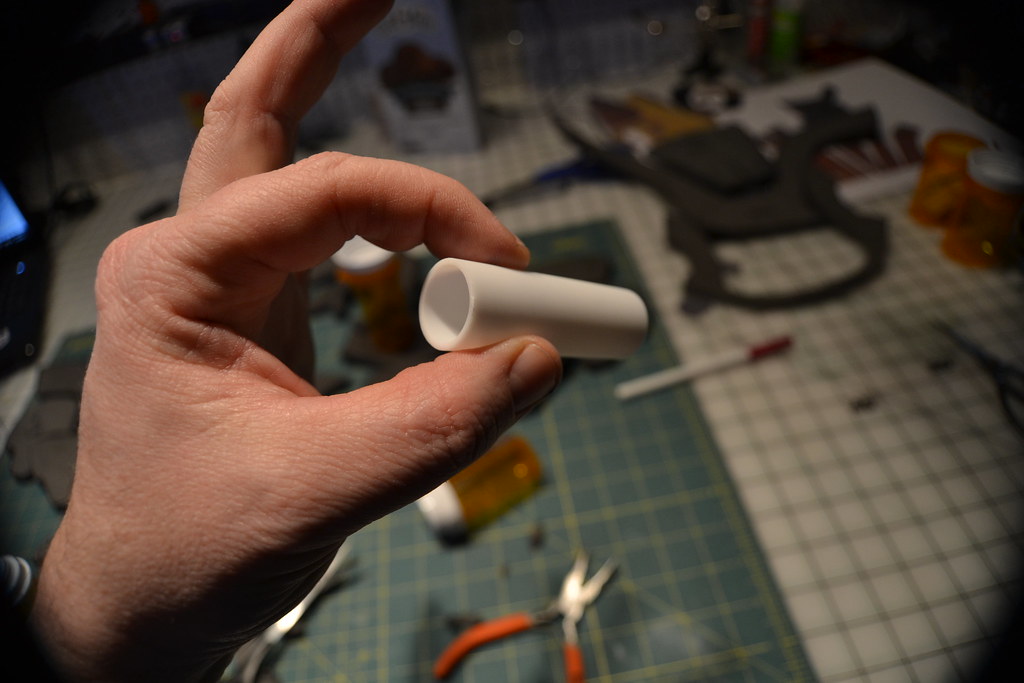

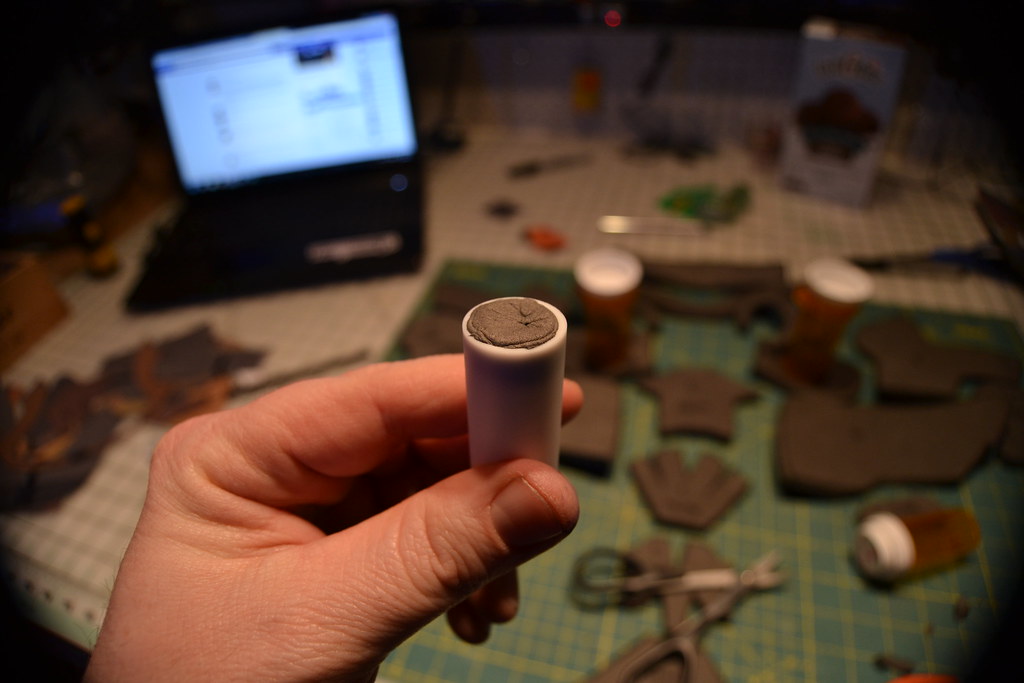

We knew that we would never be able to cut out the round pieces of the mask perfectly enough to make pefectly round shapes on the mask. We agreed that the round shapes define the mask. So, we decided to improvise those parts with things that are pre-manufactured and are already round. We had access to some "10 dram" prescription bottles, and we agreed that they would suffice.

DSC_0100 by bobby_whalen, on Flickr

DSC_0100 by bobby_whalen, on Flickr

DSC_0097 by bobby_whalen, on Flickr

DSC_0097 by bobby_whalen, on Flickr

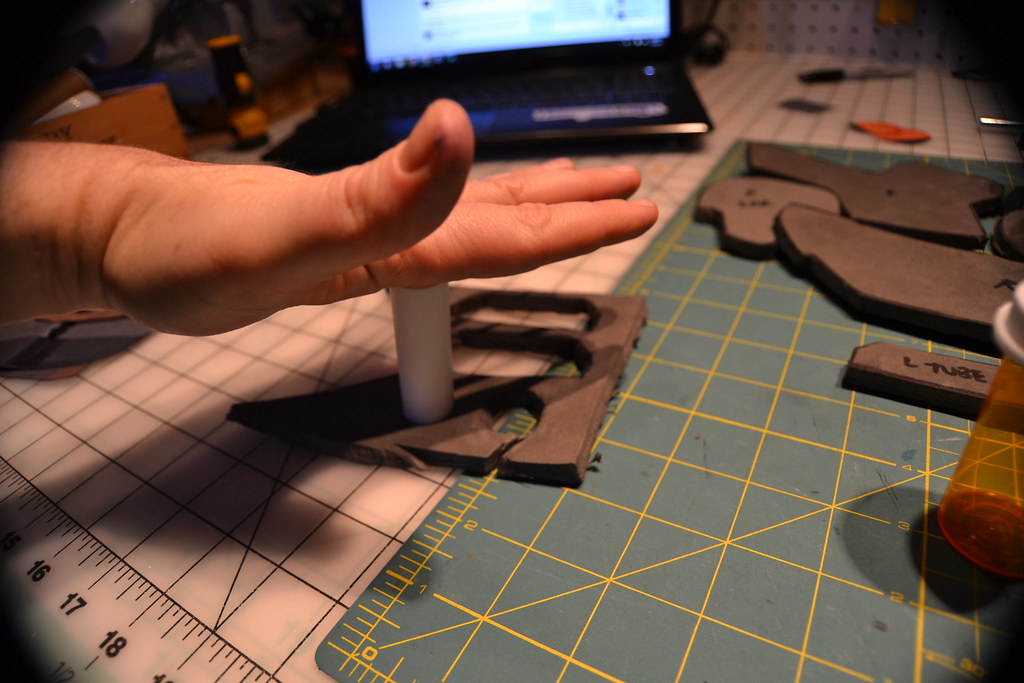

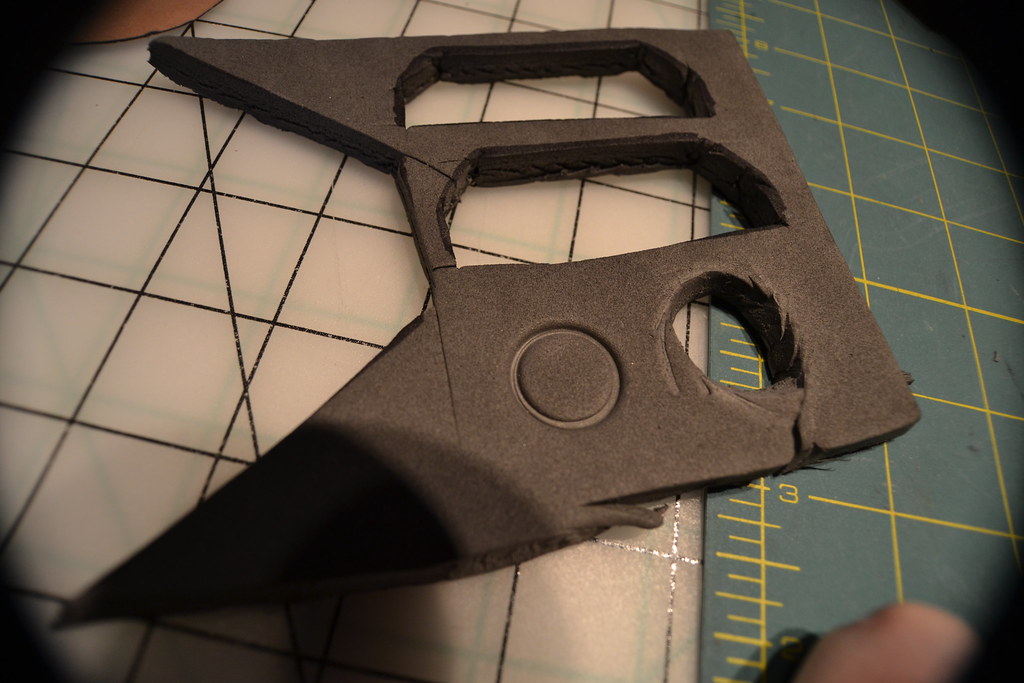

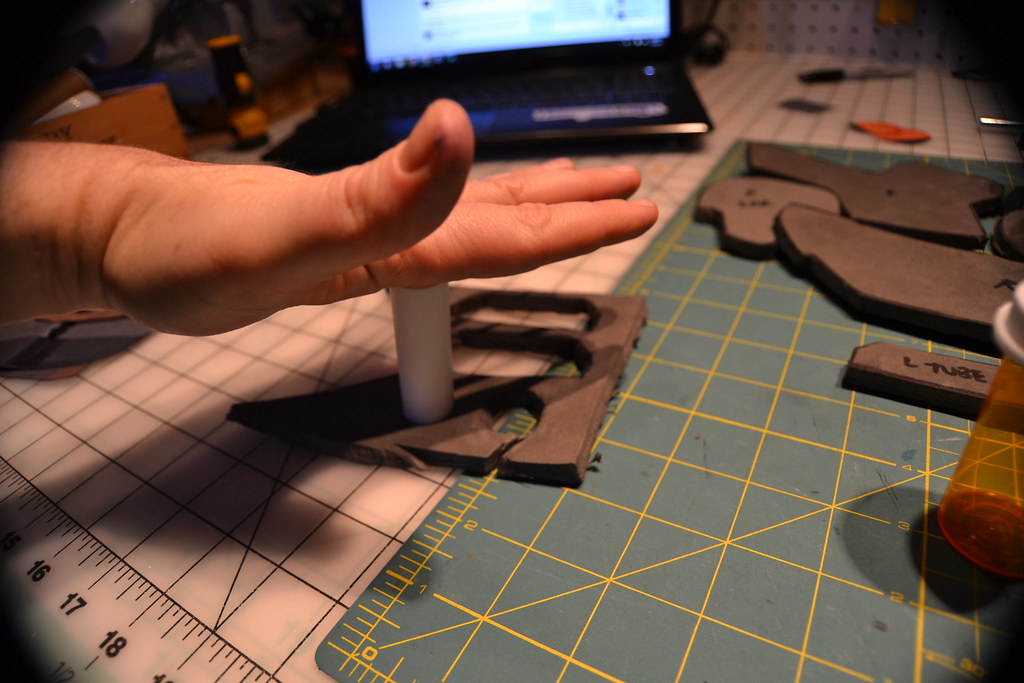

Here's a look at the foam parts laid out for assembly.

DSC_0096 by bobby_whalen, on Flickr

DSC_0096 by bobby_whalen, on Flickr

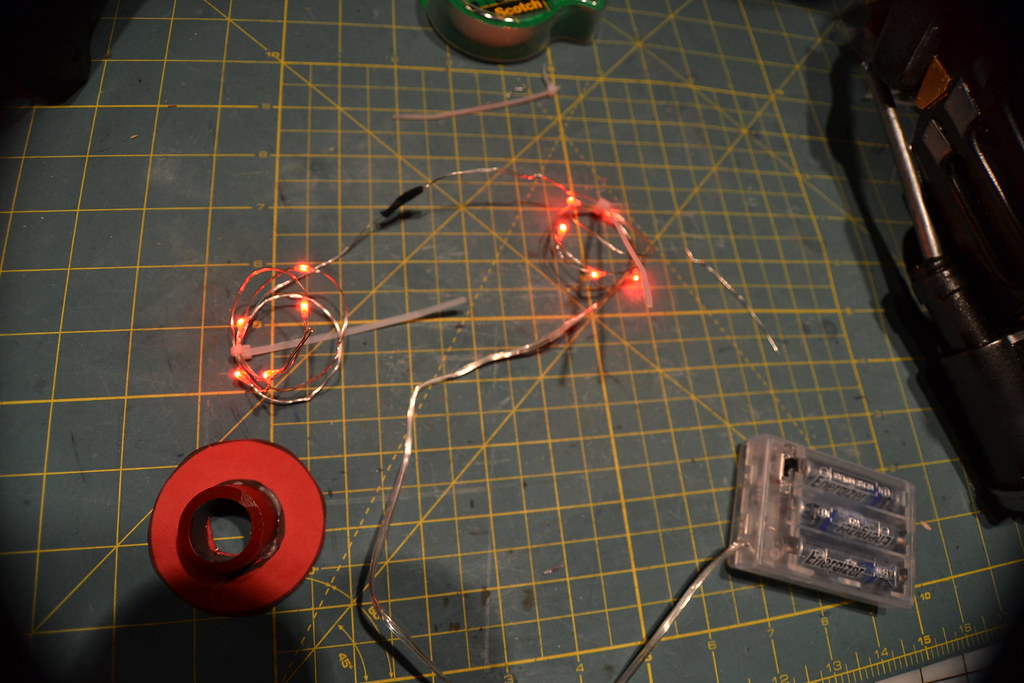

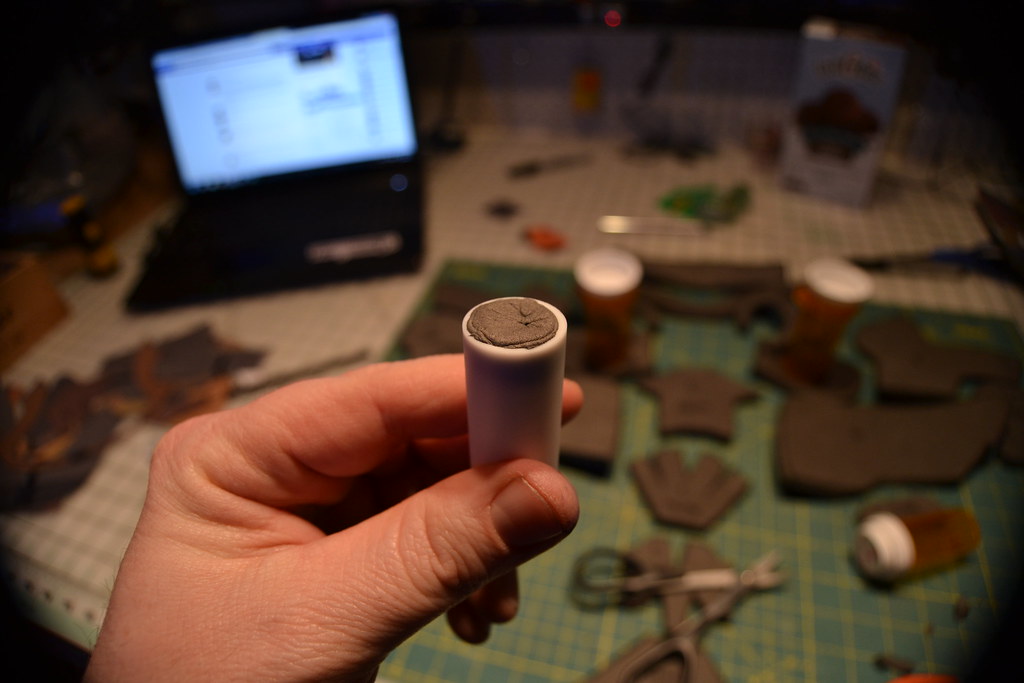

Those other round tubes are free pens I got from a hotel, and the inside of a roll from the receipt tape in a cash register.

DSC_0105 by bobby_whalen, on Flickr

DSC_0105 by bobby_whalen, on Flickr

Together, we liked the way they could be assembled into one another for the side tubing (and that they were free). As others have done with Star-Lord we also decided to use flexible drinking straws for tubing as well.

As far as tools go, we used some regular scissors, my curved lexan scissors, a hand dremel tool, some curved pliers, an x-acto knife, and a grinder.

DSC_0102 by bobby_whalen, on Flickr

DSC_0102 by bobby_whalen, on Flickr

DSC_0104 by bobby_whalen, on Flickr

DSC_0104 by bobby_whalen, on Flickr

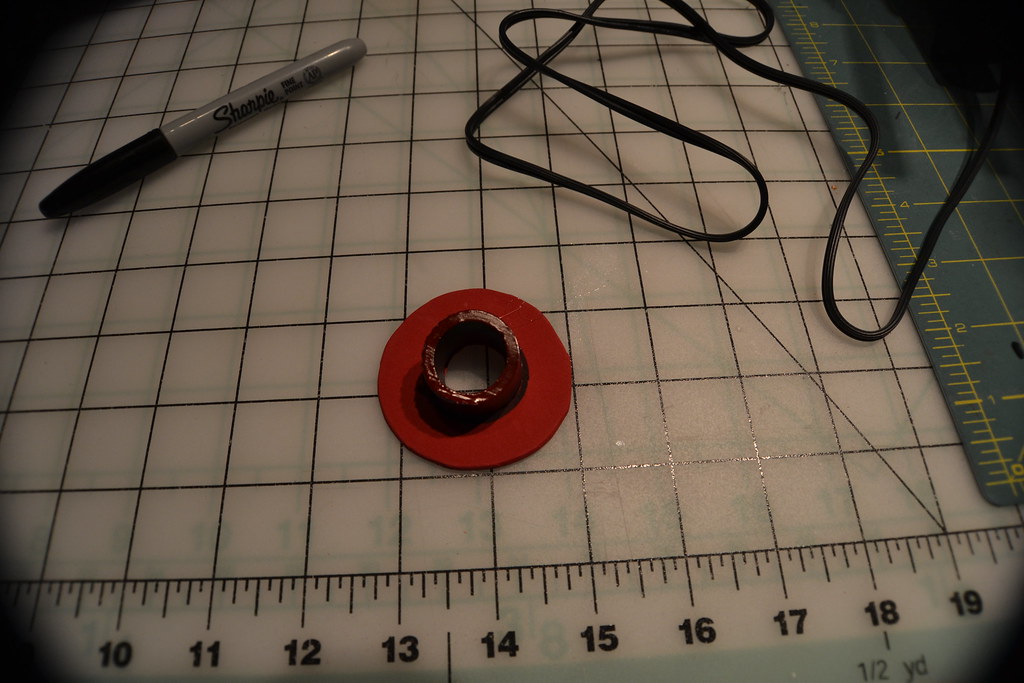

Since the different sized tubes didn't all fit into one another perfectly we used some scrap foam to make gaskets for the ends of the tubes. This would give us a way to attach them together while still keeping the angles flexible during the build process. To measure the size of the gaskets we just pressed the tubes into the foam like this.

DSC_0107 by bobby_whalen, on Flickr

DSC_0107 by bobby_whalen, on Flickr

DSC_0108 by bobby_whalen, on Flickr

DSC_0108 by bobby_whalen, on Flickr

DSC_0111 by bobby_whalen, on Flickr

DSC_0111 by bobby_whalen, on Flickr

We concluded that the diameter of the receipt tube was approximately 5/8". So, we drilled a hole in the bottom of the 10 dram bottle.

DSC_0115 by bobby_whalen, on Flickr

DSC_0115 by bobby_whalen, on Flickr

We also found a drill bit that was the same diameter of the pen.

DSC_0117 by bobby_whalen, on Flickr

DSC_0117 by bobby_whalen, on Flickr

Here goes:

First of all, gotta thank JFCustom for the pdo file! Great job. This is the version of the pepakura file we started with. Here's a link: http://www.therpf.com/f24/jfcustoms-foam-files-148889/

As with all foam peps we started by printing the file on card-stock paper, and cutting out the pieces.

DSC_0101 by bobby_whalen, on Flickr

DSC_0101 by bobby_whalen, on FlickrOnce we had the paper parts, we traced them onto the back of an anti-fatigue mat. The mat comes on a 4'x8' roll at Ollie's Bargain Outlet for $17.99. We ended up using about 1/3 of a roll.

We knew that we would never be able to cut out the round pieces of the mask perfectly enough to make pefectly round shapes on the mask. We agreed that the round shapes define the mask. So, we decided to improvise those parts with things that are pre-manufactured and are already round. We had access to some "10 dram" prescription bottles, and we agreed that they would suffice.

DSC_0100 by bobby_whalen, on Flickr

DSC_0100 by bobby_whalen, on Flickr DSC_0097 by bobby_whalen, on Flickr

DSC_0097 by bobby_whalen, on FlickrHere's a look at the foam parts laid out for assembly.

DSC_0096 by bobby_whalen, on Flickr

DSC_0096 by bobby_whalen, on FlickrThose other round tubes are free pens I got from a hotel, and the inside of a roll from the receipt tape in a cash register.

DSC_0105 by bobby_whalen, on Flickr

DSC_0105 by bobby_whalen, on FlickrTogether, we liked the way they could be assembled into one another for the side tubing (and that they were free). As others have done with Star-Lord we also decided to use flexible drinking straws for tubing as well.

As far as tools go, we used some regular scissors, my curved lexan scissors, a hand dremel tool, some curved pliers, an x-acto knife, and a grinder.

DSC_0102 by bobby_whalen, on Flickr

DSC_0102 by bobby_whalen, on Flickr DSC_0104 by bobby_whalen, on Flickr

DSC_0104 by bobby_whalen, on FlickrSince the different sized tubes didn't all fit into one another perfectly we used some scrap foam to make gaskets for the ends of the tubes. This would give us a way to attach them together while still keeping the angles flexible during the build process. To measure the size of the gaskets we just pressed the tubes into the foam like this.

DSC_0107 by bobby_whalen, on Flickr

DSC_0107 by bobby_whalen, on Flickr DSC_0108 by bobby_whalen, on Flickr

DSC_0108 by bobby_whalen, on Flickr DSC_0111 by bobby_whalen, on Flickr

DSC_0111 by bobby_whalen, on FlickrWe concluded that the diameter of the receipt tube was approximately 5/8". So, we drilled a hole in the bottom of the 10 dram bottle.

DSC_0115 by bobby_whalen, on Flickr

DSC_0115 by bobby_whalen, on FlickrWe also found a drill bit that was the same diameter of the pen.

DSC_0117 by bobby_whalen, on Flickr

DSC_0117 by bobby_whalen, on Flickr