BRDencklau

Well-Known Member

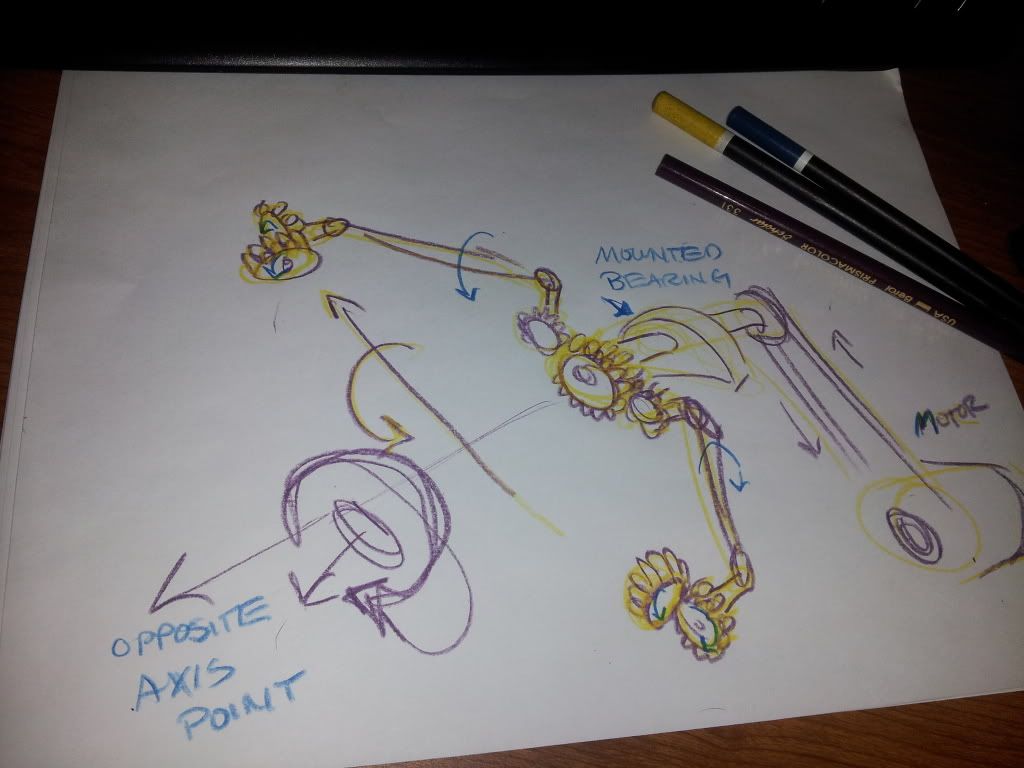

So what is that? A dual gearing that spins the mold on an axis while also toppling end over end.

That is a drive shaft through a mounted bearing connected to a drive wheel and a gear which is encased in another housing which subsequently doubles as the "drive force" gearbox. That "drive gear" will rotate the main box end for end but also turn two "sister" gears that power two opposing drive shafts connected to the opposite ends of the mold attachments through universal joints. Therefore magnifying the force applied by the motor and lowering the speed while upping the torque needed.

The problem I see with this train of thought so far is keeping the mold from spinning too fast so you can get an even coat...

That is a drive shaft through a mounted bearing connected to a drive wheel and a gear which is encased in another housing which subsequently doubles as the "drive force" gearbox. That "drive gear" will rotate the main box end for end but also turn two "sister" gears that power two opposing drive shafts connected to the opposite ends of the mold attachments through universal joints. Therefore magnifying the force applied by the motor and lowering the speed while upping the torque needed.

The problem I see with this train of thought so far is keeping the mold from spinning too fast so you can get an even coat...