Alrighty...

Test #1

This is what happens with things when you use a 7% saline solution for a couple of hours, sign vinyl and have the wires back to front...Oops? Well, no

I was actually trying to simulate what happens on those websites I visited. hardly any bubbles on the plate to be etched, so I did a switchie, to see what happens - Bubbles go mad on the surface of the brass and actually lifts off the vinyl off - it would seem the adhesive of the vinyl is enough of a resist to stop the colourisation. Using a steel sacrifice...the copper comes to the surface of the brass and anodises it !!

Test #2

Putting the wires the right way round...+ on the metal to be etched... and using the same solution, nothing seems to happen :confused

So, increased the salt solution a whole heap more...1/4 cup salt per litre...What would that do? :eheh There is action but it's not so dramatic. Might have something to do with my low amps (2.7) I have also switched to a brass sacrifice on the negative clip.

The solution becomes clouded to a carrot soup :sick colour

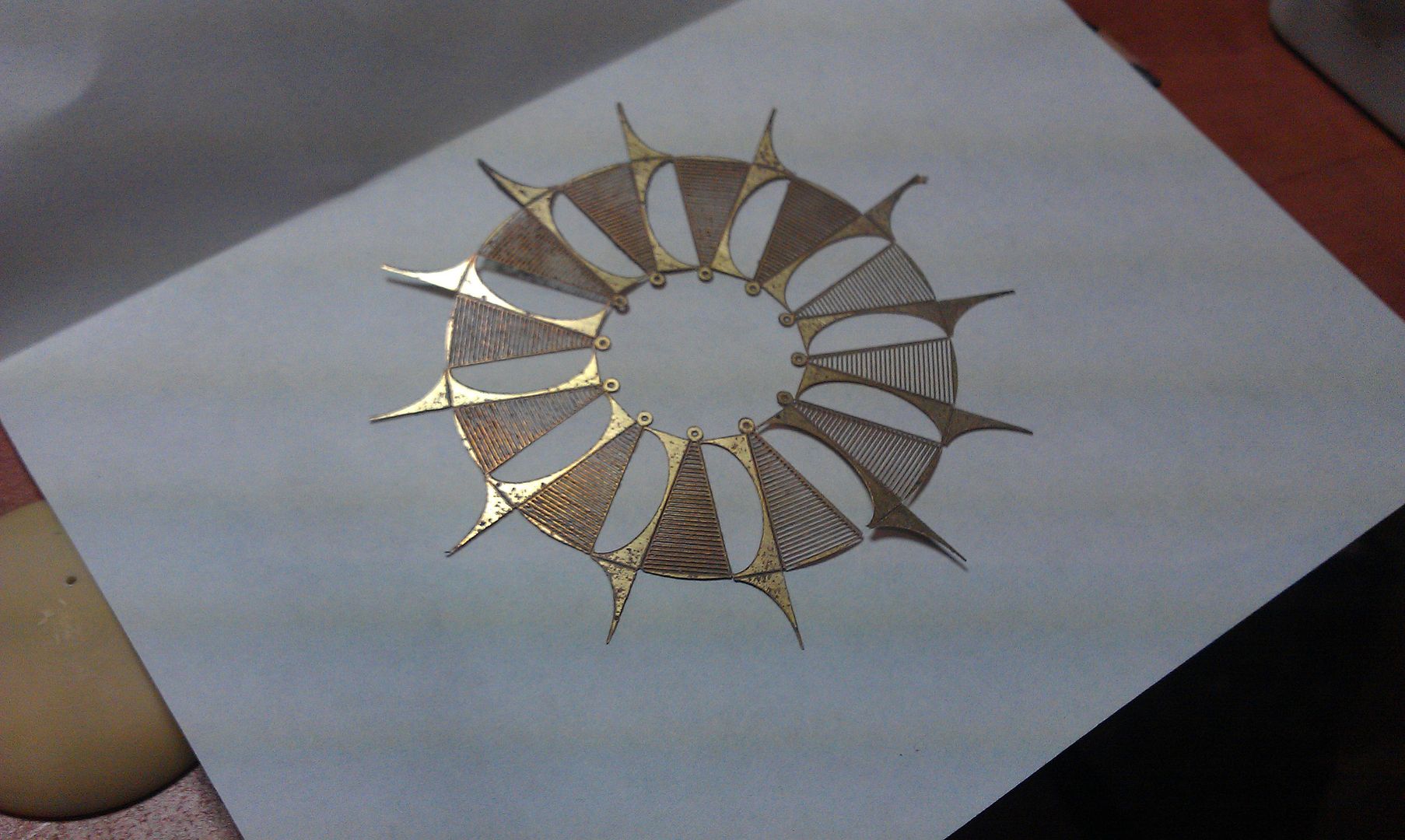

In this sample I have used sign vinyl for the patterns - stuck on first and then spray painted Wattyl Kill Rust primer. It didn't seem to take well on the surface so...I sprayed some Incralac on too. Then pealed off the vinyl......And then stuck it in for a couple of hours...

The primer has bubbled and the markings have oxidised. Burnt off the resists and sanded them back. The primer does not burn off cleanly and will take some work to get the oxidation from the inside :darnkids

The primer has bit into the metal far more than I would like. Not good if you want a smooth surface but great if you want a dimpled look.

Test #3

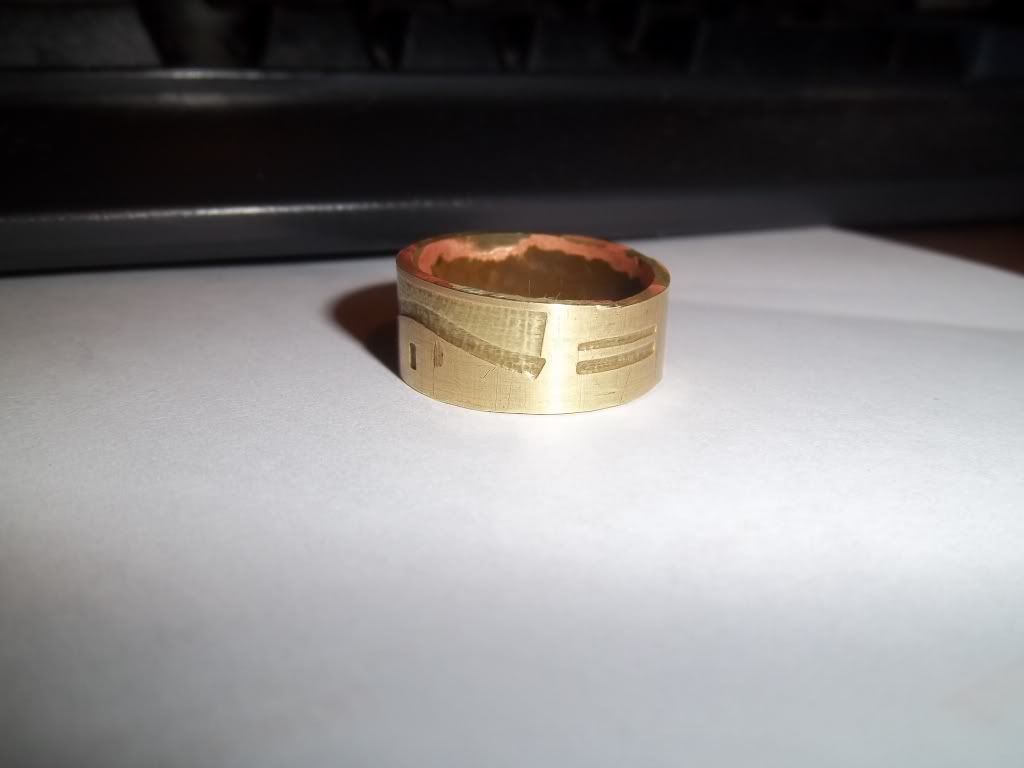

This time I just used a single coat of the Incralac and sellotape as the resist. Peeled off the vinyl for the image. The Incralac didn't work as it started to erode away. May work better with a thicker coverage. The cellotape worked brilliantly.

Tomorrow going to try the sign vinyl just by itself

Getting tape inside the tube is a bit tricky. I have found that sticking it along a length of stiff wire and threading it through the tube, then after partially sticking it down, pull out the wire...it gets the tape in there. It seems to make the best resist and burns away cleanly.

Overall the etch effect is a good'n. A nice pattination with a crisp edge with the vinyl or sellotape resist :cool