You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chopper Droid Replica WIP - Aluminium and 3D Printed

- Thread starter Studio 49

- Start date

colinjreed

Member

I designed these from scratch myself, so It's incredibly satisfying and exciting to have the tangible result of all my hours of 3D modelling and design

That is always the best part of a project, going from pixels and ideas to a tangible object. And my god, what an object you have there! I feel like you need to keep an eye on him so he doesn’t throw rocks at you.

Studio 49

Sr Member

That's very kind of you man, thanks so much for the words of encouragementIf there was a build of the year award on therpf this would take first place.. the engineering gone into this.. amazing

I'm glad that folks are enjoying what I'm building and documenting.

Couldn't agree more man! It never fails to get me excited when bruising the tangible piece!That is always the best part of a project, going from pixels and ideas to a tangible object. And my god, what an object you have there! I feel like you need to keep an eye on him so he doesn’t throw rocks at you.

And thanks for the kind words, that's very nice of you

Yep gotta watch out for this guy! I think he's just biding his time for the perfect ambush opportunity haha

Studio 49

Sr Member

I have some cool footage to share of my frame and other parts for Chopper getting cut on the water jet cutter

The company I got to cut my parts was kind enough to film some footage for me so I wanted to share it here for anything that would like a look behind the scenes at how the parts were produced from my CAD/3D designs.

The company I got to cut my parts was kind enough to film some footage for me so I wanted to share it here for anything that would like a look behind the scenes at how the parts were produced from my CAD/3D designs.

Studio 49

Sr Member

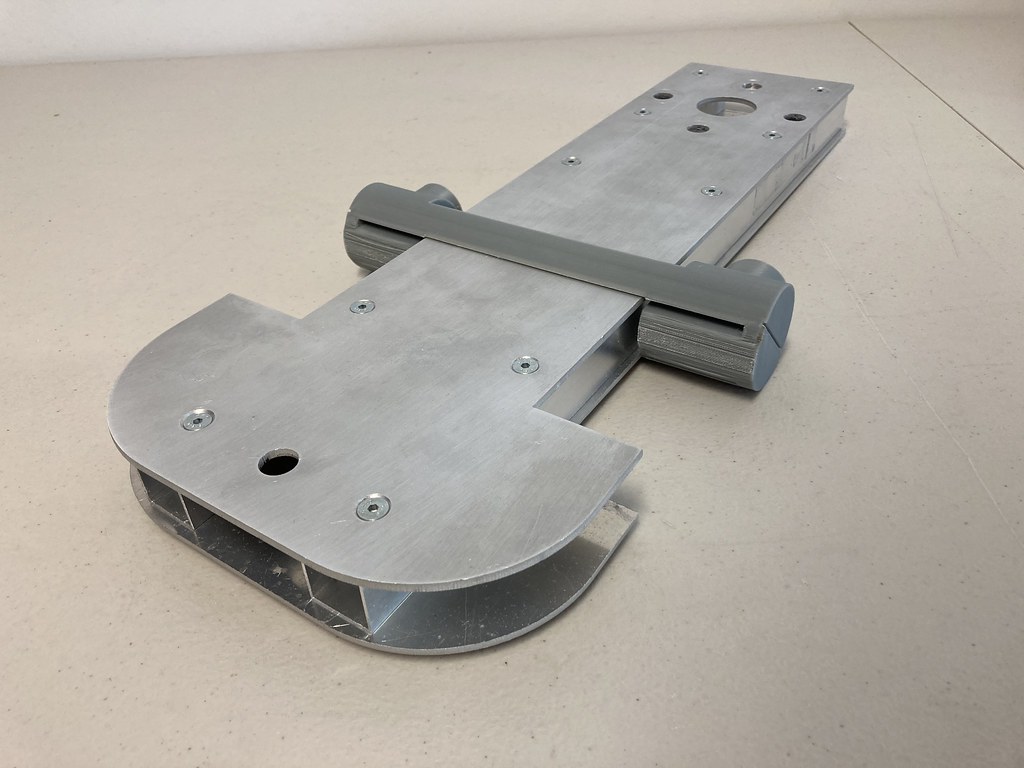

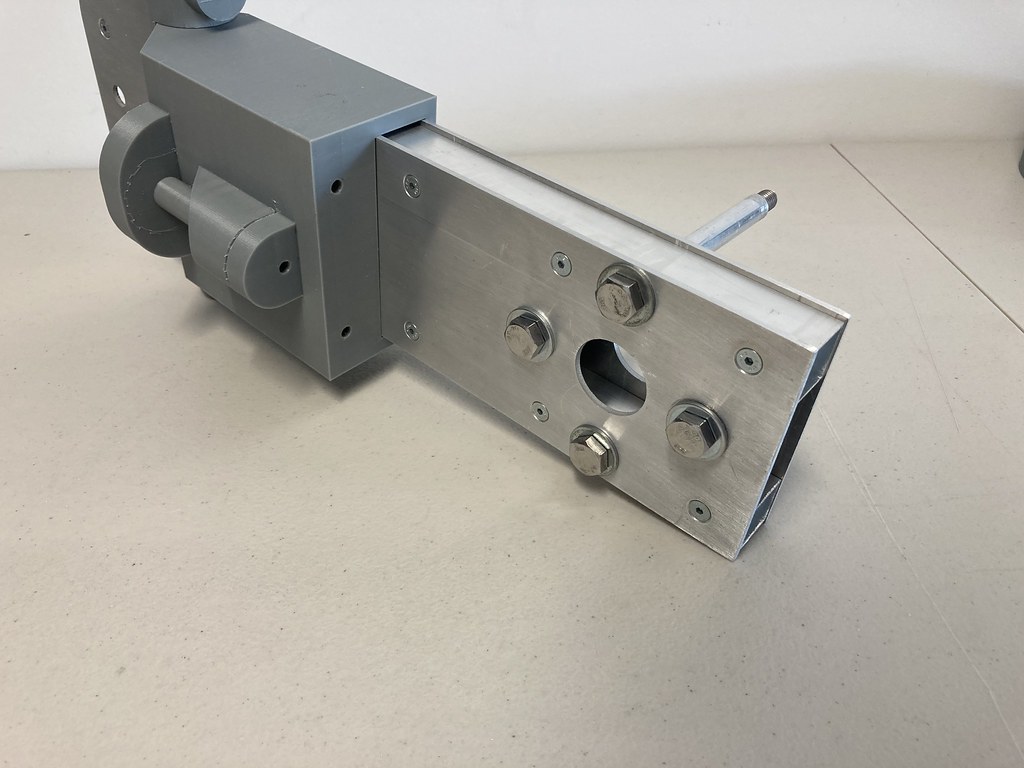

Now that I had the frame and leg substructures assembled it was time to mount the legs to the frame!

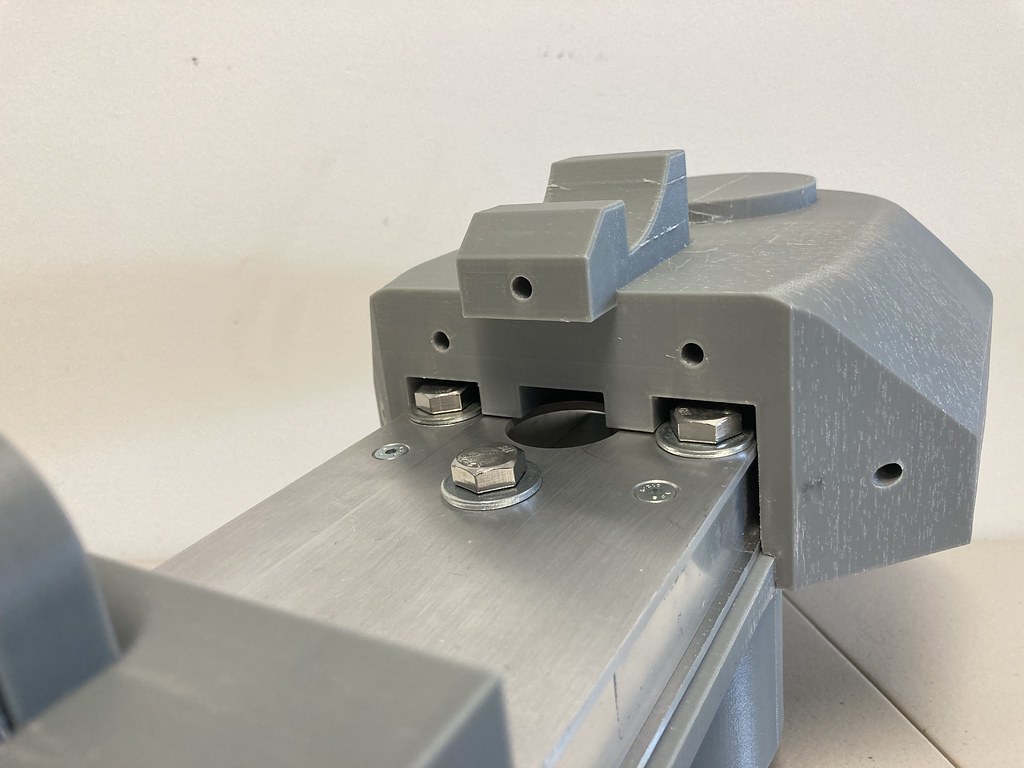

In my R2D2 build I used shoulder bolts, however to get them in the length I needed for Chopper proved to be far too expensive, so I decided to make my own

As you can see below it consists of a quite standard M10 bolt. I then found an aluminium tube that fits perfectly to the bolts. It's not too tight and not loose, so I couldn't have asked for a better find! I then added in a couple washers and I'm pleased to say the bolt assembled very nicely.

Now that I had the bolts, I commenced with assembling the part for attaching the leg. This started with sliding the bolts through the openings in the legs as you can see below:

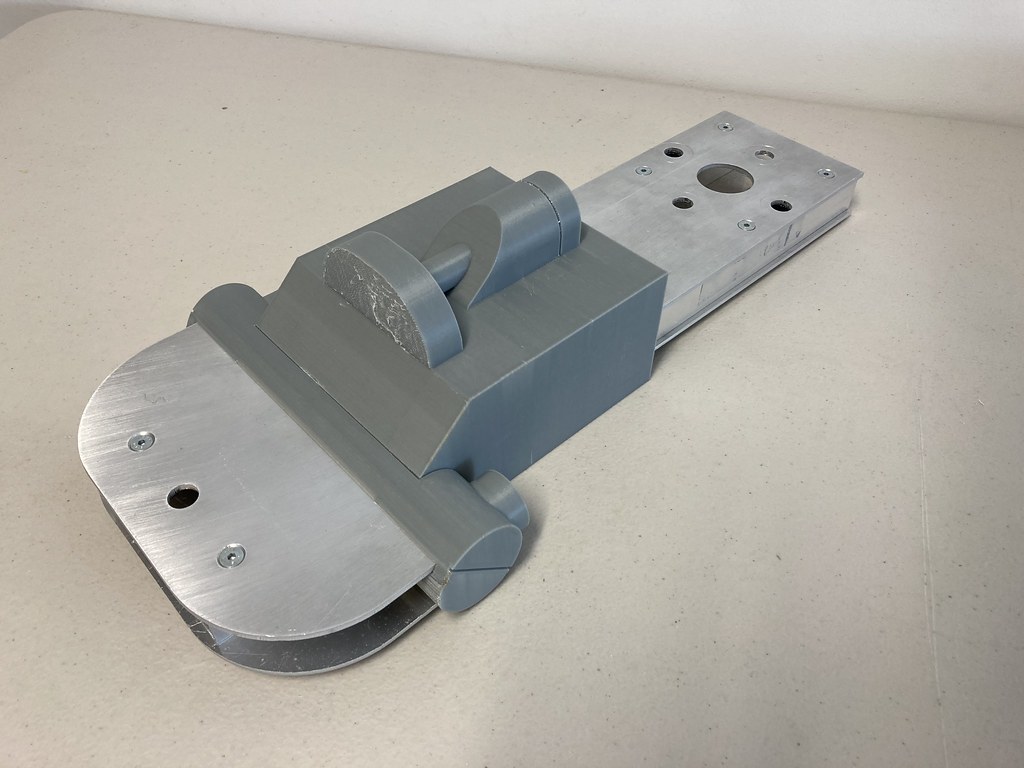

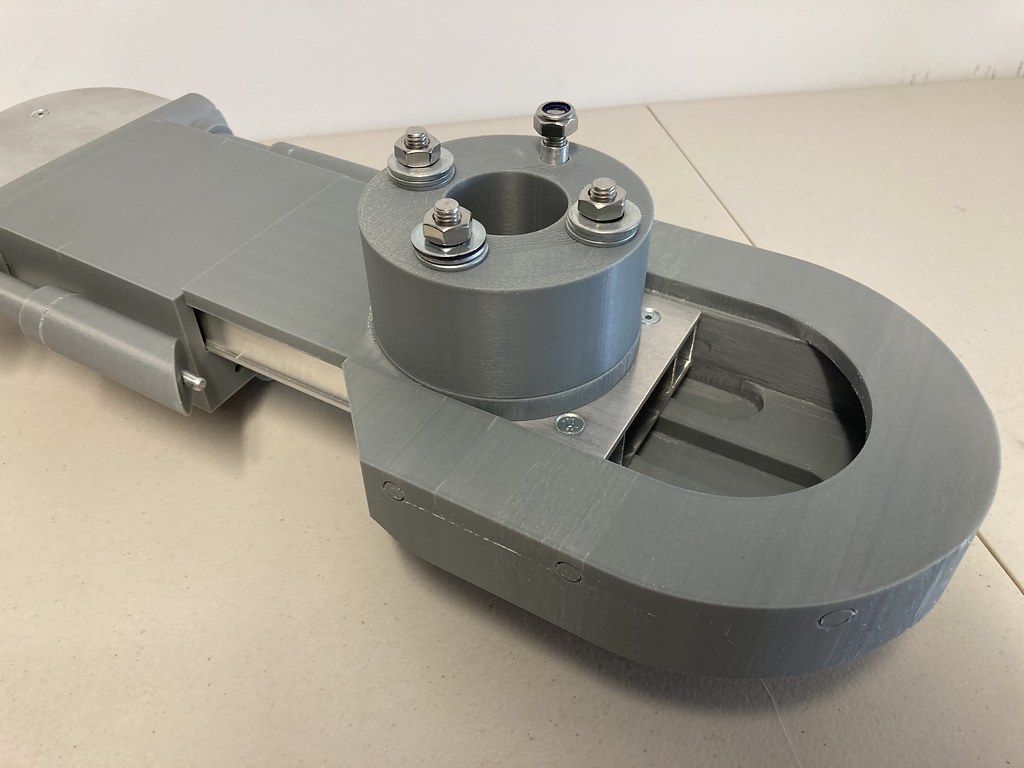

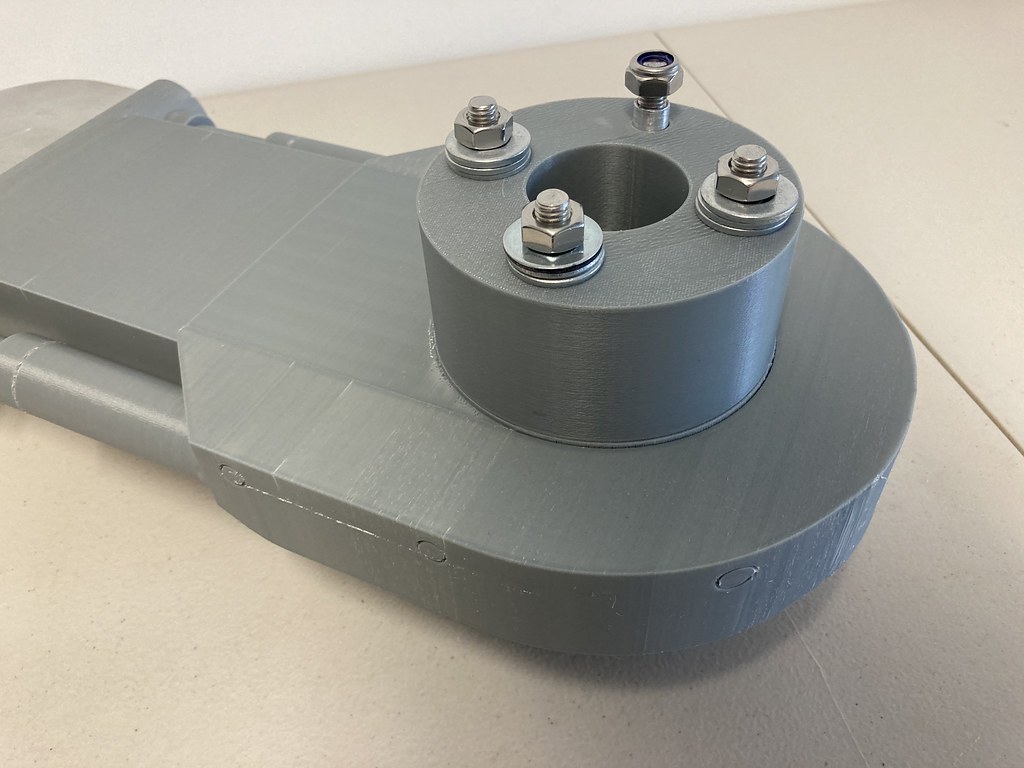

With the bolts in I slid on the first 3D printed part. This part is from the shoulder piece assembly, it may look odd currently, but it will make sense in a few posts time

Next was the shoulder connection hub that I modelled up that acts as a giant spacer between the aluminium frame and the leg assembly

And finally here you can see the leg attached and bolted on with nyloc nuts. you can also see a glimpse of how the 3D printed skin wraps around the frame and the legs connector hub

In my R2D2 build I used shoulder bolts, however to get them in the length I needed for Chopper proved to be far too expensive, so I decided to make my own

As you can see below it consists of a quite standard M10 bolt. I then found an aluminium tube that fits perfectly to the bolts. It's not too tight and not loose, so I couldn't have asked for a better find! I then added in a couple washers and I'm pleased to say the bolt assembled very nicely.

Now that I had the bolts, I commenced with assembling the part for attaching the leg. This started with sliding the bolts through the openings in the legs as you can see below:

With the bolts in I slid on the first 3D printed part. This part is from the shoulder piece assembly, it may look odd currently, but it will make sense in a few posts time

Next was the shoulder connection hub that I modelled up that acts as a giant spacer between the aluminium frame and the leg assembly

And finally here you can see the leg attached and bolted on with nyloc nuts. you can also see a glimpse of how the 3D printed skin wraps around the frame and the legs connector hub

Studio 49

Sr Member

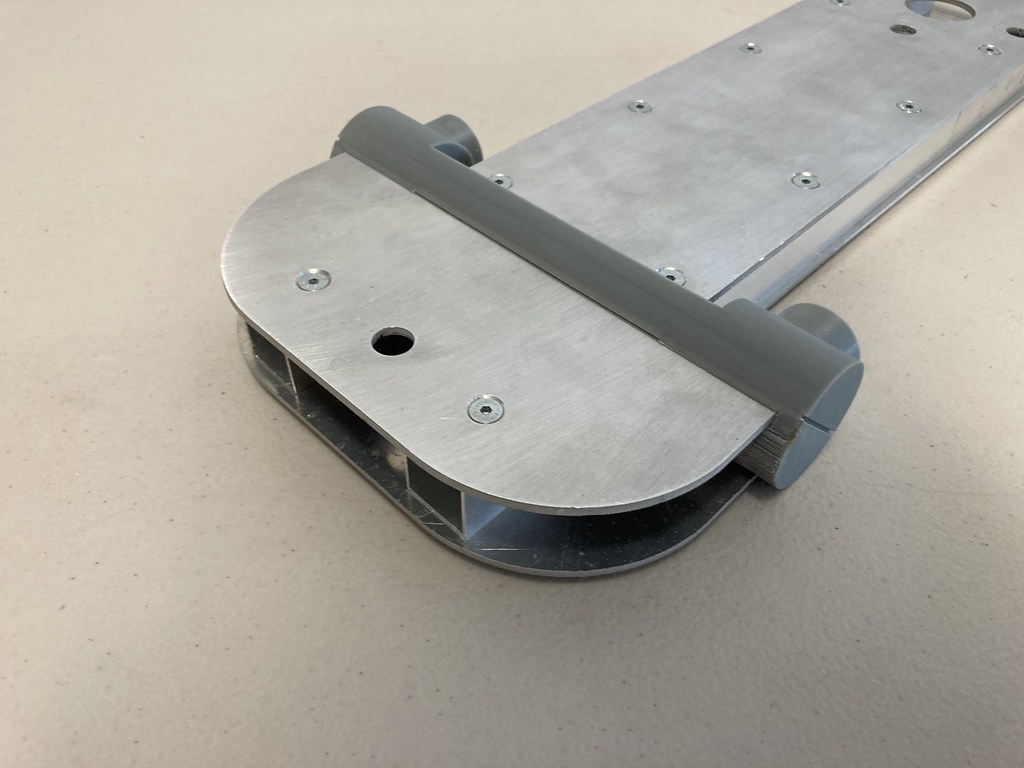

Yesterday I also assembled the feet for Chopper.

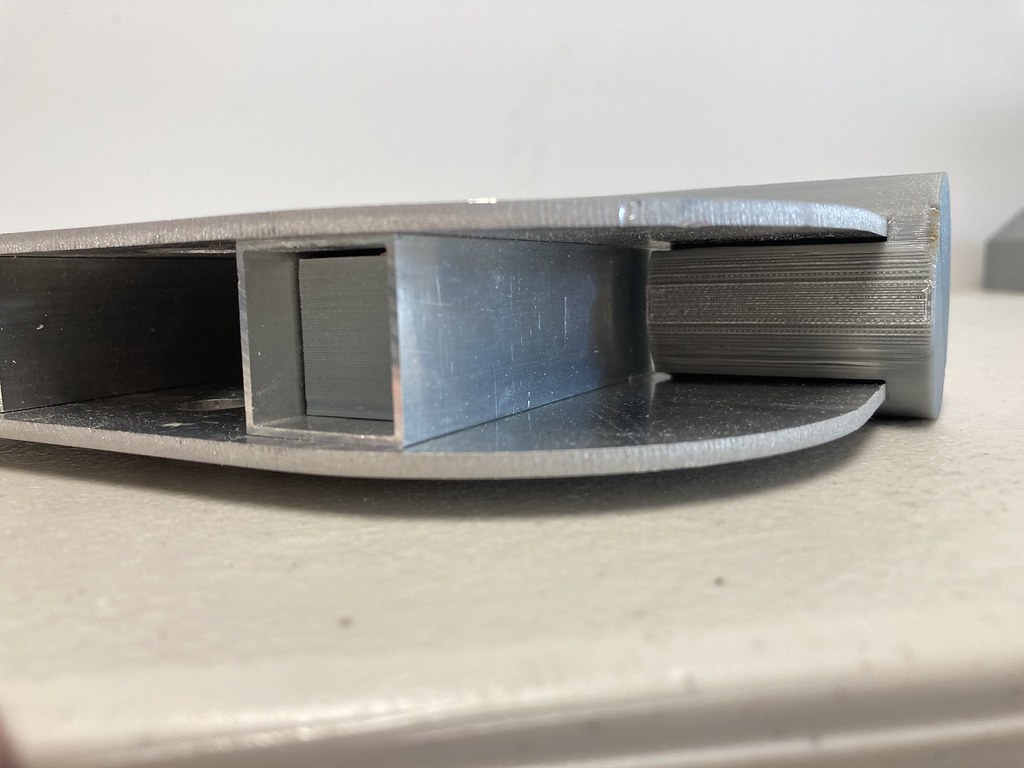

For the time being I won't be implementing motors as my R2D2 build is getting that attention. With that in mind I designed a simple drive design that can be modified and upgraded in the future should I decide to implement an RC drive system.

The current set up is very simple, it consists of 2 main wheels at the front followed by a locking castor wheel in the back.

With the outer feet sorted I worked on the mounting system for the centre foot/castor wheel.

The mounting plate of the castor wheel needs to mount onto the angled bottom surface of the frame, so I designed and angled adaptor that allowed me to mount the castor through the frame to a level surface with bolts.

For the time being I won't be implementing motors as my R2D2 build is getting that attention. With that in mind I designed a simple drive design that can be modified and upgraded in the future should I decide to implement an RC drive system.

The current set up is very simple, it consists of 2 main wheels at the front followed by a locking castor wheel in the back.

With the outer feet sorted I worked on the mounting system for the centre foot/castor wheel.

The mounting plate of the castor wheel needs to mount onto the angled bottom surface of the frame, so I designed and angled adaptor that allowed me to mount the castor through the frame to a level surface with bolts.

Great work!! Love that show, glad to see props from it>

NakedMoleRat

Legendary Member

Simply amazing.

Studio 49

Sr Member

Man you are really making excellent progress

At the rate he’s working this sucker will be mobile next week

Haha thanks mate

This has been my way of staying sane during Covid and waiting for work to start again once film production resumes.

Should have some more WIP pics soon! I also have started printing the parts for the legs

Thanks man!Great work!! Love that show, glad to see props from it>

ThanksSimply amazing.

Last edited:

Studio 49

Sr Member

I have some more exciting progress to document

Chopper now has all the parts for his first leg printed, which means I can show how I designed the parts for assembly.

I’ve put together a short video below for you all that shows it all and how all the parts fit together, and I have also posted photos of each step accompanied by a written description.

Chopper now has all the parts for his first leg printed, which means I can show how I designed the parts for assembly.

I’ve put together a short video below for you all that shows it all and how all the parts fit together, and I have also posted photos of each step accompanied by a written description.

Studio 49

Sr Member

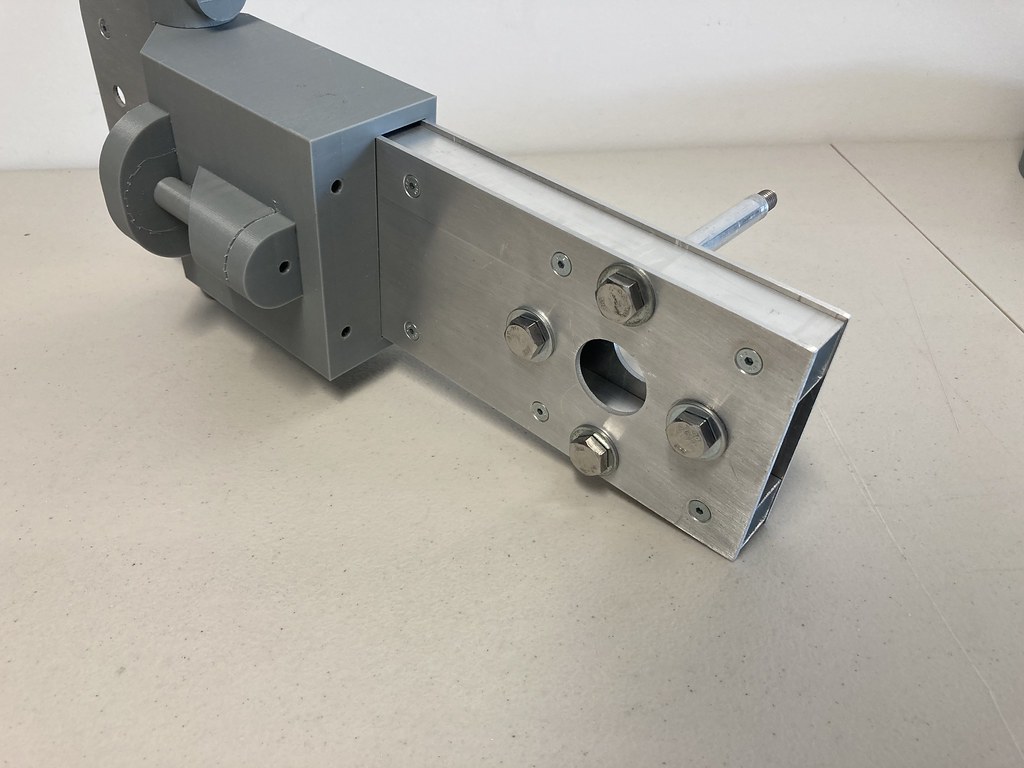

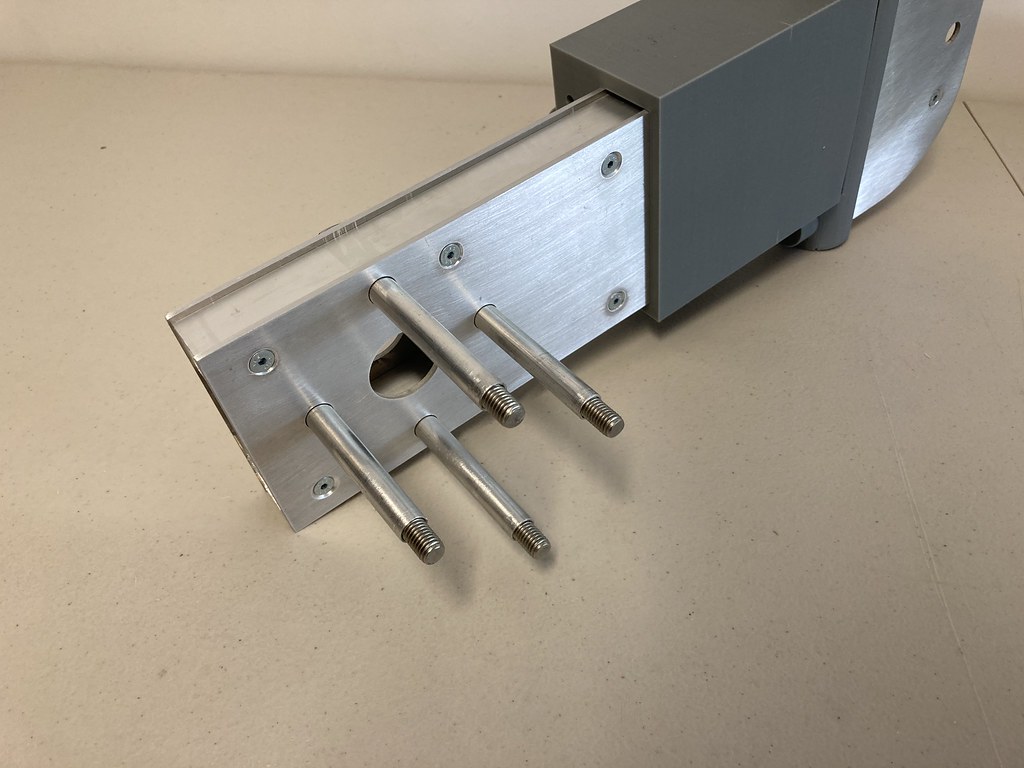

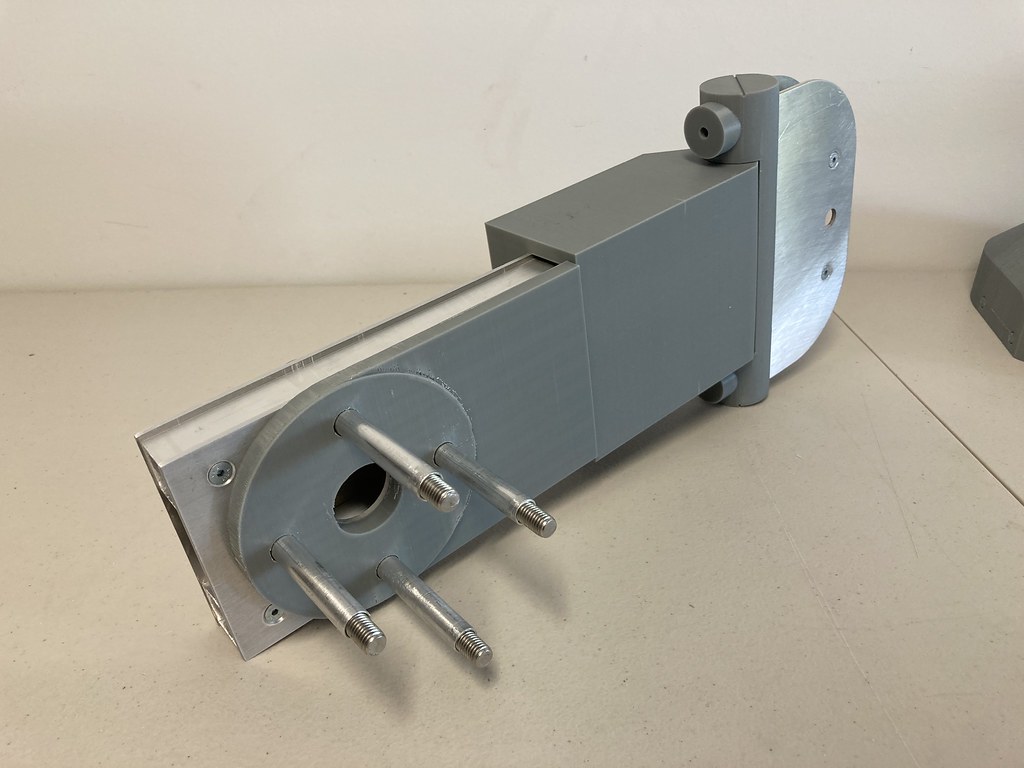

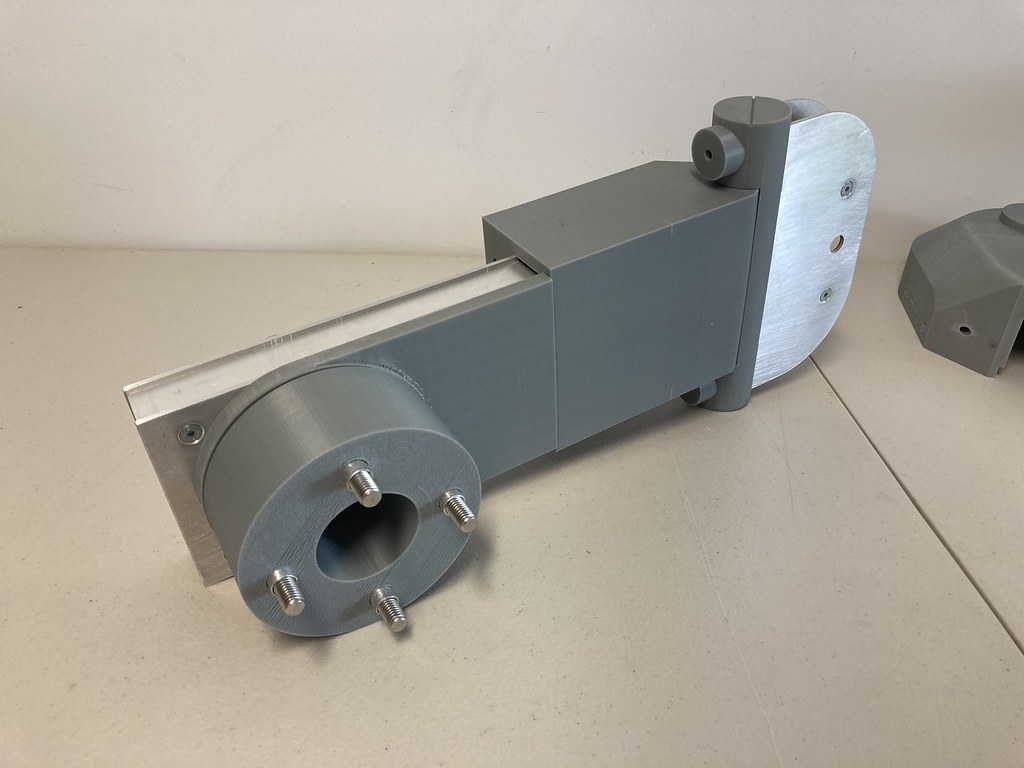

To start off with these are all the parts ready for assembly. This includes the aluminium leg that I showed earlier in the thread, all the 3D printed parts that sleeve around the Aluminium leg and then the custom shoulder bolts for mounting the leg to the frame.

First step is to sleeve this cylindrical piece down the leg. I designed this to have slots underneath that allow the printed part to have a spot on friction fit onto the 3mm aluminium plates that make up front and backside side of the aluminium leg.

Next up is the middle detail section, this simply slides down the leg and then sits neatly inside the cylindrical piece that's already seated at the bottom.

Now that these first two printed parts are on, it's time to insert the shoulder bolts.

Following the shoulder bolts, the backing plate for the top shoulder piece is inserted along with the shoulder to frame connection hub.

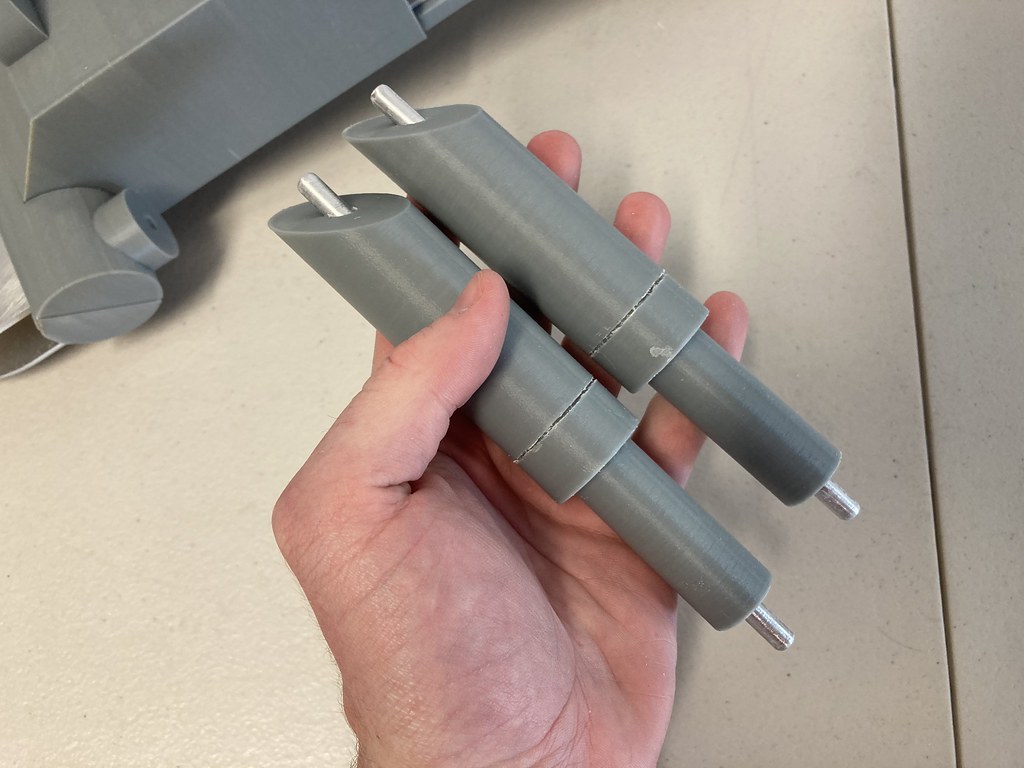

The next stage involves attaching the struts that run up either side of the leg. I've designed these to incorporate an aluminium rod the runs the length of the inside of the part for strength. This rod also protrudes from either end which allows for friction fitting it to the other parts.

As demonstrated below, the producing pins pop straight into the pre-existing mounting holes that are on the cylindrical bottom piece.

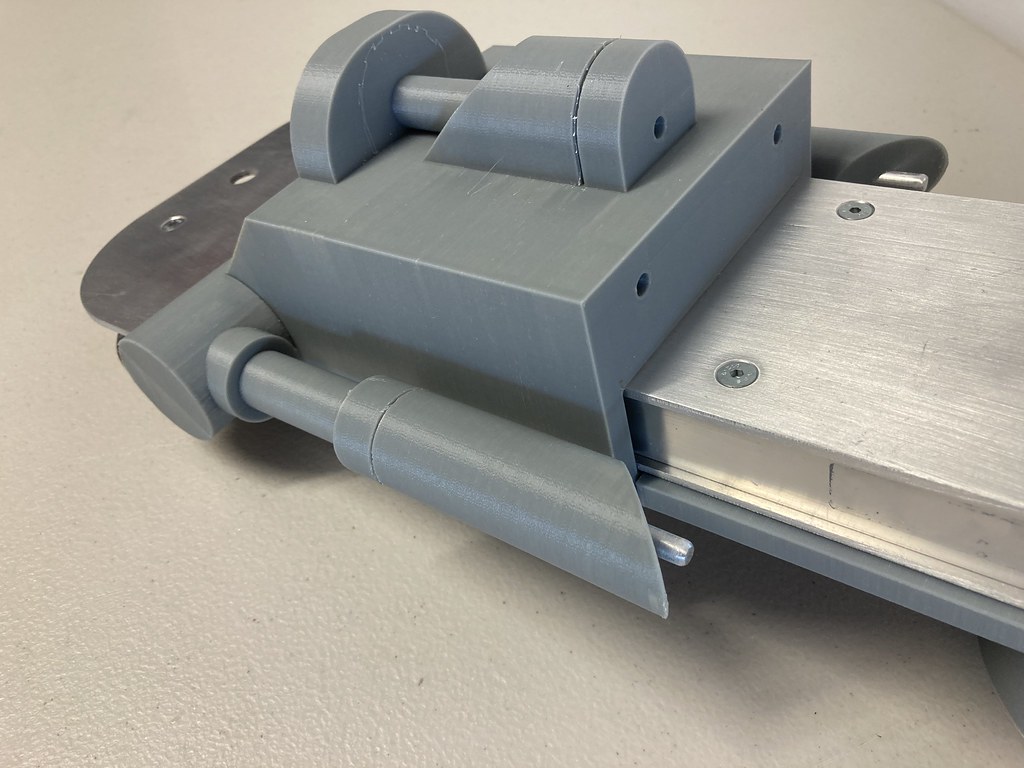

With all the parts above sorted it's time for sliding on the main shoulder piece.

I'm particular pleased with this as it has grooves so that it slides seamlessly past the shoulder bolts and around the backing plate on the other side.

As you can see here the shoulder pieces it designed to sleeve around the aluminium leg and the backing plate/connection hub perfectly.

The purpose is this is it allows the shoulder piece to be slid off at any time so I can quickly and easily access the shoulder bolts which is very handy!

And then of course, here's the assembled leg ready to be attached to the frame and the corresponding outer foot

First step is to sleeve this cylindrical piece down the leg. I designed this to have slots underneath that allow the printed part to have a spot on friction fit onto the 3mm aluminium plates that make up front and backside side of the aluminium leg.

Next up is the middle detail section, this simply slides down the leg and then sits neatly inside the cylindrical piece that's already seated at the bottom.

Now that these first two printed parts are on, it's time to insert the shoulder bolts.

Following the shoulder bolts, the backing plate for the top shoulder piece is inserted along with the shoulder to frame connection hub.

The next stage involves attaching the struts that run up either side of the leg. I've designed these to incorporate an aluminium rod the runs the length of the inside of the part for strength. This rod also protrudes from either end which allows for friction fitting it to the other parts.

As demonstrated below, the producing pins pop straight into the pre-existing mounting holes that are on the cylindrical bottom piece.

With all the parts above sorted it's time for sliding on the main shoulder piece.

I'm particular pleased with this as it has grooves so that it slides seamlessly past the shoulder bolts and around the backing plate on the other side.

As you can see here the shoulder pieces it designed to sleeve around the aluminium leg and the backing plate/connection hub perfectly.

The purpose is this is it allows the shoulder piece to be slid off at any time so I can quickly and easily access the shoulder bolts which is very handy!

And then of course, here's the assembled leg ready to be attached to the frame and the corresponding outer foot

colinjreed

Member

When will the kits for this be available?

NakedMoleRat

Legendary Member

I want that so MUCH!

Studio 49

Sr Member

If only it was that easy to build and produce haha!When will the kits for this be available?

Thanks man!INSANE!!

You're too kind man, I'm just glad folks are finding my boring essay length build thread posts interesting hahaI want that so MUCH!

Similar threads

- Replies

- 56

- Views

- 1,628

- Replies

- 85

- Views

- 6,946

- Replies

- 1

- Views

- 876