You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chopper Droid Replica WIP - Aluminium and 3D Printed

- Thread starter Studio 49

- Start date

Studio 49

Sr Member

Can I say damn on here? If so, daaaammmmnnn!

Holy Moly! Great Googly-Moogly... that drawing is amazing. The details, the mechanics, just awesome.... it would be cool just to make orthos of specific sections of Chopper and make prints of them... very cool.

So freak’n incredible!!

Thanks for the kind works folks!

I'll hopefully have some more progress posted up soon on the arm mech

Studio 49

Sr Member

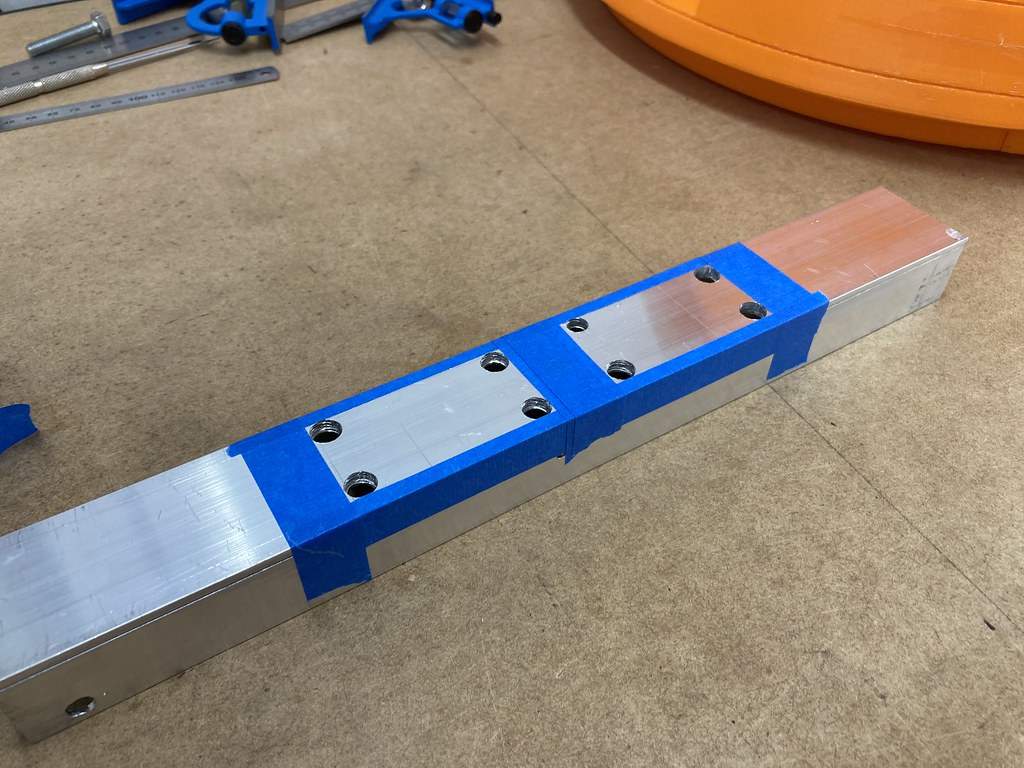

I've been making some good progress on the dome arm mechanism this week. The mech was designed so that I can create a cross beam from aluminium extrusions I have from the local hardware store. After measuring the up extrusions, I modelled them in Inventor so that I could design the beam.

I have to all this with hand saws as I don't have a lot of room for tools in my home workshop for stuff like this. First, I chopped a flat bar and right angle to length, so they'd fit nicely within the dome:

I then keyed up the surfaces of the flat bar and angles with sandpaper so I could glue them together:

After which I needed a bracket that would allow me to connect the beam to the 3D print. Essentially once I have the top plate cut and glued to the dome I can simply slot in the cross beam on the inside and then this bracket will hold the beam up against the underside of the top plate.

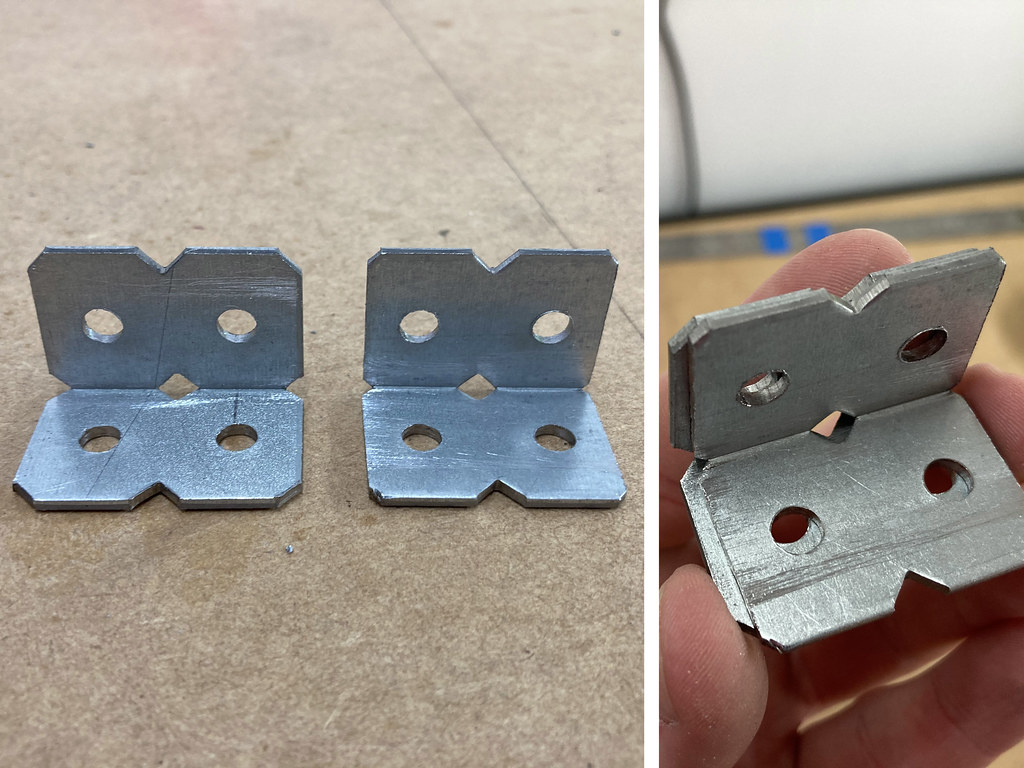

This way the entire dome arm mechanism can modular and removable if needed. I also designed my 3D printed dome to include embed M6 nuts so that I could simply use a bolt to connect the bracket. So that the bracket could fit in between the sides of the cross beam I had to trim back the overall width of the bracket. I just used my hacksaw for this, you can see the difference below:

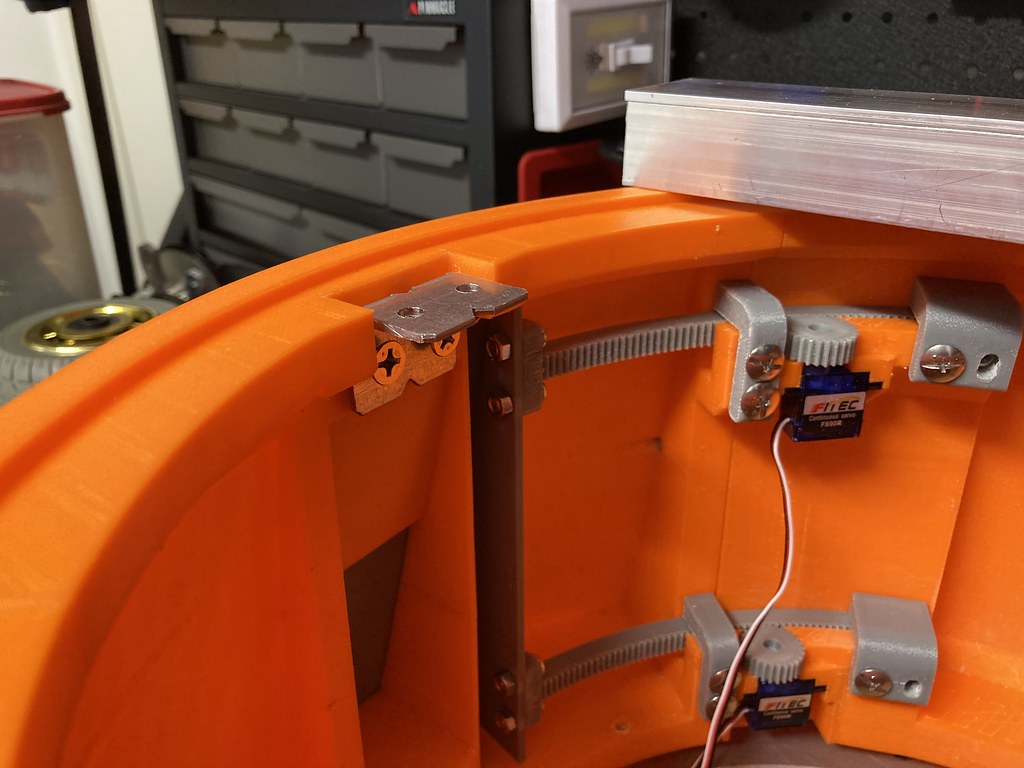

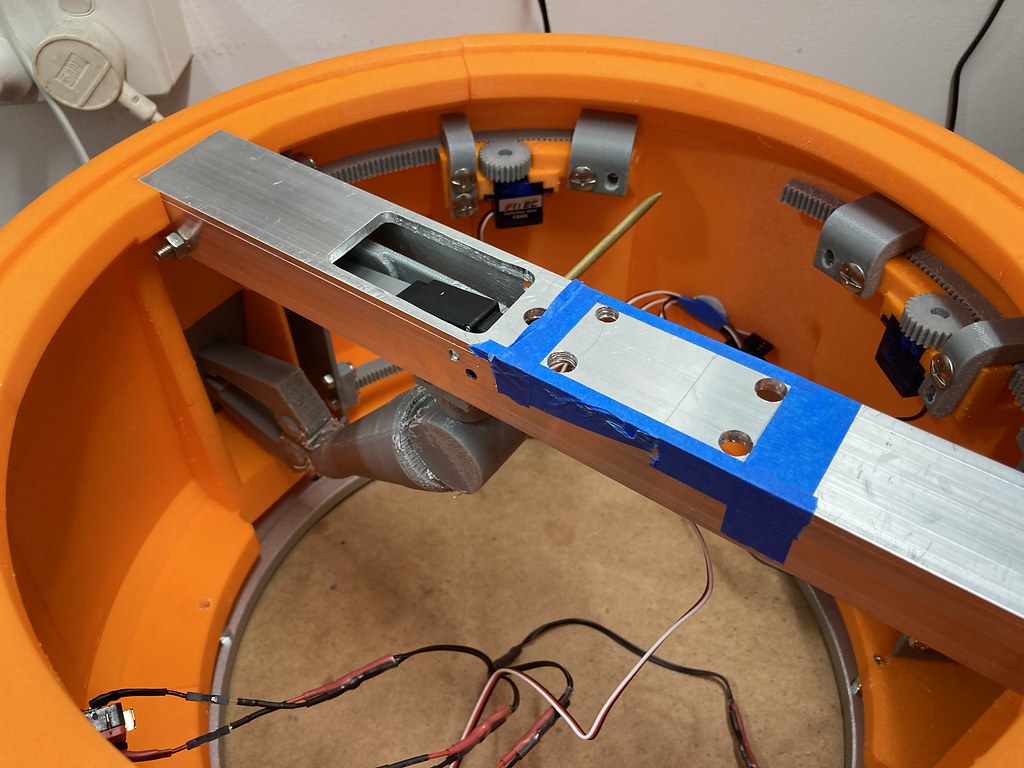

And then this is that bracket installed in the dome:

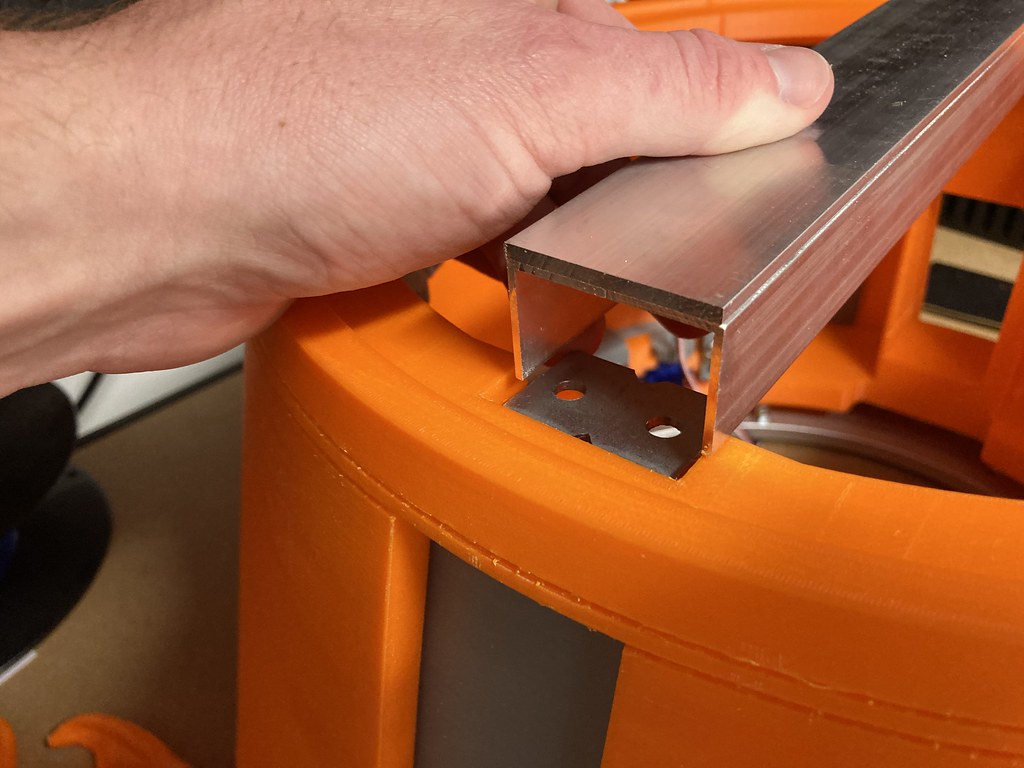

With the bracket installed you can see how the aluminium cross beam I've made slots nicely into the opening of the print and around the bracket:

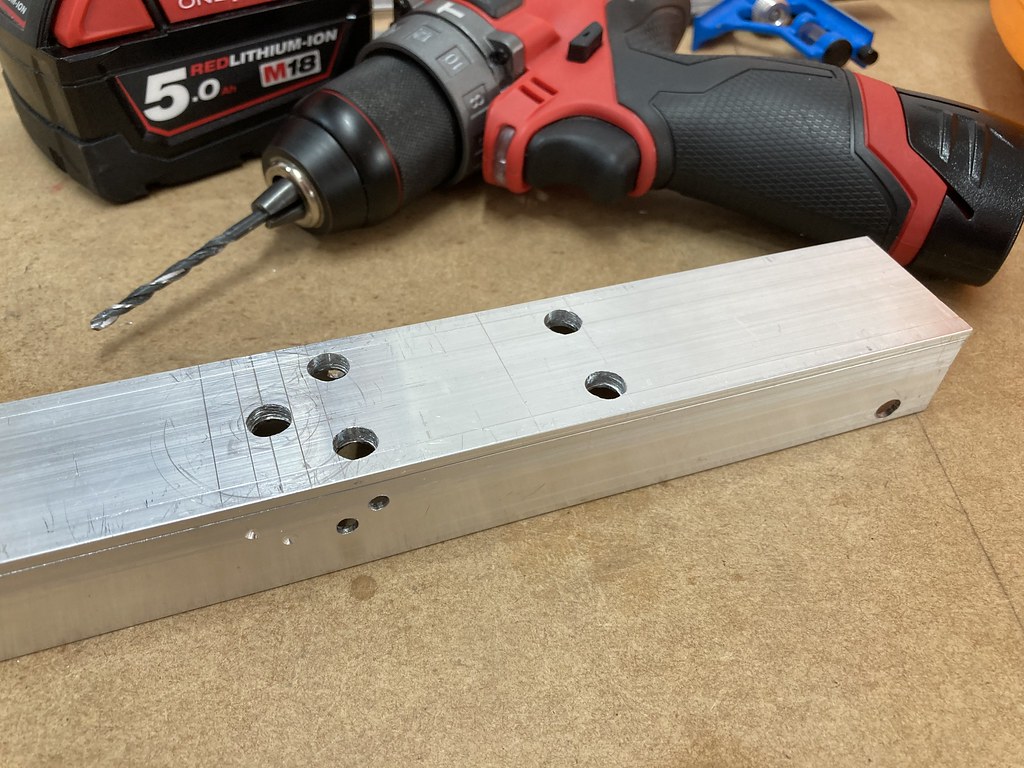

Next I needed to cut some openings in the cop of the cross beam to allow some extra head room for the linear actuators to retract. I simply drilled some holes and around the perimeter of my marked out area and then used a mini hacksaw to cut the remaining connecting material. After which the beam was placed in my vice and the inner edges filed down smooth.

I have to all this with hand saws as I don't have a lot of room for tools in my home workshop for stuff like this. First, I chopped a flat bar and right angle to length, so they'd fit nicely within the dome:

I then keyed up the surfaces of the flat bar and angles with sandpaper so I could glue them together:

After which I needed a bracket that would allow me to connect the beam to the 3D print. Essentially once I have the top plate cut and glued to the dome I can simply slot in the cross beam on the inside and then this bracket will hold the beam up against the underside of the top plate.

This way the entire dome arm mechanism can modular and removable if needed. I also designed my 3D printed dome to include embed M6 nuts so that I could simply use a bolt to connect the bracket. So that the bracket could fit in between the sides of the cross beam I had to trim back the overall width of the bracket. I just used my hacksaw for this, you can see the difference below:

And then this is that bracket installed in the dome:

With the bracket installed you can see how the aluminium cross beam I've made slots nicely into the opening of the print and around the bracket:

Next I needed to cut some openings in the cop of the cross beam to allow some extra head room for the linear actuators to retract. I simply drilled some holes and around the perimeter of my marked out area and then used a mini hacksaw to cut the remaining connecting material. After which the beam was placed in my vice and the inner edges filed down smooth.

Studio 49

Sr Member

With the bracket installed properly for the first time ever I was able test it out! And I've very pleased to say it worked great

The 3D print of the arm is still the rough prototype print I did, so that will get replaced with a far nicer and sturdier print. The arms connecting the 3D printed Arms to the cross beam will also be water jet cut Aluminium rather than the roughly printed parts you see in the video.

The 3D print of the arm is still the rough prototype print I did, so that will get replaced with a far nicer and sturdier print. The arms connecting the 3D printed Arms to the cross beam will also be water jet cut Aluminium rather than the roughly printed parts you see in the video.

NakedMoleRat

Legendary Member

There is one major part of your build that absolutely sucks! It sucks that it’s not mine. Well done. Keep it up.

Studio 49

Sr Member

You're too kind man, thanks for the encouragementThere is one major part of your build that absolutely sucks! It sucks that it’s not mine. Well done. Keep it up.

Thanks! Should hopefully have more to post soon!WOW, this is such an amazing build! Can't wait to see more.

Thanks mate! It's been great fun working on this!Dude this is incredible...

Studio 49

Sr Member

Some good news to share, I think I finally have the designs for the Aluminium frame and aluminium leg internals sorted!

So I'll be getting the water jet cutting quote revised to reflect my new design changes and I should hopefully get it cut in the next 2-4 weeks (depends on their turn around)

Very excited to be so close to having aluminium parts to play with!

So I'll be getting the water jet cutting quote revised to reflect my new design changes and I should hopefully get it cut in the next 2-4 weeks (depends on their turn around)

Very excited to be so close to having aluminium parts to play with!

Some good news to share, I think I finally have the designs for the Aluminium frame and aluminium leg internals sorted!

So I'll be getting the water jet cutting quote revised to reflect my new design changes and I should hopefully get it cut in the next 2-4 weeks (depends on their turn around)

Very excited to be so close to having aluminium parts to play with!

This is intense

Studio 49

Sr Member

Thanks so much for the kind words manOMG I haven't been back to the thread for a while, as many have said the progress & build looks incredible, very very cool

More progress photos to come in the coming days!

Studio 49

Sr Member

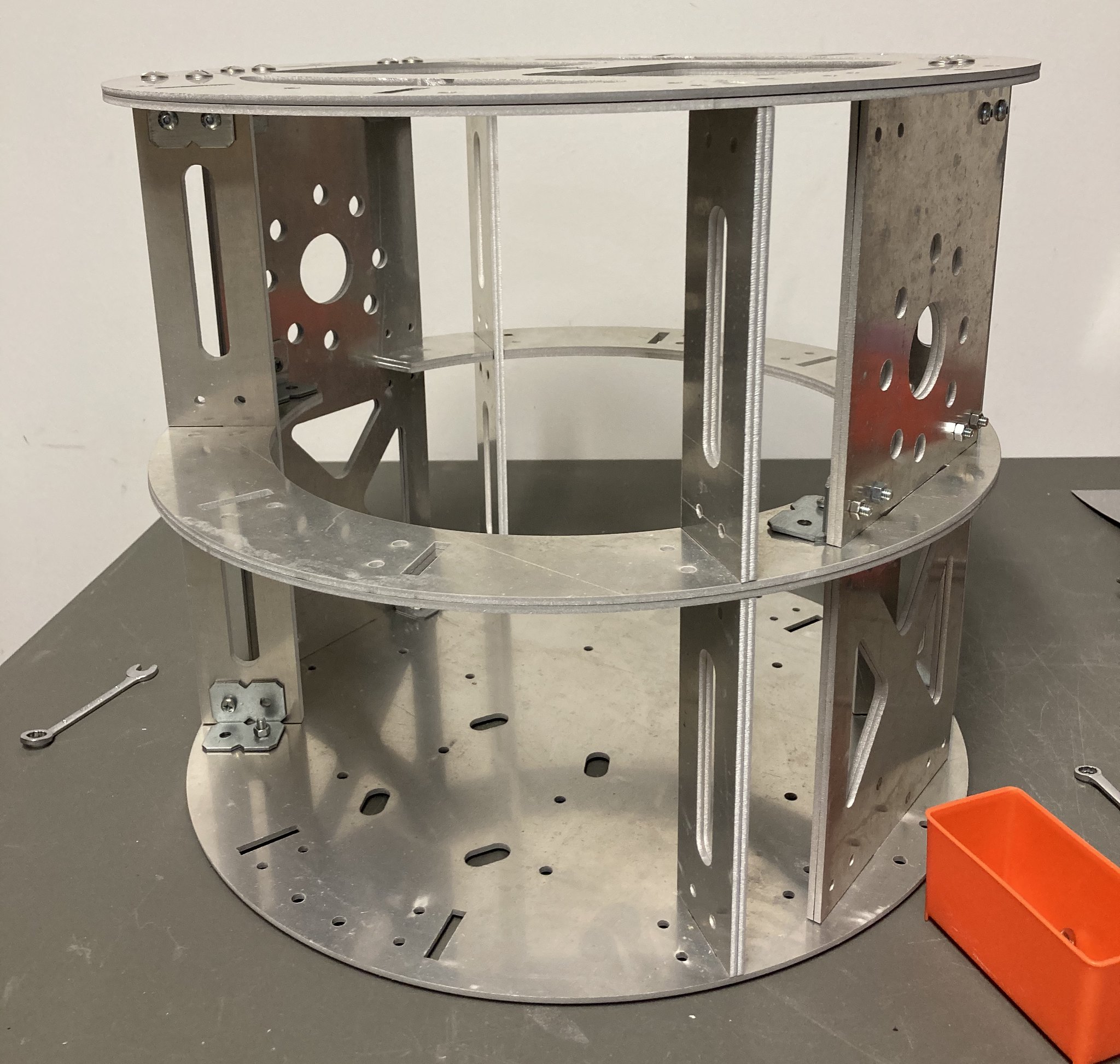

This is where the fun begins! Very excited to say that I picked up all the parts for Choppers Aluminium frame and the parts that form the internal frame of the legs.

I designed these from scratch myself, so It's incredibly satisfying and exciting to have the tangible result of all my hours of 3D modelling and design

Many more photos to come soon... assembly has already begun!

I designed these from scratch myself, so It's incredibly satisfying and exciting to have the tangible result of all my hours of 3D modelling and design

Many more photos to come soon... assembly has already begun!

Studio 49

Sr Member

This is beyond AMAZING! Very cool.

So freak’n intense

Thanks guys! Got some more photos coming right up

Studio 49

Sr Member

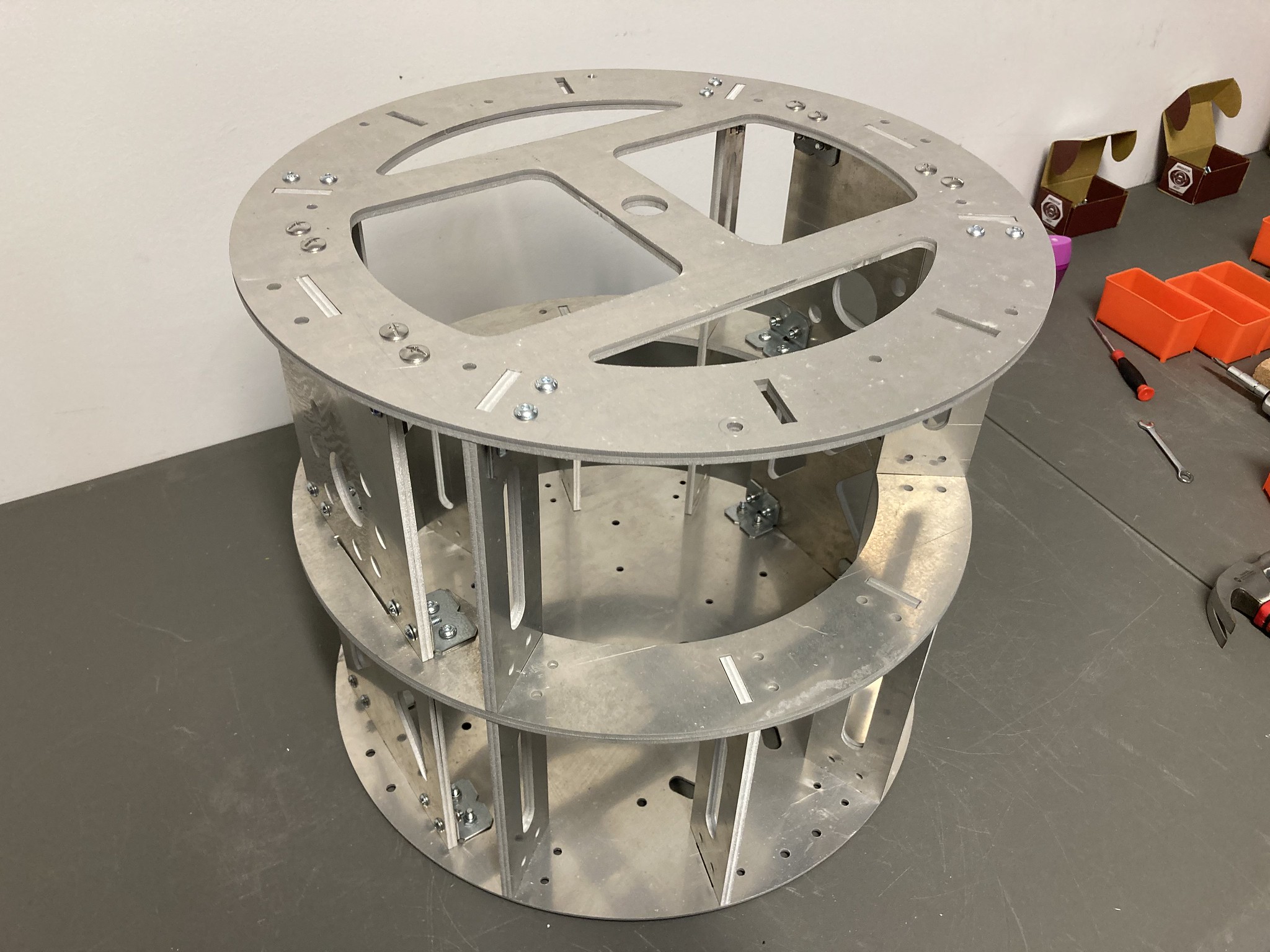

Very pleased to say I made a huge amount of progress yesterday! I was able to nearly get the frame totally assembled!

I used 3mm thick Aluminium in my build as that was material I had on hand already and by designing around using that it saved me money on materials. I designed my frame to double up layers of each part to increase the structural integrity.

In this first photo you can see the first test fit I did. At this point I only had a few bolts inserted just so I could test the tolerances of the slot and holes.

And then this is where it gets exciting!

You can see the main sections of the frame total assembled! The only items missing is the chamfered bottom ring which I'm currently 3D printing. Since I'm using doubled up layers of 3mm aluminium I figured it would more trouble than it was worth to tap threads into the parts. My solution then was to use 90 degree angle metal brackets from Bunnings and use them with M5 Nylock bolts to help connect everything together. And I'm pleased to say this frame is rock solid! No way anything is going to move now I'm done installing the bolts and it was very easy to implement.

I used 3mm thick Aluminium in my build as that was material I had on hand already and by designing around using that it saved me money on materials. I designed my frame to double up layers of each part to increase the structural integrity.

In this first photo you can see the first test fit I did. At this point I only had a few bolts inserted just so I could test the tolerances of the slot and holes.

And then this is where it gets exciting!

You can see the main sections of the frame total assembled! The only items missing is the chamfered bottom ring which I'm currently 3D printing. Since I'm using doubled up layers of 3mm aluminium I figured it would more trouble than it was worth to tap threads into the parts. My solution then was to use 90 degree angle metal brackets from Bunnings and use them with M5 Nylock bolts to help connect everything together. And I'm pleased to say this frame is rock solid! No way anything is going to move now I'm done installing the bolts and it was very easy to implement.

Last edited:

Studio 49

Sr Member

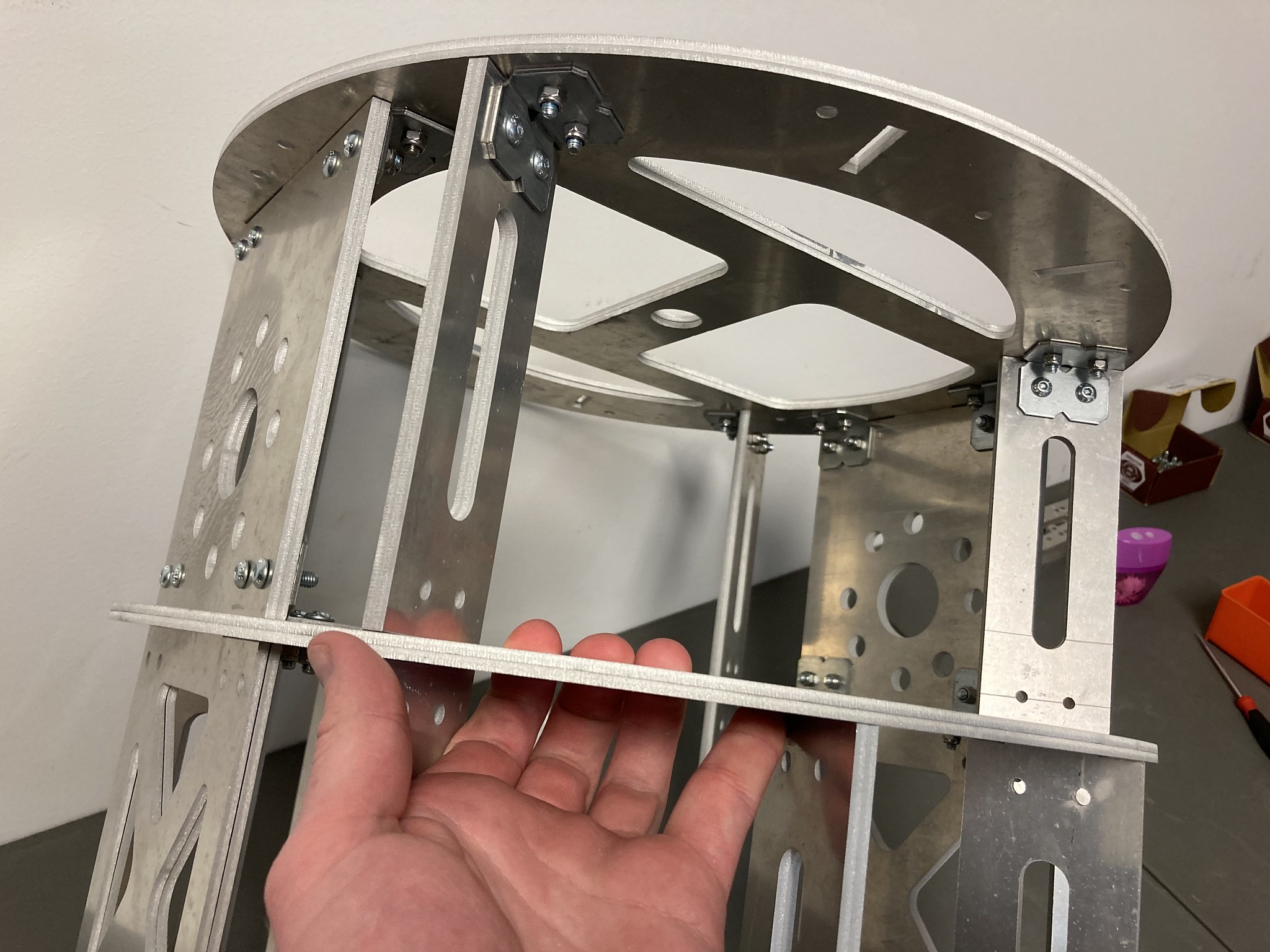

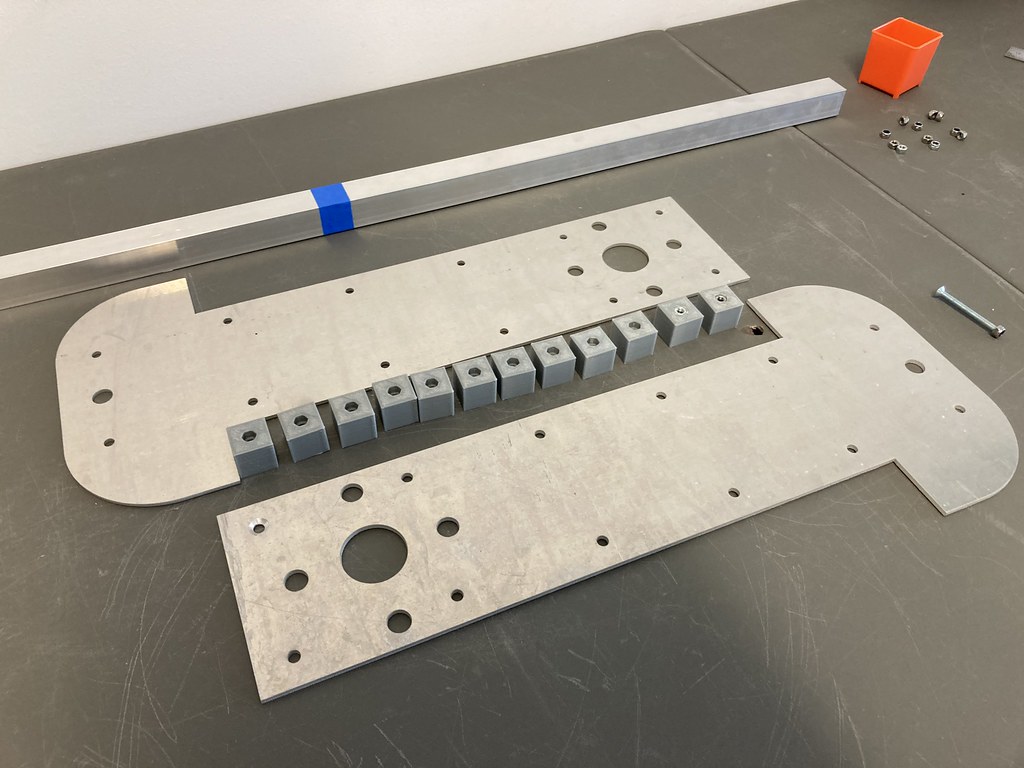

The next stage was to start the assembly of the internal framework for the outer legs. I wanted the legs to be robust but simple to assemble, so the legs consist of two plates that were cut on the water jet and then 2 pieces of square aluminium extrusions. I also designed the aluminium parts so I could then sleeve 3D printed parts around them.

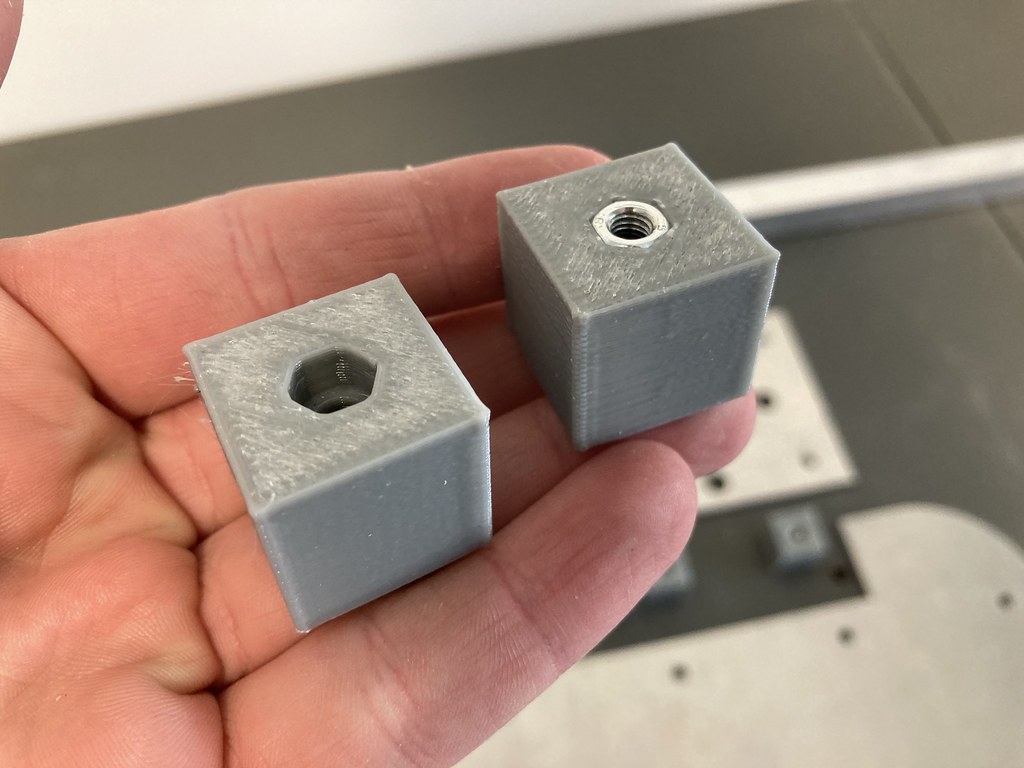

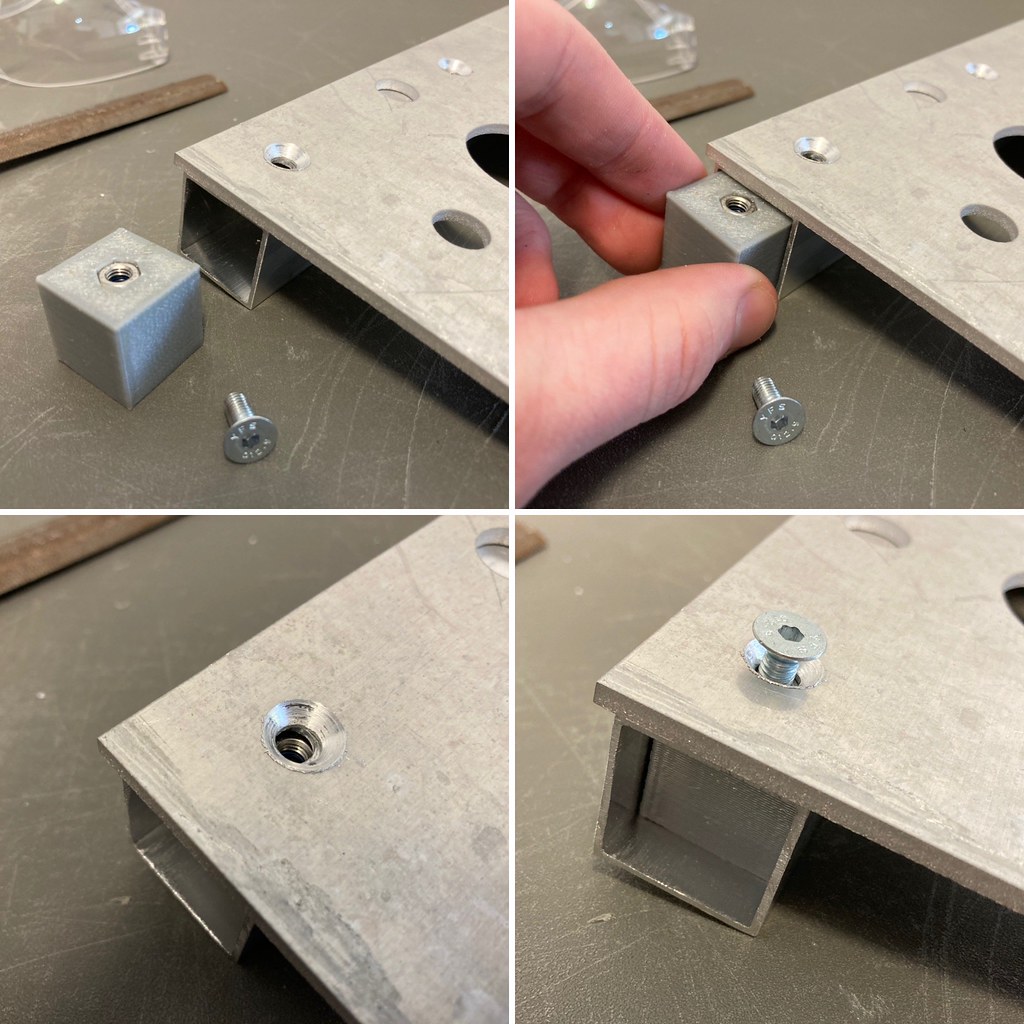

Since the assembly with the 3D printed parts relies on the printed part sliding down around the aluminium parts I needed to be able to have the two plates bolted together and still be flush on both sides. This meant I couldn't just run a bolt through on side and have a nut poking out the other side.

To result in a flush fit I needed to run a bunch of Nyloc Nuts along the inside of the square aluminium extrusion and I needed to work out how to thread a nut onto a bolt that's 300mm down inside a narrow aluminium square extrusion.

My solution was I designed up this little 3D printed block that allows me to friction fit nylock nuts into the 3D print which slides down inside the square extrusion. This way when I thread the bolt into nyloc the 3D printed cube prevents the nyloc from spinning, essentially acting as a spanner.

And then here's all the aluminium parts assembled.

Very pleased with the result and it's extremely strong as well!

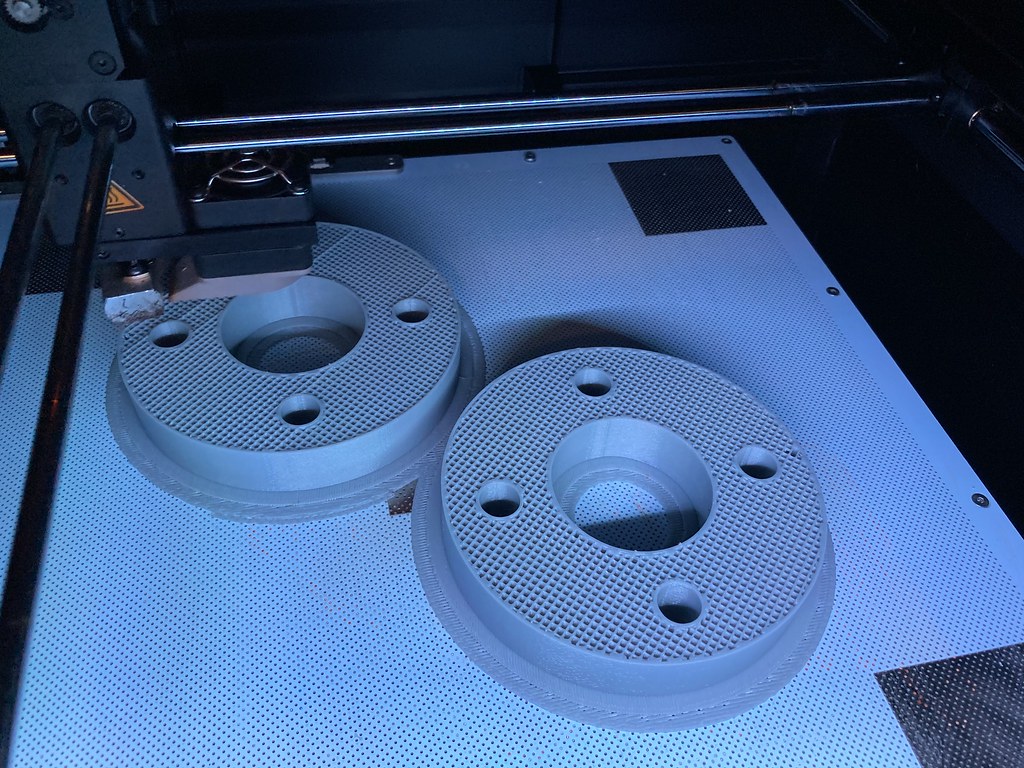

And then here's the leg connection hubs that I'm also 3D printing at the moment

Since the assembly with the 3D printed parts relies on the printed part sliding down around the aluminium parts I needed to be able to have the two plates bolted together and still be flush on both sides. This meant I couldn't just run a bolt through on side and have a nut poking out the other side.

To result in a flush fit I needed to run a bunch of Nyloc Nuts along the inside of the square aluminium extrusion and I needed to work out how to thread a nut onto a bolt that's 300mm down inside a narrow aluminium square extrusion.

My solution was I designed up this little 3D printed block that allows me to friction fit nylock nuts into the 3D print which slides down inside the square extrusion. This way when I thread the bolt into nyloc the 3D printed cube prevents the nyloc from spinning, essentially acting as a spanner.

And then here's all the aluminium parts assembled.

Very pleased with the result and it's extremely strong as well!

And then here's the leg connection hubs that I'm also 3D printing at the moment

Similar threads

- Replies

- 54

- Views

- 1,549

- Replies

- 85

- Views

- 6,916

- Replies

- 1

- Views

- 874