You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

building an agonizer

- Thread starter ranallace

- Start date

TheSt.LouisKid

Sr Member

Cool. Great to see you making something from the ground up.

robn1

Master Member

That'll work good as a sealer. But you'll also need some putty and primer. Give it a coat of primer to see where the trouble spots are. Fill with putty, sand and primer again. When it's smooth and all traces of wood grain are gone, paint it with a good flat paint. The mold will pick up whatever texture it has, so make sure the finish is what you want for your final castings.

And I would strongly suggest using silicone mold rubber. Silicone is catalyzed and will cure all the way through. Latex just dries by evaporation, and thick applications could take days to dry. Several coats will be needed.

And I would strongly suggest using silicone mold rubber. Silicone is catalyzed and will cure all the way through. Latex just dries by evaporation, and thick applications could take days to dry. Several coats will be needed.

ranallace

Well-Known Member

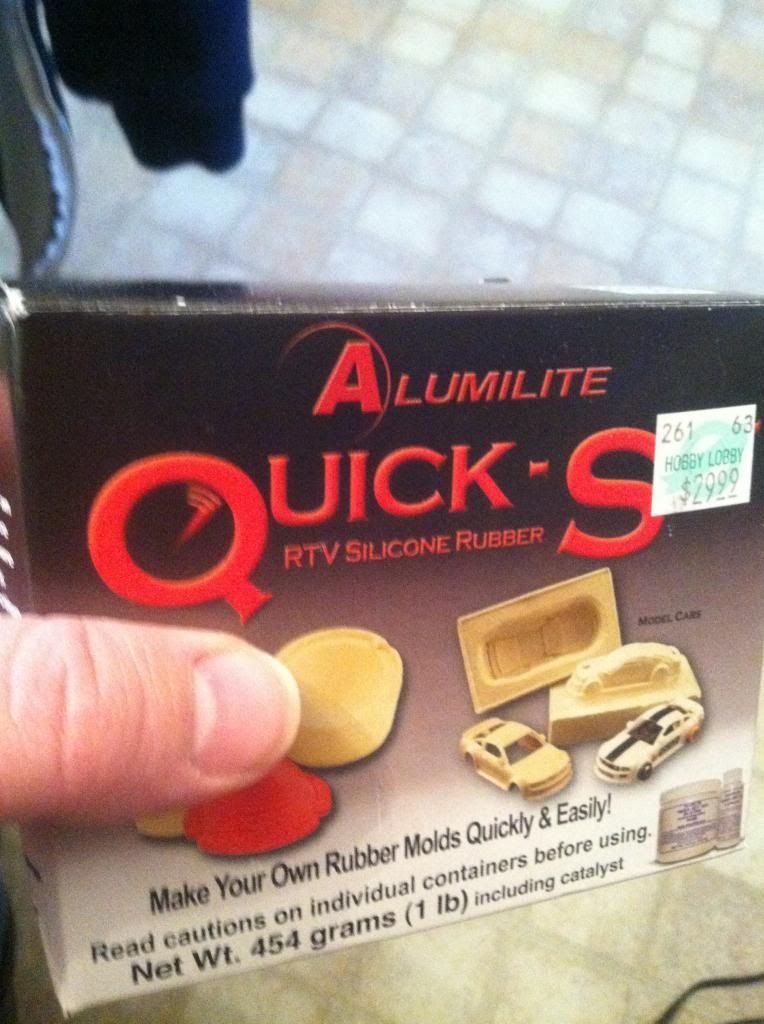

ok ... its ready to mold ... sprayed with 4 coats of clear yesterday .....bought the alumilite quick set rtv rubber .....its the 1lb. package (including catalist] , is that enuff ???.... do i need mold release ?? - i have some but guy at hobby lobby said no , but i need a pro opinion ...already wasted 30 bucks on that last try, which failed

robn1

Master Member

That's plenty of silicone. And no you don't need a release for this. But like I said, make certain the surface finish is just they way you want it. The mold will pick up EXACTLY what it is. Make sure all the seams and wood grain are filled smooth. Also the rubber will pick up the shiny finish, and so will your resin. if you want your casts to be shiny then that's fine.

Looks good. Nice job and congrats.

ranallace

Well-Known Member

thanks SB !!! .....my own "piece of the action" ....LOL

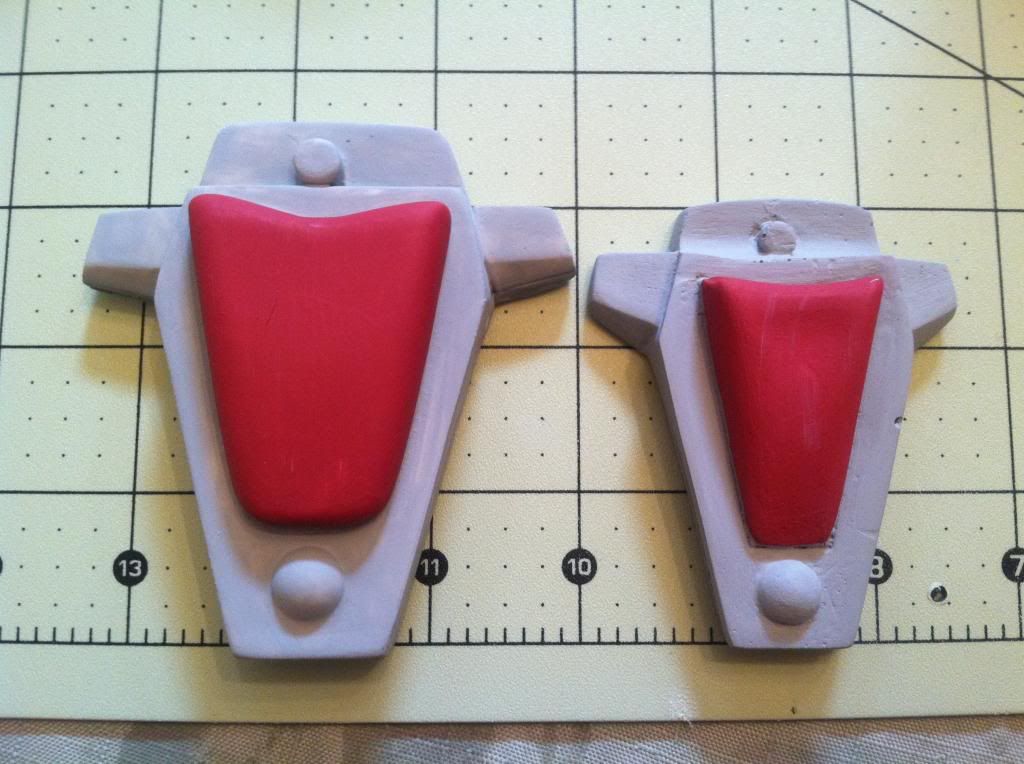

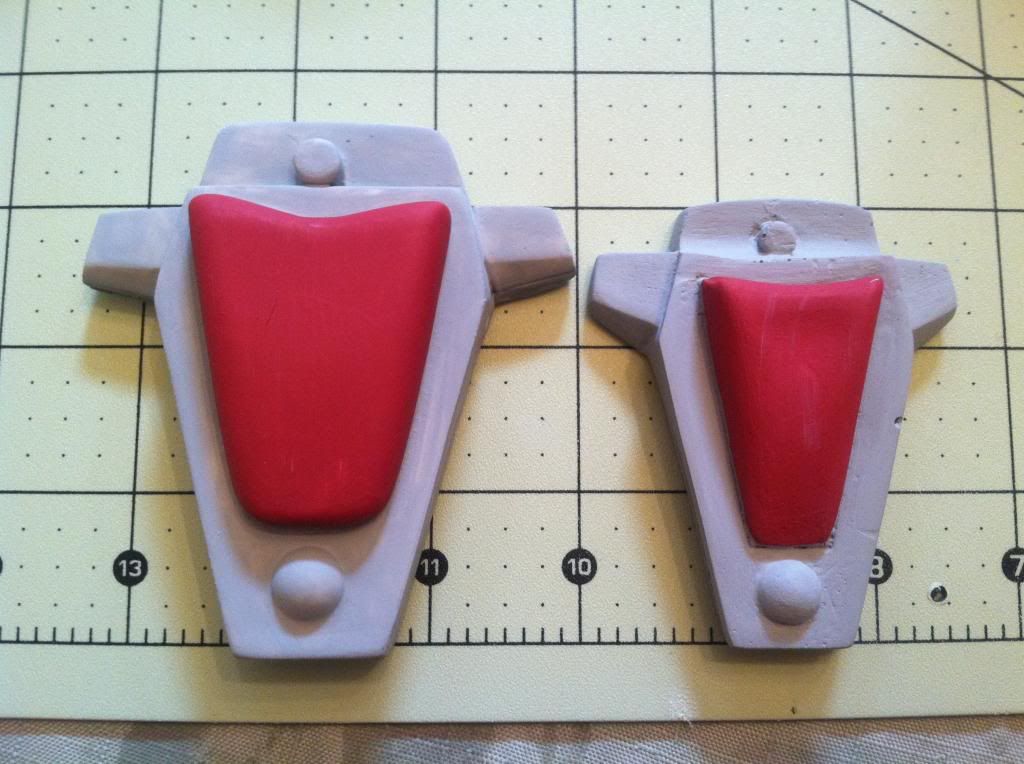

-painted up number 2 to see how could look - cheap acrylic paint , not dry yet , just to see what looks like

mine compared to one i got at a con which seems to be the common size i have found most everywhere , mines sized more for a man , LOL

- number 2 on left - number 3 on right

*** edited for better photos

-painted up number 2 to see how could look - cheap acrylic paint , not dry yet , just to see what looks like

mine compared to one i got at a con which seems to be the common size i have found most everywhere , mines sized more for a man , LOL

- number 2 on left - number 3 on right

*** edited for better photos

Last edited:

Similar threads

- Replies

- 0

- Views

- 121

- Replies

- 10

- Views

- 1,126

- Replies

- 20

- Views

- 2,210