You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bubbles in my clear resin

- Thread starter jake88

- Start date

jake88

Sr Member

Its a polyurethane mold. Can I smooth the bubble impressions with silicone caulk then recast? I dont have a vacuum..Looks like bumps, caused by bubbles in you silicone.

Yeah, if you've got bubbles like that, it's in the mold. Beyond making new molds, you could just cut these warts off with an X-acto knife or just sand them down. If you've got bubbles in the grips themselves, you'll probably need a de-gassing and pressure chamber if you want crystal clear and fully detailed grips.

I'm working on a scratch-mod PKD myself, and I can get really great details but I lack and don't have the funds to invest in a pressure or de-gassing pot, but I'm want a more rougher looking thing, so some tiny bubbles really don't bother me. In fact, they actually add some texture to the overall look.

I'm working on a scratch-mod PKD myself, and I can get really great details but I lack and don't have the funds to invest in a pressure or de-gassing pot, but I'm want a more rougher looking thing, so some tiny bubbles really don't bother me. In fact, they actually add some texture to the overall look.

robn1

Master Member

Yeah this will work, as long as there are no bubbles in the resin. Then polish the surface to restore clarity.you could just cut these warts off with an X-acto knife or just sand them down

Did you pressure cast? Bumps like this usually only happen when pressure casting, the pressure causes bubbles in the mold to collapse and form bumps on the resin. The bubbles are just below the mold surface so you may not know they are there.Its a polyurethane mold. Can I smooth the bubble impressions with silicone caulk then recast? I dont have a vacuum..

If you have the equipment to pressure cast, you can make your molds under pressure as well (as long as your original pattern can take the pressure).

jake88

Sr Member

Nope just pour and cast. Nothing fancyYeah this will work, as long as there are no bubbles in the resin. Then polish the surface to restore clarity.

Did you pressure cast? Bumps like this usually only happen when pressure casting, the pressure causes bubbles in the mold to collapse and form bumps on the resin. The bubbles are just below the mold surface so you may not know they are there.

If you have the equipment to pressure cast, you can make your molds under pressure as well (as long as your original pattern can take the pressure).

jake88

Sr Member

That makes sense. Not sureYeah this will work, as long as there are no bubbles in the resin. Then polish the surface to restore clarity.

Did you pressure cast? Bumps like this usually only happen when pressure casting, the pressure causes bubbles in the mold to collapse and form bumps on the resin. The bubbles are just below the mold surface so you may not know they are there.

If you have the equipment to pressure cast, you can make your molds under pressure as well (as long as your original pattern can take the pressure).

I killed one of the grips during the initial cast. So it is what it is I guess...Recast the molds. Much less work. If you don't have vacuum or pressure cast the silicone by creating a thin stream of silicone. That will get rid of most of the bubbles.

Thanks for the tips though. Im Forest Gumping my way through this one.

jake88

Sr Member

Any advise, or tips on cleaning this up and polishing? Its clear cast epoxy resin from Michael's.Nope just pour and cast. Nothing fancy

JPH

Sr Member

all those bubbles lined up like clone troopers in the diamonds and you see multiple imperfections in the smooth portions of the resin cast as well.

I agree with start over. Mix slower, degas. Low humidity environment.

I know you lost a grip in the process, but you are going to spend many more hours fixing this instead of starting over and making molds you can use over and over.

I agree with start over. Mix slower, degas. Low humidity environment.

I know you lost a grip in the process, but you are going to spend many more hours fixing this instead of starting over and making molds you can use over and over.

Any advise, or tips on cleaning this up and polishing? Its clear cast epoxy resin from Michael's.

I say "don't". Start over with new molds, pour the silicone into the deepest part and in a thin stream from high above the master, and get rid of that Michael's crap. It will never be anything better. Believe me; I've played with it all and dumped more money I'm proud to admit trying to spin crap into gold. Get yourself some Clear-Cast resin from Smooth-On. It's pricier, but it will give you much better results.

JPH

Sr Member

Michaels alumitite resin is good for basic molds, but you can't stir it vigorously. Also, low humidity is a must. It wont be see through either.

A degasser helps with resin. I resisted, and then kicked myself when I broke down and got one.

Once you need a prop, you see the world in props. Look for a cheapo kids toy with similar grip or mirror you surviving grip.

I remember wanting to make Crysis armor, and I saw the hex pattern in a urinal splash guard...I was like EUREKA! you never know when you will find a fix.

A degasser helps with resin. I resisted, and then kicked myself when I broke down and got one.

Once you need a prop, you see the world in props. Look for a cheapo kids toy with similar grip or mirror you surviving grip.

I remember wanting to make Crysis armor, and I saw the hex pattern in a urinal splash guard...I was like EUREKA! you never know when you will find a fix.

jake88

Sr Member

How do you make a mirror of the surviving grip?Michaels alumitite resin is good for basic molds, but you can't stir it vigorously. Also, low humidity is a must. It wont be see through either.

A degasser helps with resin. I resisted, and then kicked myself when I broke down and got one.

Once you need a prop, you see the world in props. Look for a cheapo kids toy with similar grip or mirror you surviving grip.

I remember wanting to make Crysis armor, and I saw the hex pattern in a urinal splash guard...I was like EUREKA! you never know when you will find a fix.

JPH

Sr Member

If you make a mold of the right-sided grip, it is left-sided.

If you make a mold of the right-sided, then make a mold of the left-sided, it is now right sided.

Put your left hand to your right hand, they match because they are mirror images.

Chirality!

I hope that helps.

Not to be confused iwth the magic user spell

If you make a mold of the right-sided, then make a mold of the left-sided, it is now right sided.

Put your left hand to your right hand, they match because they are mirror images.

Chirality!

I hope that helps.

Not to be confused iwth the magic user spell

Zinger

Active Member

For bubble free casting of translucent parts without a pressure pot I like to use Smooth-On's EpoxACast 690. It has a 5 hour pot life so plenty of time for the bubbles to rise to the surface. If it's an open mold, you can pop them by waving a torch quickly across the surface.

Rescuing the castings you have isn't impossible, but it is a lot of work.

As a couple people have said, you can cut off the bumps and then sand and polish it. I have had some good luck with a final coat of clear gloss, once the sanding/polishing phase is done. For the final polish, I like to use finger nail polishing/buffing boards. They have 4 progressively finer grades of surfaces. The final surface feels almost glossy-smooth, but polishes up acrylic really well.

If you have bubbles or pits in your casting, it gets trickier. I have saved some of my clear castings by cutting into the bubbles to create a bowl. Then I carefully dab in some more casting resin into the "bubble bowls". Once the resin has cured, I sand and polish it smooth.

It is very tedious; but if you are dead set on salvaging these castings, that is what has worked for me.

....and of course, this does nothing for any interior bubbles. (if you have any)

As a couple people have said, you can cut off the bumps and then sand and polish it. I have had some good luck with a final coat of clear gloss, once the sanding/polishing phase is done. For the final polish, I like to use finger nail polishing/buffing boards. They have 4 progressively finer grades of surfaces. The final surface feels almost glossy-smooth, but polishes up acrylic really well.

If you have bubbles or pits in your casting, it gets trickier. I have saved some of my clear castings by cutting into the bubbles to create a bowl. Then I carefully dab in some more casting resin into the "bubble bowls". Once the resin has cured, I sand and polish it smooth.

It is very tedious; but if you are dead set on salvaging these castings, that is what has worked for me.

....and of course, this does nothing for any interior bubbles. (if you have any)

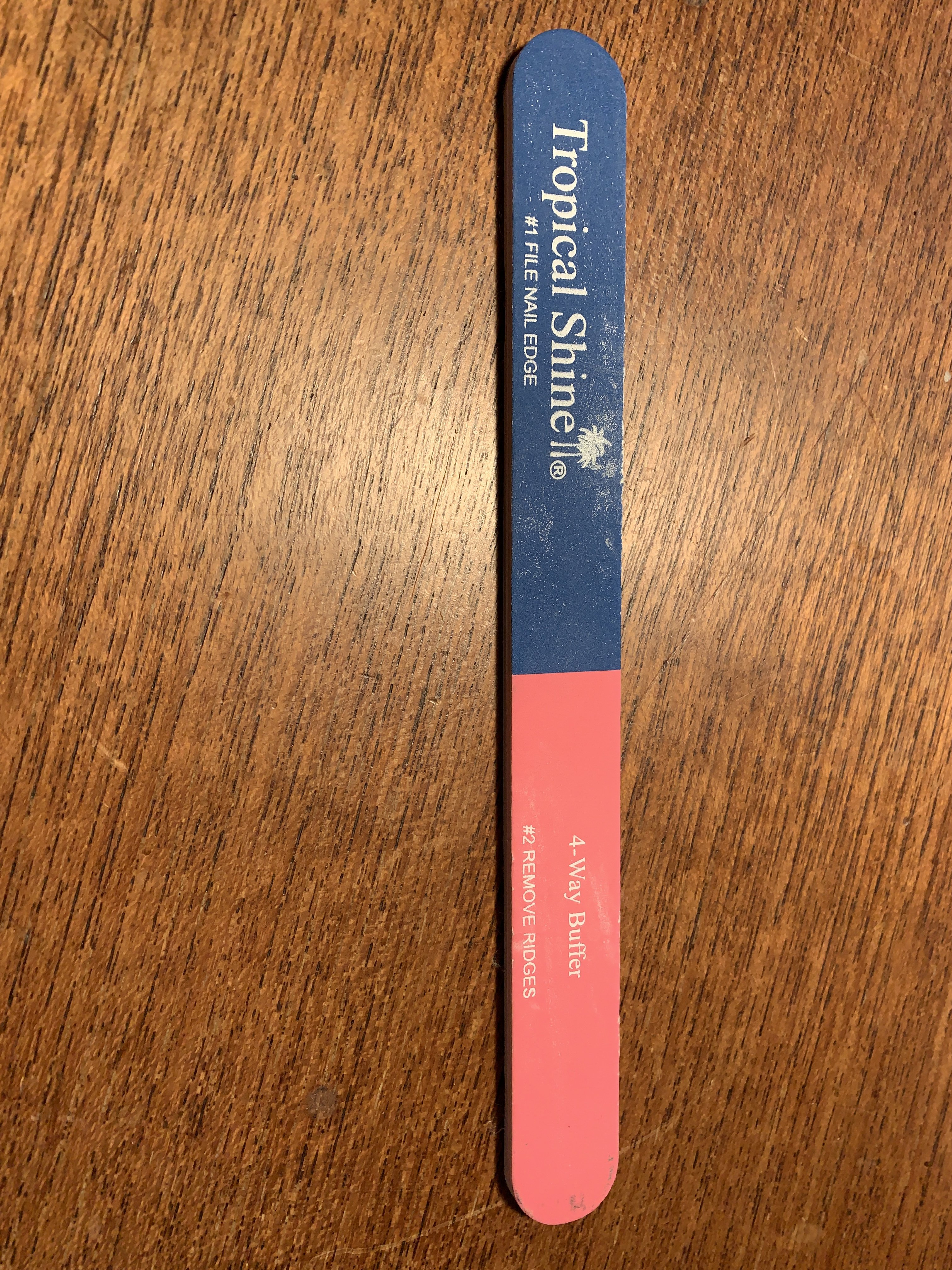

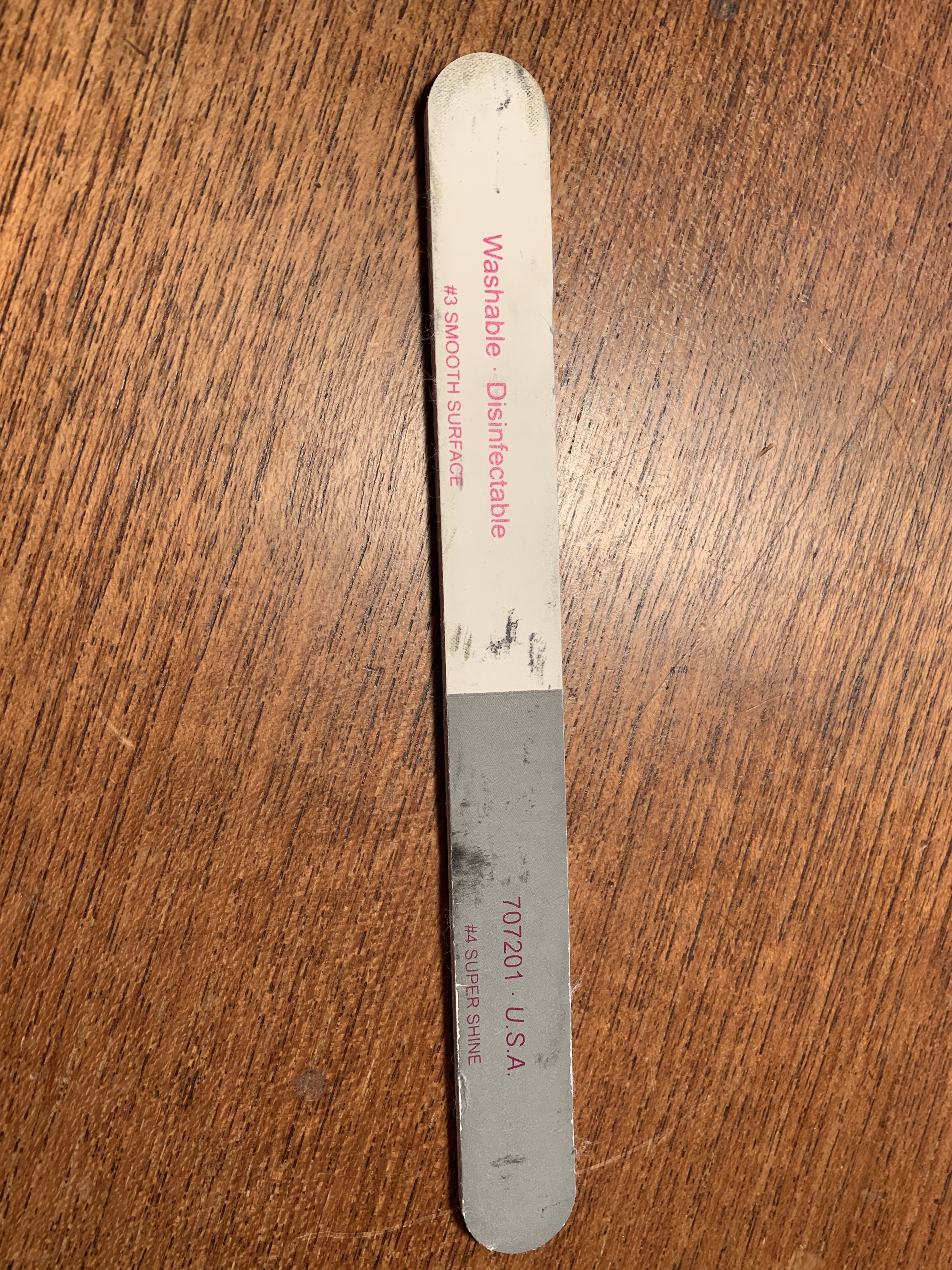

Here's the polishing board I like to use. They are really cheap to get from places like Sally's Beauty Supply or places like that.

Hobby suppliers sell the same things at a huge mark-up.

The first picture shows the 2 courser grits. Blue first, then pink.

The second Pic shows the other side of the board. White and then finally gray for the final polish.

Works great!

Hobby suppliers sell the same things at a huge mark-up.

The first picture shows the 2 courser grits. Blue first, then pink.

The second Pic shows the other side of the board. White and then finally gray for the final polish.

Works great!

jake88

Sr Member

Thanks Duncanator. I plan to make a new silicone mold of my remaining original and sand and doctor up the best left side casting. Then mold that one and hopefully get 2 decent grips. I found that wet sanding brings all my pits and bumps down to a nice smooth surface. I also did a test and dipped one in future floor shine. It dried quickly and had a very nice glow to it. Also a very durable surface. With some time I think I might pull this off.Here's the polishing board I like to use. They are really cheap to get from places like Sally's Beauty Supply or places like that.

Hobby suppliers sell the same things at a huge mark-up.

The first picture shows the 2 courser grits. Blue first, then pink.

The second Pic shows the other side of the board. White and then finally gray for the final polish.

Works great!

View attachment 1271414

View attachment 1271415

Similar threads

- Replies

- 6

- Views

- 641

- Replies

- 28

- Views

- 3,819

- Replies

- 2

- Views

- 622

- Replies

- 8

- Views

- 1,061

- Replies

- 31

- Views

- 1,269