Loess

Member

I got something cool in the mail today.

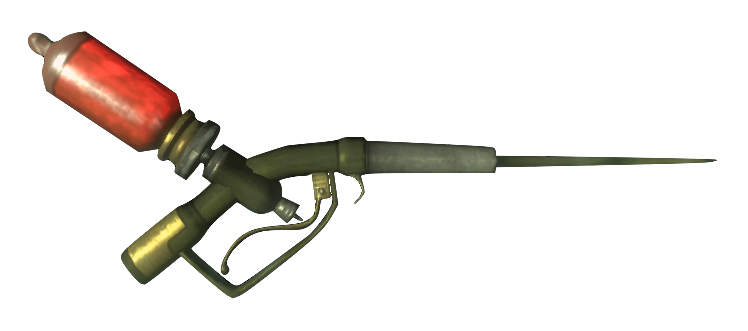

I managed to acquire an accurate Buckeye gas nozzle off ebay. This is the closest thing anyone I'm aware of has managed to find to the nozzle that 2K based the Little Sisters' ADAM syringes on. I'm hoping to put this in some rubber soon, and make some casts available for people who don't want to chop-up a $100 antique to make an ADAM syringe.

In other news, I got some pictures of my failed attempt to blow-mold a lexan dome. This piece is the reason that I went and ordered one.

I had the too-clever-by-half idea that I could heat up a piece of lexan, lay it on a board with a hole in it, clamp it down with a frame that had the correct hole in it, and form it to shape by blowing compressed air in underneath it.

Yeah, that didn't work too well. I overheated the lexan, and caused it to bubble, couldn't seal it properly, and when I failed to nicely inflate it to shape I tried to push it by hand (in gloves) and mangled the shape of it.

Epic Fail... lesson learned.

Make a proper vac-forming rig, or a much better blow molding machine before trying that again.

Annie found that she could hear surprisingly well when we were test fitting the helm a while ago, but we hadn't fitted the lexan yet, so I don't know how that'll change when it's done.

The helm is going to be supported on the chest/shoulder mantle, which we're going to pad and strap to hold it in place.

Ignore the pegs, those are temporary, and we'll be replacing them with a concealed system... of some type.

I managed to acquire an accurate Buckeye gas nozzle off ebay. This is the closest thing anyone I'm aware of has managed to find to the nozzle that 2K based the Little Sisters' ADAM syringes on. I'm hoping to put this in some rubber soon, and make some casts available for people who don't want to chop-up a $100 antique to make an ADAM syringe.

In other news, I got some pictures of my failed attempt to blow-mold a lexan dome. This piece is the reason that I went and ordered one.

I had the too-clever-by-half idea that I could heat up a piece of lexan, lay it on a board with a hole in it, clamp it down with a frame that had the correct hole in it, and form it to shape by blowing compressed air in underneath it.

Yeah, that didn't work too well. I overheated the lexan, and caused it to bubble, couldn't seal it properly, and when I failed to nicely inflate it to shape I tried to push it by hand (in gloves) and mangled the shape of it.

Epic Fail... lesson learned.

Make a proper vac-forming rig, or a much better blow molding machine before trying that again.

Annie found that she could hear surprisingly well when we were test fitting the helm a while ago, but we hadn't fitted the lexan yet, so I don't know how that'll change when it's done.

The helm is going to be supported on the chest/shoulder mantle, which we're going to pad and strap to hold it in place.

Ignore the pegs, those are temporary, and we'll be replacing them with a concealed system... of some type.

Last edited: