Hello!

In order to not shanghai another thread that I've been active in, I'm going to do some documentation of my own Robocop Build in here =)

I have splurged on two separate models, and done some modelling myself.

The original 3d model I purchased had a lot of things that needed changing, so I redesigned some parts, like the neck, the helmet, the biceps...

But the work I've done today is the midsection, the abs.

I've decided to go with building this out of EVA foam, glued with contact cement on a lycra undersuit.

So, I've started working on my EVA foam midsection. I've used a lycra undersuit (got 4 of them) to try and do some glue tests on, and foam sticks well with contact cement!

After trying to remove all glue tests, I started a proper attempt.

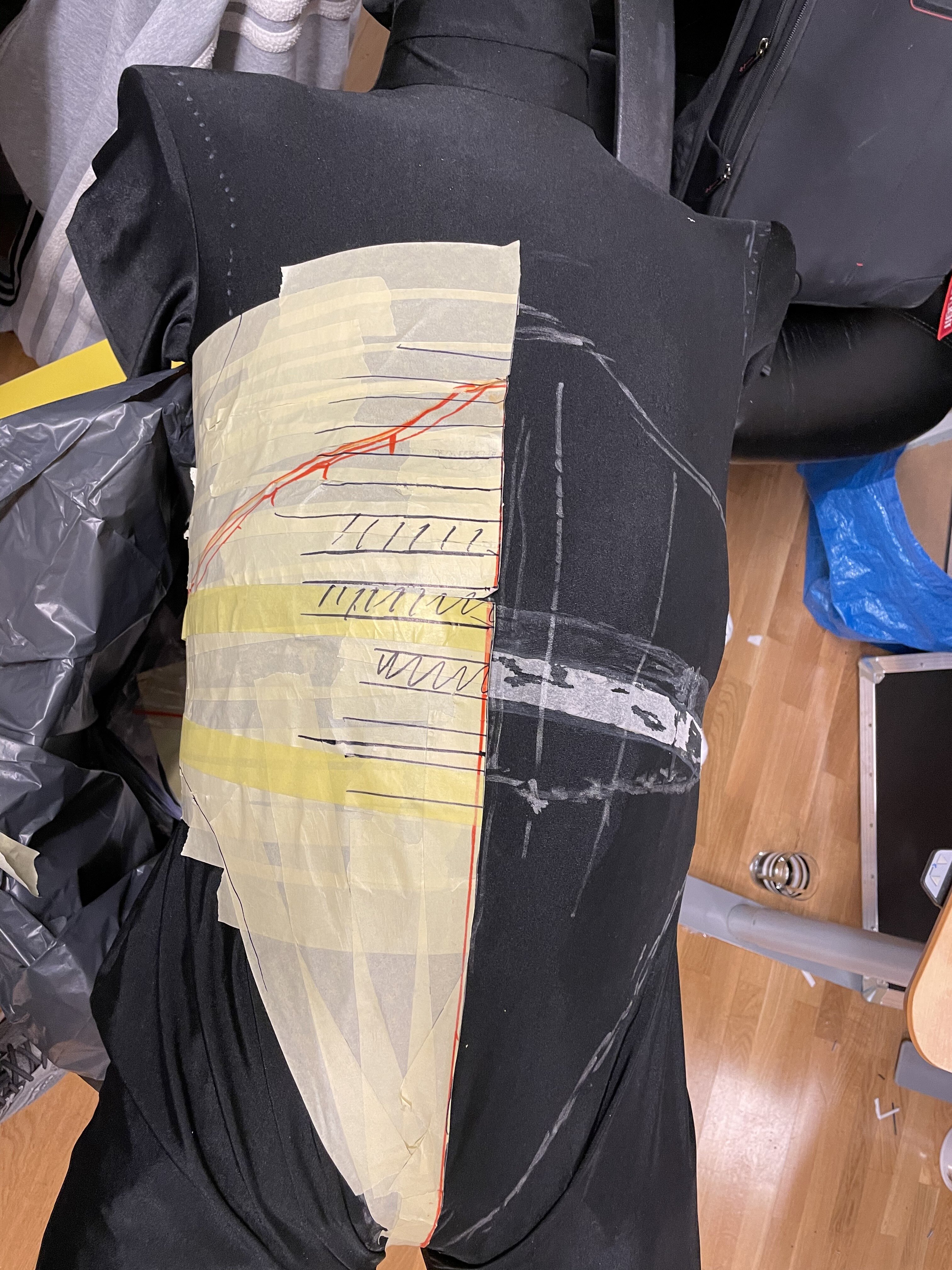

First off, I used masking tape to create a template that I then removed, flattened and cut out.

As the mid section is made of horisontal strips, that's how I decided to build it. In strips.

Here's the right section left on the lycra suit on the dummy after I removed the left part and cut out..

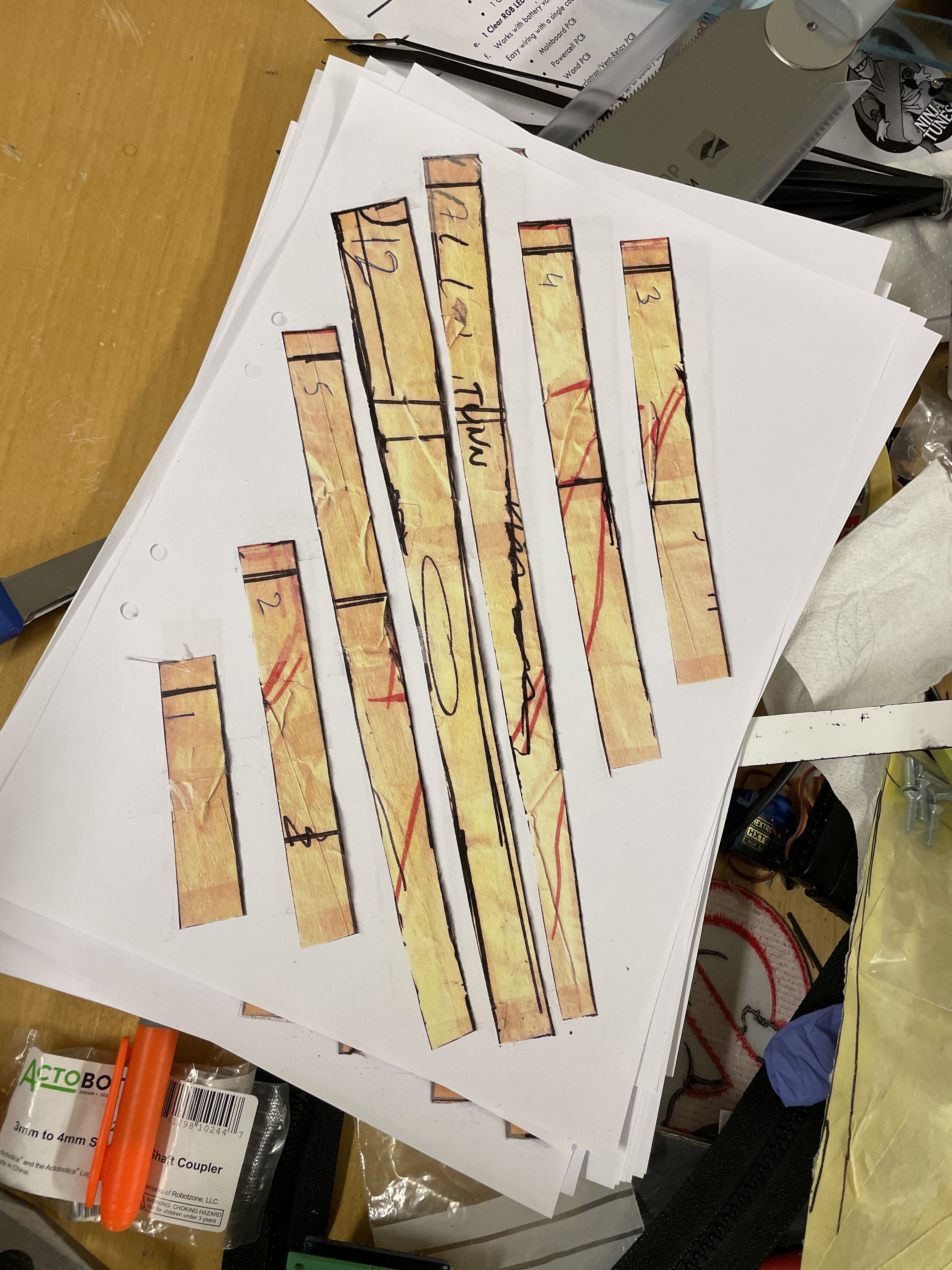

... and cut out the individual strips and mounted them to papers which I photocopied (since I didn't have the computer with me in the workshop today)

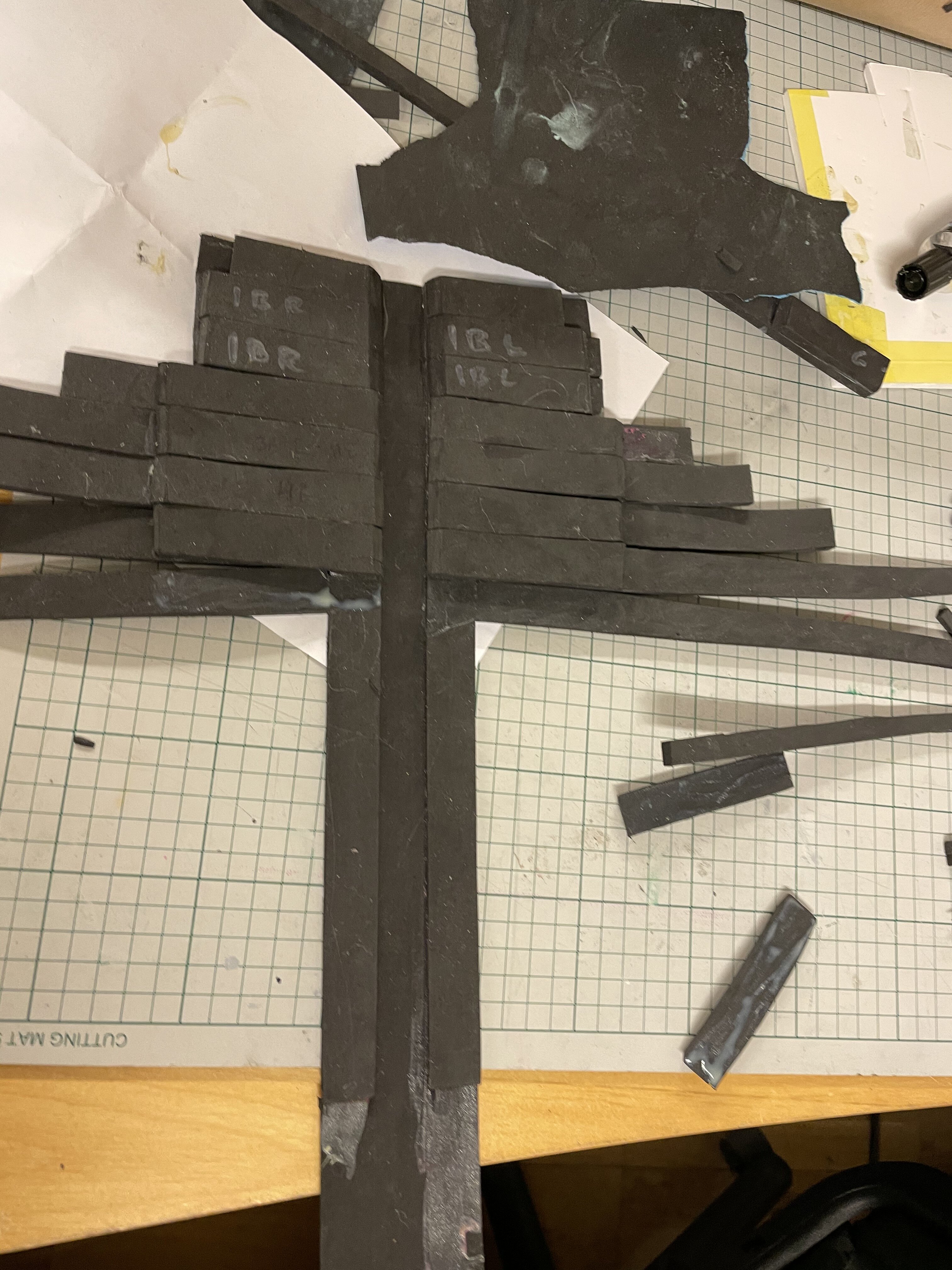

Then I built a mid section for the chest and started attaching the "ribs" as I started seeing them as from the top down..

The ribs will all be glued down one at the time to the Lycra undersuit.

There is still more work to do on these finished ribs. Some sanding and possibly dremel work to smooth everything out before finally heat sealing the foam with a heat gun (which will also make the ribs more pronounced) and painting it with plasti-dip.

A quick test with the torso looks promising, I think:

In order to not shanghai another thread that I've been active in, I'm going to do some documentation of my own Robocop Build in here =)

I have splurged on two separate models, and done some modelling myself.

The original 3d model I purchased had a lot of things that needed changing, so I redesigned some parts, like the neck, the helmet, the biceps...

But the work I've done today is the midsection, the abs.

I've decided to go with building this out of EVA foam, glued with contact cement on a lycra undersuit.

So, I've started working on my EVA foam midsection. I've used a lycra undersuit (got 4 of them) to try and do some glue tests on, and foam sticks well with contact cement!

After trying to remove all glue tests, I started a proper attempt.

First off, I used masking tape to create a template that I then removed, flattened and cut out.

As the mid section is made of horisontal strips, that's how I decided to build it. In strips.

Here's the right section left on the lycra suit on the dummy after I removed the left part and cut out..

... and cut out the individual strips and mounted them to papers which I photocopied (since I didn't have the computer with me in the workshop today)

Then I built a mid section for the chest and started attaching the "ribs" as I started seeing them as from the top down..

The ribs will all be glued down one at the time to the Lycra undersuit.

There is still more work to do on these finished ribs. Some sanding and possibly dremel work to smooth everything out before finally heat sealing the foam with a heat gun (which will also make the ribs more pronounced) and painting it with plasti-dip.

A quick test with the torso looks promising, I think:

Last edited: