pyxl

Well-Known Member

I have only had my cnc for a few months. I'm learning lots of things about carving with regards to materials, speeds, ramp values....all good stuff to know. I have recently been tweaking those ramp values as I do 3D. I wanted to try a project that would allow me to carve up a full 4' x 8' sheet. Cost at my place is certainly a factor- so I experiment on less expensive materials.

The work can be seen in more detail at: Haffner Signs Journal

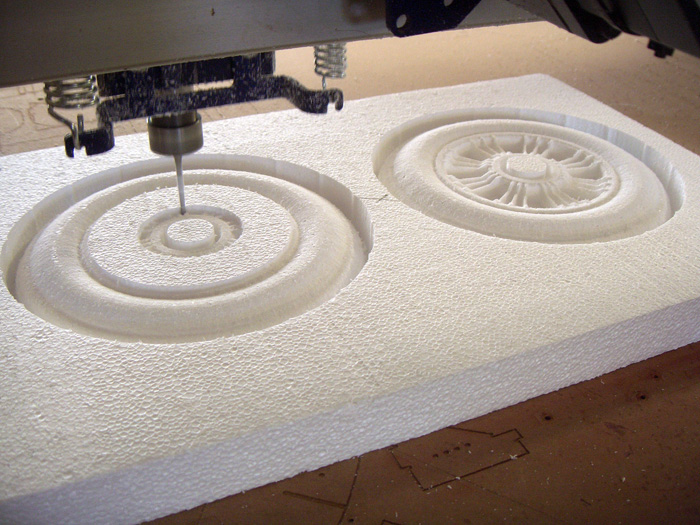

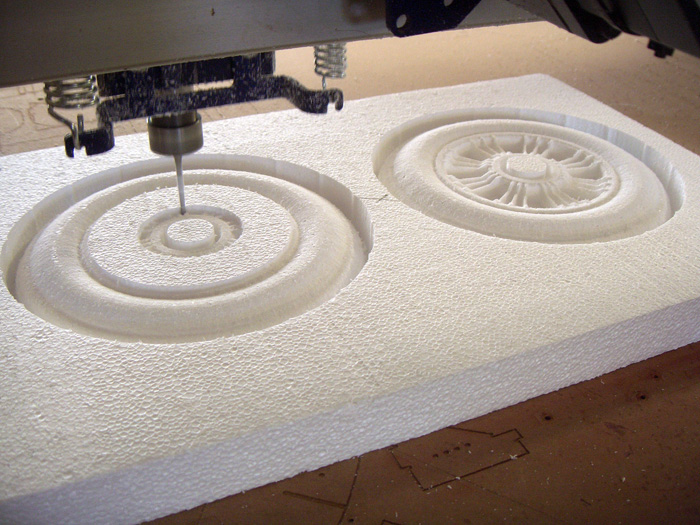

Here is the wheel carve:

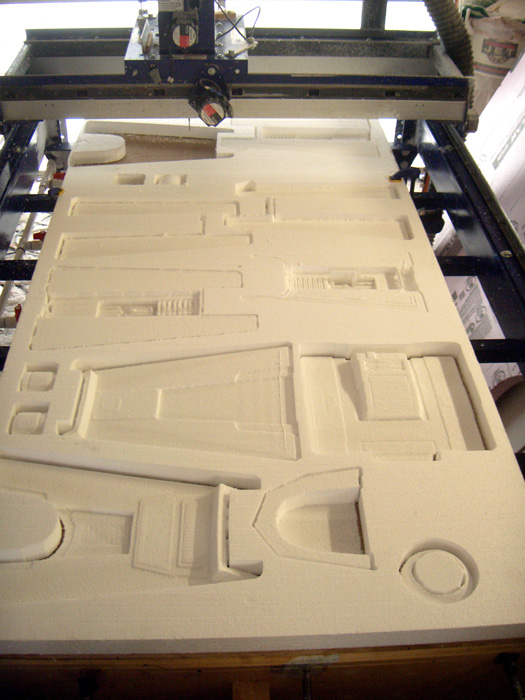

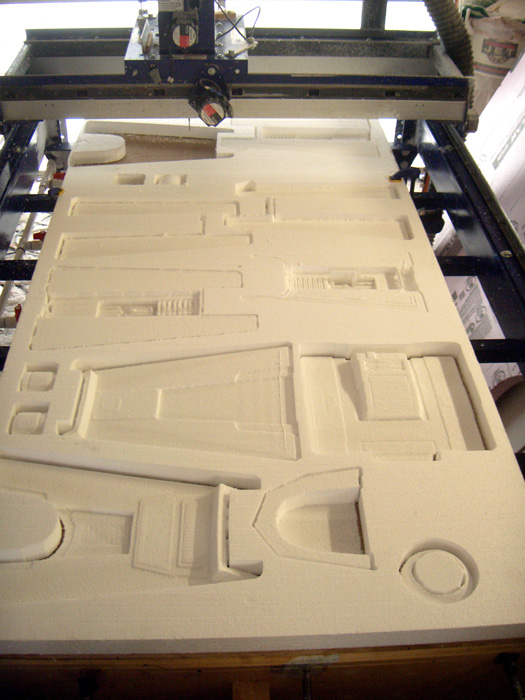

and here is the full 4' x 8' sheet.

I glued up the parts and here it is next to my shop helper.

This morning, I spent some time sanding him and getting a better finish on him. No, white foam isn't the best choice for this. It was really about learning the max speeds/quality on the machine, but why not finish him?

I did carve the center slices of the wheel out of pvc to give it some strength.

The work can be seen in more detail at: Haffner Signs Journal

Here is the wheel carve:

and here is the full 4' x 8' sheet.

I glued up the parts and here it is next to my shop helper.

This morning, I spent some time sanding him and getting a better finish on him. No, white foam isn't the best choice for this. It was really about learning the max speeds/quality on the machine, but why not finish him?

I did carve the center slices of the wheel out of pvc to give it some strength.

Last edited: