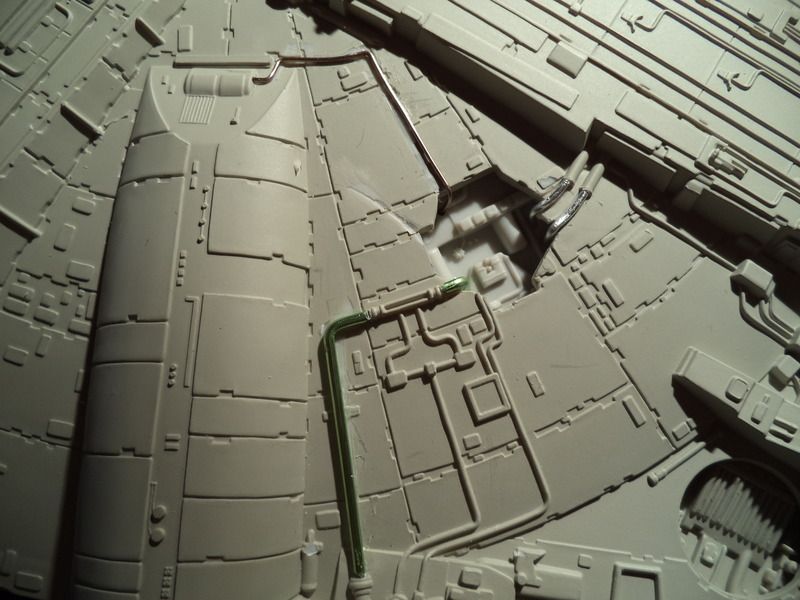

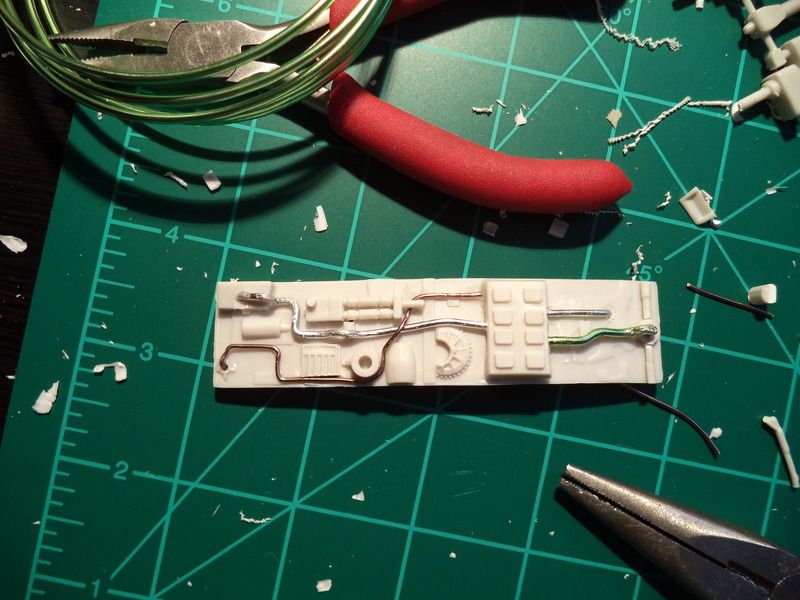

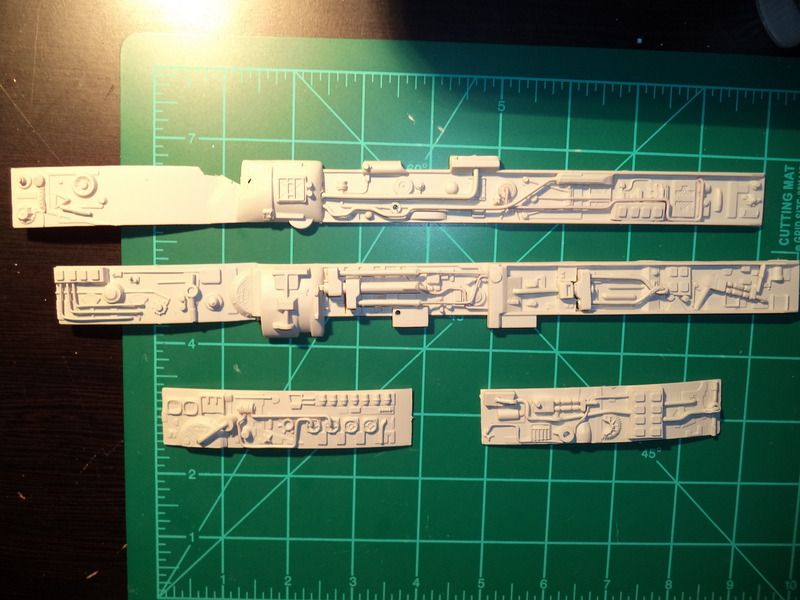

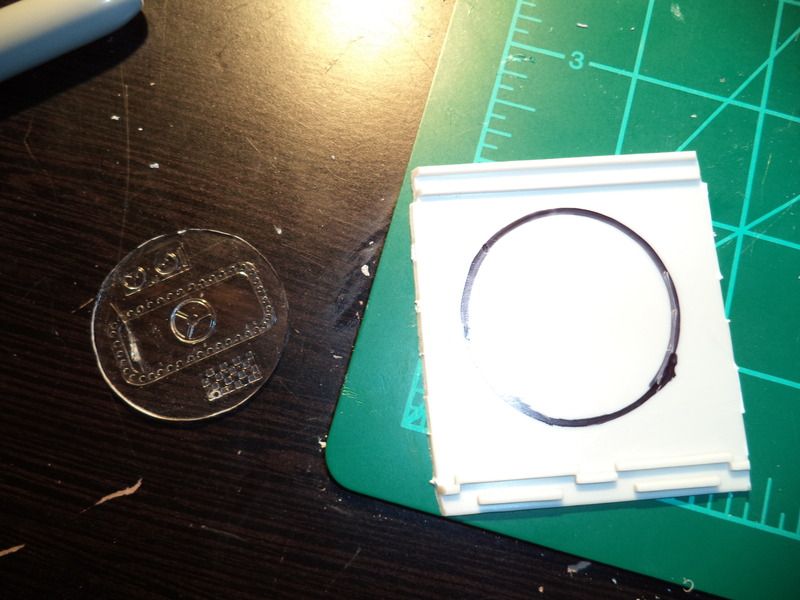

Well, I am sad to report that ALL progress has stopped on Falcon1 due to the stupid cockpit piece not fitting in any way, shape, or form with the molded cockpit area of the top half of the falcon. I do not have the skill to solve this problem so I am afraid I will screw up my Falcon >=o/

Stupid MPC molders.

Plus I am completely stumped about the interior of the cockpit. The only thing I have come up with is placing colored film over drilled holes and placing a white light behind the cockpit wall to give the illusion of multiple colored lights. My brother in law and I have no experience with LEDs and he says that think material may melt due to the heat of the light.

Any ideas gang?

Thanks,

Lee

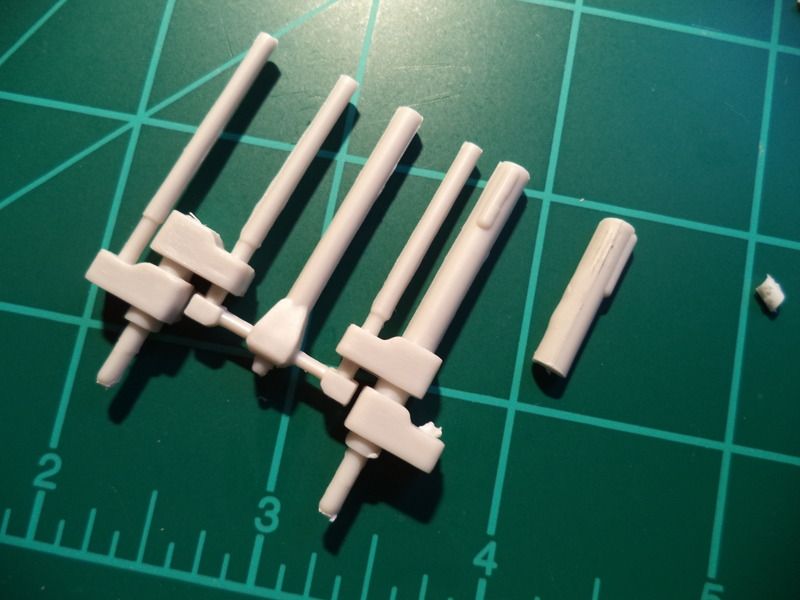

P.s. I also need a rear engine grill or the material to make one if anyone knows where I can get it..whatever it is.

P.s.s. I found an awesome lighting kit for the 1/72 Falcon that I am happy with and will perfectly fit my beginner's need. If you need one it was about $40 (US) and you can find it here if you are interested. By the way, the guy is super nice and easy to deal with, a gentleman named Chris from the UK whos EBAY name is bloater079.

http://www.ebay.com/itm/221997874794?_trksid=p2057872.m2749.l2648&ssPageName=STRK:MEBIDX:IT