You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printer / Printing discussion

- Thread starter Mockle

- Start date

OBI WAN KEN0B1

Sr Member

That turned out great. How many hours did it take to print ?

Mockle

Sr Member

That turned out great. How many hours did it take to print ?

About 25 hours

skynet23

Well-Known Member

I have been using a Prussa i3 for a few years now and would highly recommend it to a first timer. You have to be prepared to tinker and mess around with it but that’s the best way to learn. They are inexpensive and can produce quality which matches any other printer out there once you get the settings down. When you know if it’s something you really want to take further, just sell it on and treat yourself to a beast. I have decided to stay with the i3 as the community is very helpful. Remember you can always print your own upgrades, mine gets bigger by the day. If anybody needs help, feel free to PM me.

CommonGround

New Member

I am the king lurker here, so bear that in mind. I will agree with skynet23 the Prussa I3 or clone is an awesome way to get into this. I got a mono price maker select and could not be happier with it for price paid. It is very opened sourced so there is a ton of users out there to help and all parts are easy to replace or upgrade. I spent the first 30 hours of printing on test samples and printer upgrades. I have $350 in the machine shipped, and maybe another $100 in parts I bought to upgrade it....new bearings, new cooling fan and a full metal extruder. All very well documented online. All easy for the normal tinkerer that can follow instructions. I've shown parts to co-workers who are shocked by the output of this cheap machine. It will plug and play, I had prints running in less than 1/2 hour from unbox, but to get the most of the machine you do have to mess around with it and all the settings in your slicer, pretty much like any of them. My biggest problem with it is what do I make?...It can print almost anything, and you can download almost anything to print with it. It is a little overwhelming when it's sitting on your table waiting for you to hit the go button.....where do I start? All in all awesome questions to have to ask yourself, and a great tool to have in the shop. Sorry to sound like an add, but I'm having a blast with this thing and don't see an end to its use.

Have a great one.

MJ

Have a great one.

MJ

Last edited by a moderator:

allartburns

New Member

Another data point: I'm building my third home-studio FDM, a BigBox Dual Titan (my previous printers were Cupcake #235 and a MendleMax 1.5). I consider these prototype printers, I use them to verify that my model is solid and that my parts are close enough. For a final 3d print I go to Shapeways and pay between $5 and $10 for a print from a professional machine. If it's something other people might want, I put it for sale in my shapeways store. The only thing that sells frequently is that switch for the discontinued Rowenta iron. I made one for my wife (who sells vintage clothing) and sold enough on shapeways to pay for a shiny new irons.

allartburns

New Member

XTC-3D question: anyone have cautions not covered in the MSDS? This looks too-good-to-be-true, like when a friend was trying to convince me to airbrush furniture polish as a clear-coat. (He was right, it didn't ruin my airbrush and it looked great.)

MatterMaker

Well-Known Member

XTC-3D question: anyone have cautions not covered in the MSDS? This looks too-good-to-be-true, like when a friend was trying to convince me to airbrush furniture polish as a clear-coat. (He was right, it didn't ruin my airbrush and it looked great.)

It's 2 part epoxy. So as a rule of thumb I'd consider taking the same precautions you would take with any kind of 2 part epoxy. I always use gloves and an OV mask and good exhaust ventilation. I seem to recall XTC seems to downplay their safety precautions.

I got a Flashforge Creator Pro a bit over a month ago. It's worked almost perfectly straight out of the box and the quality has been brilliant. I'd been looking at the Prnterbot Simple Metal but getting one with a heated bed is kinda tricky here in the UK. Anyway, very happy with the Flashforge, works a treat.

I too have recently purchased the flashforge as well, the biggest surprise for me is the build surface that came with the printer, it has been the most resilient build platform I have ever used; four months into printing I'm still on the first sheet.

RocFoamArmory

Active Member

XTC-3D question: anyone have cautions not covered in the MSDS? This looks too-good-to-be-true, like when a friend was trying to convince me to airbrush furniture polish as a clear-coat. (He was right, it didn't ruin my airbrush and it looked great.)

I use the XTC stuff, it works really nicely. I've tried alternating thin layers of that and filler primer, with a little sanding in between for bumpy spots, and it works well. Having worked with fiberglass resins and xtc, the xtc stuff does not smell as bad as the fiberglass resin. Doesn't necessarily mean it's less bad to breathe in, but I can use the stuff indoors. Fiberglass resin gives me a headache right away.

Always better to be safe than sorry though

RocFoamArmory

Active Member

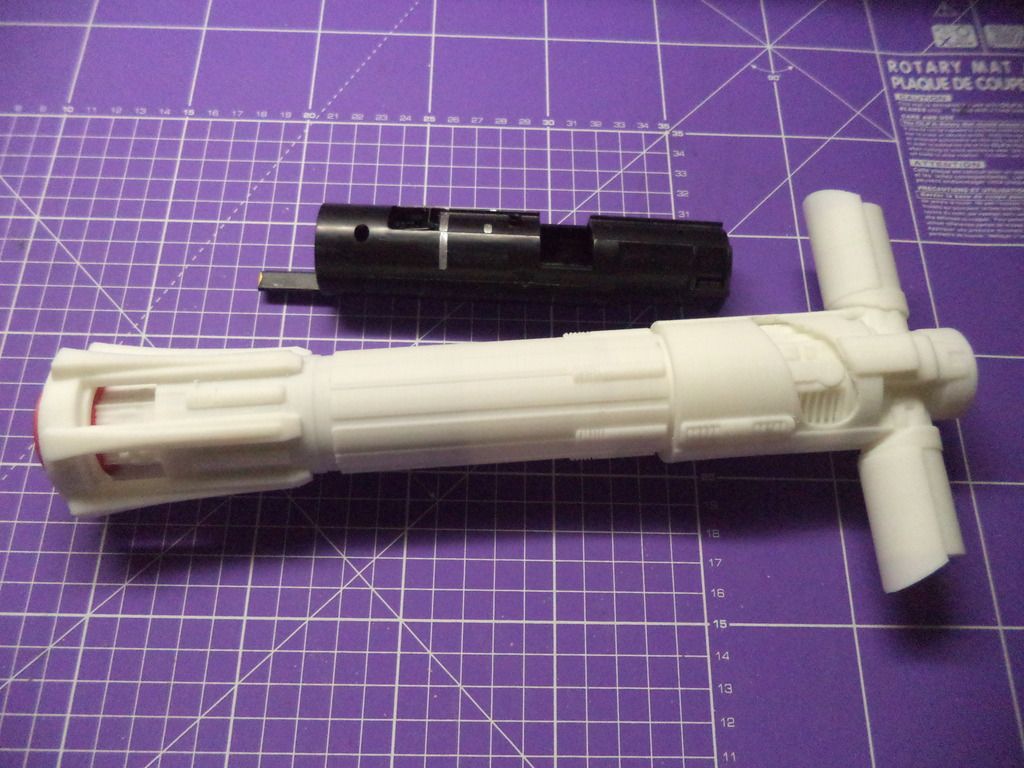

Hey all, here's a bit of example work from my printer. I have a Monoprice Maker Select, which is a clone of the Wanhao duplicator. I'm not sure which version it clones, but either way it's a great printer! I've had it running a total of 17 days since I bought it several months ago!

Halo energy sword

Halo magnum

Guess what that is!!

There it is, hard at work!

So there you go guys. These are in different stages of completion, you can expect separate build threads for each of these, along with better quality photos. Feel free to give me a follow and check those out when they happen!

I got a lot of cool projects coming up, can't wait to show you guys!

As always, keep making.

Halo energy sword

Halo magnum

Guess what that is!!

There it is, hard at work!

So there you go guys. These are in different stages of completion, you can expect separate build threads for each of these, along with better quality photos. Feel free to give me a follow and check those out when they happen!

I got a lot of cool projects coming up, can't wait to show you guys!

As always, keep making.

jennifernichole

New Member

I have an M3D, definitely not the best quality out there, but I've had pretty good luck with it and the price point is way below most others. Good for printing up to 4 in x 4 in objects. The only complaint I have is with getting prints to stick to the print bed - easily fixed by lining the bed with painter's tape.

They are coming out with an M3D pro which seems to address a lot of concerns folks have had with the original model as well.

I've uploaded a few prints to thingaverse if you want to see examples - jennifer 987. I'll be uploading more in the next few months as I'll be bulk loading some HO scale stuff I've been working on.

They are coming out with an M3D pro which seems to address a lot of concerns folks have had with the original model as well.

I've uploaded a few prints to thingaverse if you want to see examples - jennifer 987. I'll be uploading more in the next few months as I'll be bulk loading some HO scale stuff I've been working on.

phunkymunky

Well-Known Member

Did you resize the file? I tried printing it in PLA, but the pieces just don't seem to connect - bottom and top main body

Mockle

Sr Member

Did you resize the file? I tried printing it in PLA, but the pieces just don't seem to connect - bottom and top main body

I printed ABS @ 2mm cleaned and worked fine.

smith59

New Member

I've got the opportunity to pick up a new Airwolf AW3D HDX for pretty cheap, and I like the print area, but I haven't been able to track down any reasonable reviews on it.

read this article cheap 3d printer

I found reviews for the HD and the HD2X, but only one review for this particular model, and that makes me wary. Also, the filament feeder comes into the head from the rear of the unit and not the top, and it apparently causes problems with clogging sometimes and 'mousebite'...

Anybody have any experience with these machines, or any of the Airwolfs? If I was paying retail, I would probably just go with an ultimaker 2/ 2 extended for that much money, but I'm looking at getting this airwolf for a bit under 2k so I thought I should give it a serious look.....

read this article cheap 3d printer

I found reviews for the HD and the HD2X, but only one review for this particular model, and that makes me wary. Also, the filament feeder comes into the head from the rear of the unit and not the top, and it apparently causes problems with clogging sometimes and 'mousebite'...

Anybody have any experience with these machines, or any of the Airwolfs? If I was paying retail, I would probably just go with an ultimaker 2/ 2 extended for that much money, but I'm looking at getting this airwolf for a bit under 2k so I thought I should give it a serious look.....

OBI WAN KEN0B1

Sr Member

I have a question what brand of filament is everyone using ? I have tried a few different brands now and the hatchbox i order from amazon seams to work the best for me on my Robo 3D.

Similar threads

- Replies

- 3

- Views

- 1,513

- Replies

- 319

- Views

- 16,755

- Replies

- 10

- Views

- 1,947

- Replies

- 1

- Views

- 1,706