vaderman1701

Sr Member

Hey All,

Been very busy the last few weeks on the new job, but rest assured work for AW Studios is still going on. As some of you may know, I purchased Richard's (REL) original 1/350th Romulan BOP masters with his permission to use it to create a vacuform version of this kit.

Well we are almost there. First I want to say that Richard really did a fantastic job with this model. I had to separate the wings from the body in order to properly vacuform this model.

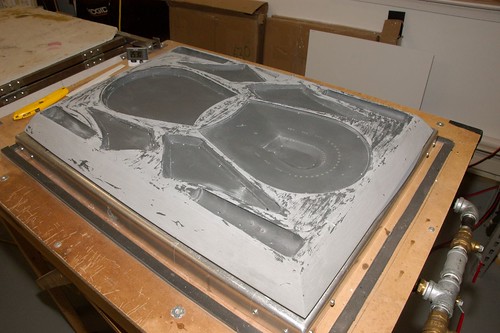

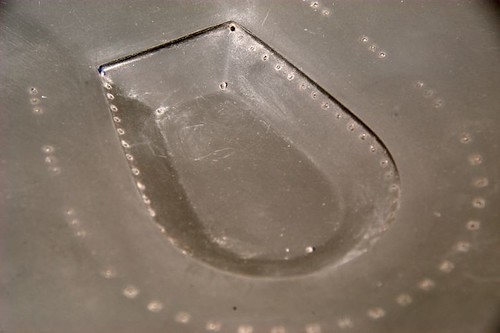

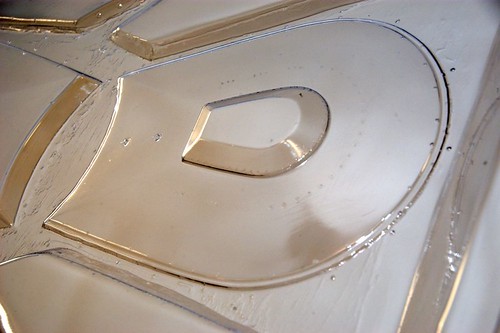

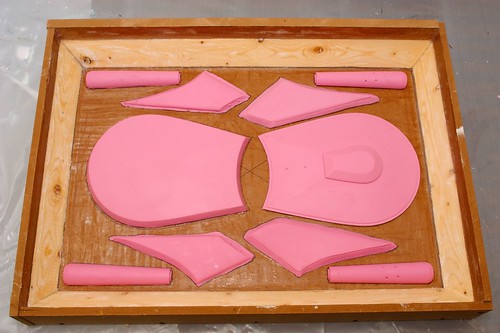

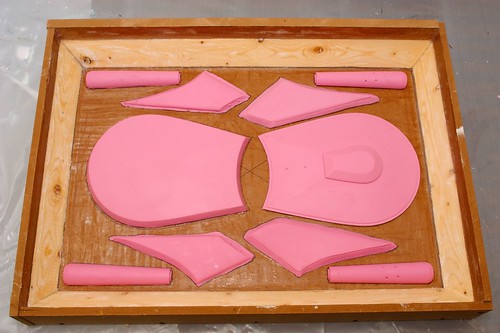

The engine detail and Plasma cannon have been molded and are ready for casting. Richard provided me with the original mold for the top fin of the ship, so that is ready to go. Finally, we have molded all of the ship parts and have created positive silicone molds in order to create the negative vacuform mold. Here are some pictures of the silicone parts laid out in the vacuform box we will be pouring the resin into. The box has tappered walls to extract the plastic more easily. The wood has also been given a coat of silicone to seal the wood to prevent the vacuform resin from sticking to it and also for the silicone molds to stick to the surface.

We are waiting for the Slow Kast vacuform resin to arrive and then we will pour the resin and then drill the holes. Once that is done then we will start pulling plastic and a build-up will be done. Hope you all enjoy.... these kits will be available soon.

Additional photos at a higher resolution can be found here:

http://tk386.com/aws/bird_of_prey_mold_box/

Later all.

Scott

AW Studios

Been very busy the last few weeks on the new job, but rest assured work for AW Studios is still going on. As some of you may know, I purchased Richard's (REL) original 1/350th Romulan BOP masters with his permission to use it to create a vacuform version of this kit.

Well we are almost there. First I want to say that Richard really did a fantastic job with this model. I had to separate the wings from the body in order to properly vacuform this model.

The engine detail and Plasma cannon have been molded and are ready for casting. Richard provided me with the original mold for the top fin of the ship, so that is ready to go. Finally, we have molded all of the ship parts and have created positive silicone molds in order to create the negative vacuform mold. Here are some pictures of the silicone parts laid out in the vacuform box we will be pouring the resin into. The box has tappered walls to extract the plastic more easily. The wood has also been given a coat of silicone to seal the wood to prevent the vacuform resin from sticking to it and also for the silicone molds to stick to the surface.

We are waiting for the Slow Kast vacuform resin to arrive and then we will pour the resin and then drill the holes. Once that is done then we will start pulling plastic and a build-up will be done. Hope you all enjoy.... these kits will be available soon.

Additional photos at a higher resolution can be found here:

http://tk386.com/aws/bird_of_prey_mold_box/

Later all.

Scott

AW Studios