Right on!! Glad you like them!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Men in Black MIB Pulsar project

- Thread starter Zombie Killer

- Start date

In a bid to get this project done within a 10 year period.....cough cough....... Finally have my lathe running so i made these over the last week. I also fixed all the broken picture links in the thread. Hope they stay awhile as i dont see me doing that again. What a PITA.

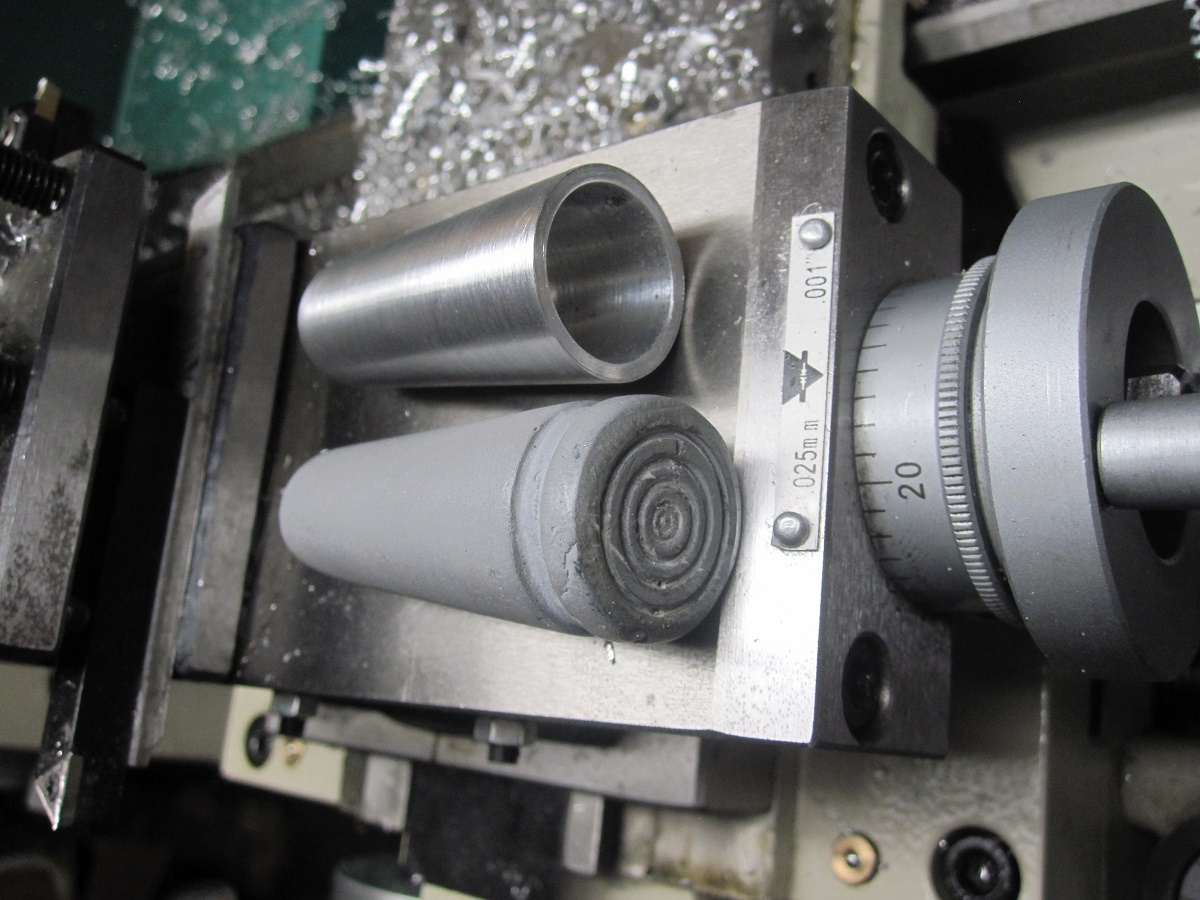

Tear drops for the top of the guns, i will be drilling and tapping some holes that will face down to hold setscrews that will keep the buttons in. I also plan to add a spring on the inside to make them "pushable" or spring loaded. One teardrop is longer the other shorter and fatter. Also the buttons are different on each side. I did my best to copy them but hey, these were the first thing i made on the lathe. They will all be a tad different since im not a CNC machine but they will look great compared to what i had .

Also made some little washer thingies that go on the tear drops with aluminum tube underneath. The mounting screw goes through and holds the tear to the gun. Also decided to redo the barrel end pieces. These get glued from the inside of the barrel end on the top hole.

Lastly did a test run of the missing little side bullet thingie. I need to make it a tad thicker and a bunch shorter but this was just a guestimate. There is a little push button on these i still need to locate.

Tear drops for the top of the guns, i will be drilling and tapping some holes that will face down to hold setscrews that will keep the buttons in. I also plan to add a spring on the inside to make them "pushable" or spring loaded. One teardrop is longer the other shorter and fatter. Also the buttons are different on each side. I did my best to copy them but hey, these were the first thing i made on the lathe. They will all be a tad different since im not a CNC machine but they will look great compared to what i had .

Also made some little washer thingies that go on the tear drops with aluminum tube underneath. The mounting screw goes through and holds the tear to the gun. Also decided to redo the barrel end pieces. These get glued from the inside of the barrel end on the top hole.

Lastly did a test run of the missing little side bullet thingie. I need to make it a tad thicker and a bunch shorter but this was just a guestimate. There is a little push button on these i still need to locate.

Last edited:

Green with jealousy!

Getting back on this over the last few weeks. I removed the side upper panels so they can get chrome plated and closed up the holes and also removed all the side resin parts and closed up those holes also. Still got a bunch of hours of work to do though. I really need to remove the top cover things in front of the alien tube because they need to be chrome plated like the original prop. Ill need to close those holes up too. All the side parts and top rails will all be replaced with aluminum parts like the Hero prop. I have all the aluminum and brass ordered along with all the tooling for my mill to make all the parts. Also have the stainless hoses that go in the barrel vents on the way. I still need to figure out the magazine though. At least 2 of these will be going up on an interest thread in the next weeks so keep your eyes out . Full disclosure, they will not be cheap, i have a big azz wad of cash tied up in them and will have probably 60+ hours in these 3 shells before they are presentable. Another 20+ in the front grip slides. Never mind the money and time i spent getting to the point where i could pour silicone over the original. I will have who knows how many hours in machining yet to do, plus add chrome to the 6 parts ( side panels, grips halves, top cover and barrel end) and you can see its a heck of an expensive project. I will be going with Alumaluster for the one im keeping and chroming the listed parts. I think this is the best way to mimic the original props since they were not chromed either. I do realize someone may want to spend the big bucks to get the gun shell chromed too so its something i need to plan out with whoever ends up getting in on the project. Like i said i will put up an interest thread in the next weeks and plan out the final stretch with those willing to get in.

There is a run!! A run of 3.....lol.

Have i mentioned i hate fiberglass work ?..........6 hours later and i have 1 side mostly cleaned up and the second side 50% cleaned up. Some filling in a few spots needed. I also cut off all the top caps in front of the alien tank, unfortunately im Mr Dumass and forgot my resin at moms house so i cant do any more on that until i get back over there. Hopefully tomorrow ill have this one cleaned up and half of the second.

Looking for one more person to get this across the line. Interest thread is posted in the project section of the junkyard

Got 2 through part 1 of the side cleanup and a bit of smoothing to the whole gun and a bit of cleanup on the interior. Still need to do the 3rd gun and then i'll start filling anything that needs filling and fiberglass/epoxying a few areas that have exposed themselves. I won't be doing too much more to the sides until i have some parts machined so i can fit them properly.

Its like Christmas in november. V-blocks to hold the tubing for the top strip while its cut in half, slitting saw for same plus to slot the brass thumbscrews, knurling tool for thumbscrews, hold down kit for the mill and a set of covid infused end mills. Also the aluminum for front sight bases, aluminum strip for the top bowed aluminum pieces and solid brass for knurled knobs have arrived.

Ready to rock and roll.....

Ready to rock and roll.....

Stainless corrugated hose for the barrel slots arrived. Only $19.10 each ! A roll of this hose is over a grand.......

I'll make some clips or brackets to hold them using the screws that sit between the slots. Im going to have to order some longer hardware once i know what length to buy.

Got my big arse vise for the mill and parallels and 50 lbs of aluminum. I should have enough stuff to start getting in trouble.....lol

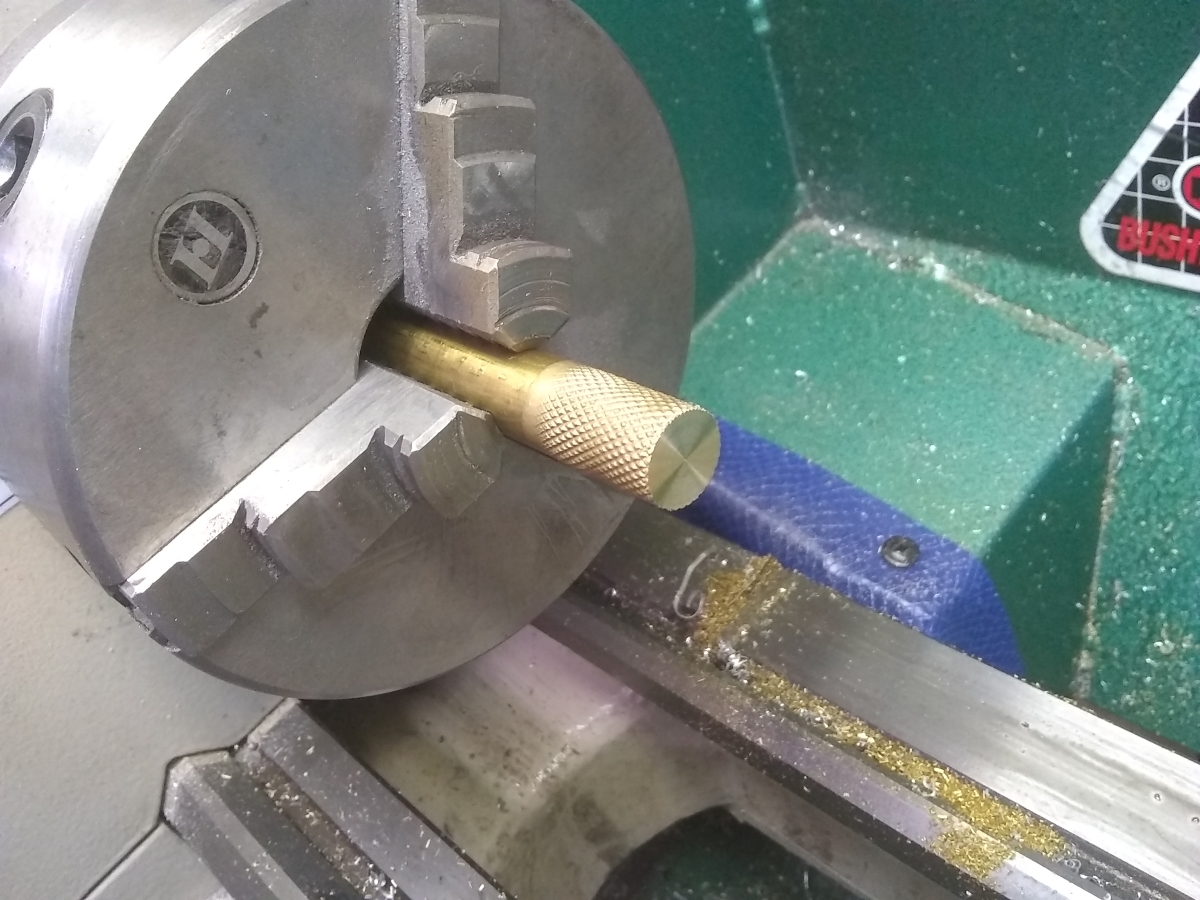

I should have gotten a mill a long time ago..... still need to drill and tap the back of all but one of the thumbscrews. Thats a tomorrow project.

I have a new found respect for the price of machined parts...lol.

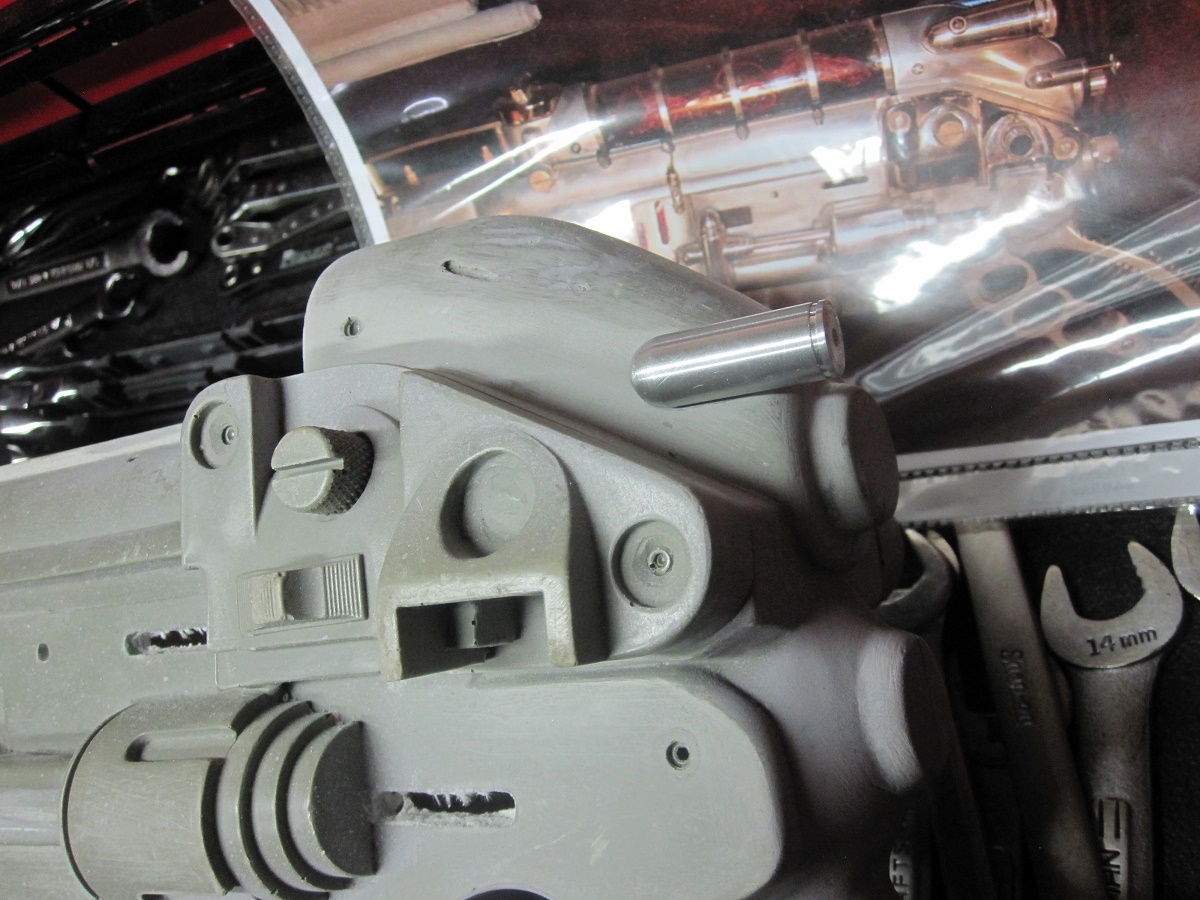

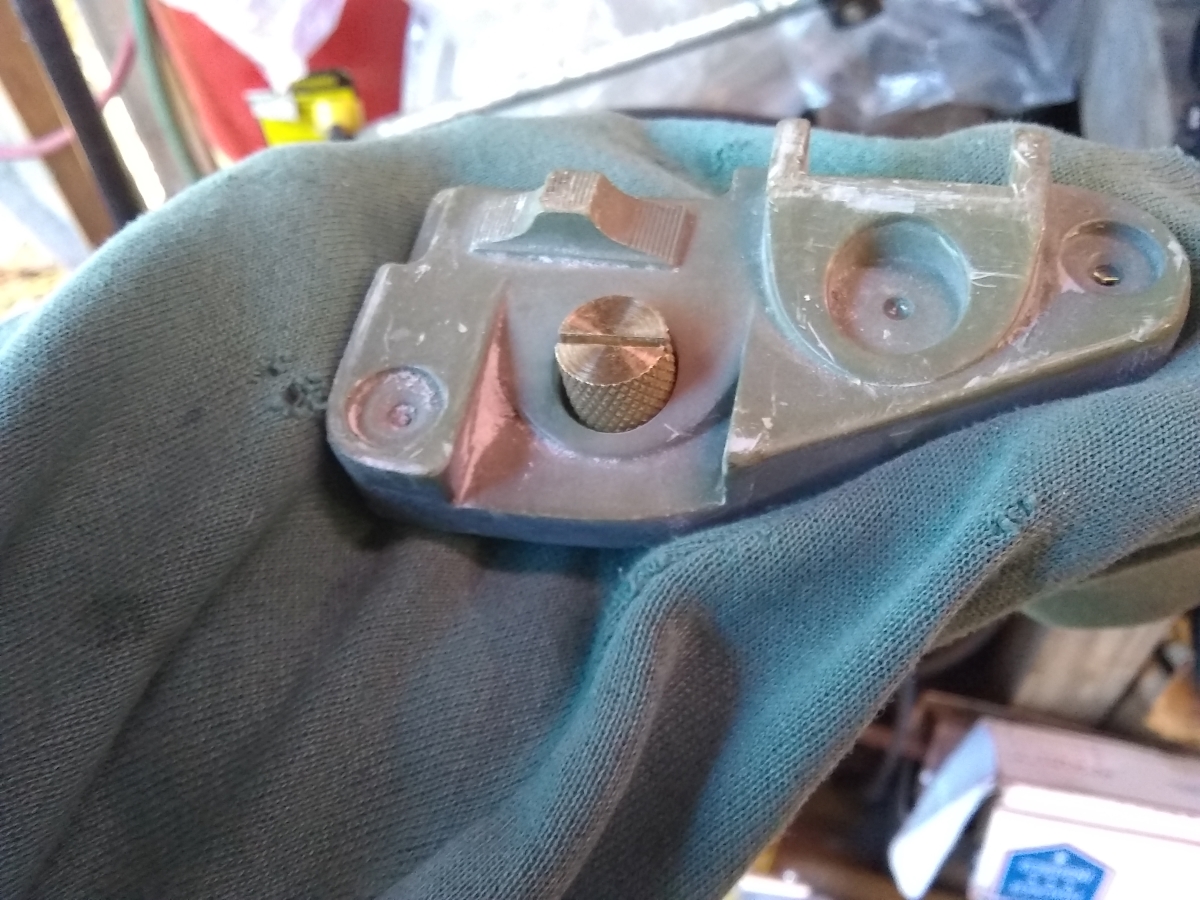

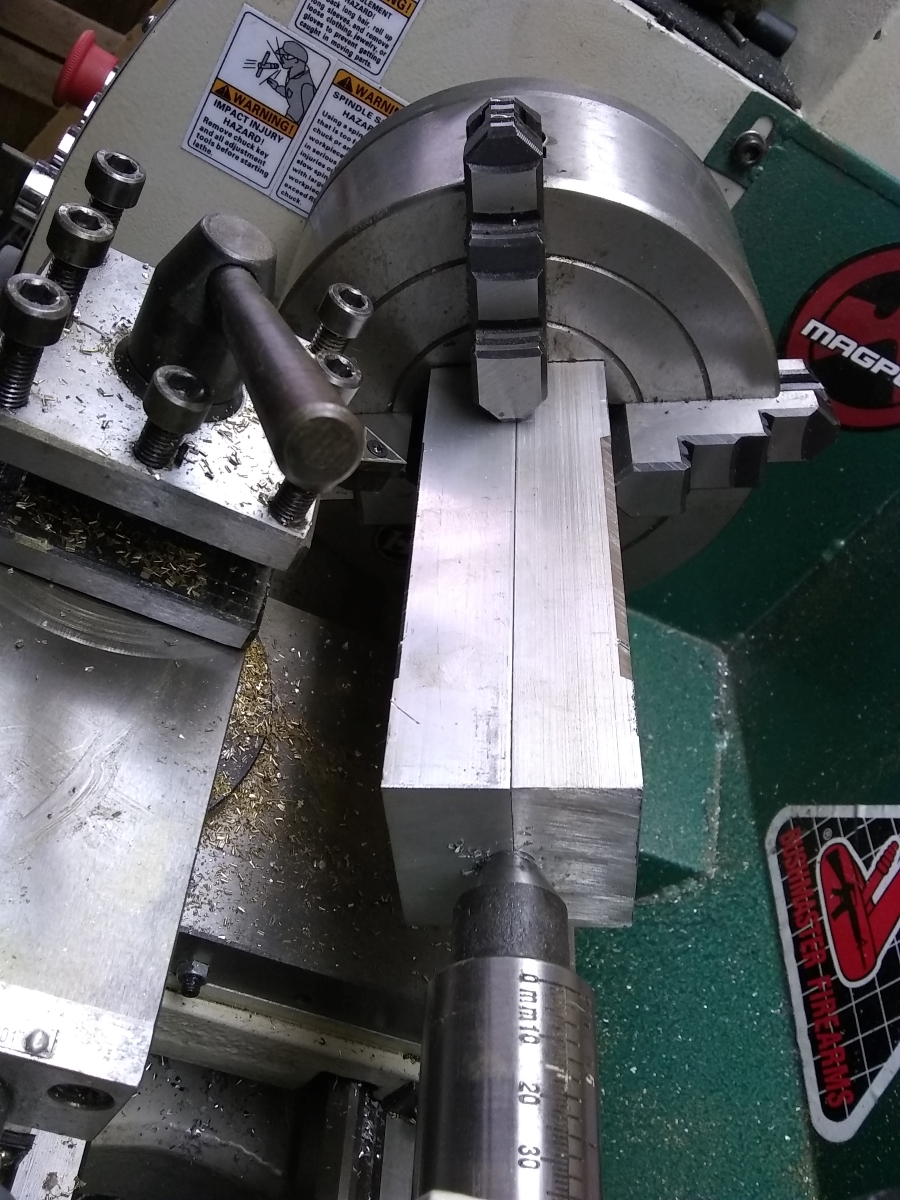

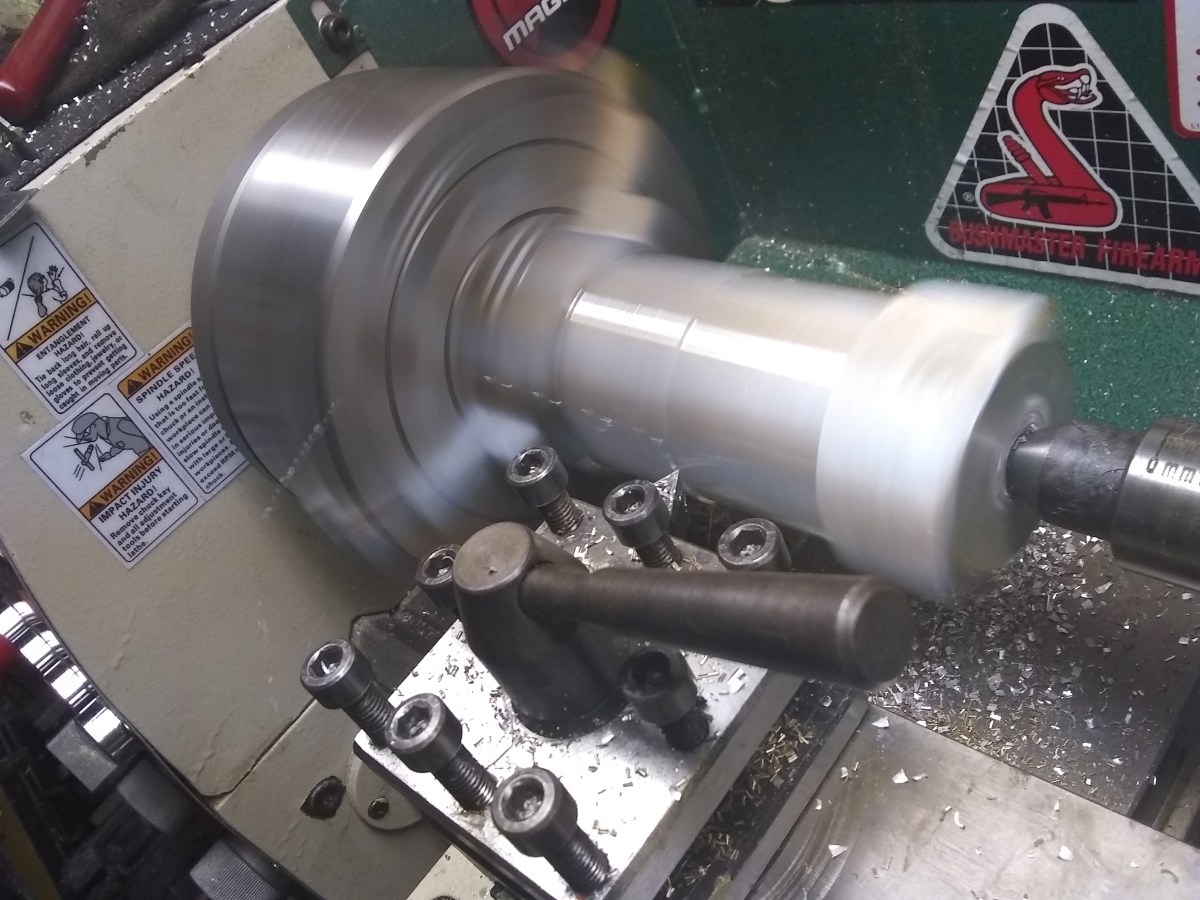

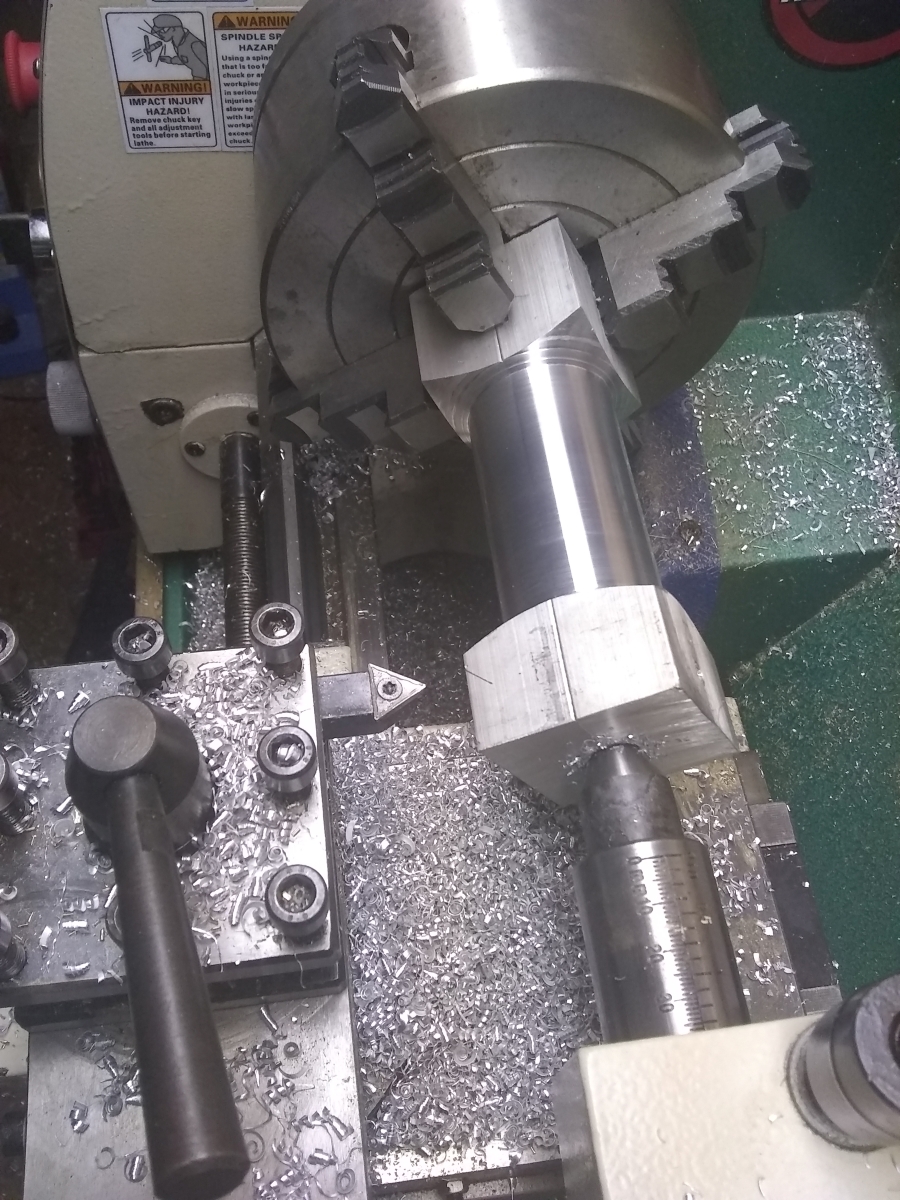

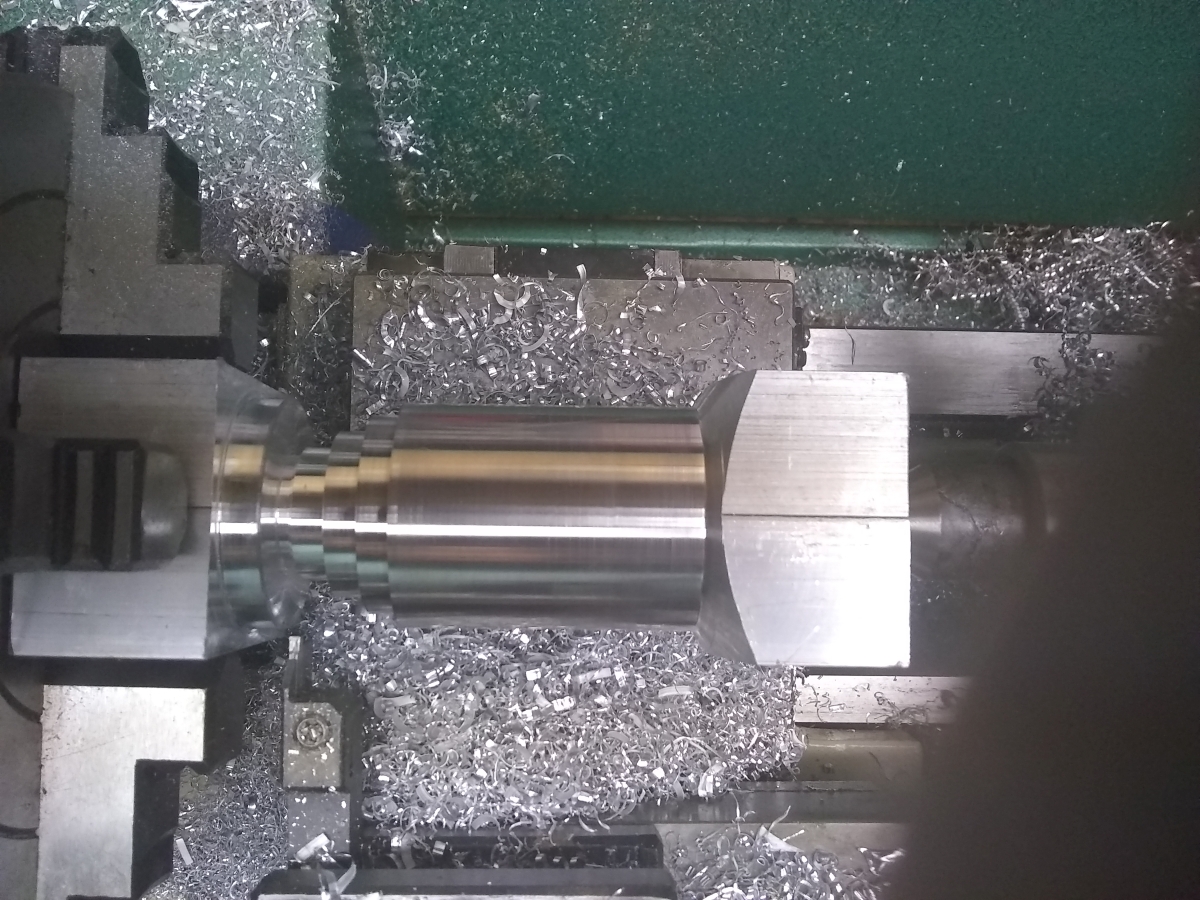

Finished up the threading of the thumbscrews. Decided to tackle the hardest of the parts next, the side cylinder things. Quite the pain in the butt to do it this way but the other option was make these out of round stock then try to cut them in half and i didnt think that was going to work too well. Real PITA to get this block centered on the 4 jaw and also parallel to the tail stock with the dial indicator.. Took me a good 5 hours to get to this point, ill try to finish the lathe portion tonight and mill the slots in it tomorrow. still need to figure out some stuff like whether i cut square ends off now or just one side because at some point i need to mill a hole in one side for the "hammer" rod to get inserted. And not sure if it will be better to have a sacrificial point to stick in the vise so as to not mar the part. Just not sure yet. There is also another thicker rod that goes near the center but luckily they are not actually connected to the cylinder on the prop, it just sits butted up against it. I have the rear part of the cylinder done now have to do the front side. Then i can plan the next steps.

Finished up the threading of the thumbscrews. Decided to tackle the hardest of the parts next, the side cylinder things. Quite the pain in the butt to do it this way but the other option was make these out of round stock then try to cut them in half and i didnt think that was going to work too well. Real PITA to get this block centered on the 4 jaw and also parallel to the tail stock with the dial indicator.. Took me a good 5 hours to get to this point, ill try to finish the lathe portion tonight and mill the slots in it tomorrow. still need to figure out some stuff like whether i cut square ends off now or just one side because at some point i need to mill a hole in one side for the "hammer" rod to get inserted. And not sure if it will be better to have a sacrificial point to stick in the vise so as to not mar the part. Just not sure yet. There is also another thicker rod that goes near the center but luckily they are not actually connected to the cylinder on the prop, it just sits butted up against it. I have the rear part of the cylinder done now have to do the front side. Then i can plan the next steps.

Similar threads

- Replies

- 21

- Views

- 1,098

- Replies

- 4

- Views

- 932