Greetings All !

I thought I'd start a build thread for this year's Halloween costume. And this year, I may have bitten-off more than I can chew...in a single year:

Of course, immediately after LAST Halloween, my friends (and wife) started asking: What are you going to do next? Well, last year, I made a 7 foot tall Velociraptor, which turned out surprisingly good, considering that I was using a cloth-pattern to mimic its skin/scales. But of course, I was thinking to myself: How do I TOP that? (Everybody always suggests a Transformer...that actually transforms. Yeah, there's a small project.)

Whatever I choose each year HAS to excite me.

And so, I surprised myself by committing to this idea back in January. (Unfortunately, I've barely done anything with it until this week!)

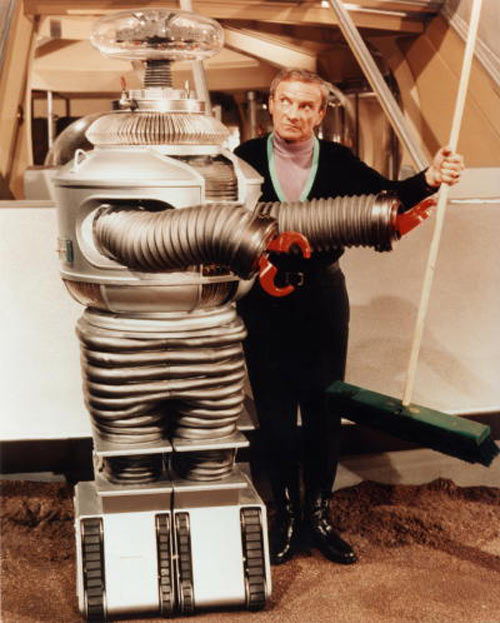

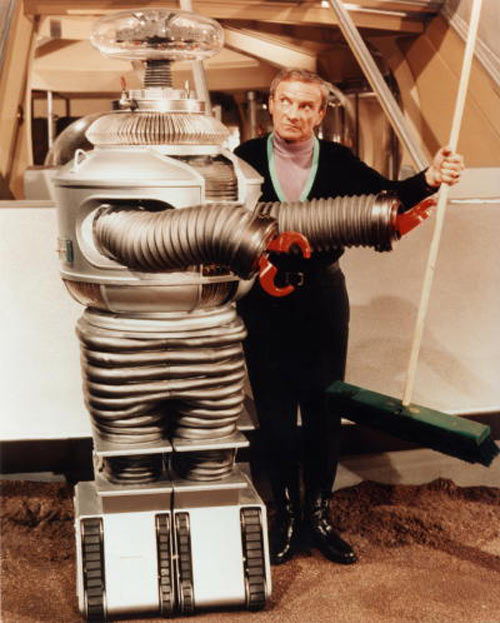

I decided that I would like to build a B9 robot (the robot from the "Lost In Space" TV show from the 1960's) costume.

My decision met several of my "usual criteria" for my Halloween costumes.:

Now, there are a fair number of folks across the U.S. who build their own B9 robot MODELS. Some of these do have some animated movement to them. There may be a couple that actually move on their own. (But some research with the B9 Robot Builders Club suggests that very few folks have accomplished that.) However, the PARTS for building such models (some of which are club-member fabricated) are very EXPENSIVE. On the other hand, they are also very, very accurate. And such accuracy may be overkill for a Halloween costume. (Yeah, if it ends up being more than a one-year-wearing, I'd be thrilled.)

I decided that my goals for such a costume, if it were going to "wow" anybody, should be:

I'm about to talk a little bit about #1 and #2. Please, please, if you have ANY ideas or comments that might help me avoid problems or advance this project, please post a reply here! This is one HUGE reason I'm posting here today.

So, how to accomplish motorized movement?

Well, I tried researching online the concept of building a 4 wheel mobile, wheeled platform. But overwhelmingly, I found info on how to build homemade Segways instead. Most such devices begin by purchasing wheelchair motors, gearboxes, and wheels as individual units. Folks buy two of those, some batteries, a battery charger, and then some sort of controller. The controller part intimidated me a bit. I don't know much about those and I'm sure there'd be a learning curve there, assembling all of this. And I still may run into that.

But, based on pricing I was seeing on eBay and Craig's List, it seemed like I'd be better-off buying an entire used electric wheelchair, with all of these parts installed and already working.

And so, on Saturday night, I bought this from a local guy off of eBay:

Used chair, but new batteries, and a built-in charger... all for $425...delivered to my door!

Now, obviously, I'm going to start removing the seat and anything "extra", while trying to maintain the joystick controls connection. And I'm going to have to study the wheel situation and see if the casters can be moved inward, a bit.

I should mention that, thanks to the B9 Builders Club, I have printed off the blueprints of B9. Based on my own height, I felt I should expand his dimensions by... oh, I can't remember off the top of my head if it's 8% or 10%. But I have that written down in my file on this. So, I know how big my B9's base will have to be...and I'm going to have to compare those dimensions with the wheelchair base dimensions as I go about stripping down the chair.

Now, regarding B9's voice, I just ordered a CD containing over 300 phrases said by the robot during the TV show, cleaned up. There are apparently two different CDs sold by two different B9 Builders Club members. I bought what members said was the better one, "iB9 Talk". I just ordered that a few minutes ago.

That CD comes with a built-in interface to let you run a sort of "soundboard" on a PC and use that to select phrases / to make B9 "talk". However, I'm going to have to figure out a way for this to be controlled remotely, by someone other than me (because I'll be having a hard enough time steering B9 and moving BOTH arms). Now, how to do this? I'm not sure yet. That's one major "line of research" I'll have to do. Someone in the B9 club told me they use a Bluetooth transmitter to send to their B9. My wife and I both have Nexus 7's, but they don't come with any sort of Bluetooth transmission capabilities (I think?).

So, this is certainly a long enough post for today!

If you have ideas for construction or materials-sources, please let me know! (I have done a bit of digging regarding the arms, but I'll save that post for another day.)

Thank you!

-= Dave R. =-

I thought I'd start a build thread for this year's Halloween costume. And this year, I may have bitten-off more than I can chew...in a single year:

Of course, immediately after LAST Halloween, my friends (and wife) started asking: What are you going to do next? Well, last year, I made a 7 foot tall Velociraptor, which turned out surprisingly good, considering that I was using a cloth-pattern to mimic its skin/scales. But of course, I was thinking to myself: How do I TOP that? (Everybody always suggests a Transformer...that actually transforms. Yeah, there's a small project.)

Whatever I choose each year HAS to excite me.

And so, I surprised myself by committing to this idea back in January. (Unfortunately, I've barely done anything with it until this week!)

I decided that I would like to build a B9 robot (the robot from the "Lost In Space" TV show from the 1960's) costume.

My decision met several of my "usual criteria" for my Halloween costumes.:

1) It should be something that's easily recognizable by both adults and kids.

2) It shouldn't be overly scary.

3) It should be something that I find particularly challenging.

4) It should be something that I don't see very many people do.

2) It shouldn't be overly scary.

3) It should be something that I find particularly challenging.

4) It should be something that I don't see very many people do.

Now, there are a fair number of folks across the U.S. who build their own B9 robot MODELS. Some of these do have some animated movement to them. There may be a couple that actually move on their own. (But some research with the B9 Robot Builders Club suggests that very few folks have accomplished that.) However, the PARTS for building such models (some of which are club-member fabricated) are very EXPENSIVE. On the other hand, they are also very, very accurate. And such accuracy may be overkill for a Halloween costume. (Yeah, if it ends up being more than a one-year-wearing, I'd be thrilled.)

I decided that my goals for such a costume, if it were going to "wow" anybody, should be:

1) Motorized movement. (Nobody wants to see him "walk".)

2) He should talk in the true B9's voice.

3) Of course, the arms should move /expand/contract and his torso should be able to turn, to complete the illusion.

4) And, of course, at least his lights should be present and flashing. (Not sure if I'll have time to rig up the spinning whirly-gigs on the side of his head.)

2) He should talk in the true B9's voice.

3) Of course, the arms should move /expand/contract and his torso should be able to turn, to complete the illusion.

4) And, of course, at least his lights should be present and flashing. (Not sure if I'll have time to rig up the spinning whirly-gigs on the side of his head.)

I'm about to talk a little bit about #1 and #2. Please, please, if you have ANY ideas or comments that might help me avoid problems or advance this project, please post a reply here! This is one HUGE reason I'm posting here today.

So, how to accomplish motorized movement?

Well, I tried researching online the concept of building a 4 wheel mobile, wheeled platform. But overwhelmingly, I found info on how to build homemade Segways instead. Most such devices begin by purchasing wheelchair motors, gearboxes, and wheels as individual units. Folks buy two of those, some batteries, a battery charger, and then some sort of controller. The controller part intimidated me a bit. I don't know much about those and I'm sure there'd be a learning curve there, assembling all of this. And I still may run into that.

But, based on pricing I was seeing on eBay and Craig's List, it seemed like I'd be better-off buying an entire used electric wheelchair, with all of these parts installed and already working.

And so, on Saturday night, I bought this from a local guy off of eBay:

Used chair, but new batteries, and a built-in charger... all for $425...delivered to my door!

Now, obviously, I'm going to start removing the seat and anything "extra", while trying to maintain the joystick controls connection. And I'm going to have to study the wheel situation and see if the casters can be moved inward, a bit.

I should mention that, thanks to the B9 Builders Club, I have printed off the blueprints of B9. Based on my own height, I felt I should expand his dimensions by... oh, I can't remember off the top of my head if it's 8% or 10%. But I have that written down in my file on this. So, I know how big my B9's base will have to be...and I'm going to have to compare those dimensions with the wheelchair base dimensions as I go about stripping down the chair.

Now, regarding B9's voice, I just ordered a CD containing over 300 phrases said by the robot during the TV show, cleaned up. There are apparently two different CDs sold by two different B9 Builders Club members. I bought what members said was the better one, "iB9 Talk". I just ordered that a few minutes ago.

That CD comes with a built-in interface to let you run a sort of "soundboard" on a PC and use that to select phrases / to make B9 "talk". However, I'm going to have to figure out a way for this to be controlled remotely, by someone other than me (because I'll be having a hard enough time steering B9 and moving BOTH arms). Now, how to do this? I'm not sure yet. That's one major "line of research" I'll have to do. Someone in the B9 club told me they use a Bluetooth transmitter to send to their B9. My wife and I both have Nexus 7's, but they don't come with any sort of Bluetooth transmission capabilities (I think?).

So, this is certainly a long enough post for today!

If you have ideas for construction or materials-sources, please let me know! (I have done a bit of digging regarding the arms, but I'll save that post for another day.)

Thank you!

-= Dave R. =-