With the success of WandaVision, it was only a matter of time before a Wanda project kicked off in my little corner of the universe.

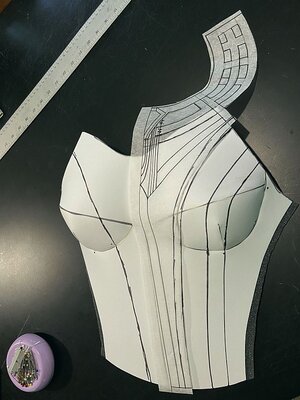

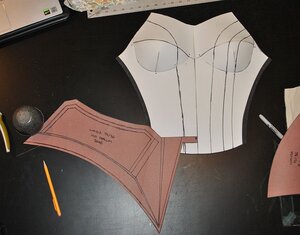

The starting point for the project was building a bodice mock-up that would fit the client, who was remote. As usual, I began in muslin, sent it off for a fitting, and then started sketching the details on the altered toile.

With the details roughly sketched out and the pattern fit confirmed, the toile was cut apart and the base construction began.

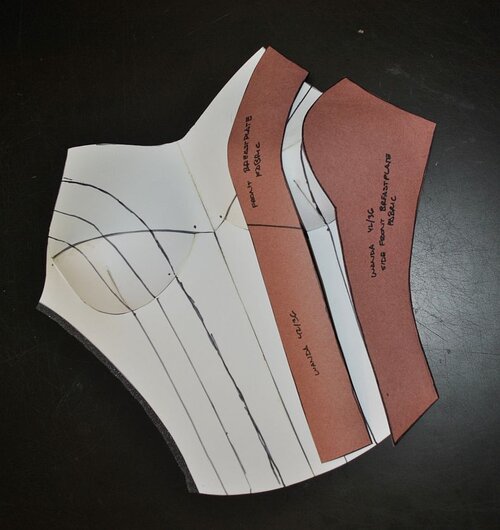

This costume build is similar to the Captain Marvel suit - it has a layered, very structured front with a lot of detail and needs a foundation that can support that structure but still be light, thin, and flexible. So, to create this piece, I wanted to create a breastplate template that could be built in 2mm EVA foam backed with headliner for comfort and padding.

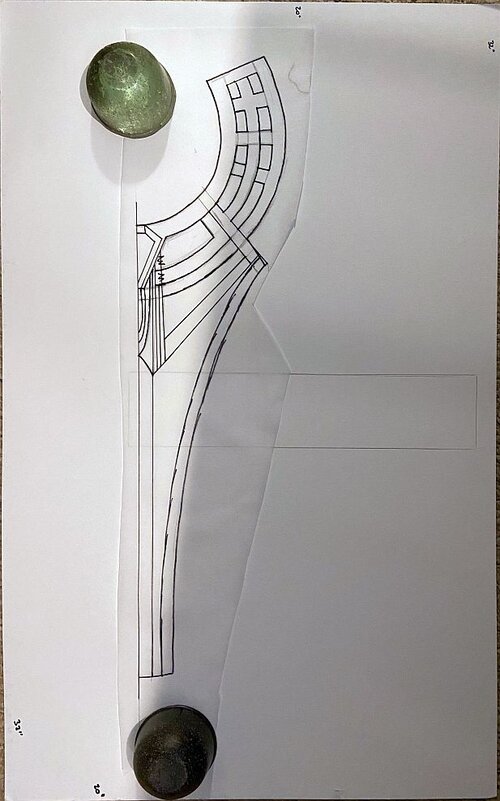

Once the breastplate was assembled, the detail pieces were made using Swedish tracing paper to create rough sketches to scale.

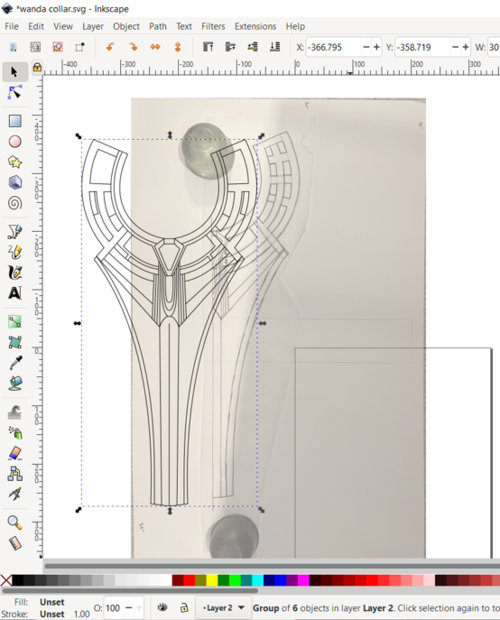

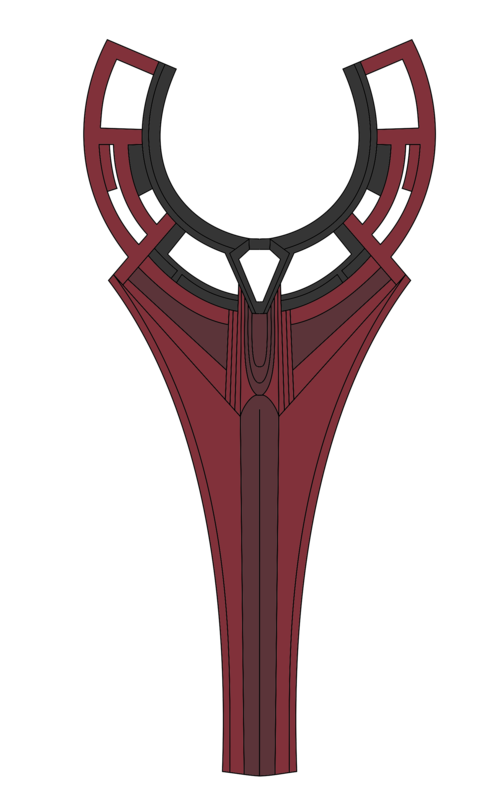

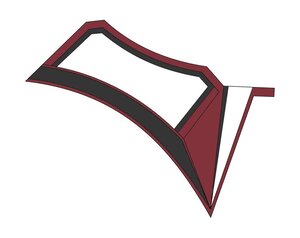

To create the detail pieces for the bodice, I photographed the sketches on a board with set dimensions, imported the images into Inkscape, and then traced them to create full-scale, clean templates for the pieces.

At the same time, I created the templates for the peplum and the headpiece in the same manner.

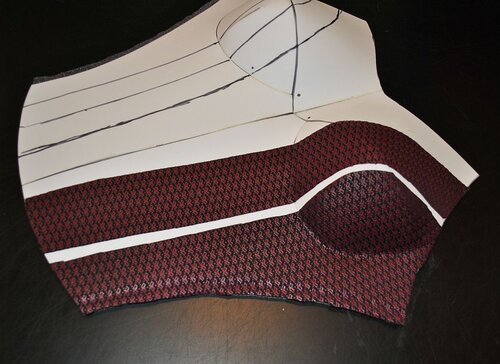

In the meantime, the specialty fabrics were ordered. These are silicone printed spandex in burgundy and black from Parallel Life Studios in France.

Once the fabrics arrived, I began by creating patterns for the breastplate for the areas to be covered with the fabric. I didn’t want to completely cover the breastplate with the printed fabrics for 2 reasons:

In order to increase wearing ease and movement, I didn’t want the entire bodice made of foam. So, the sides and back of the bodice (again, like Captain Marvel) were made in the printed fabric backed with broadcloth. I created the patterns for those pieces using the altered toile and added the sides to the breastplate.

The finished bodice zips down the sides so, at this point, I needed to finish the edges at the arms and bottom. These edges were bound in a burgundy thin faux leather that matches the printed fabric.

Next up: The back of the bodice and foam detail pieces get underway. Stay tuned!

The starting point for the project was building a bodice mock-up that would fit the client, who was remote. As usual, I began in muslin, sent it off for a fitting, and then started sketching the details on the altered toile.

With the details roughly sketched out and the pattern fit confirmed, the toile was cut apart and the base construction began.

This costume build is similar to the Captain Marvel suit - it has a layered, very structured front with a lot of detail and needs a foundation that can support that structure but still be light, thin, and flexible. So, to create this piece, I wanted to create a breastplate template that could be built in 2mm EVA foam backed with headliner for comfort and padding.

Once the breastplate was assembled, the detail pieces were made using Swedish tracing paper to create rough sketches to scale.

To create the detail pieces for the bodice, I photographed the sketches on a board with set dimensions, imported the images into Inkscape, and then traced them to create full-scale, clean templates for the pieces.

At the same time, I created the templates for the peplum and the headpiece in the same manner.

In the meantime, the specialty fabrics were ordered. These are silicone printed spandex in burgundy and black from Parallel Life Studios in France.

Once the fabrics arrived, I began by creating patterns for the breastplate for the areas to be covered with the fabric. I didn’t want to completely cover the breastplate with the printed fabrics for 2 reasons:

- The fabric is quite expensive and I have a limited amount, so I didn’t want to use it anywhere other than where it will be seen.

- When I glue the foam detail pieces to the breastplate, I want them to be glued directly to the breastplate and not to the fabric. That way, there’s not risk of the pieces pulling away from the base. Also, the foam detail pieces will lock the edges of the fabric down.

In order to increase wearing ease and movement, I didn’t want the entire bodice made of foam. So, the sides and back of the bodice (again, like Captain Marvel) were made in the printed fabric backed with broadcloth. I created the patterns for those pieces using the altered toile and added the sides to the breastplate.

The finished bodice zips down the sides so, at this point, I needed to finish the edges at the arms and bottom. These edges were bound in a burgundy thin faux leather that matches the printed fabric.

Next up: The back of the bodice and foam detail pieces get underway. Stay tuned!