***EDIT***

I changed the title to reflect the direction this thread was heading - plaster casting. See posts #5 through #7 for the change of direction.

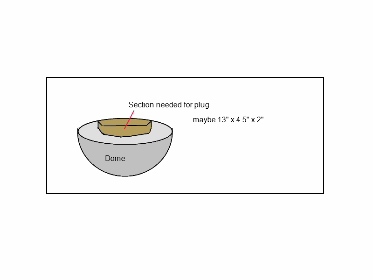

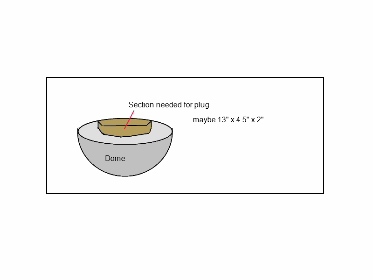

I want to vac form part of the inside of an acrylic dome that is too big to put on my little vac form box. I want to make some thin detail panels to apply to the outside of the dome.

My first plan was to press some clay onto the inner surface of the dome and pull it out (hopefully intact) and use it as a plug for my vac form box

Questions:

(I am trying to keep this down to what I have on hand if possible.)

1. I am plannning on using a medium sculpting clay I normally use for molding and casting. I am betting I will have trouble with it sticking to the inside of the dome when I want to remove it for use as a plug. Is there a 'clay realease' I can use for this, or some other trick?

2. This is not a clay that will harden with backing or anything. If left cold for long enough it will stiffin somewhat. I want to form .020" styrene over it in the vac form box. Will the heated plastic distort the clay when the vac forming proccess takes place?

3. Is it possible to pour resin into the acrylic dome using powder as a release agent and just let is swirl and pool to make the surface of my plug? It would be thin, but I would back it with lots of clay and can putty/sand the surface to get out any glaring omperfections to make the vac form plug.

I changed the title to reflect the direction this thread was heading - plaster casting. See posts #5 through #7 for the change of direction.

I want to vac form part of the inside of an acrylic dome that is too big to put on my little vac form box. I want to make some thin detail panels to apply to the outside of the dome.

My first plan was to press some clay onto the inner surface of the dome and pull it out (hopefully intact) and use it as a plug for my vac form box

Questions:

(I am trying to keep this down to what I have on hand if possible.)

1. I am plannning on using a medium sculpting clay I normally use for molding and casting. I am betting I will have trouble with it sticking to the inside of the dome when I want to remove it for use as a plug. Is there a 'clay realease' I can use for this, or some other trick?

2. This is not a clay that will harden with backing or anything. If left cold for long enough it will stiffin somewhat. I want to form .020" styrene over it in the vac form box. Will the heated plastic distort the clay when the vac forming proccess takes place?

3. Is it possible to pour resin into the acrylic dome using powder as a release agent and just let is swirl and pool to make the surface of my plug? It would be thin, but I would back it with lots of clay and can putty/sand the surface to get out any glaring omperfections to make the vac form plug.

Last edited: