Tatsutetsu

Member

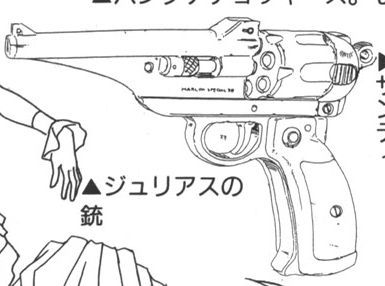

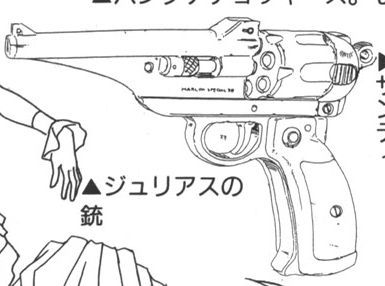

Here’s my build log for a scratch built Frank Marlon Special revolver, a signature firearm from the Trigun universe I’ve wanted to make for a while now due to its distinct look and its significance to the story in the episode it featured in

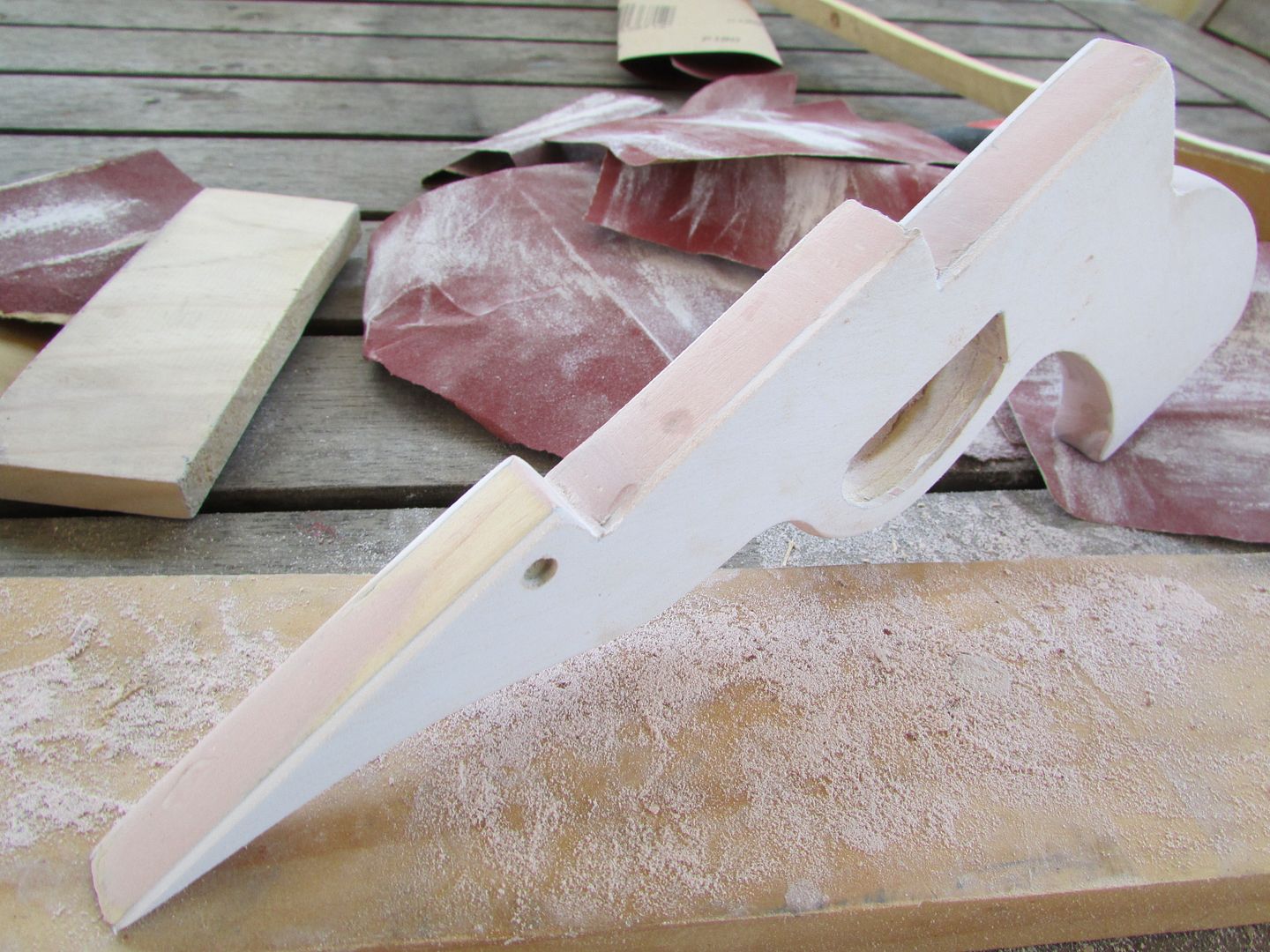

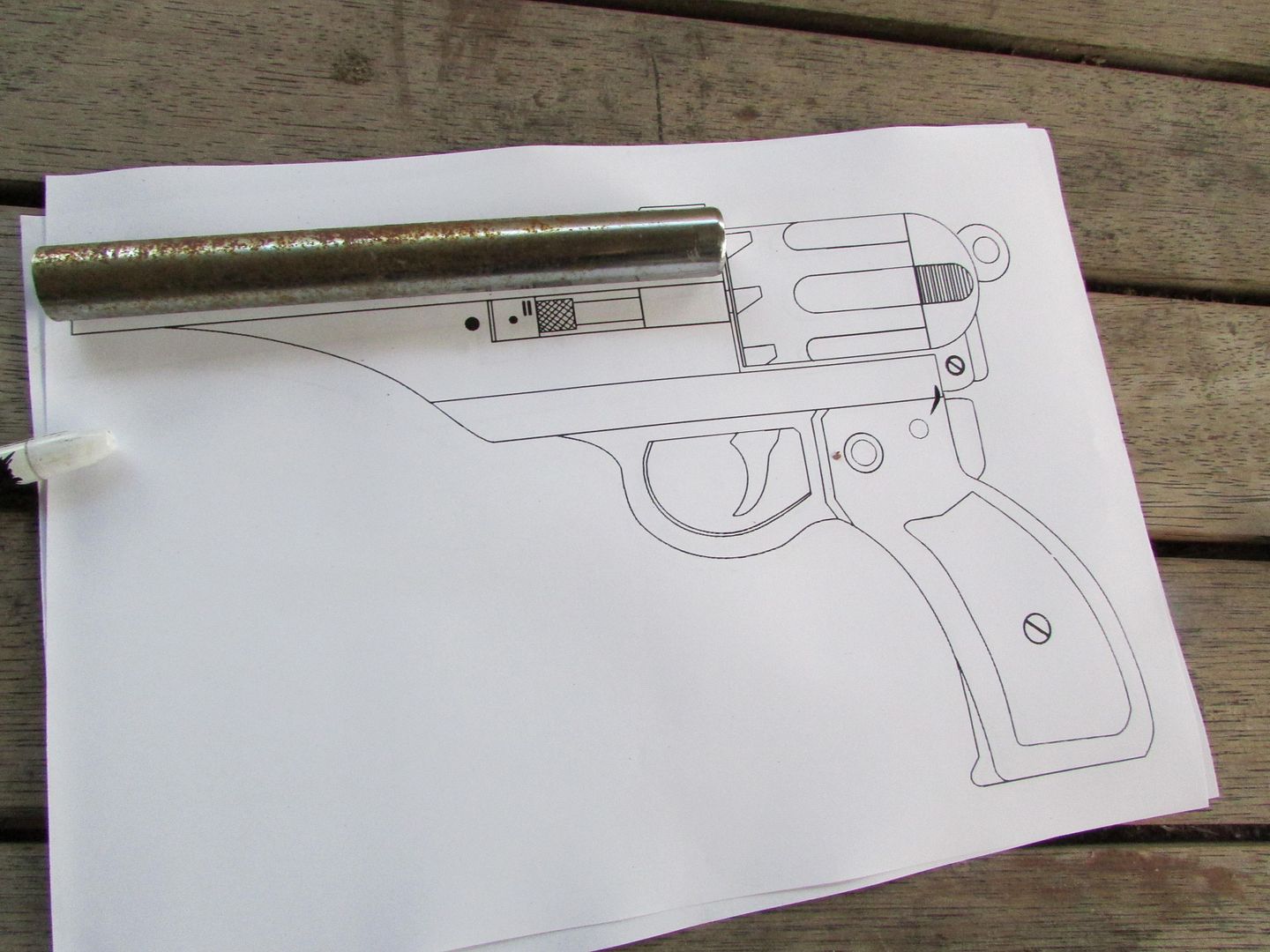

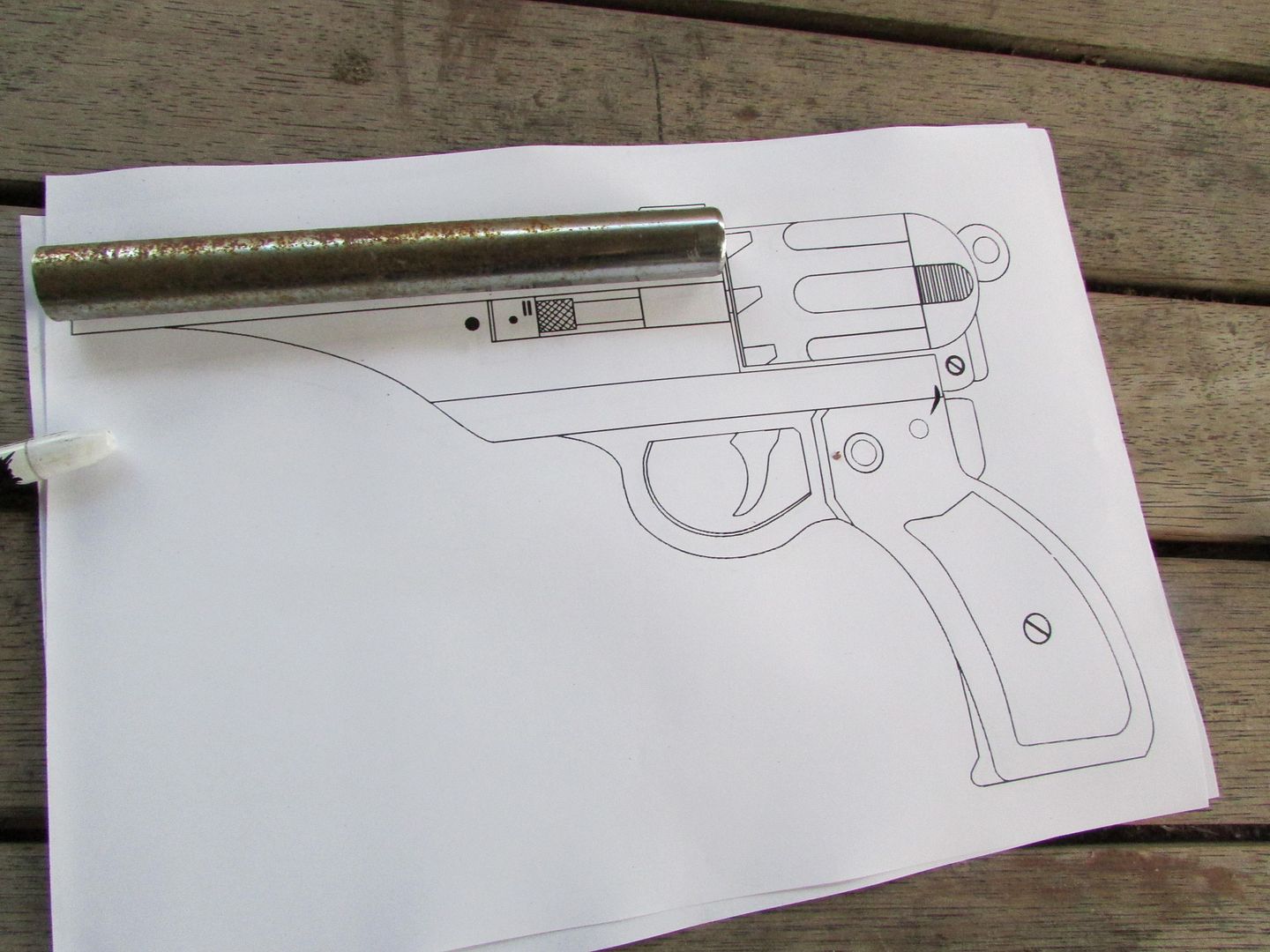

To begin with in terms of scaling, using what glimpses of the gun that the episode provided I decided to base off the dimensions of the revolver with reference to my own thumb as the length of the cylinder and then scaled all related parts to that baseline length and the reference from the concept artbook, resulting in a set of plans I could then use for the build.

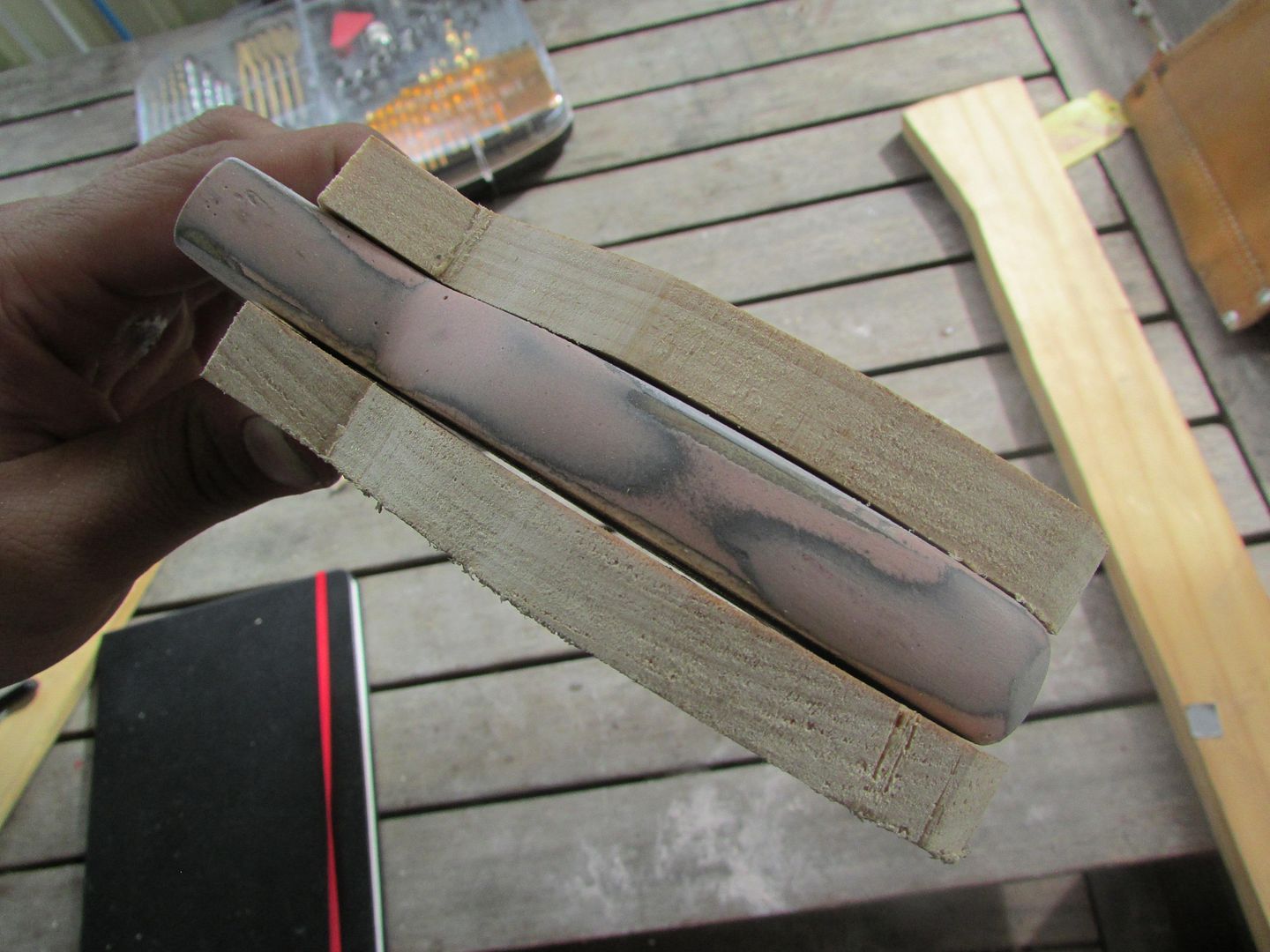

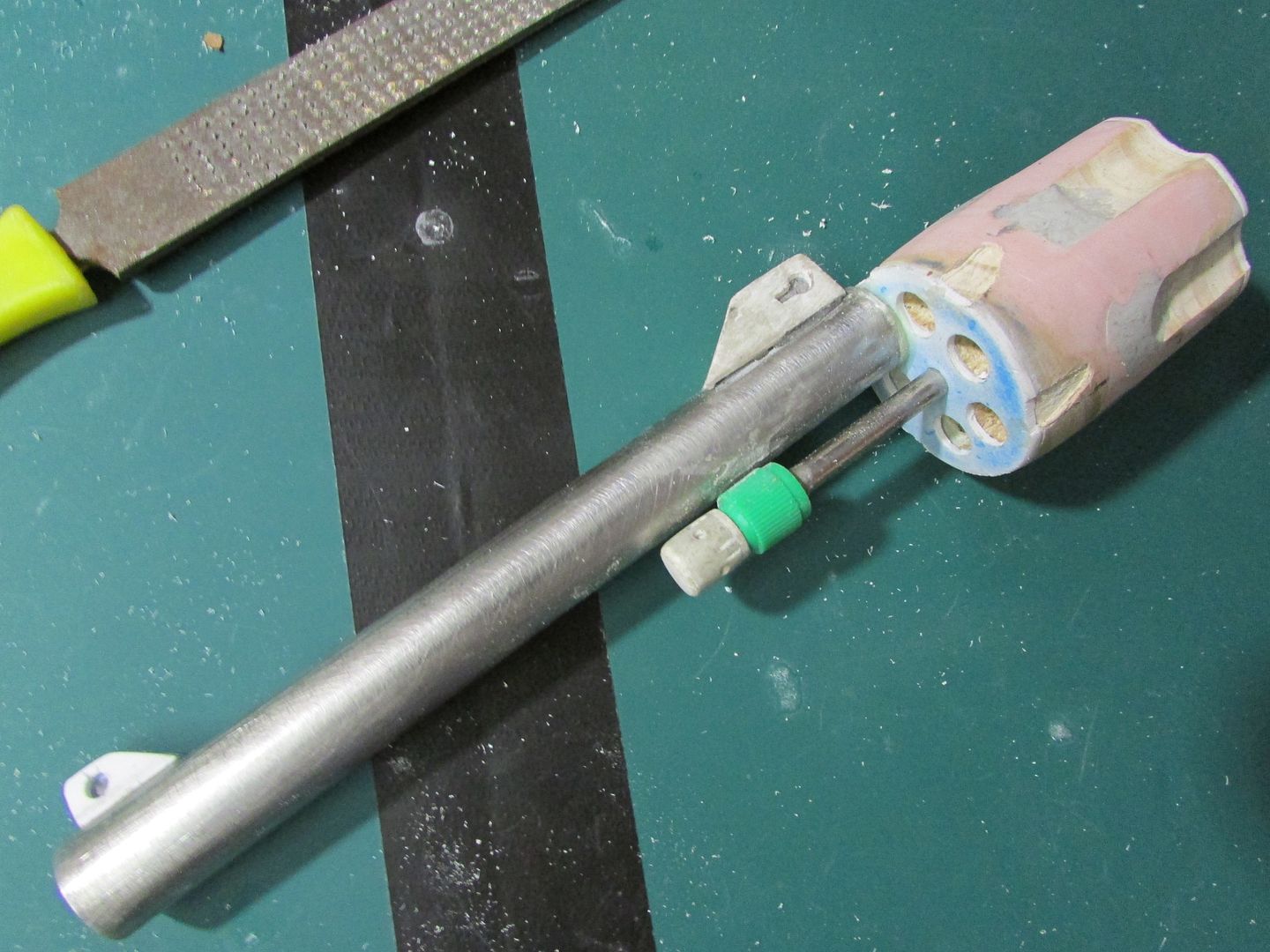

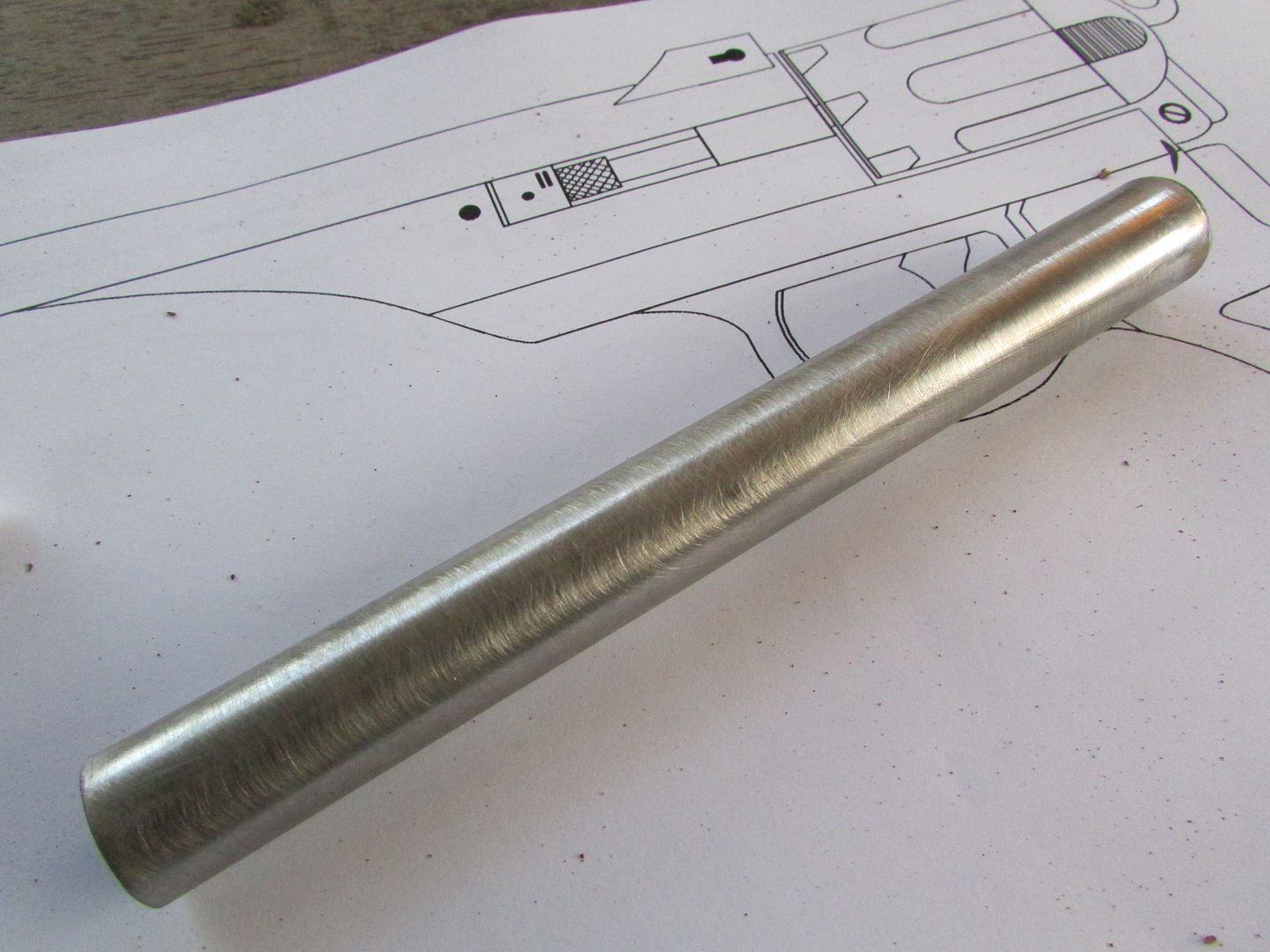

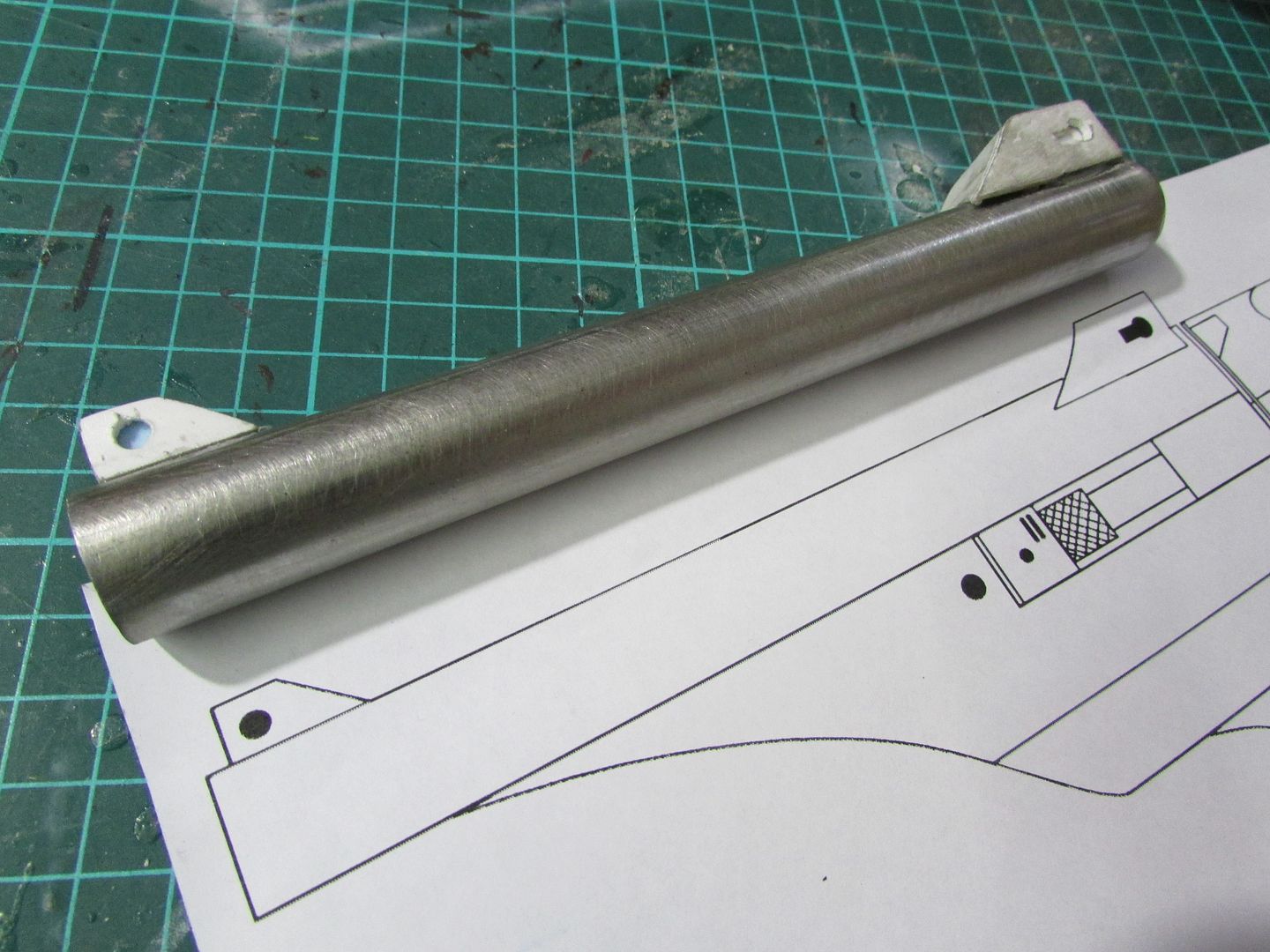

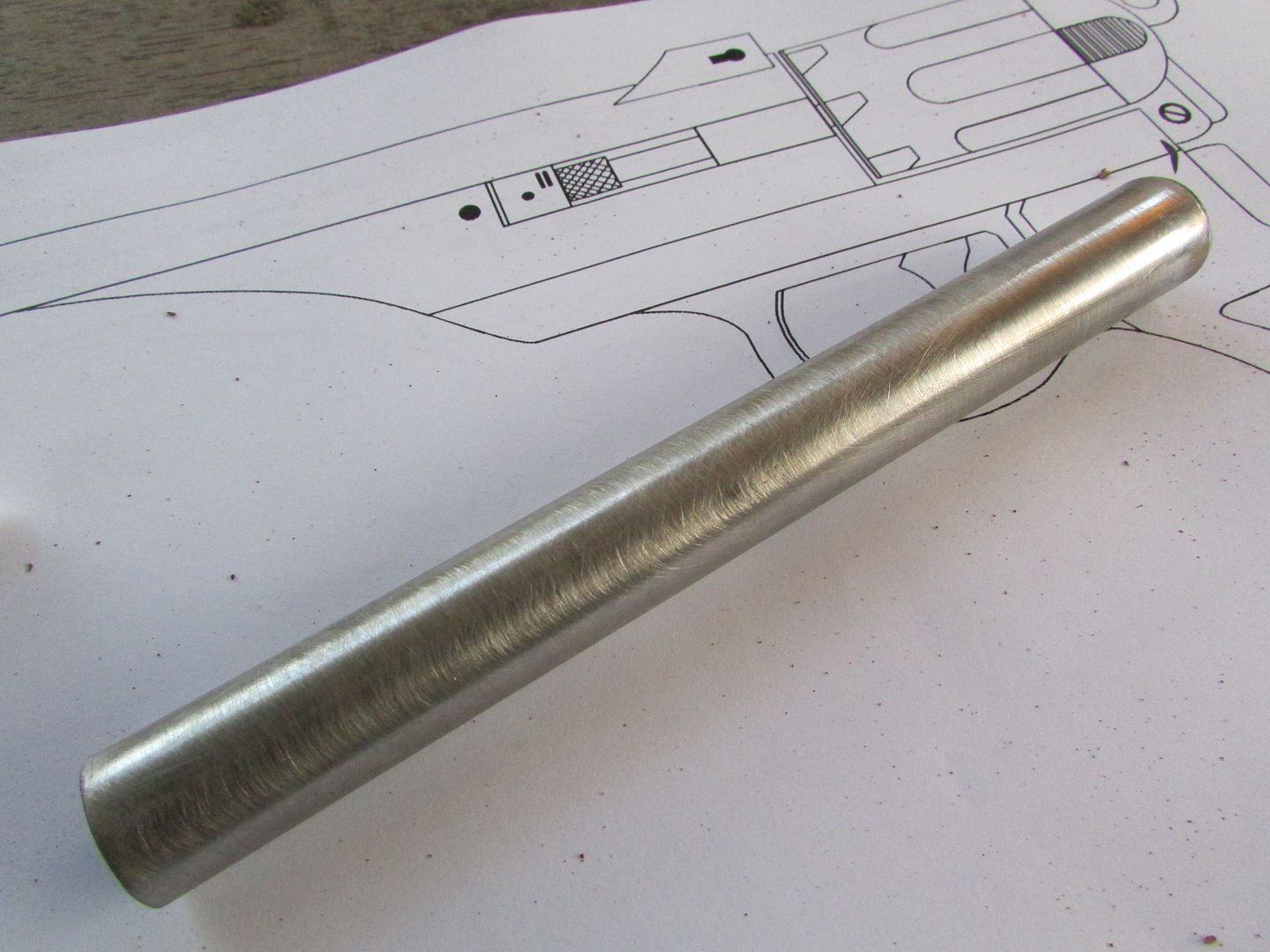

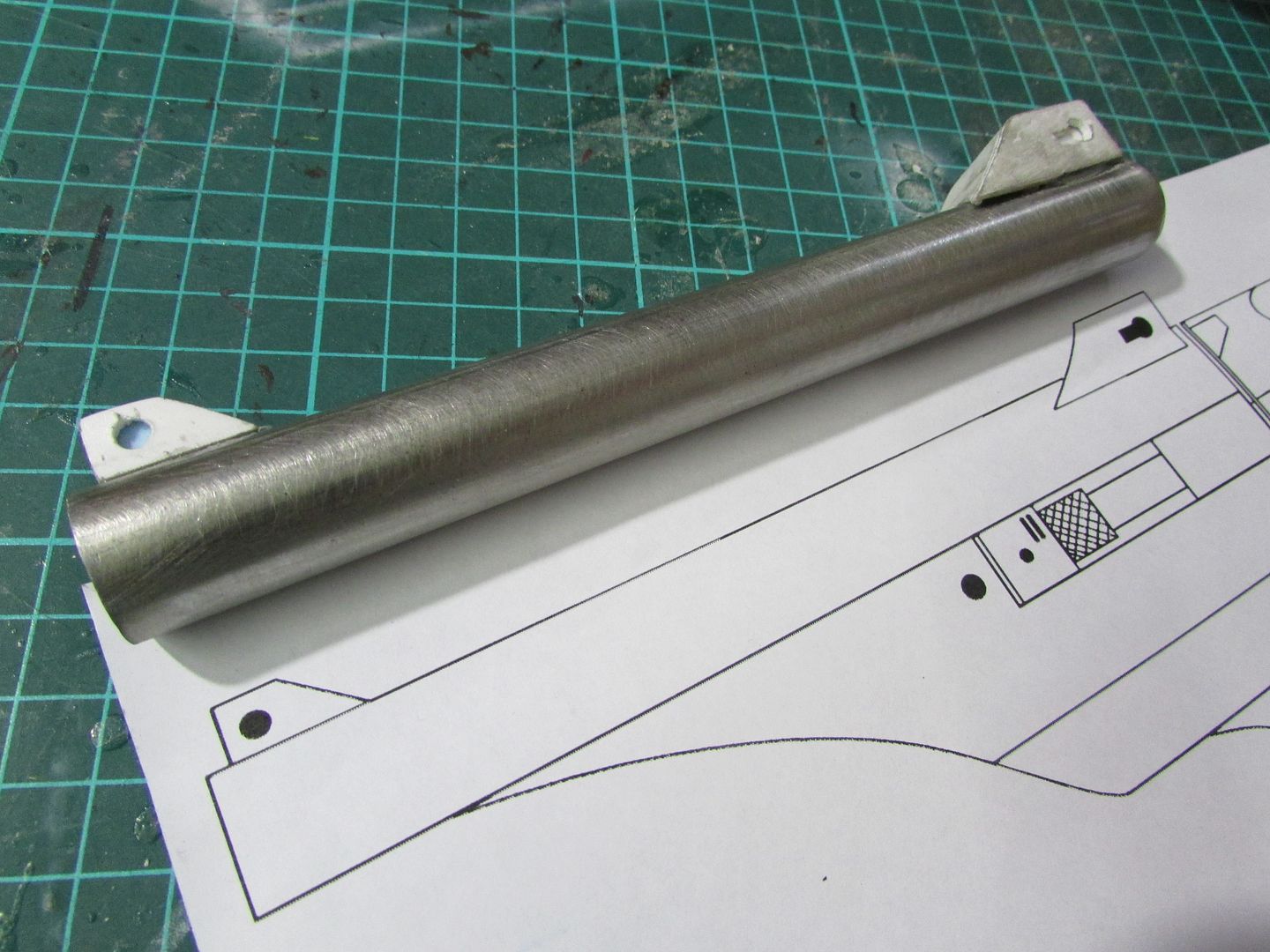

Starting off with the barrel of the gun, I found an old rusted steel tube from what was once a clothes dryer, whose diameter (18mm) suited the scaled dimensions of the plans.So I cut it to length using a hacksaw and roughened the cut edge using some 80 grit sandpaper to eliminate the risk of cutting oneself.

To clean off the rust build up I used some 240 grit sandpaper to get it back to its pristine state, and at 175mm in length the barrel will do just fine.

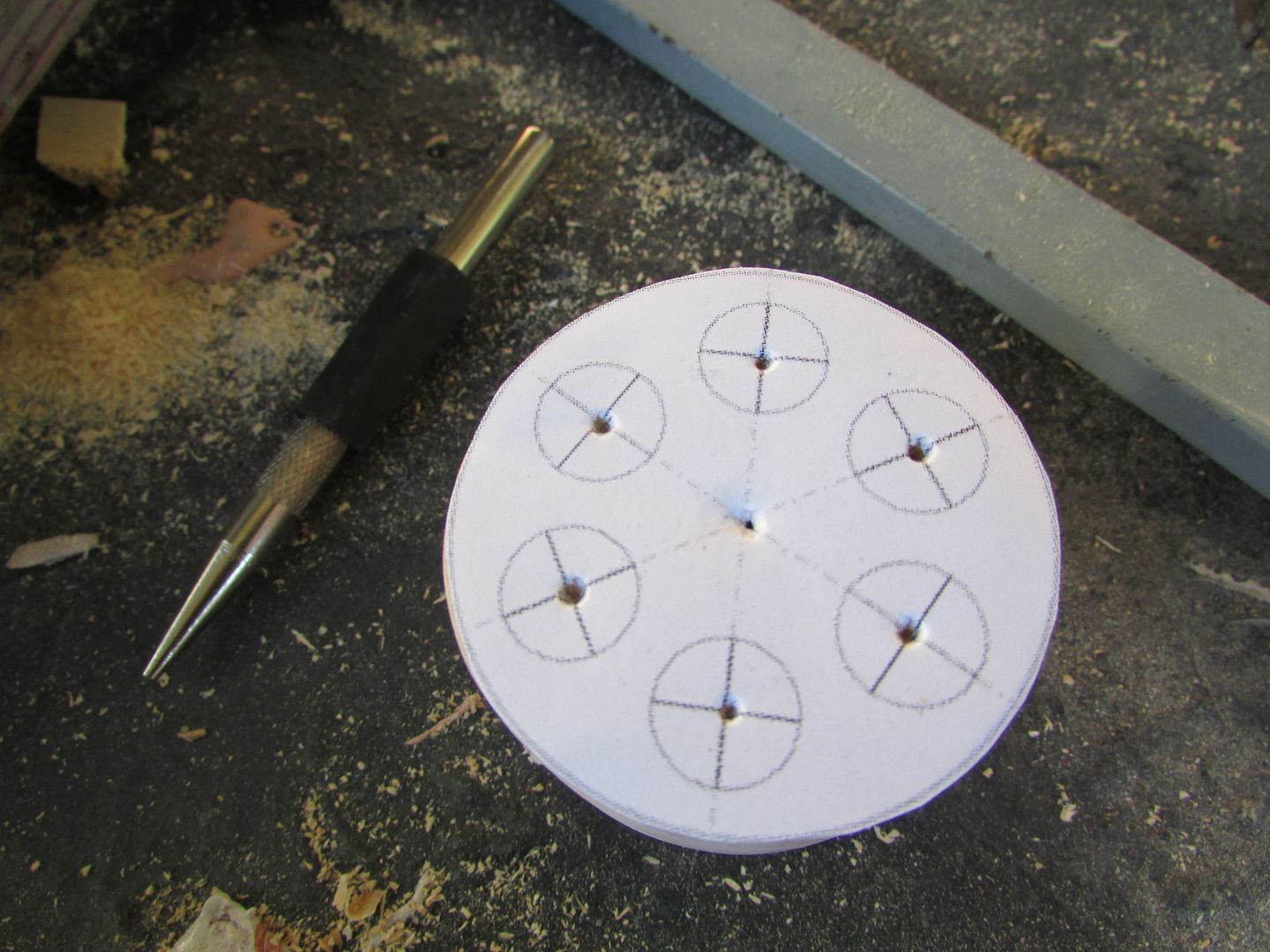

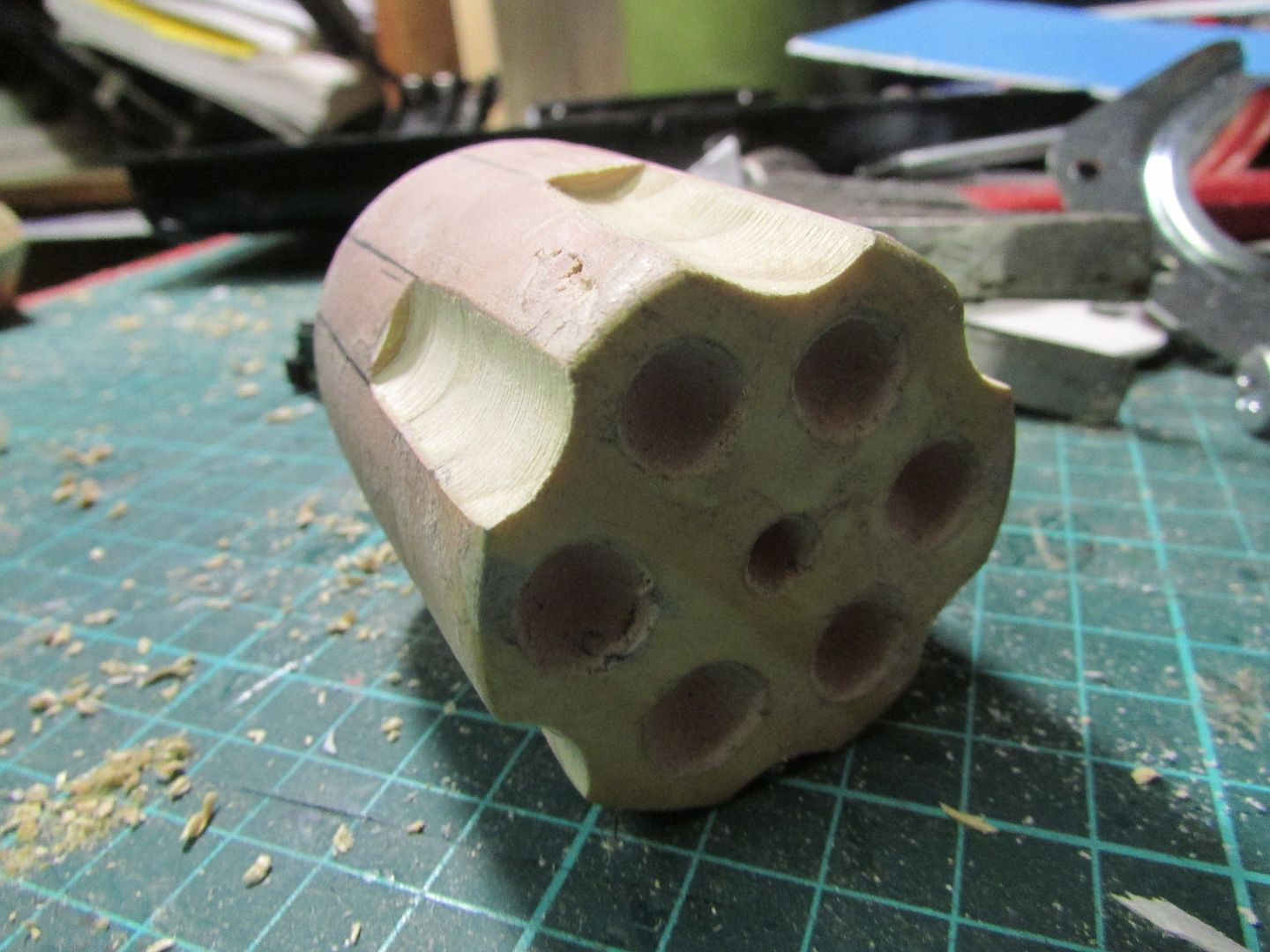

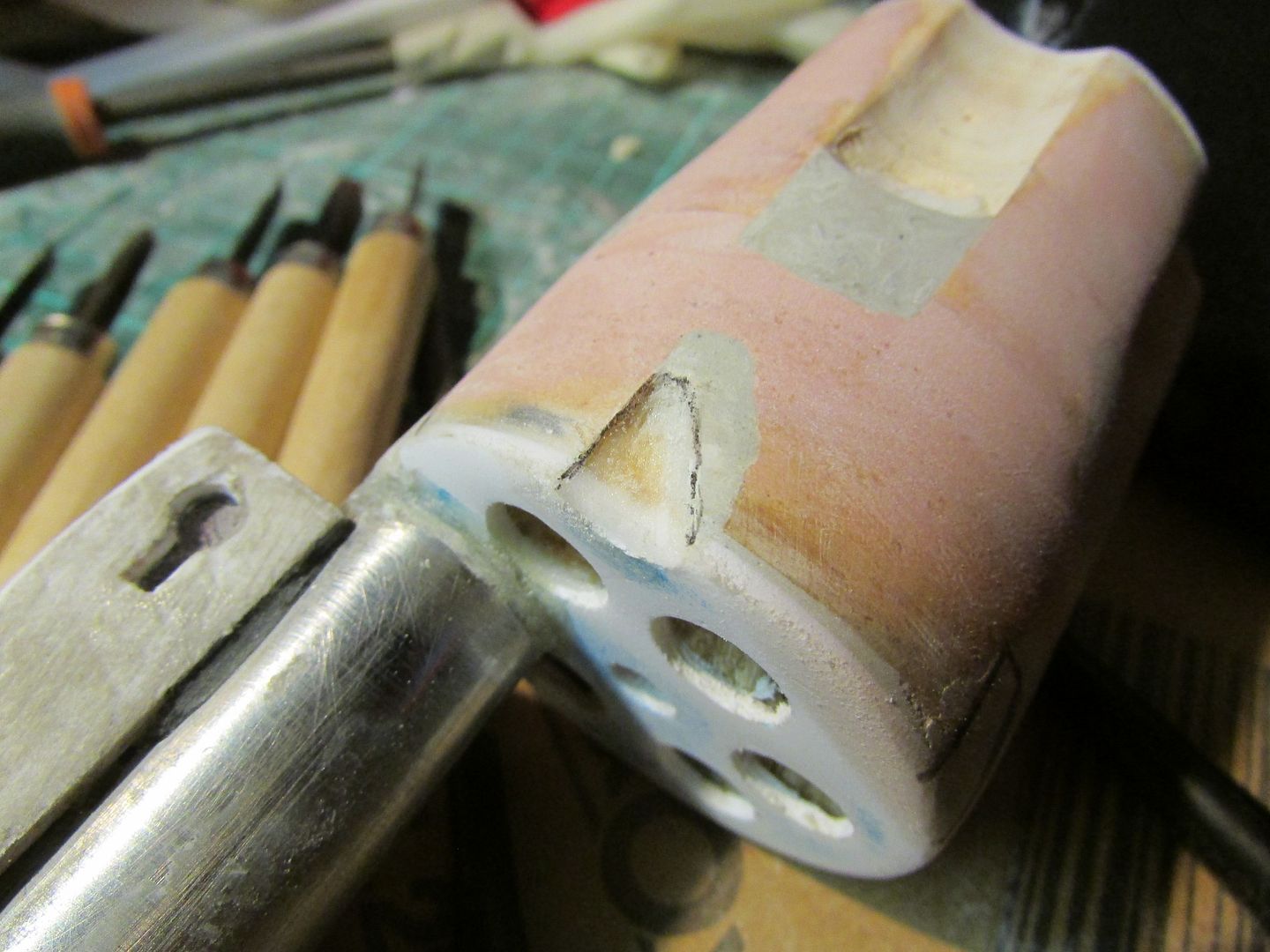

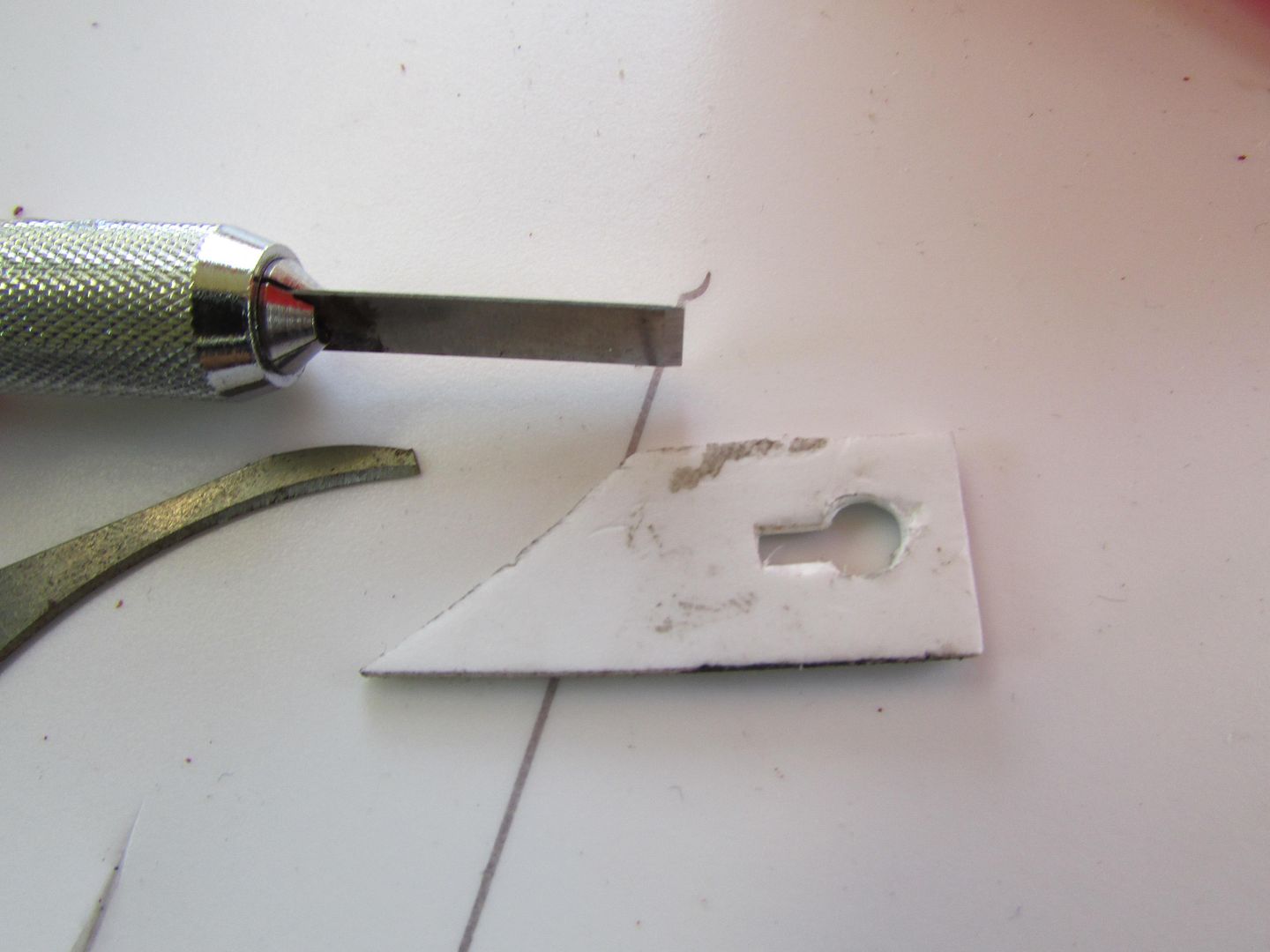

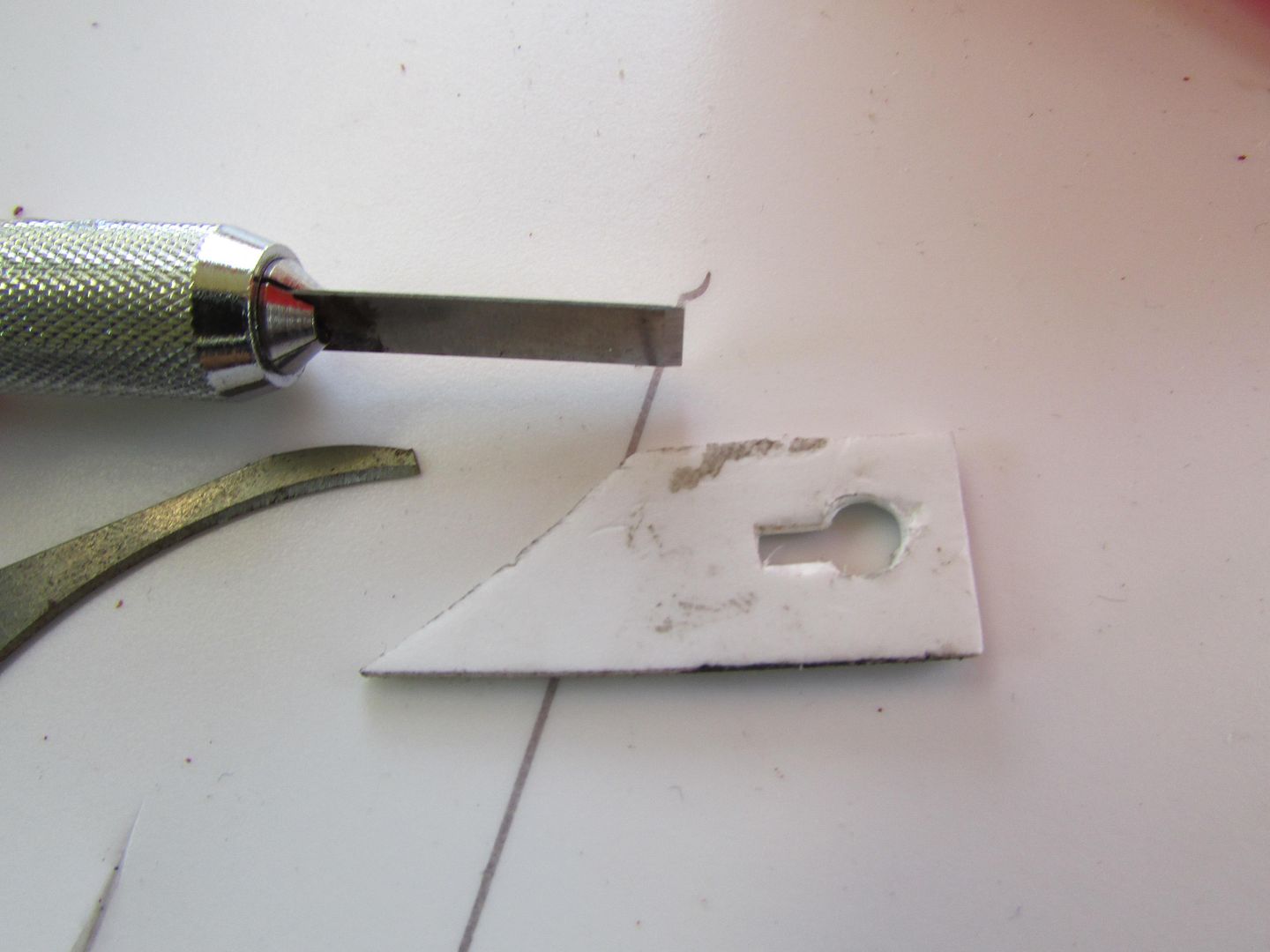

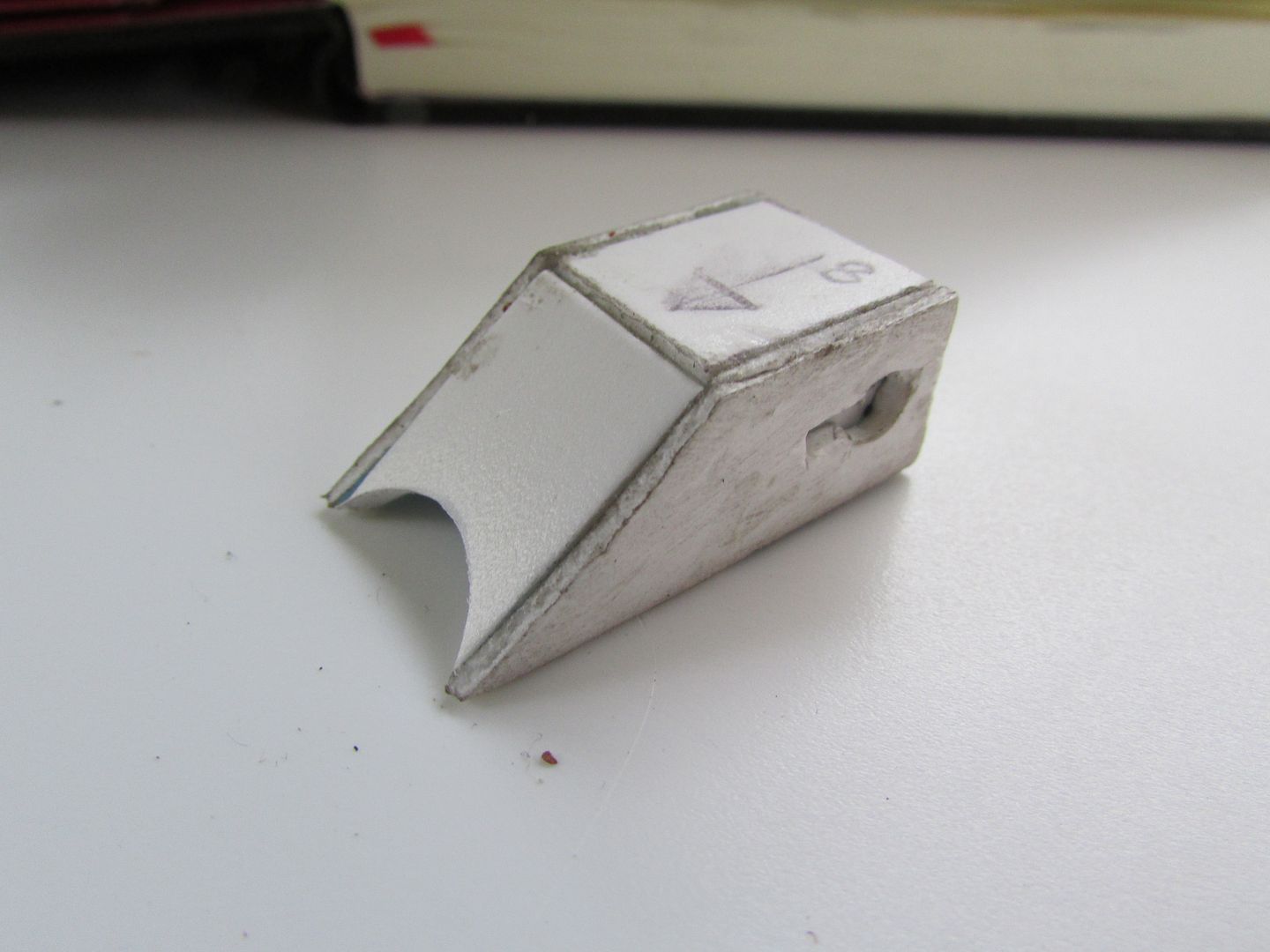

Moving on to making the sights on the barrel I decided to use some plastic sheeting, and starting with the side pieces and gradually built the component so it would be able to eventually sit on the barrel and detailing the pieces using a drill and a hobby knife kit.

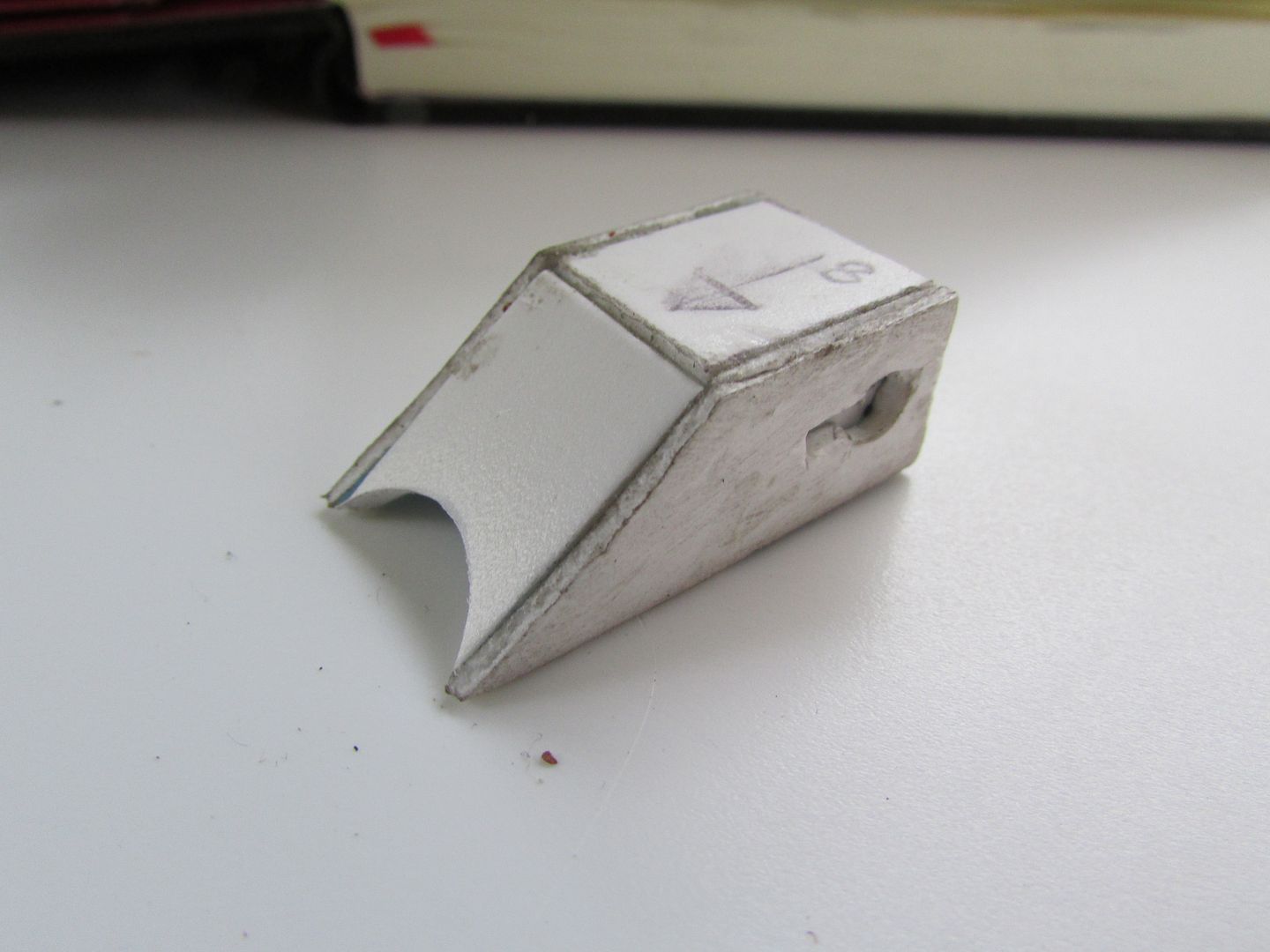

However when it finally came to the front and back panels of the sight, to be able to accommodate the curvature of the barrel so it would maintain alignment and sit flush I used a rotary tool with a grinding drum bit and incrementally widdled away the edges until it sat flush with the barrel but still maintained alignment.

With a nice sit I then used some epoxy adhesive to attach it to the barrel proper and repeated a similar process for the sight at the end of the barrel.

To begin with in terms of scaling, using what glimpses of the gun that the episode provided I decided to base off the dimensions of the revolver with reference to my own thumb as the length of the cylinder and then scaled all related parts to that baseline length and the reference from the concept artbook, resulting in a set of plans I could then use for the build.

Starting off with the barrel of the gun, I found an old rusted steel tube from what was once a clothes dryer, whose diameter (18mm) suited the scaled dimensions of the plans.So I cut it to length using a hacksaw and roughened the cut edge using some 80 grit sandpaper to eliminate the risk of cutting oneself.

To clean off the rust build up I used some 240 grit sandpaper to get it back to its pristine state, and at 175mm in length the barrel will do just fine.

However when it finally came to the front and back panels of the sight, to be able to accommodate the curvature of the barrel so it would maintain alignment and sit flush I used a rotary tool with a grinding drum bit and incrementally widdled away the edges until it sat flush with the barrel but still maintained alignment.

With a nice sit I then used some epoxy adhesive to attach it to the barrel proper and repeated a similar process for the sight at the end of the barrel.

Last edited: