I've been a Trekkie since high school in the 70's. Not a Trekker or a Trekkist, just a good old fashioned Trekkie. I'm a geek, and proud of it! I've always wanted to make a Phaser. During high school, and college, I tried on several occasions to make one, out of whatever materials I had on hand, balsa wood, plaster, foam... at the time my skill set just wasn't developed and none of these attempts came to fruition. The funny thing, is that I've been a professional movie and TV prop and model maker for more than 25 years now, and I never got around to making my phaser. Until now...

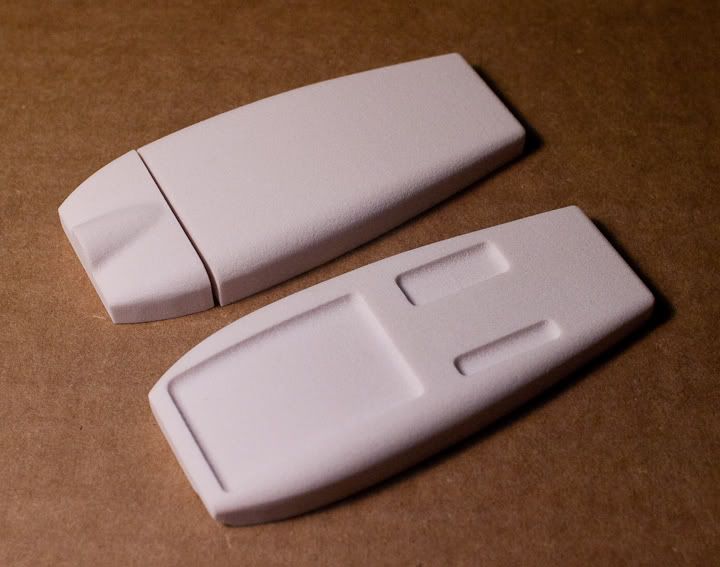

The first step is to make a CG model the phasers, both the Type One hand phaser and Type Two pistol grip in Rhino. From this model, the bodies of the phasers will be milled out of high density urethane foam on my CNC router. From those pieces, molds and castings.

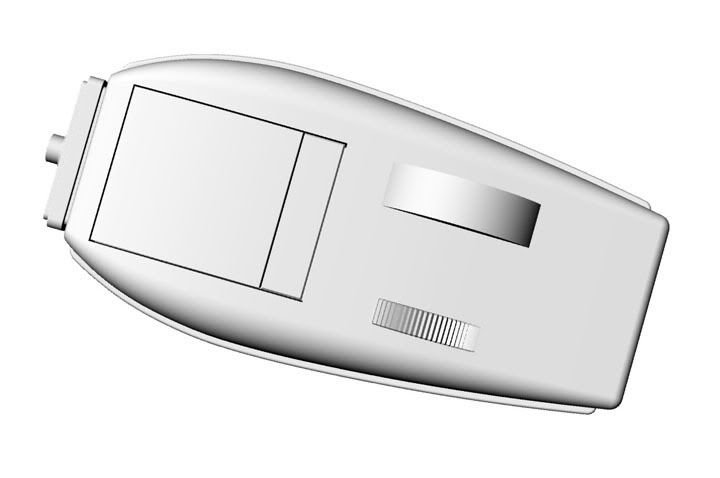

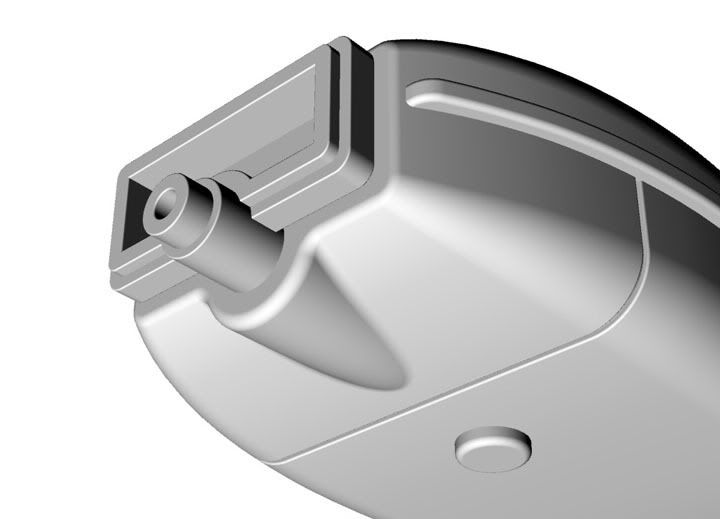

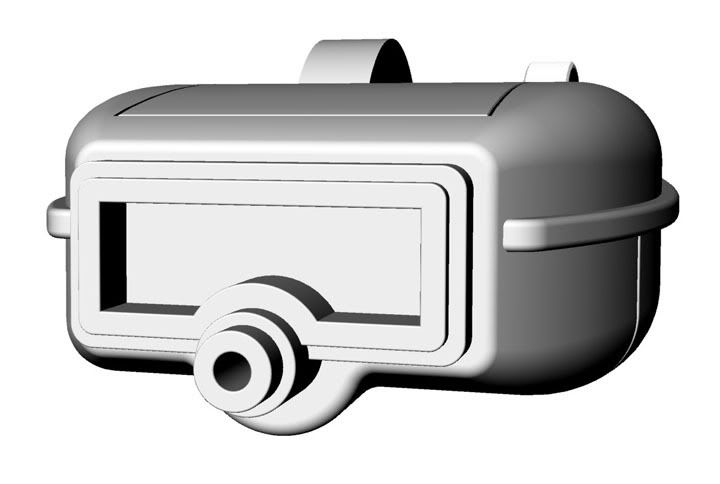

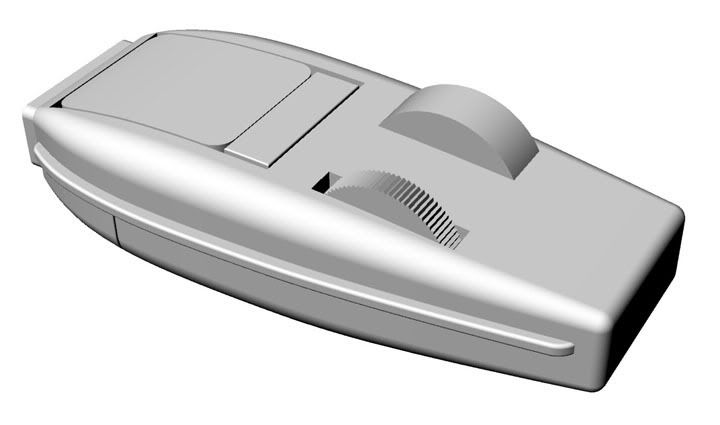

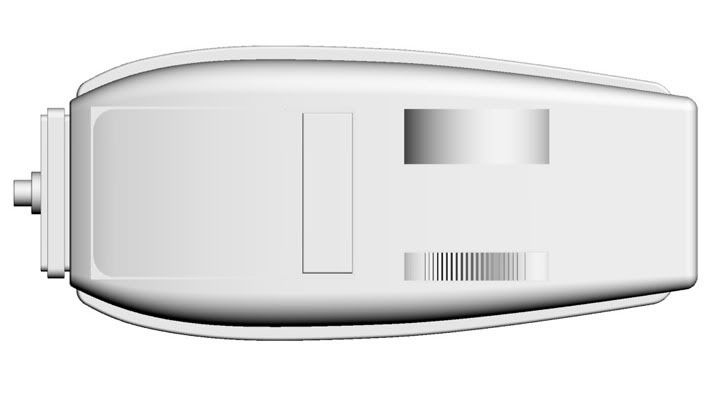

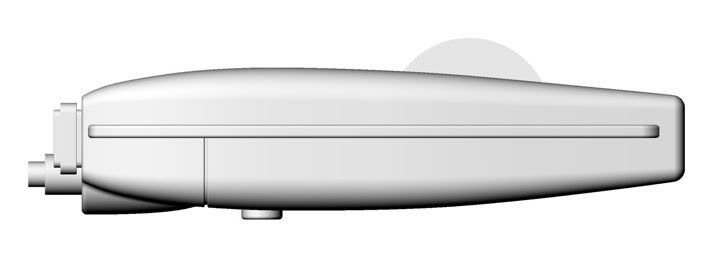

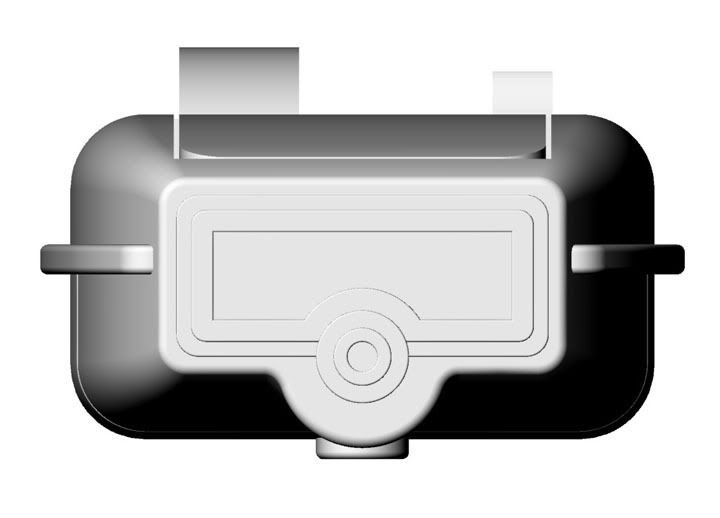

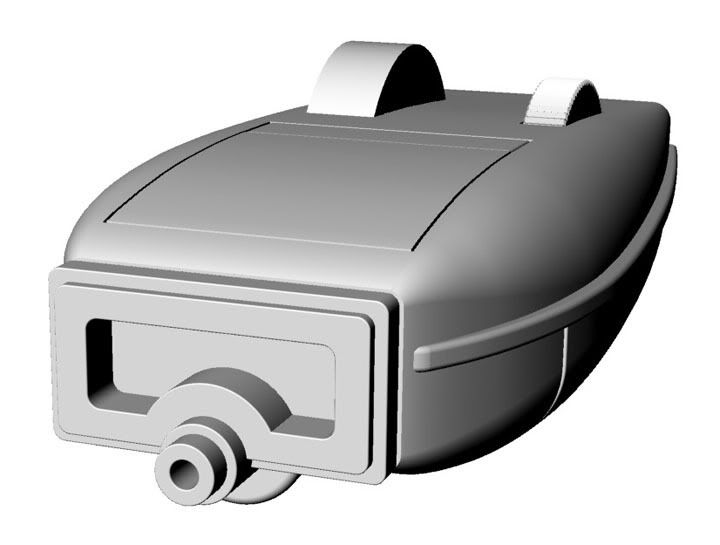

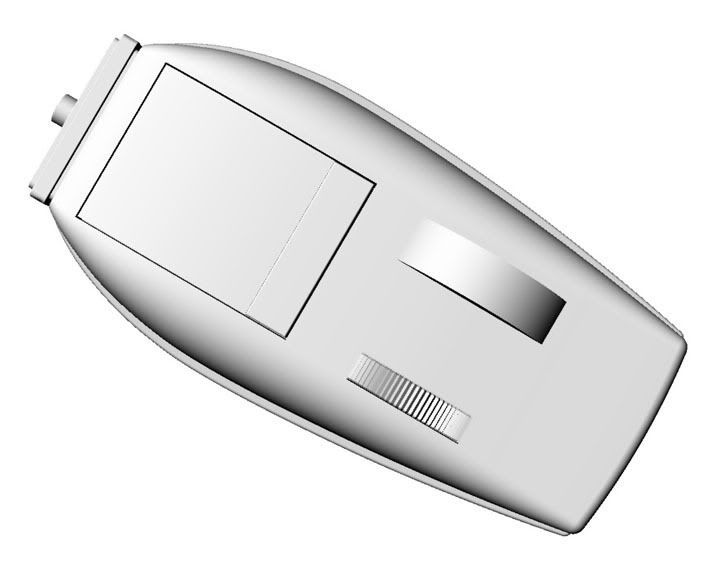

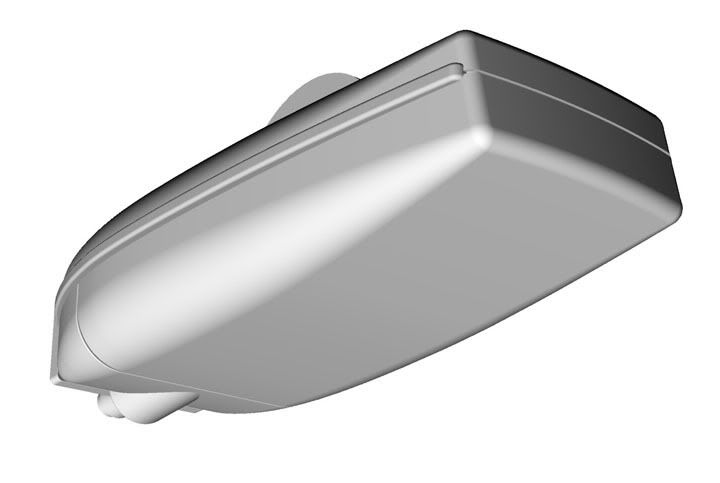

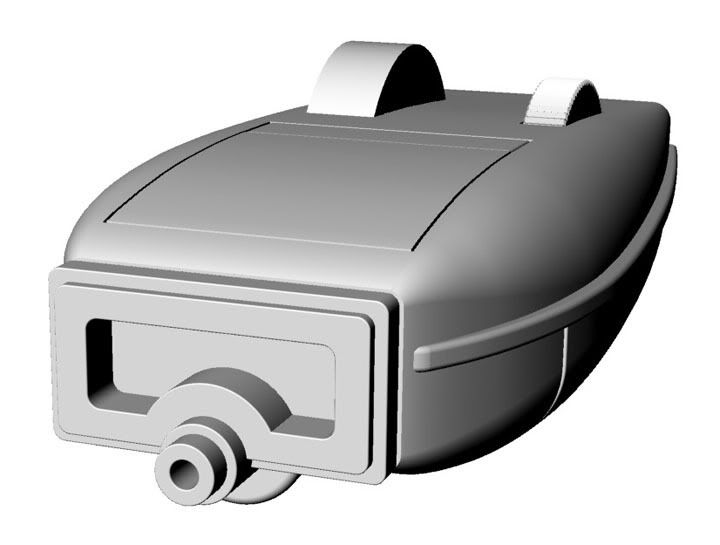

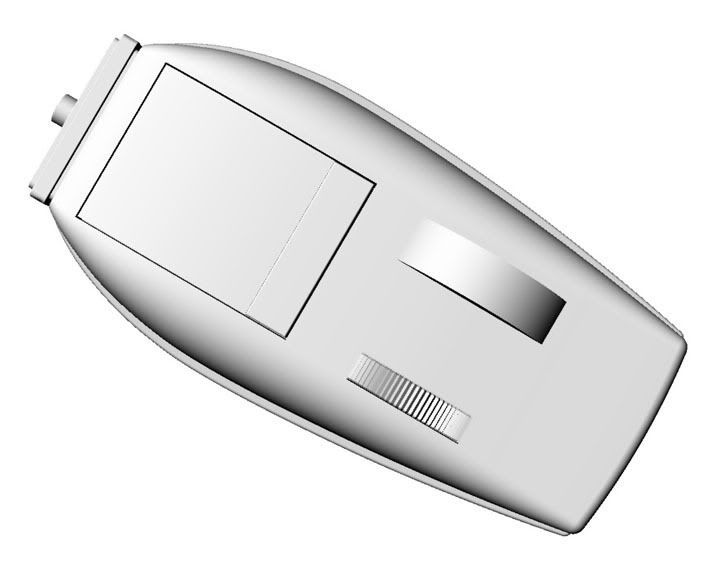

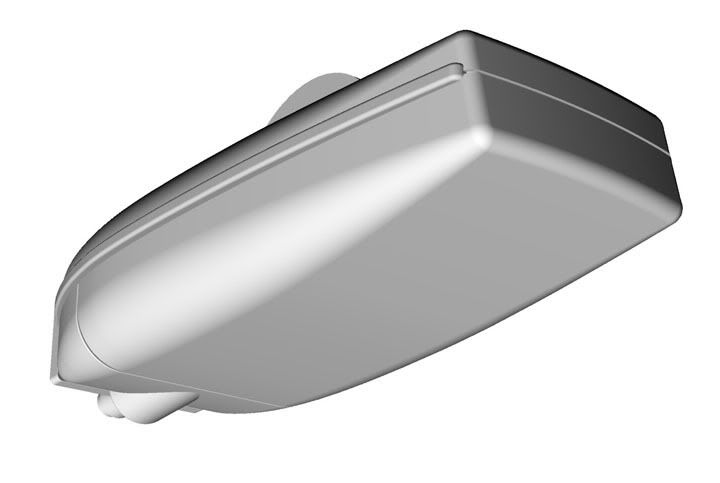

Here are some work in progress renderings of the Type One Phaser. It's not completely done. I'm not happy with the emitter fairing on the bottom and it still needs the latching recess modeled in as well as the screw on the bottom. The texture for the "crispy" grill will be modeled separately as a die that will be milled flat and used to embose the texture into thin aluminum sheet, which can then be gently bent to match the curve of the top surface. If any of you TOS experts out there see something that I did wrong, or missed, let me know.

The first step is to make a CG model the phasers, both the Type One hand phaser and Type Two pistol grip in Rhino. From this model, the bodies of the phasers will be milled out of high density urethane foam on my CNC router. From those pieces, molds and castings.

Here are some work in progress renderings of the Type One Phaser. It's not completely done. I'm not happy with the emitter fairing on the bottom and it still needs the latching recess modeled in as well as the screw on the bottom. The texture for the "crispy" grill will be modeled separately as a die that will be milled flat and used to embose the texture into thin aluminum sheet, which can then be gently bent to match the curve of the top surface. If any of you TOS experts out there see something that I did wrong, or missed, let me know.

Last edited: