feek61

Sr Member

I have been working on a studio scale TOS shuttlecraft for a while now. I had to take about a year break but now I’m back to work on it. I am trying to finish the hull and get rid of all of the blemishes but the only thing I’ve been using is Bondo. There has to be something better for detail work. What is best for filling small holes and contour variations? The work here on the RPF is really quite stunning and the detail some of you guys are getting is incredible. What are you using to get the smooth lines you are achieving? Here are a few pictures of what I've done. Keep in mind that I'm an amateur so don't be too harsh :lol

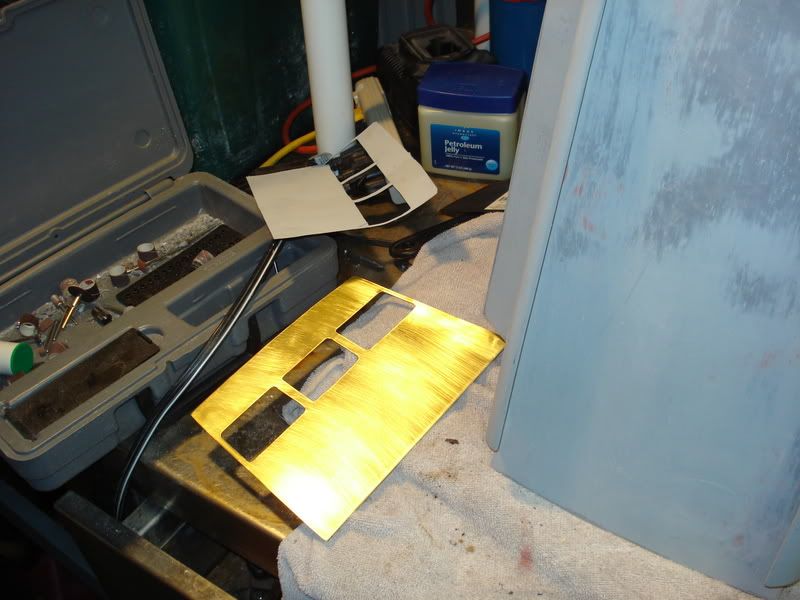

I know there has to be a better way to do this but I just did the best I could. I made a tool from aluminum and brass and imprinted it into . . .you guessed it bondo at the top and I tried epoxy at the bottom.

See the little gaps on the edge there? What would be the best thing to fill them with? What about other very small depressions in the body? I need something thin.

I disassembled the pylons and nacelles to work on the body. This is what it looks like now.

Thanks

Will

I know there has to be a better way to do this but I just did the best I could. I made a tool from aluminum and brass and imprinted it into . . .you guessed it bondo at the top and I tried epoxy at the bottom.

See the little gaps on the edge there? What would be the best thing to fill them with? What about other very small depressions in the body? I need something thin.

I disassembled the pylons and nacelles to work on the body. This is what it looks like now.

Thanks

Will

Last edited: