monsterpartyhat

Sr Member

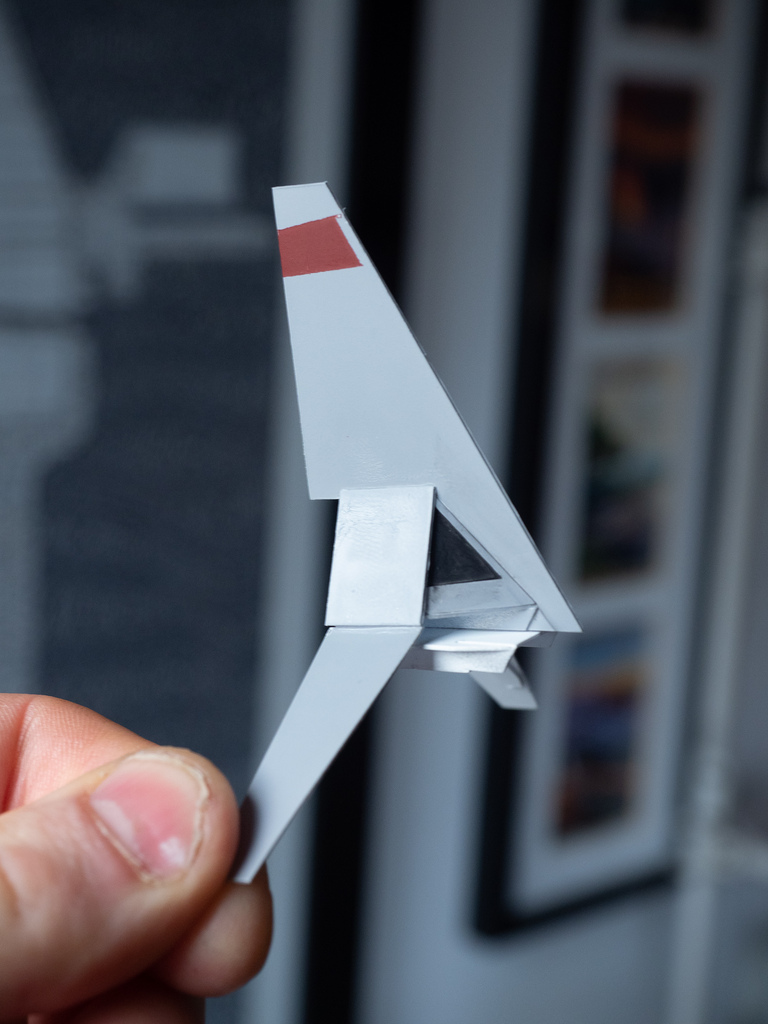

Over a year or ago I scratch built a T-16 Skyhopper out of styrene sheet stock (photos here). I was pretty happy with it as a one-off, and my first completely scratch built model, but it had some issues (inaccurate pattern, too thick main wing, sloppy panel lines). I started working on plans to make a second, more accurate version, but it kept getting pre-empted by other projects and kits.

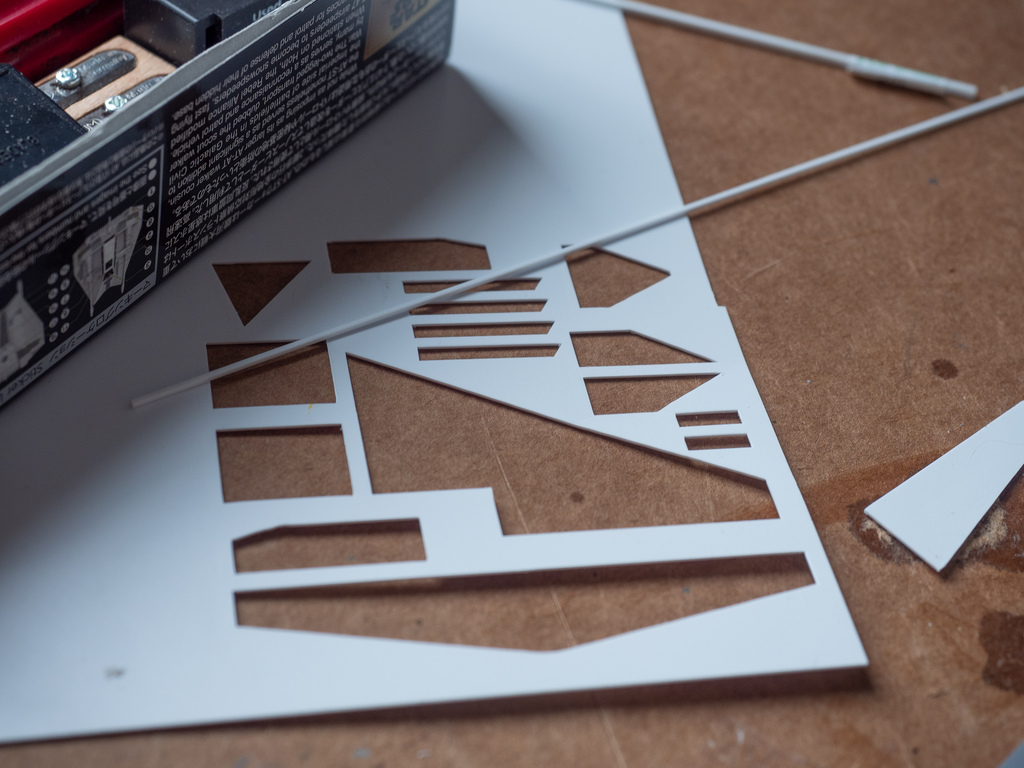

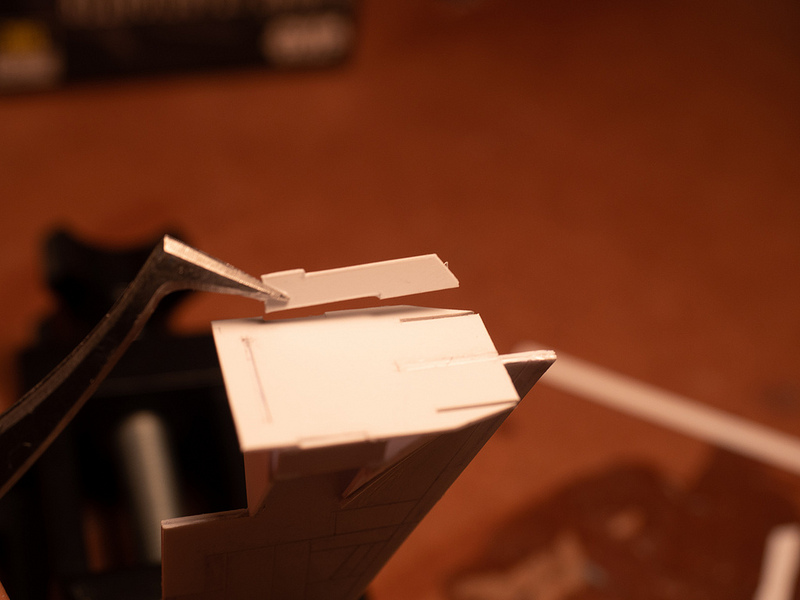

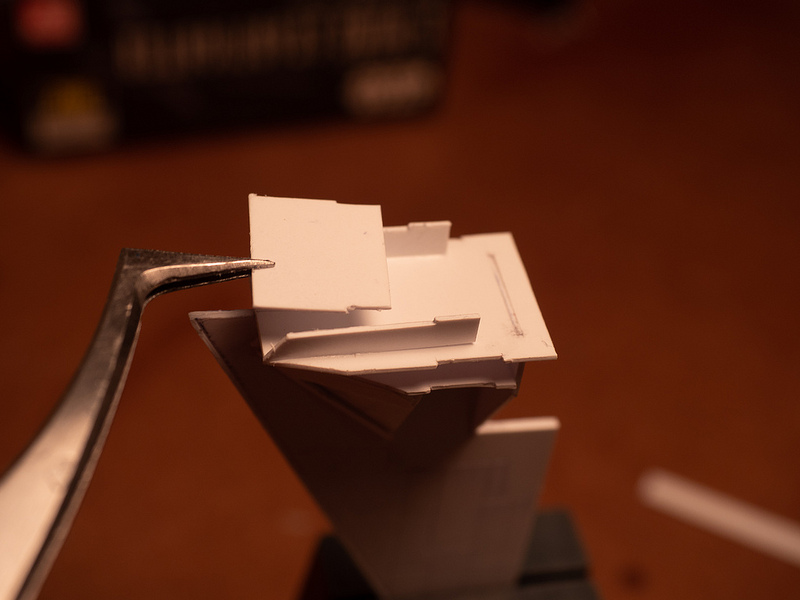

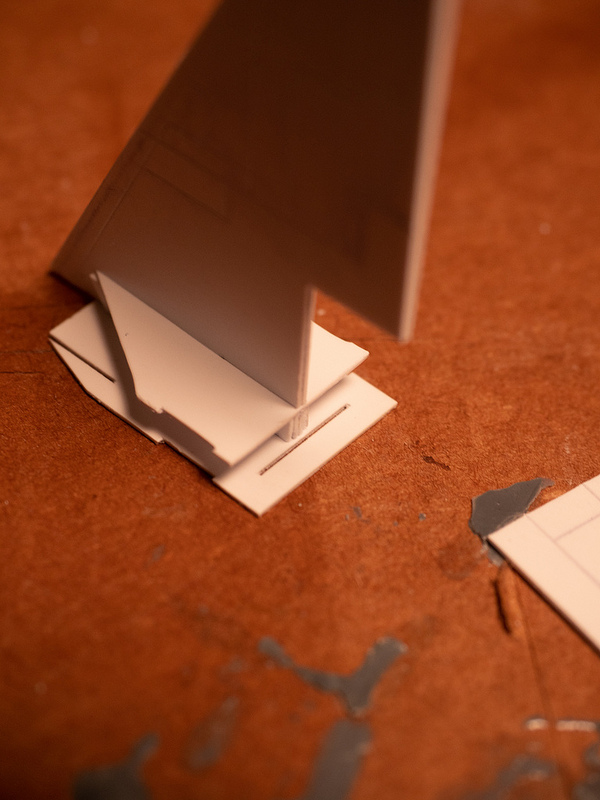

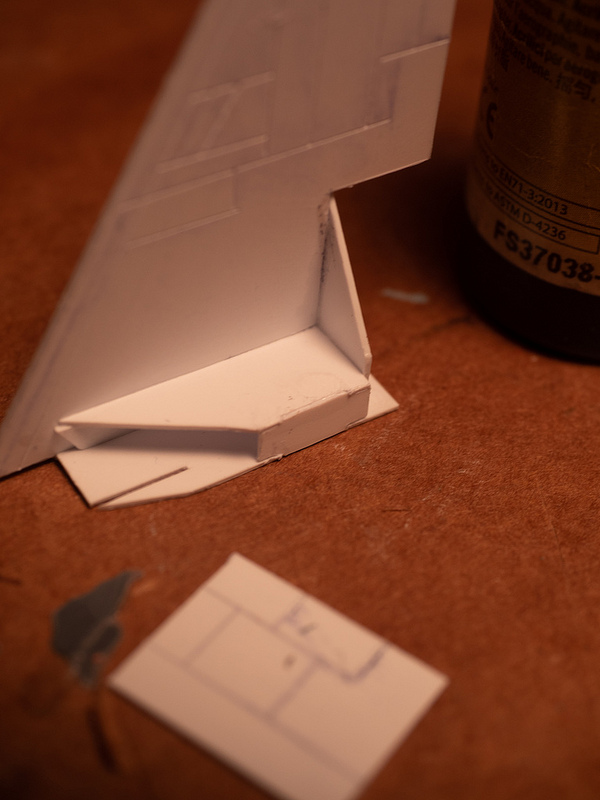

Fast forward to earlier this month, my wife got me a Cricut Maker (electronic die-cutting machine) for my birthday, and the very first thing I tried out on it was cutting my T-16 pattern out of .020" styrene - drew the patterns out in 2D, and it cuts very precisely.

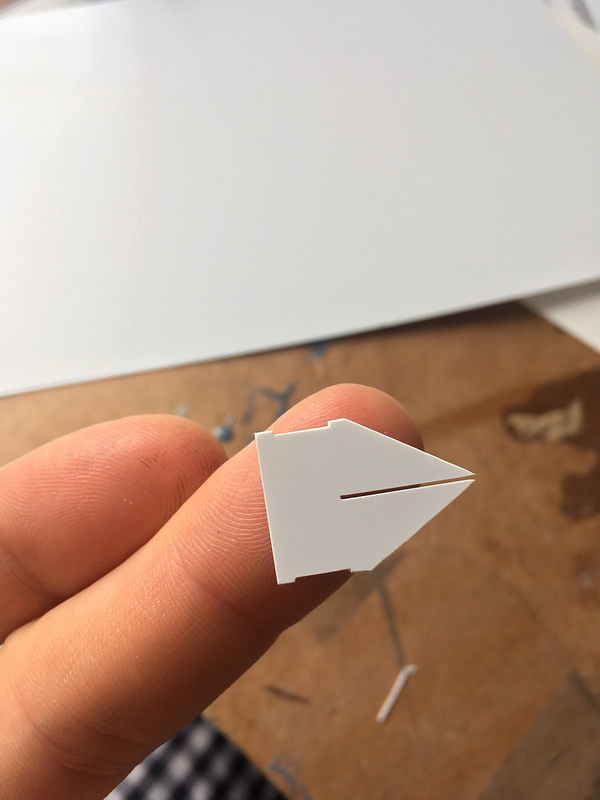

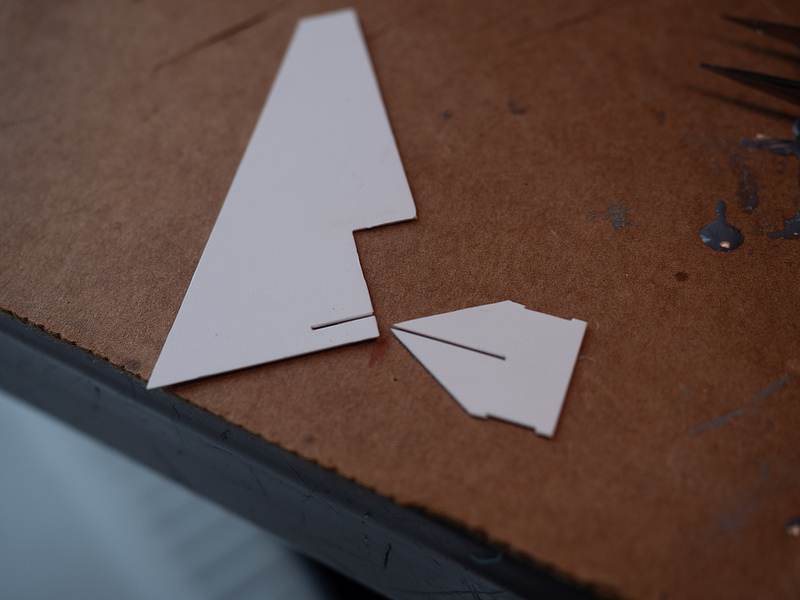

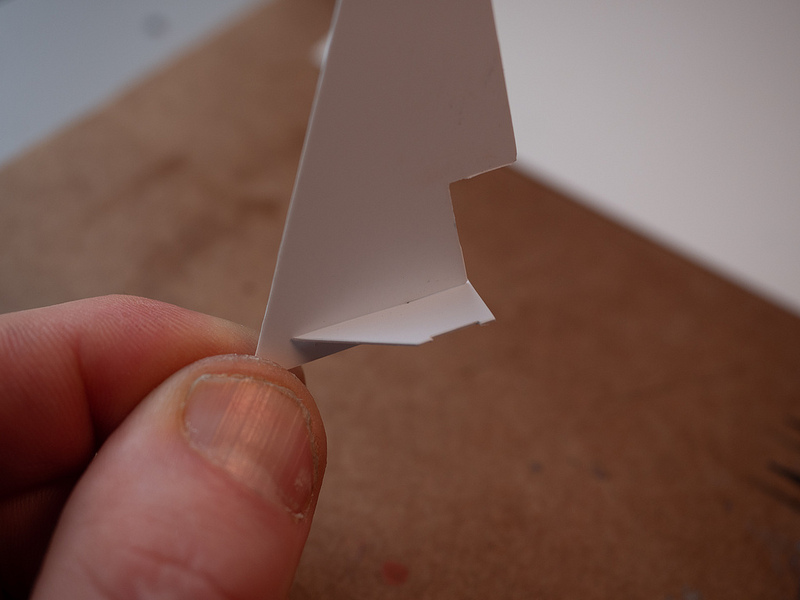

In fact, it cuts so precisely that I was able to modify the pattern to include slots and tabs for assembly.

Naturally, once I got this far obsession started kicking in, and I started reworking the pattern to include alignment tabs everywhere I could, to ensure a good build.

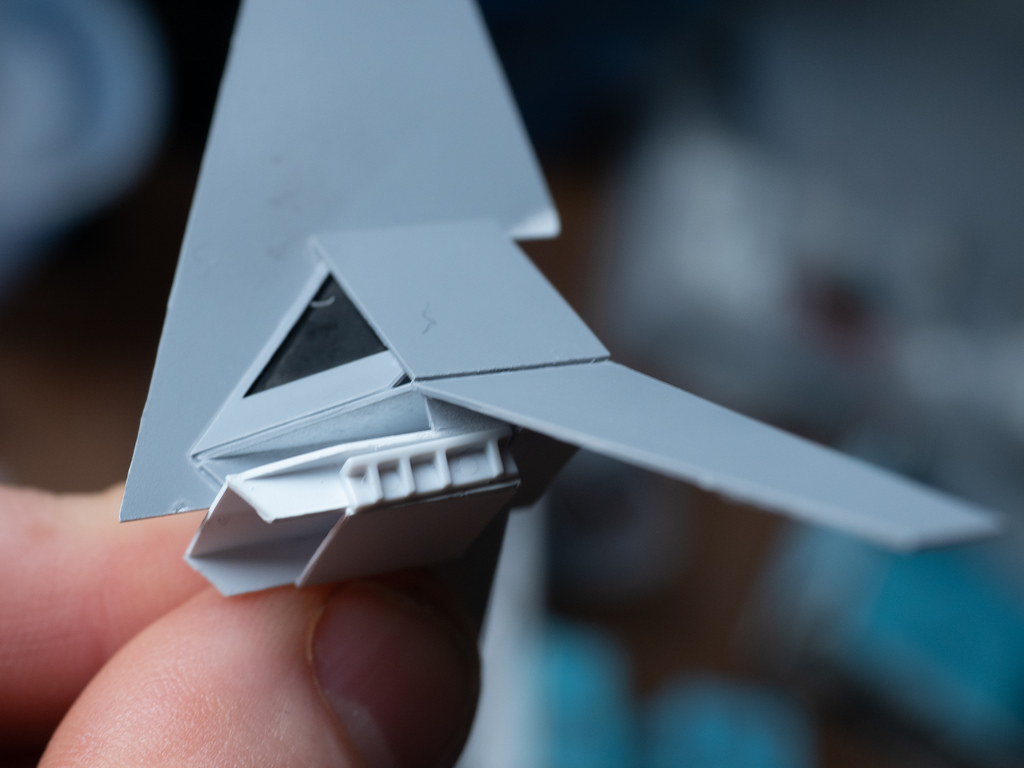

This is neat - one of the pieces of the Bandai Vehicle Model T-65 X-wing works pretty well as one of the side greeblies on the T-16:

Fast forward to earlier this month, my wife got me a Cricut Maker (electronic die-cutting machine) for my birthday, and the very first thing I tried out on it was cutting my T-16 pattern out of .020" styrene - drew the patterns out in 2D, and it cuts very precisely.

In fact, it cuts so precisely that I was able to modify the pattern to include slots and tabs for assembly.

Naturally, once I got this far obsession started kicking in, and I started reworking the pattern to include alignment tabs everywhere I could, to ensure a good build.

This is neat - one of the pieces of the Bandai Vehicle Model T-65 X-wing works pretty well as one of the side greeblies on the T-16: