cabour

Sr Member

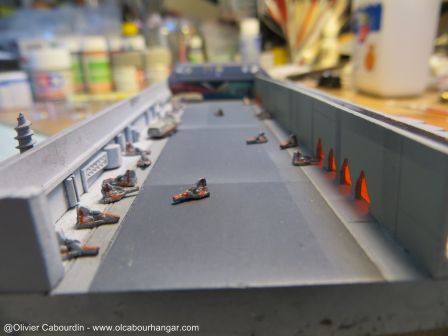

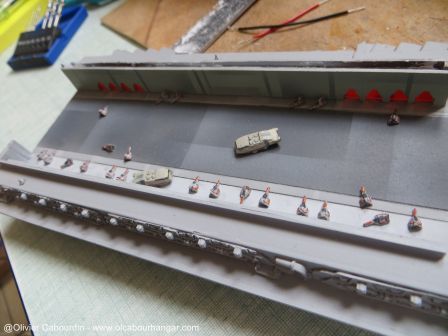

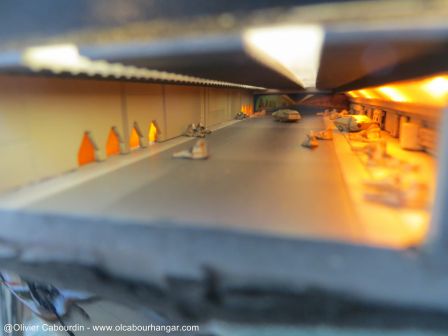

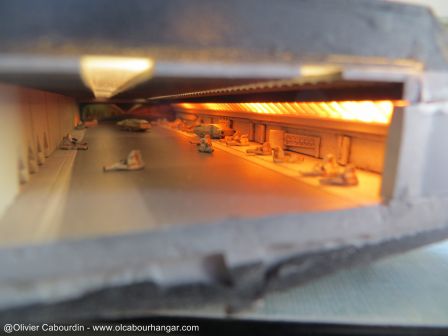

To populate the sheds, I need mini vipers and a few colonial shuttles.

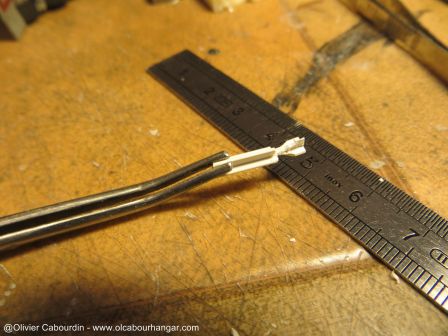

The Viper in this scale is 4.5 mm long.

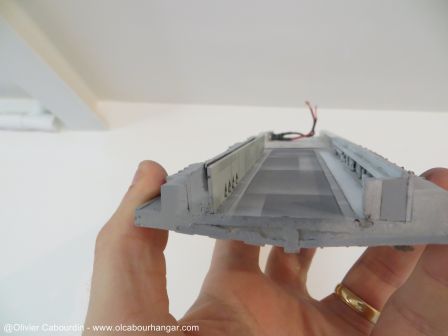

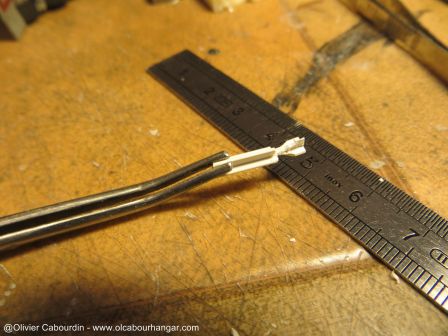

I'm going with T-channel as a base. I tested 2 and I go on the widest.

After few cuts, and add of two small rods, it looks like a viper.

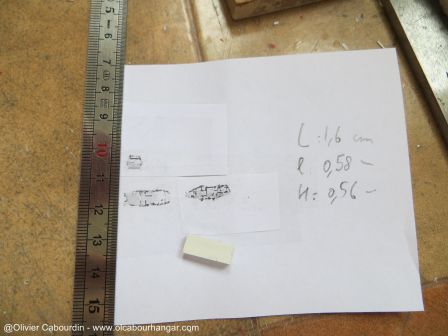

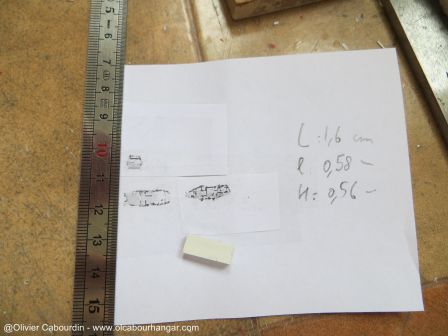

For the master of the shuttle, I used a section of a PVC strip.

I mark the corners following a blueprint, and cut.

I added the pads and graved the cockpit windows.

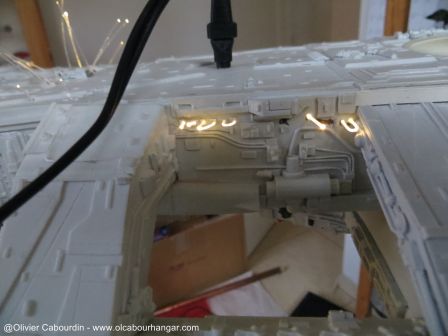

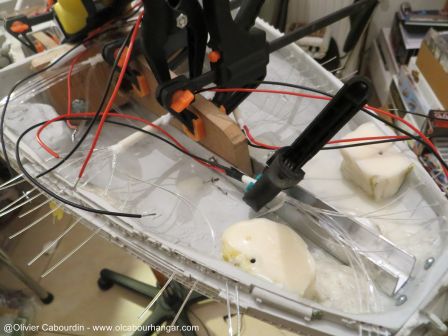

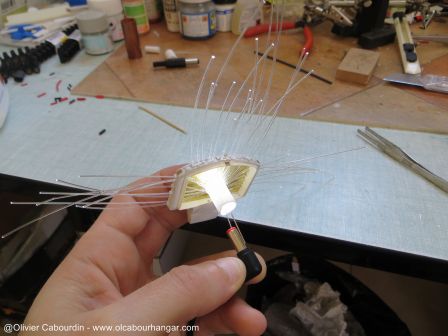

I realize a first mold with Siligum.

And I get my first casts.

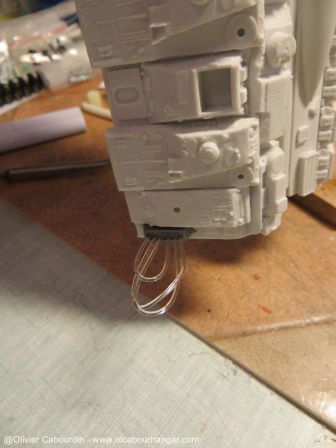

After a dozen runs, the Viper mold is dead, but that does not matter because now I can get into a second mold with a whole squadron, which was the goal

I use standard rtv, which will hold better than Siligum.

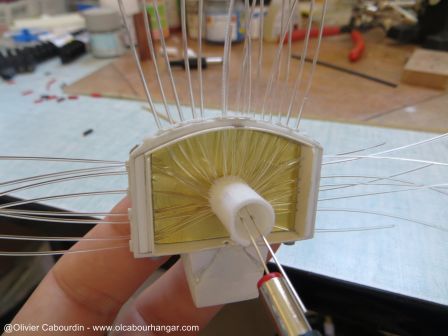

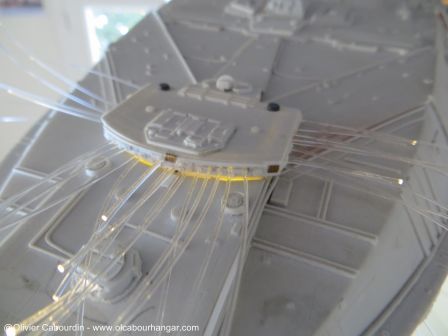

Vipers clusters !

The Viper in this scale is 4.5 mm long.

I'm going with T-channel as a base. I tested 2 and I go on the widest.

After few cuts, and add of two small rods, it looks like a viper.

For the master of the shuttle, I used a section of a PVC strip.

I mark the corners following a blueprint, and cut.

I added the pads and graved the cockpit windows.

I realize a first mold with Siligum.

And I get my first casts.

After a dozen runs, the Viper mold is dead, but that does not matter because now I can get into a second mold with a whole squadron, which was the goal

I use standard rtv, which will hold better than Siligum.

Vipers clusters !