-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Limited Run RUN CLOSED * DL-44 ESB Blaster Machined Parts Set * RUN CLOSED

- Thread starter Boba Debt

- Start date

2keepandbear

Well-Known Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

There are some good shots of them here: http://www.therpf.com/showthread.php?t=230129

Just so I get the correct photos to go with each version of the blaster available, is anyone able to provide me with some decent shots? I'm not the blaster expert you guys are.

There are some good shots of them here: http://www.therpf.com/showthread.php?t=230129

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

Perfect! Thank you!

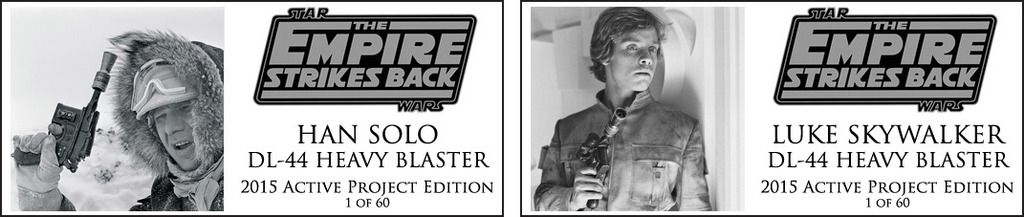

As far as styles go, to keep this from being incredibly complicated, they will all have to be the same style. I can do different ones for the different characters but Bobadebt has decided to just go with the plaque that the majority wants. Ill mock up ones with pictures and then people can voice their opinion. If the one that gets picked is not your style, you can always have me make you a custom one later.

Perfect! Thank you!

As far as styles go, to keep this from being incredibly complicated, they will all have to be the same style. I can do different ones for the different characters but Bobadebt has decided to just go with the plaque that the majority wants. Ill mock up ones with pictures and then people can voice their opinion. If the one that gets picked is not your style, you can always have me make you a custom one later.

ImperialWalker

Well-Known Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

I personally feel these are too busy.

The multiple fonts, sizes and weights, along with the photos make these feel like there is too much going on. Admittedly, I tend towards a more minimalist style in general, so I would have probably just went for the following:

DL-44 Heavy Blaster

RPF 2015

1 of 60

No photos, no logos, no names.

For me the reason is that I already know all the information (who's blaster, that it is from Star Wars, etc). For anyone looking at it, there is enough information to spark a conversation, without giving so much away that there isn't much reason to ask.

Another idea I might go for is more of a museum type description, like perhaps it was being displayed as such. What I mean is, it would be something like:

DL-44 Heavy Blaster

BlasTech Industries

1000 BBY - 37 ABY

RPF Active Project Edition - 2015

1 of 60

But, that is just me.

I personally feel these are too busy.

The multiple fonts, sizes and weights, along with the photos make these feel like there is too much going on. Admittedly, I tend towards a more minimalist style in general, so I would have probably just went for the following:

DL-44 Heavy Blaster

RPF 2015

1 of 60

No photos, no logos, no names.

For me the reason is that I already know all the information (who's blaster, that it is from Star Wars, etc). For anyone looking at it, there is enough information to spark a conversation, without giving so much away that there isn't much reason to ask.

Another idea I might go for is more of a museum type description, like perhaps it was being displayed as such. What I mean is, it would be something like:

DL-44 Heavy Blaster

BlasTech Industries

1000 BBY - 37 ABY

RPF Active Project Edition - 2015

1 of 60

But, that is just me.

Daddy Solo

Active Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

I agree - pics kind clutter it up too much. I'm OK w/ logos though

I agree - pics kind clutter it up too much. I'm OK w/ logos though

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

Hi all,

So I got the first batch of scopes and pistons back. First off, I want to say that as much as I try to make the waxes perfect when taking them into the foundry, there *will* be minor cosmetic flaws with the bronze castings. It's just the nature of the beast. I suspect if you're doing weathered blaster, this won't be a big issue, but if you're trying to go for that "new, out-of-the-box" look", you're going to be disappointed. Here are some pics of some of the scopes and pistons so you know what to expect. I'm including pics of the better examples first, followed some with more cosmetic imperfections. That said, any of these imperfections could be corrected with a little filler before paint.

Pics of pistons to follow.

I'm going to take in another batch to the foundry and I think we'll have more clean castings in the next batch, but again, there is no way we're going to get perfect castings with a "cast and clip" service. I could pay to have them weld and chase the spots that aren't perfect, but that would bring the costs up significantly. Seems more sensible to touch up the spots that you feel need touching up with filler. Thoughts?

Piston pics. Best to worst. Keep in mind that the holes are going to be drilled out.

tJ

Hi all,

So I got the first batch of scopes and pistons back. First off, I want to say that as much as I try to make the waxes perfect when taking them into the foundry, there *will* be minor cosmetic flaws with the bronze castings. It's just the nature of the beast. I suspect if you're doing weathered blaster, this won't be a big issue, but if you're trying to go for that "new, out-of-the-box" look", you're going to be disappointed. Here are some pics of some of the scopes and pistons so you know what to expect. I'm including pics of the better examples first, followed some with more cosmetic imperfections. That said, any of these imperfections could be corrected with a little filler before paint.

Pics of pistons to follow.

I'm going to take in another batch to the foundry and I think we'll have more clean castings in the next batch, but again, there is no way we're going to get perfect castings with a "cast and clip" service. I could pay to have them weld and chase the spots that aren't perfect, but that would bring the costs up significantly. Seems more sensible to touch up the spots that you feel need touching up with filler. Thoughts?

Piston pics. Best to worst. Keep in mind that the holes are going to be drilled out.

tJ

2keepandbear

Well-Known Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

I think they look great.

I think they look great.

IndustrialActn

Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

The scope is definitely a bit rougher than I expected but it is still doable for me personally. It'll take some work to fix it up but that's ok with me. They will be hollow and have lenses, correct?

The scope is definitely a bit rougher than I expected but it is still doable for me personally. It'll take some work to fix it up but that's ok with me. They will be hollow and have lenses, correct?

2keepandbear

Well-Known Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

If I am not mistaken that is an option that Boba Debt is offering with this run. Once he gets the scopes for "clean up" you have the option of them being hollow or solid.

The scope is definitely a bit rougher than I expected but it is still doable for me personally. It'll take some work to fix it up but that's ok with me. They will be hollow and have lenses, correct?

If I am not mistaken that is an option that Boba Debt is offering with this run. Once he gets the scopes for "clean up" you have the option of them being hollow or solid.

Country Paul

Sr Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

Looking pretty good to me

cast bronze even with a few imperfections beats my current resin scopes any day :lol

thanks for the update (& for doing this), I look forward to more of them

Looking pretty good to me

cast bronze even with a few imperfections beats my current resin scopes any day :lol

thanks for the update (& for doing this), I look forward to more of them

ImperialWalker

Well-Known Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

I want to start off with an apology. I'm sorry if my thought will sound harsh. I just want to make sure I am clear and to the point so I don't sound "fluffy".

My experience with lost wax casting, especially in bronze is quite limited. What experience I do have comes mostly from art college. While myself and other classmates made some beautiful jewelry....I am admittedly no expert so I may be way off with my critique here. From my perspective it appears that the test pieces above are suffering from air bubbles, residual wax in the mold, and perhaps freeze lines (cooled bronze mixing with warm bonze).

If it were me, I would find a way to eliminate as many of these issues as possible to cut down on the amount of cleanup needed. The issue I have with requiring that much filler/cleanup is that it sort of negates the reason for doing a bronze cast if a significant amount of detail needs to be rebuilt with resin. Not only is it a tad difficult for people who don't have experience doing this, but it adds time, money, and materials to the process.

Also, it is hard to determine what is defects from the casting process, and what is simply a reproduction of the original, without being able to see them side by side.

...

So that brings me to my thoughts.

If these casts can't be cleaned up before hand, then my suggestion is to determine the price to have them professionally cleaned up before sale. It may add to the cost, but in the end the cost in time, materials, and frustration for most people will end up being the same if not more. Also, if the casts are fixed using bronze, then it eliminates the need to use another material, giving us flexibility to color it using methods other than paint.

That said, perhaps the solution is to ask whether this is the right method/material for the job.

I understand that people want a metal version because they want to stay away from resin replicas, but if this casting method is consistently reproducing unavoidable issues, maybe it needs to be looked at again.

Anyway, these are just my thoughts. I don't mean to sound like I am crapping all over the hard work you've done. I just want to be honest about things so we can make sure we have the best possible end result.

I hope this helps.

Hi all,

So I got the first batch of scopes and pistons back. First off, I want to say that as much as I try to make the waxes perfect when taking them into the foundry, there *will* be minor cosmetic flaws with the bronze castings. It's just the nature of the beast. I suspect if you're doing weathered blaster, this won't be a big issue, but if you're trying to go for that "new, out-of-the-box" look", you're going to be disappointed. Here are some pics of some of the scopes and pistons so you know what to expect. I'm including pics of the better examples first, followed some with more cosmetic imperfections. That said, any of these imperfections could be corrected with a little filler before paint.

Pics of pistons to follow.

I'm going to take in another batch to the foundry and I think we'll have more clean castings in the next batch, but again, there is no way we're going to get perfect castings with a "cast and clip" service. I could pay to have them weld and chase the spots that aren't perfect, but that would bring the costs up significantly. Seems more sensible to touch up the spots that you feel need touching up with filler. Thoughts?

Piston pics. Best to worst. Keep in mind that the holes are going to be drilled out.

tJ

I want to start off with an apology. I'm sorry if my thought will sound harsh. I just want to make sure I am clear and to the point so I don't sound "fluffy".

My experience with lost wax casting, especially in bronze is quite limited. What experience I do have comes mostly from art college. While myself and other classmates made some beautiful jewelry....I am admittedly no expert so I may be way off with my critique here. From my perspective it appears that the test pieces above are suffering from air bubbles, residual wax in the mold, and perhaps freeze lines (cooled bronze mixing with warm bonze).

If it were me, I would find a way to eliminate as many of these issues as possible to cut down on the amount of cleanup needed. The issue I have with requiring that much filler/cleanup is that it sort of negates the reason for doing a bronze cast if a significant amount of detail needs to be rebuilt with resin. Not only is it a tad difficult for people who don't have experience doing this, but it adds time, money, and materials to the process.

Also, it is hard to determine what is defects from the casting process, and what is simply a reproduction of the original, without being able to see them side by side.

...

So that brings me to my thoughts.

If these casts can't be cleaned up before hand, then my suggestion is to determine the price to have them professionally cleaned up before sale. It may add to the cost, but in the end the cost in time, materials, and frustration for most people will end up being the same if not more. Also, if the casts are fixed using bronze, then it eliminates the need to use another material, giving us flexibility to color it using methods other than paint.

That said, perhaps the solution is to ask whether this is the right method/material for the job.

I understand that people want a metal version because they want to stay away from resin replicas, but if this casting method is consistently reproducing unavoidable issues, maybe it needs to be looked at again.

Anyway, these are just my thoughts. I don't mean to sound like I am crapping all over the hard work you've done. I just want to be honest about things so we can make sure we have the best possible end result.

I hope this helps.

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

Your thoughts don't sound harsh. I'm not looking for sugar coating. I feel like these can be better. Some of the defects (ones I haven't pictured) were a result of either bad waxes (bubbles) or careless removal from the investment. I think most people still want bronze even if it means some cleanup. These are on the worse end of what I expect from future casts. My first batch of wax wasn't the greatest. I've got several new waxes made from a fresh batch of wax and these are coming out a lot better. BUT they will still have some imperfections. If that is an issue for you, I understand. Having them fix the imperfections at the foundry will easily cost double what the castings at the foundry costs. Right now we're looking at $70 per scope, $25 per set of pistons.

The good pistons are quite good and the new ones coming out of my molds are way better than the first ones. I expect nobody will getting pistons that look like the worst ones in the pics I posted above. I just wanted you all to see what I'm dealing with. I have to eat the costs of the cast offs. If anyone is willing to accept a rough piece with the understanding that they'll want to clean it up, I may sell them at a reduced cost just to reduce my overhead.

tJ

I want to start off with an apology. I'm sorry if my thought will sound harsh. I just want to make sure I am clear and to the point so I don't sound "fluffy".

Your thoughts don't sound harsh. I'm not looking for sugar coating. I feel like these can be better. Some of the defects (ones I haven't pictured) were a result of either bad waxes (bubbles) or careless removal from the investment. I think most people still want bronze even if it means some cleanup. These are on the worse end of what I expect from future casts. My first batch of wax wasn't the greatest. I've got several new waxes made from a fresh batch of wax and these are coming out a lot better. BUT they will still have some imperfections. If that is an issue for you, I understand. Having them fix the imperfections at the foundry will easily cost double what the castings at the foundry costs. Right now we're looking at $70 per scope, $25 per set of pistons.

The good pistons are quite good and the new ones coming out of my molds are way better than the first ones. I expect nobody will getting pistons that look like the worst ones in the pics I posted above. I just wanted you all to see what I'm dealing with. I have to eat the costs of the cast offs. If anyone is willing to accept a rough piece with the understanding that they'll want to clean it up, I may sell them at a reduced cost just to reduce my overhead.

tJ

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

Since BD is offering clean up and machining services for these parts, I think it would probably be best to see what he can do before we decide on settling for using other materials. Besides, since TJ is offering the bronze parts separately and everything in this project is pretty much being offered a la carte, no one is really obligated to buy anything. I'm sure there are some people planning on using a real M19\M32 or a resin one. Even though I prefer a metal scope, they're pretty damn heavy. Kinda throws off the balance of the gun if you ask me, but I still prefer it.

But yeah, I think they're fine for now. Let's wait and see how much it takes to clean one of these up.

That said, perhaps the solution is to ask whether this is the right method/material for the job.

Since BD is offering clean up and machining services for these parts, I think it would probably be best to see what he can do before we decide on settling for using other materials. Besides, since TJ is offering the bronze parts separately and everything in this project is pretty much being offered a la carte, no one is really obligated to buy anything. I'm sure there are some people planning on using a real M19\M32 or a resin one. Even though I prefer a metal scope, they're pretty damn heavy. Kinda throws off the balance of the gun if you ask me, but I still prefer it.

But yeah, I think they're fine for now. Let's wait and see how much it takes to clean one of these up.

ImperialWalker

Well-Known Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

First, please don't eat the cost of anything. I, and I am sure most people understand that these things take effort and have no issues having some of the cost of your time and materials factored in. If it means the scopes costs $90 instead, so be it. I would much rather you have the freedom to make these as amazing as possible, than risk saying, "good 'nuff" because it becomes too costly out of pocket.

I understand that not everyone has endless amounts to spend on a blaster scope, but for me anyway, I would much rather spend a bit more and get a scope as close to perfect as possible (within reason), than have the cost be cheaper by a few bucks and have to spend time fixing things.

Anyway, I'm glad you're doing what you can to make sure these are top notch. I respect the time and effort you're putting in.

Your thoughts don't sound harsh. I'm not looking for sugar coating. I feel like these can be better. Some of the defects (ones I haven't pictured) were a result of either bad waxes (bubbles) or careless removal from the investment. I think most people still want bronze even if it means some cleanup. These are on the worse end of what I expect from future casts. My first batch of wax wasn't the greatest. I've got several new waxes made from a fresh batch of wax and these are coming out a lot better. BUT they will still have some imperfections. If that is an issue for you, I understand. Having them fix the imperfections at the foundry will easily cost double what the castings at the foundry costs. Right now we're looking at $70 per scope, $25 per set of pistons.

The good pistons are quite good and the new ones coming out of my molds are way better than the first ones. I expect nobody will getting pistons that look like the worst ones in the pics I posted above. I just wanted you all to see what I'm dealing with. I have to eat the costs of the cast offs. If anyone is willing to accept a rough piece with the understanding that they'll want to clean it up, I may sell them at a reduced cost just to reduce my overhead.

tJ

First, please don't eat the cost of anything. I, and I am sure most people understand that these things take effort and have no issues having some of the cost of your time and materials factored in. If it means the scopes costs $90 instead, so be it. I would much rather you have the freedom to make these as amazing as possible, than risk saying, "good 'nuff" because it becomes too costly out of pocket.

I understand that not everyone has endless amounts to spend on a blaster scope, but for me anyway, I would much rather spend a bit more and get a scope as close to perfect as possible (within reason), than have the cost be cheaper by a few bucks and have to spend time fixing things.

Anyway, I'm glad you're doing what you can to make sure these are top notch. I respect the time and effort you're putting in.

Boba Debt

Master Member

Re: DL-44 ESB Blaster Active Project Machined Parts Set $100

I just wanted to say that when Think Jedi did the scopes and pistons from my run in 2004 they looked great once they were cleaned up and painted black.

I don't remember any having the really bad issues some of these have but they did have tiny flaws and to the best of my knowledge, no one was unhappy with their parts.

Now to clear up what I will be doing for these parts.

Think Jedi will send them to me in rough condition "clipped" from the sprues.

EVERY scope will have to under go the clean up machining process. During that process the shop will mill the sprue remnants off the feet and drill and tap them for the scope bolts.

Then they will machine the side boss where the light socket is installed.

The second process will be optional and it will include machining both ends of the scope so that a glass lens can be installed it will be held in place with a machined brass lens ring.

This process will be done differently then my 2004 run so can't even begin to guess at how much it is going to cost.

I will say that we have exceeded the 60 part price point so I will be subsidizing the "Clean Up" portion of the scope process with the money saved by producing more of each part.

I don't know how much that's going to be but every little bit helps

I just wanted to say that when Think Jedi did the scopes and pistons from my run in 2004 they looked great once they were cleaned up and painted black.

I don't remember any having the really bad issues some of these have but they did have tiny flaws and to the best of my knowledge, no one was unhappy with their parts.

Now to clear up what I will be doing for these parts.

Think Jedi will send them to me in rough condition "clipped" from the sprues.

EVERY scope will have to under go the clean up machining process. During that process the shop will mill the sprue remnants off the feet and drill and tap them for the scope bolts.

Then they will machine the side boss where the light socket is installed.

The second process will be optional and it will include machining both ends of the scope so that a glass lens can be installed it will be held in place with a machined brass lens ring.

This process will be done differently then my 2004 run so can't even begin to guess at how much it is going to cost.

I will say that we have exceeded the 60 part price point so I will be subsidizing the "Clean Up" portion of the scope process with the money saved by producing more of each part.

I don't know how much that's going to be but every little bit helps

Similar threads

- Replies

- 4

- Views

- 445

- Replies

- 0

- Views

- 503

- Replies

- 9

- Views

- 1,415

- Replies

- 54

- Views

- 8,190

- Replies

- 9

- Views

- 355