LM1

New Member

A newbie here and his first post so here goes....

Need some advice from all the experts regarding this current project I am about to start after a 2 year break.

I am planning to build the 1/350 Deluxe Minicraft Titanic along with all the PE parts and the hundreds of changes catelogued over at the TRMA forum and Rivet Counter. I have also decided to plate the entire hull with individual plates, rivets etc with sheet styrene and need some advice.

As you can see by Pic 1, the plating isnt perfect so have decided to remove it ( call me a sucker for punishment )..

Pic 2 is the hull with sanding commenced;

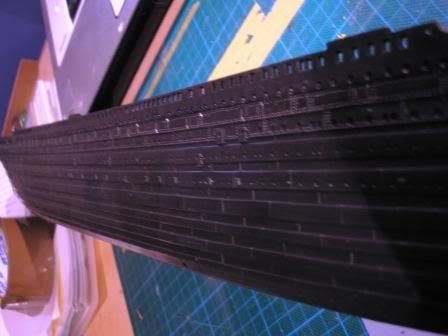

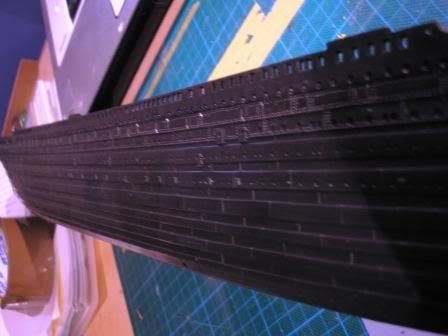

And Pic 3 is a sample that I started about 2.5 years ago, which hasn't been touched for 2 years.

My question is, with the sample hull, I used a combination of either Tamiya Cement, Tamiya Extra Thin Cement and/or M.E.K, which did work well, but on the odd occasion the glue would essentially dry before applying the individual plates and when applying more glue, it left blotches in the 0.005 styrene.

Would slow acting/drying CA glue allow me the 10 -20 second window I need to propery align the plates and avoid the unsightly blotches.

Any advice, recomendations would be greatly appreciated and its great to finally be on board.

Need some advice from all the experts regarding this current project I am about to start after a 2 year break.

I am planning to build the 1/350 Deluxe Minicraft Titanic along with all the PE parts and the hundreds of changes catelogued over at the TRMA forum and Rivet Counter. I have also decided to plate the entire hull with individual plates, rivets etc with sheet styrene and need some advice.

As you can see by Pic 1, the plating isnt perfect so have decided to remove it ( call me a sucker for punishment )..

Pic 2 is the hull with sanding commenced;

And Pic 3 is a sample that I started about 2.5 years ago, which hasn't been touched for 2 years.

My question is, with the sample hull, I used a combination of either Tamiya Cement, Tamiya Extra Thin Cement and/or M.E.K, which did work well, but on the odd occasion the glue would essentially dry before applying the individual plates and when applying more glue, it left blotches in the 0.005 styrene.

Would slow acting/drying CA glue allow me the 10 -20 second window I need to propery align the plates and avoid the unsightly blotches.

Any advice, recomendations would be greatly appreciated and its great to finally be on board.