A great idea to 'geeblie up' some hidden areas Read, but you do realise you need to lower the McLaren tub by around 12mm right?.By the way, about that underside business...

View attachment 1572563

... I was just pranking you guys. There are no dressings on the underside, and I just had a lot of spare greeblies and thought it would be fun to try my hand at ILM-freestyle for an area that wouldn't get seen.

I thought you would know I was joking by the phrase "hysterically accurate" but since nobody came forth to call my bluff, I'm fessing up here.

But still, it looks kind of cool, no?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Our Collective 5-Foot Millennium Falcon Build

- Thread starter Studio Kitbash

- Start date

Stu,A great idea to 'geeblie up' some hidden areas Read, but you do realise you need to lower the McLaren tub by around 12mm right?.

Funny you mention it -- I was just getting to the point of asking whether I had to "lower the McLaren tub" or "raise the Sheridan" height?

So, alas, most of my genius greeblie work on that lower rim will be scraped off before its all said and done -- but it sure was fun for the week it got to stay on there!

Do we salute when they raise the Sheridan?^^

This phrase: "lower the McLaren tub" or "raise the Sheridan's height"...my dirty mind cannot erase it ;-p

Do you remember that list from years ago about the top ten most suggestive lines of Star Wars?

My favorite was, "I don't care what you smell, get in there you big hairy oaf!" in reference to the trash compactor scene.

Never fails to elicit a chuckle...

My favorite was, "I don't care what you smell, get in there you big hairy oaf!" in reference to the trash compactor scene.

Never fails to elicit a chuckle...

Anyone on here know how to dial in the Anycubic Photon Mono X resin 3D printer? If so, please PM me and I'll reward you in premium prints or original greeblies. Having some serious, various, and repeated issues and can't seem to get it dialed in. Have tried the validation matrix, new resin, clean FEP, stable temperature, etc, and Monday will e-mail/call manufacturer for Tech Support. But meanwhile, would love to talk to someone who's worked with this particular printer and knows a hierarchy of troubleshooting steps to take for various issues.

Anyone on here know how to dial in the Anycubic Photon Mono X resin 3D printer? If so, please PM me and I'll reward you in premium prints or original greeblies. Having some serious, various, and repeated issues and can't seem to get it dialed in. Have tried the validation matrix, new resin, clean FEP, stable temperature, etc, and Monday will e-mail/call manufacturer for Tech Support. But meanwhile, would love to talk to someone who's worked with this particular printer and knows a hierarchy of troubleshooting steps to take for various issues.

PM sent...

Dan

Got a favorite gun turret window?

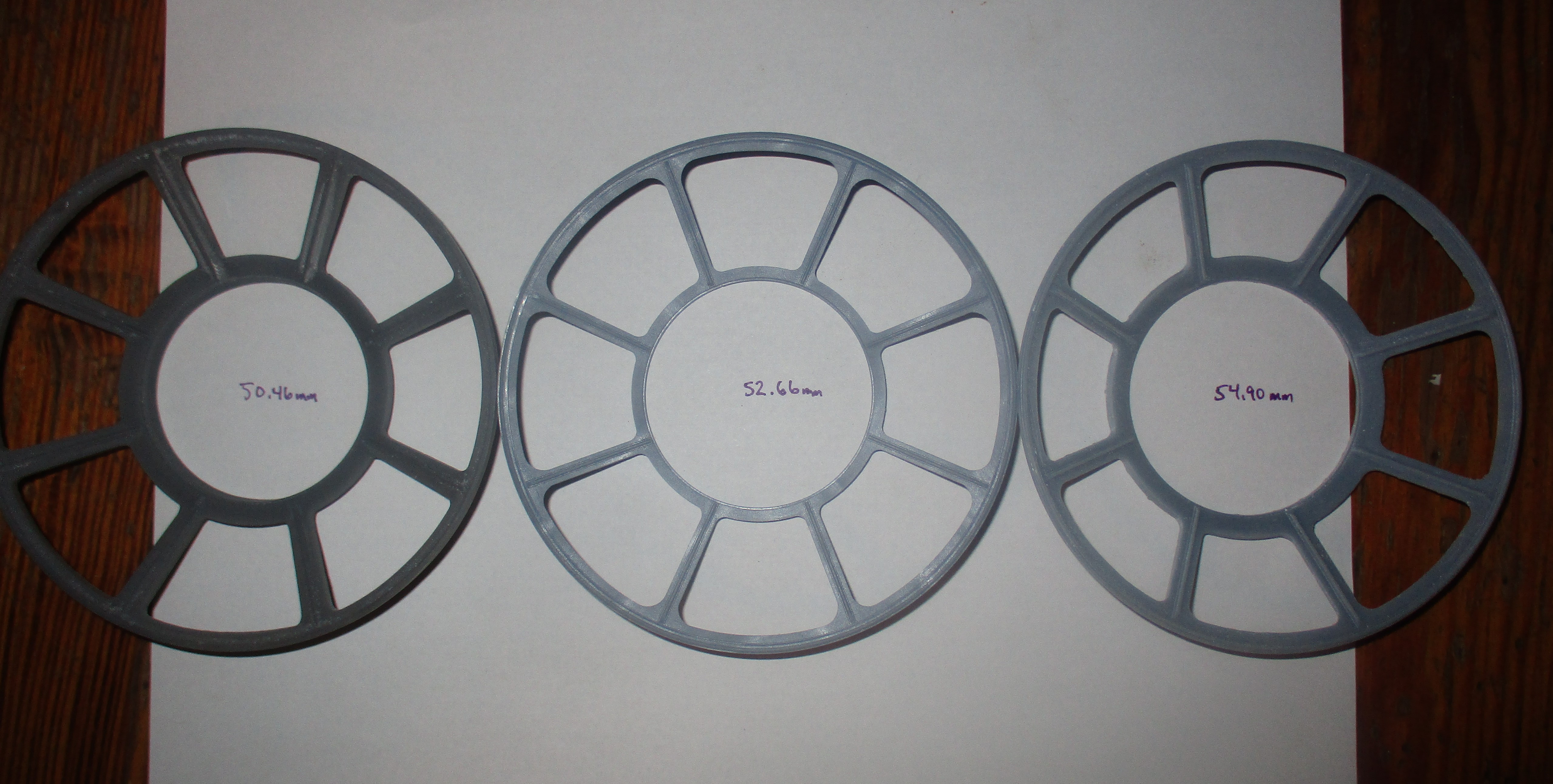

The OD on all three hovers between 113.34 mm and 114.86 -- a difference of 1.5mm. That's not even noticeable once it gets framed by the window opening.

But the ID on all three shows quite a difference, as does the thickness of the framing. The ID measurements, pictured below, have a range of 4.44mm - that's a LOT of difference!

Two questions, possibly with the same answer:

1.) Which one looks better to your eye?

2.) Which one do you surmise is more accurate to the studio prop original?

The OD on all three hovers between 113.34 mm and 114.86 -- a difference of 1.5mm. That's not even noticeable once it gets framed by the window opening.

But the ID on all three shows quite a difference, as does the thickness of the framing. The ID measurements, pictured below, have a range of 4.44mm - that's a LOT of difference!

Two questions, possibly with the same answer:

1.) Which one looks better to your eye?

2.) Which one do you surmise is more accurate to the studio prop original?

I like the middle one. The others seems to bulky to me.Got a favorite gun turret window?

The OD on all three hovers between 113.34 mm and 114.86 -- a difference of 1.5mm. That's not even noticeable once it gets framed by the window opening.

But the ID on all three shows quite a difference, as does the thickness of the framing. The ID measurements, pictured below, have a range of 4.44mm - that's a LOT of difference!

Two questions, possibly with the same answer:

1.) Which one looks better to your eye?

2.) Which one do you surmise is more accurate to the studio prop original?

View attachment 1574598

Last edited:

To you and me, they are super valuable, super rare, super hard-to-find treasures to be cherished...

But to children, they are just boxes with which you can make a fort.

Perspective is everything.

But to children, they are just boxes with which you can make a fort.

Perspective is everything.

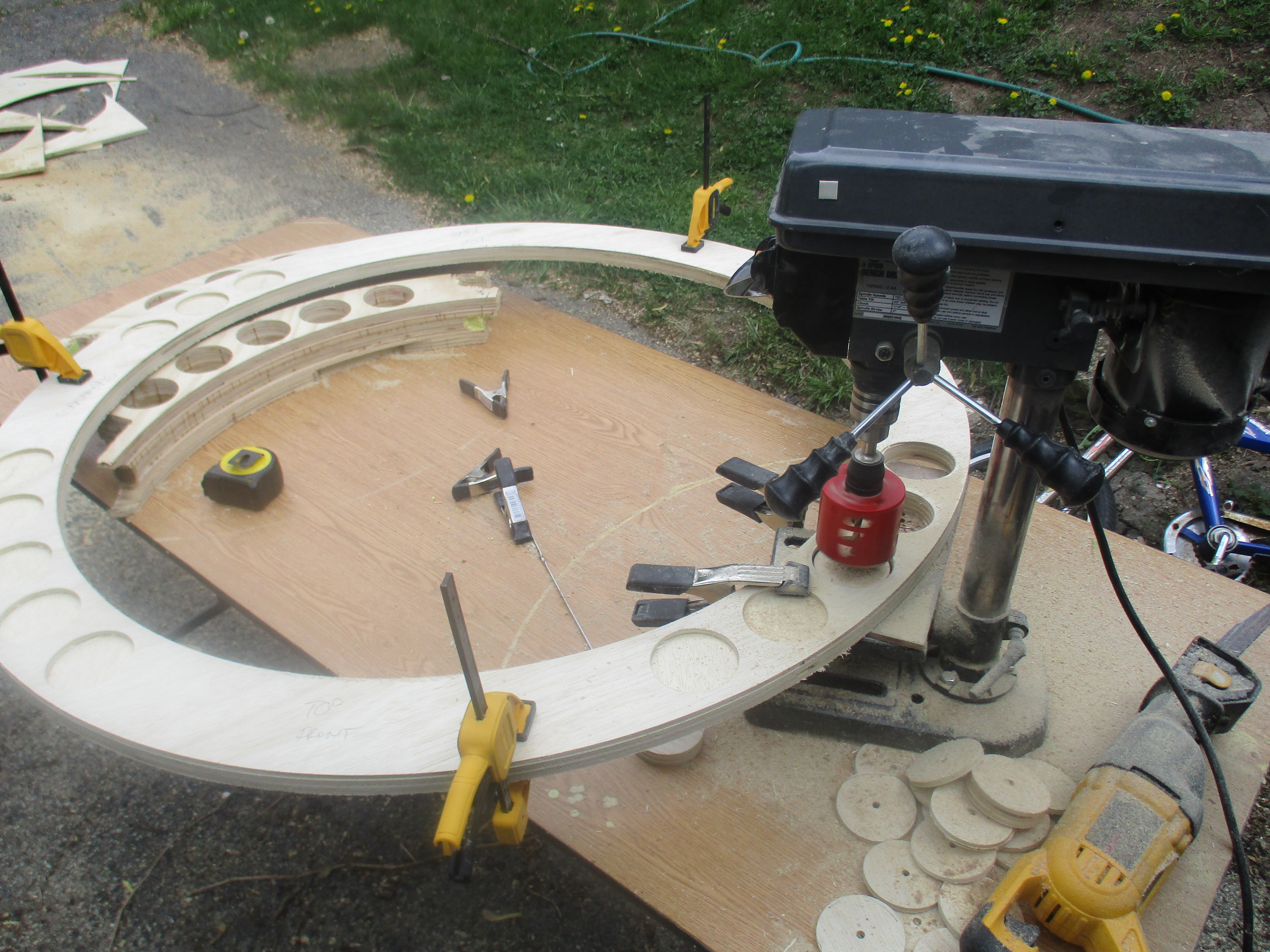

I am BACK to the drawing board with armature core rings.

Was going to use a CNC router shop, but that was a $500 price tag on TOP of the $180 for the plywood. So I'm trying it "by hand" one more time, and if it fails this time, I'll go the computer-aided machinery route for the third and final try.

Step One: choose a sunny day 2-1/2 years into your build, and get your plywood sheets cut in half for free at Home Depot. Choose the lightest-weight plywood you can find - in my case Douglas Fir for the 3/4" and Luan for the 1/4." Get your handy-dandy Rockler circle-cutting jig all set up with your cordless DeWalt router that will need four battery changes by the time it's all over...

Step Two: Humiliate yourself by taking out your previously failed armature ring, cutting it off the aluminum armature in pieces, and keep these pieces in your peripheral vision The Whole Time you are cutting the new ones. Remind yourself with every minute: IF I screw this up again, I'll be throwing away the same amount of lumber, time, and effort, and now at 50% markup thanks to wood prices and inflation. So measure three times, cut one-- actually wait a minute -- measure four times, now cu--- actually measure five times... until you're really seriously committed and ready to... throw away more money at what you keep insisting to your wife is "the learning curve"...

Step Three: Cut out all your rings, making sure they are perfectly aligned on Inner Dimension and Outer Dimension, the whole time repeating to yourself, "It's okay that it's 1/16th off, which is only 1/8" off around the whole thing, because it's off by too much in the right direction -- and you can compensate for that missing 1/8 by adding a 1/16-inch (okay, 1.5mm, close enough!) piece of cardstock all the way around to glue your original greeblies to make a strong styrene-on-styrene bond." Keep telling yourself this -- an important part of the psychology of the whole thing -- instead of telling yourself, "I measured this FIVE times, HOW could I be off by so much?" -- which narrative will only kill your morale.

Step Four - Using the old, broken, ruined, discarded, disgusting, beneath-your-contempt failed armature as a guide, mark your inner 3-inch lightening holes and, regarding placement, remind yourself that a.) these were originally handmade, b.) getting 1/2" from the inside while getting 3/4" from the outside is a fool's errand, so just aim for dead center and you'll be off anyway, c.) that CNC router perfection is only for those who demand perfection and Don't Want the ILM handmade look, and d.) NONE of this will be seen, ever, by anyone, except you (and the whole Internet should you post the pictures...)

Step Five - Go Inside for Brunch to Celebrate your Son's "May the 4th Be With You" Star Wars 8th birthday, with his requested favorite, a Swedish pancake breakfast, only two weeks late after the actual birthday... which is pretty good compared to that one kid who's now 22 and still complains about the time his birthday breakfast never even happened...

Step Six... spend the rest of the day, and let's be honest, the rest of the week, cutting out 16 holes per ring on your hand-plunge drill press from Harbor Freight tools, whose 5-speed variable rpm is not "quite" as advertised...

Step Seven: Using ONLY your imagination, pretend that it's the right size, the right fit, and the right dimensions to line up perfectly with your aluminum armature and IMAGINE that it's all going to work out just brilliantly -- the way life always does -- and ENJOY that feeling, because imagining perfection is most likely the subconscious motivation that got you into model building in the first place...

Will post again with pictures when I've perfected the armature-core assembly.

(i.e., Expect to hear from me within, if not the week, then at least within the decade...)

Was going to use a CNC router shop, but that was a $500 price tag on TOP of the $180 for the plywood. So I'm trying it "by hand" one more time, and if it fails this time, I'll go the computer-aided machinery route for the third and final try.

Step One: choose a sunny day 2-1/2 years into your build, and get your plywood sheets cut in half for free at Home Depot. Choose the lightest-weight plywood you can find - in my case Douglas Fir for the 3/4" and Luan for the 1/4." Get your handy-dandy Rockler circle-cutting jig all set up with your cordless DeWalt router that will need four battery changes by the time it's all over...

Step Two: Humiliate yourself by taking out your previously failed armature ring, cutting it off the aluminum armature in pieces, and keep these pieces in your peripheral vision The Whole Time you are cutting the new ones. Remind yourself with every minute: IF I screw this up again, I'll be throwing away the same amount of lumber, time, and effort, and now at 50% markup thanks to wood prices and inflation. So measure three times, cut one-- actually wait a minute -- measure four times, now cu--- actually measure five times... until you're really seriously committed and ready to... throw away more money at what you keep insisting to your wife is "the learning curve"...

Step Three: Cut out all your rings, making sure they are perfectly aligned on Inner Dimension and Outer Dimension, the whole time repeating to yourself, "It's okay that it's 1/16th off, which is only 1/8" off around the whole thing, because it's off by too much in the right direction -- and you can compensate for that missing 1/8 by adding a 1/16-inch (okay, 1.5mm, close enough!) piece of cardstock all the way around to glue your original greeblies to make a strong styrene-on-styrene bond." Keep telling yourself this -- an important part of the psychology of the whole thing -- instead of telling yourself, "I measured this FIVE times, HOW could I be off by so much?" -- which narrative will only kill your morale.

Step Four - Using the old, broken, ruined, discarded, disgusting, beneath-your-contempt failed armature as a guide, mark your inner 3-inch lightening holes and, regarding placement, remind yourself that a.) these were originally handmade, b.) getting 1/2" from the inside while getting 3/4" from the outside is a fool's errand, so just aim for dead center and you'll be off anyway, c.) that CNC router perfection is only for those who demand perfection and Don't Want the ILM handmade look, and d.) NONE of this will be seen, ever, by anyone, except you (and the whole Internet should you post the pictures...)

Step Five - Go Inside for Brunch to Celebrate your Son's "May the 4th Be With You" Star Wars 8th birthday, with his requested favorite, a Swedish pancake breakfast, only two weeks late after the actual birthday... which is pretty good compared to that one kid who's now 22 and still complains about the time his birthday breakfast never even happened...

Step Six... spend the rest of the day, and let's be honest, the rest of the week, cutting out 16 holes per ring on your hand-plunge drill press from Harbor Freight tools, whose 5-speed variable rpm is not "quite" as advertised...

Step Seven: Using ONLY your imagination, pretend that it's the right size, the right fit, and the right dimensions to line up perfectly with your aluminum armature and IMAGINE that it's all going to work out just brilliantly -- the way life always does -- and ENJOY that feeling, because imagining perfection is most likely the subconscious motivation that got you into model building in the first place...

Will post again with pictures when I've perfected the armature-core assembly.

(i.e., Expect to hear from me within, if not the week, then at least within the decade...)

That was brilliant! Lol. Well done.

Similar threads

- Replies

- 11

- Views

- 1,091