ARKM

Sr Member

Hi everyone.

Here's what ARKM's been up to lately...

I thought I'd share with you some saber-staff couplers I came up with. The reason behind their invention is that I always wanted a saber-staff coupler that allowed both halves of a saber-staff to look perfectly identical when separated into two sabers. There is nothing wrong with any of the existing saber-staff couplers that people have come up with so far, however none of the ones I have personally seen have achieved this feature. As the saying goes, "Necessity is the mother of all invention.". As such, I created three new saber-staff couplers (well technically four as you'll see later in this post) that fit my needs.

There is one drawback to this feature however... in order to have both halves of a saber-staff be perfectly identical when separated, you cannot have all the buttons of both saber halves be along the same axis when in staff mode. A good example of this would be the Darth Maul saber-staff. It has all the buttons on the same axis when in staff mode. However in order for both halves of that saber-staff to be perfectly identical when separated, when joining it into staff mode, the buttons on each half would have to be rotated 180 degrees apart. It's either that or have the coupler in one half of the staff, rotated 180 degrees from it's counterpart. In that situation, the sabers would not be perfectly identical when separated but then you could have all the buttons be along the same axis.

One thing I want to get out of the way right now is that I did not make these couplers for profit. I will not be making and selling these couplers (unless pre-installed in a saber-staff I may or may not build and sell someday). I made them to share with the saber building/saber collecting community in hopes that someone may think one or more of them have promise and possibly improve upon them for the betterment of the community. I don't know if any of my couplers are worthy of that. It is just my hope that they are. I don't have the means or knowledge to make them better than they are now but I hope that someone else does. That said, I do not consider any of the couplers that I invented to be my intellectual properly, only my invention. I have no problems whatsoever with ANYONE modifying them, improving upon them or making them for profit by mass producing and selling them (again, if you think any of the couplers have merit and is something that you would be interested in doing) nor do I expect any money from anyone who may choose to do that. If one were to do this, please don't make them your intellectual property. I want these couplers to be available for everyone to make and possibly profit from. Also, if one of you were to do this, I would not mind a nod towards me by listing the name ARKM as the inventor but that is not necessary. It is only desired by my ego, lol.

I will compare these couplers to each other as well as to the most excellent version that was invented by Corbin (which I personally believe is still the strongest as well as the easiest to make) and will list the pros and cons of each. I will also provide blueprints for each coupler.

You may notice after viewing the pictures and video, that I use flush-mounted set screws to pin the couplers into the hilt bodies via pressure as well as to pin both saber halves together in staff mode. The reason for this is that it allows for palm spins when in staff mode. Regular screws can of course, be used instead and can go through multiple parts for more securing power when in staff mode if desired. One very important thing to know is that when using set screws to hold something via pressure, (IMHO) the screws should be pinned against hard metals, not soft ones like aluminum. This is why you will see that most of the couplers in this post have permanently mounted (via metal epoxy) set screws in them for the other set screws to pin against.

Just a note, I took some shortcuts in building these couplers (as well as the two hilt bodies that I show them installed in) in order to crank them out faster for this very thread. That is why some screw holes may not be perfectly aligned, finishes are crude, etc.

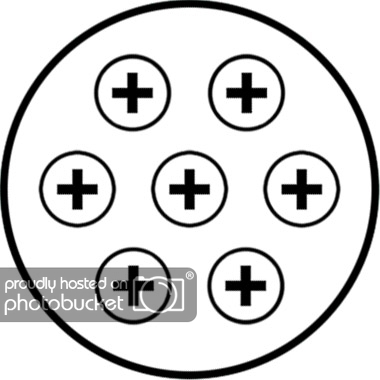

When mounting coupler pieces in the hilt via screws, I recommend that you have either four or six rows of screws. The reason I do not recommend three rows is that when the two saber halves are joined together in staff mode, WITH the buttons on each half of the saber-staff being rotated 180 degrees apart, your screw row alignment would look like this...

All of these couplers can be scaled down to fit into smaller hilts such as a Hasbro Force FX Darth Maul lightsaber for example.

Below is a video showing all of the couplers in action, followed by descriptions and pics of each coupler. Then a list of the pros and cons of each.

First up we have Corbin's saber-staff coupler. Corbin invented this coupler several years ago and shared it with the saber community via YouTube and the TCSS forum. It is a super strong coupler, easy to make and works extremely well. In my opinion it is the strongest of all the couplers presented in this post and the easiest to make.

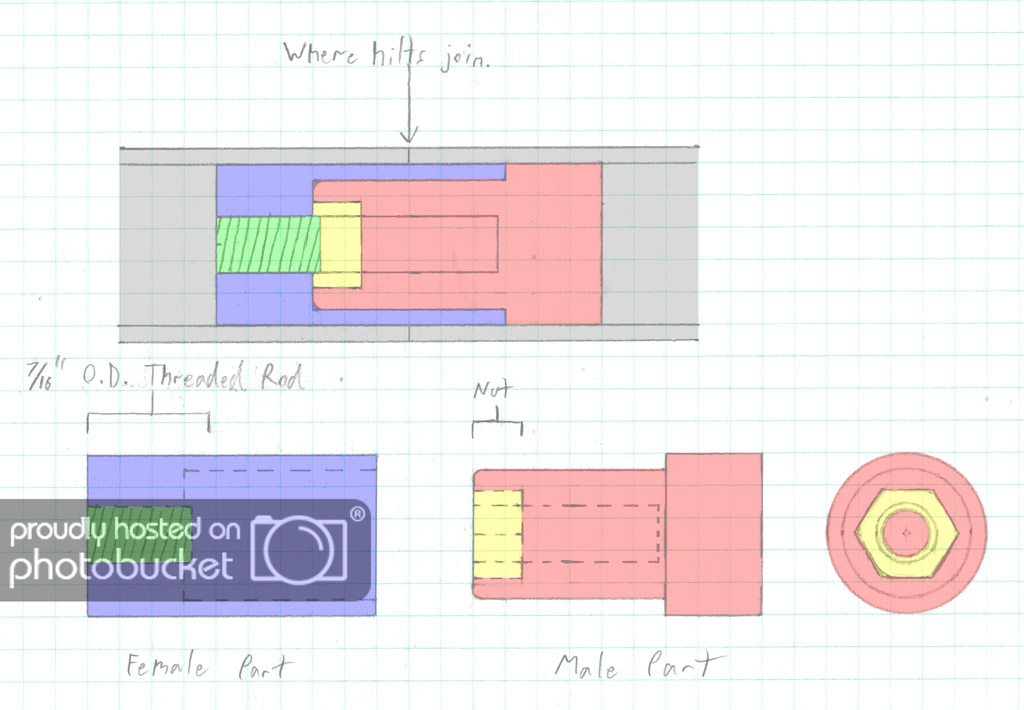

Since then, at least two people have made saber-staff couplers based off of Corbin's concept. That being Lord Maul of the TCSS forums and myself. When I made my versions for a couple of saber-staves I built, I decided to add a nut and bolt to the center axis of the coupler pieces. Those additions were probably not necessary and made the coupler pieces harder to make but allowed for greater strength in keeping the saber halves together when in staff mode. There are some machining tricks that need to be done in order to have the nut and bolt perfectly centered. If you have any questions on that, please send me a PM. So far I have made all of my versions of this coupler from solid round bar however it can also be done using tubes. One of the very nice things about this coupler is that If using tubes, one could probably make this without the use of any power tools.

With nut and bolt...

Without nut and bolt...

Blueprint...

Next up we have my coupler # 01. This is probably the second strongest of the couplers in this thread (Corbin's being the strongest). This one was made from tubes as opposed to solid rods. This coupler as well as coupler # 02 are best made using a CNC or if possible a wire, EDM. The second best choice would be a mill with a rotary table and dividing plate (sometimes called an indexing plate). I do not have access to a CNC, wire EDM or a rotary table that fits my mill. This was all done on my mini-mill with no rotary table. As such, this coupler and coupler #2 are far from accurate and were a pain to make. However they still work fine and the fit when in staff mode, is very nice.

This next pic is a blueprint of a notched variant version of Coupler 01. The notches would allow for the two saber halves to be slightly rotated once pushed all the way together so that once rotated, the saber halves could not be pulled apart until rotated back. This same design concept can also be applied to coupler # 02.

This pic is of a coupler I did not make and won't make but also allows both sabers to be perfectly identical when separated. The reason I won't make it is because it looks horrible to me. It's the same concept as coupler # 01 but has only one "prong/tongue" per saber instead of three. Also, this is the only coupler that cannot hold itself together with it's other half, outside of the hilts (unless based off coupler # 02).

Next is coupler # 02. Again this one was made with tubes. It's the same design concept as coupler # 01 only with two tubes with a 1/8" wall thickness instead of one tube with a 1/4" wall-thickness. The tubes have a 60 degree offset from each other. This is probably the weakest of all the couplers and as such, should probably not be made from aluminum as seen here. Instead I recommend it be made from harder metals such as brass or much better yet, steel.

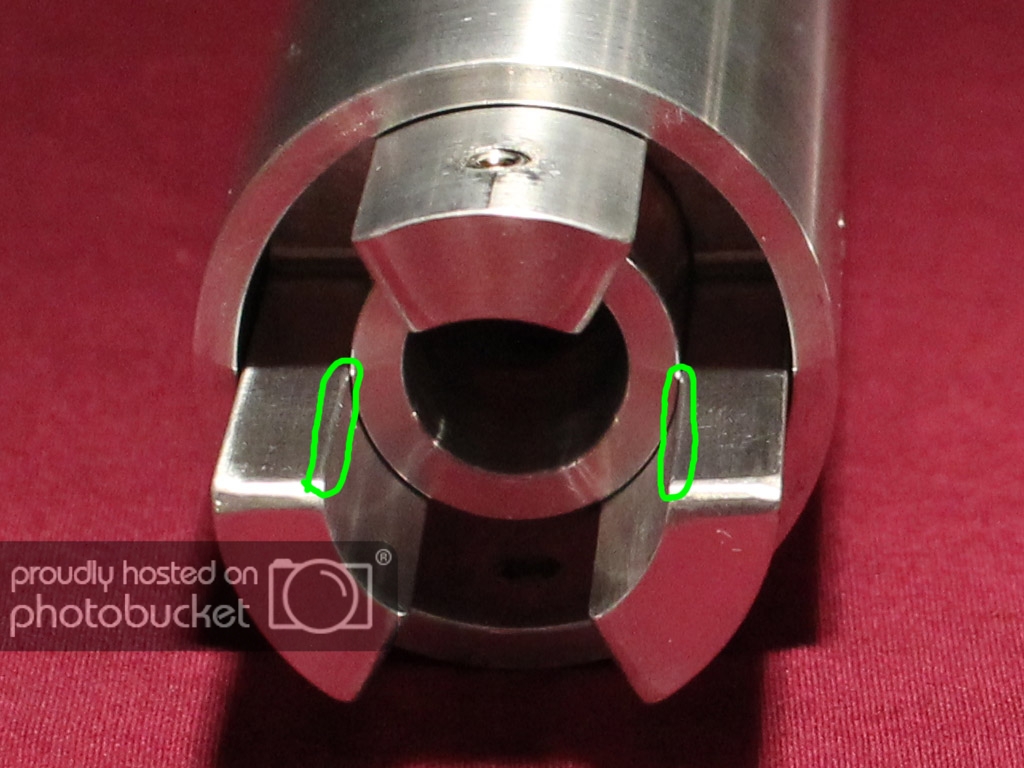

This next pic is of coupler # 01 but what I want to show in it also applies to coupler # 02. The parts circled in green need to be filed down much more than what I did for both coupler's 01 and 02. I thought I did a good job on filing them but apparently they are still too sharp, especially on coupler # 02 that coupler gets harder to separate every time it's joined due to those edges digging into the piece beneath them and leaving scratches.

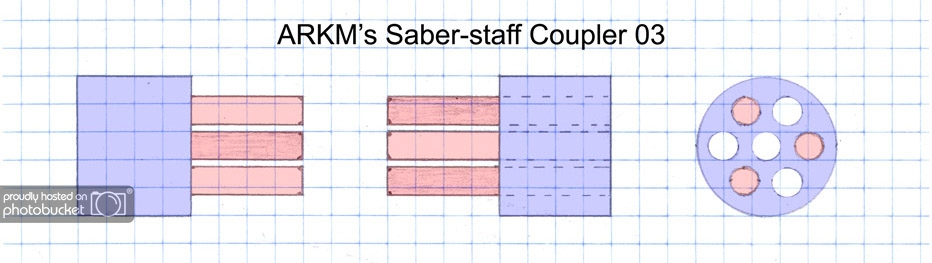

Last but not least is coupler # 03. This is the second easiest coupler to make. Technically one could make this coupler with only one power tool needed. That being a drill press with a vise (preferably on a cross-slide table) or if lacking a drill press, using a mill as a drill press. While a drill press is the only power tool required, a lathe comes in mighty handy for getting the outer diameter and center holes, just right. This coupler takes up much less room in the hilt than the other ones (1.25" less in each half of the saber-staff for a total of 2.5" less space used). However it does not look as cool when separated into two sabers.

The six rods are 1/4" in diameter and are made from 303 stainless steel. They are held in place via metal epoxy. To make sure all the holes line up properly, I used one 2-1/16" long piece of 1.25" round bar and drilled the six outer holes through it without moving it in the vise. The vise was on a cross-slide table so I just moved the table. If you don't have a cross-slide table and have to change the orientation of the vise on your drill press table, just make sure that the orientation of the part being drilled always faces the same way. For example, if the outer diameter axis that is closest to the edge of Hole # 1, is facing perfectly due North when making said hole, make sure that same axis is always facing perfectly due North when drilling all the other holes. This is to make absolutely sure that all the holes are drilled at the same angle and is just one of the reasons why a cross-slide table is preferable over the basic ones that come with a drill press.

After that, I made a mark on both ends of the piece along the same axis, drilled the center hole on the lathe and then cut the piece in half using a hack saw (the marks are so I know which hole on each half aligns with the other). This made for perfect hole alignment and these coupler halves slide together perfectly and smoothly. This coupler is best used with one half of the coupler extending from one hilt bottom by about 1/32". Sure that slightly messes up the whole "both hilts looking identical when separated" thing but it also assures that light does not shine through the saber-staff where the two halves meet, should any imperfections be present in that area.

This is a hole drilling template for coupler #03. When printed at 100% scale, it will print out to the scale for a 1.25" diameter coupler.

Alright, now to sum up...

Three new couplers invented by ARKM being shown alongside the awesome one invented several years ago by Corbin.

I will not be making or selling these and do not consider them my intellectual property, only my invention. As such, I don't care what anyone does or does not do with these designs, even if that someone mass produces them and sells them without me seeing even one penny. I won't come after you.. unless you have Chocodiles (chocolate covered Twinkies from Hostess). I will come after your Chocodiles.

All of these couplers can be scaled down to fit into smaller hilts such as a Hasbro Force FX Darth Maul lightsaber for example.

ARKM is awesome.

Now for the Pros and Cons...

Corbin's Saber-staff Coupler - Pros:

Easiest of all the couplers to make.

Strongest of all the couplers.

Can be made without the use of ANY power tools (via tubes and metal epoxy).

Can have the buttons on both saber halves be along the same axis (or any axis for that matter) when in staff mode without affecting the appearance of the hilt when separated.

Allows for the use of an additional nut and bolt along the center axis for extra strength when in staff mode.

Corbin's Saber-staff Coupler - Cons:

Does not allow both saber halves to be perfectly identical when separated. Geez this is the only con? Gotta love this coupler.

Wait I thought of one more... it was not invented by me.

ARKM's Saber-staff Coupler 01 - Pros:

Allows both saber halves to be perfectly identical when separated.

It's strong.

It looks cool.

ARKM's Saber-staff Coupler 01 - Cons:

Cannot have the buttons on both saber halves be along the same axis when in staff mode without affecting the appearance of the hilt when separated.

Requires a CNC, Wire EDM or mill with a rotary table and divider plate to make properly.

ARKM's Saber-staff Coupler 02 - Pros:

Allows both saber halves to be perfectly identical when separated.

It looks cool. Possibly the coolest looking of all the couplers (subjective).

ARKM's Saber-staff Coupler 02 - Cons:

Cannot have the buttons on both saber halves be along the same axis when in staff mode without affecting the appearance of the hilt when separated.

Requires a CNC, Wire EDM or mill with a rotary table and divider plate to make properly.

It's the most difficult of all the couplers to make.

It's probably the weakest of all the couplers and therefore should not be made out of soft metals such as aluminum. However one made from hard steel would probably be strong enough for heavy dueling.

ARKM's Saber-staff Coupler 03 - Pros:

It's easy to make.

Only requires one power tool, that being a drill press with a vise (and also preferably a cross-slide table). However a lathe comes in handy for getting the outer diameter and center hole, just right.

It's strong.

It takes up much less room in the hilt than the other couplers.

ARKM's Saber-staff Coupler 03 - Cons:

Cannot have the buttons on both saber halves be along the same axis when in staff mode without affecting the appearance of the hilt when separated.

Not all that aesthetically pleasing. It looks like a cattle prod, lol. Hmm, maybe it could be used as one with the right electronics. "Don't tase me bro!" "ZAP!" "Hee hee".

Sticks out the bottom of the hilt 1/4" longer than all the other couplers.

May require one coupler half to extend from the bottom of the hilt by 1/32" (which means the other half is sunk in by 1/32") to avoid seeing light shining through the hilt where the two halves meet.

Well there you have it. I hope you like my new couplers. If you have any questions on how to build one of these for yourself, please let me know. If you want to view the pics at their full size as well as see the non color-coded blueprints, please visit these Photobucket albums...

Corbin's Saber-staff Coupler...

http://s6.photobucket.com/user/Evil-Henchman/library/Corbins Saber Staff Coupler?sort=9&page=1

ARKM's Saber-staff Couplers...

http://s6.photobucket.com/user/Evil...ilts/ARKMs Saber-staff Couplers?sort=9&page=1

Thanks for reading.

Here's what ARKM's been up to lately...

I thought I'd share with you some saber-staff couplers I came up with. The reason behind their invention is that I always wanted a saber-staff coupler that allowed both halves of a saber-staff to look perfectly identical when separated into two sabers. There is nothing wrong with any of the existing saber-staff couplers that people have come up with so far, however none of the ones I have personally seen have achieved this feature. As the saying goes, "Necessity is the mother of all invention.". As such, I created three new saber-staff couplers (well technically four as you'll see later in this post) that fit my needs.

There is one drawback to this feature however... in order to have both halves of a saber-staff be perfectly identical when separated, you cannot have all the buttons of both saber halves be along the same axis when in staff mode. A good example of this would be the Darth Maul saber-staff. It has all the buttons on the same axis when in staff mode. However in order for both halves of that saber-staff to be perfectly identical when separated, when joining it into staff mode, the buttons on each half would have to be rotated 180 degrees apart. It's either that or have the coupler in one half of the staff, rotated 180 degrees from it's counterpart. In that situation, the sabers would not be perfectly identical when separated but then you could have all the buttons be along the same axis.

One thing I want to get out of the way right now is that I did not make these couplers for profit. I will not be making and selling these couplers (unless pre-installed in a saber-staff I may or may not build and sell someday). I made them to share with the saber building/saber collecting community in hopes that someone may think one or more of them have promise and possibly improve upon them for the betterment of the community. I don't know if any of my couplers are worthy of that. It is just my hope that they are. I don't have the means or knowledge to make them better than they are now but I hope that someone else does. That said, I do not consider any of the couplers that I invented to be my intellectual properly, only my invention. I have no problems whatsoever with ANYONE modifying them, improving upon them or making them for profit by mass producing and selling them (again, if you think any of the couplers have merit and is something that you would be interested in doing) nor do I expect any money from anyone who may choose to do that. If one were to do this, please don't make them your intellectual property. I want these couplers to be available for everyone to make and possibly profit from. Also, if one of you were to do this, I would not mind a nod towards me by listing the name ARKM as the inventor but that is not necessary. It is only desired by my ego, lol.

I will compare these couplers to each other as well as to the most excellent version that was invented by Corbin (which I personally believe is still the strongest as well as the easiest to make) and will list the pros and cons of each. I will also provide blueprints for each coupler.

You may notice after viewing the pictures and video, that I use flush-mounted set screws to pin the couplers into the hilt bodies via pressure as well as to pin both saber halves together in staff mode. The reason for this is that it allows for palm spins when in staff mode. Regular screws can of course, be used instead and can go through multiple parts for more securing power when in staff mode if desired. One very important thing to know is that when using set screws to hold something via pressure, (IMHO) the screws should be pinned against hard metals, not soft ones like aluminum. This is why you will see that most of the couplers in this post have permanently mounted (via metal epoxy) set screws in them for the other set screws to pin against.

Just a note, I took some shortcuts in building these couplers (as well as the two hilt bodies that I show them installed in) in order to crank them out faster for this very thread. That is why some screw holes may not be perfectly aligned, finishes are crude, etc.

When mounting coupler pieces in the hilt via screws, I recommend that you have either four or six rows of screws. The reason I do not recommend three rows is that when the two saber halves are joined together in staff mode, WITH the buttons on each half of the saber-staff being rotated 180 degrees apart, your screw row alignment would look like this...

All of these couplers can be scaled down to fit into smaller hilts such as a Hasbro Force FX Darth Maul lightsaber for example.

Below is a video showing all of the couplers in action, followed by descriptions and pics of each coupler. Then a list of the pros and cons of each.

First up we have Corbin's saber-staff coupler. Corbin invented this coupler several years ago and shared it with the saber community via YouTube and the TCSS forum. It is a super strong coupler, easy to make and works extremely well. In my opinion it is the strongest of all the couplers presented in this post and the easiest to make.

Since then, at least two people have made saber-staff couplers based off of Corbin's concept. That being Lord Maul of the TCSS forums and myself. When I made my versions for a couple of saber-staves I built, I decided to add a nut and bolt to the center axis of the coupler pieces. Those additions were probably not necessary and made the coupler pieces harder to make but allowed for greater strength in keeping the saber halves together when in staff mode. There are some machining tricks that need to be done in order to have the nut and bolt perfectly centered. If you have any questions on that, please send me a PM. So far I have made all of my versions of this coupler from solid round bar however it can also be done using tubes. One of the very nice things about this coupler is that If using tubes, one could probably make this without the use of any power tools.

With nut and bolt...

Without nut and bolt...

Blueprint...

Next up we have my coupler # 01. This is probably the second strongest of the couplers in this thread (Corbin's being the strongest). This one was made from tubes as opposed to solid rods. This coupler as well as coupler # 02 are best made using a CNC or if possible a wire, EDM. The second best choice would be a mill with a rotary table and dividing plate (sometimes called an indexing plate). I do not have access to a CNC, wire EDM or a rotary table that fits my mill. This was all done on my mini-mill with no rotary table. As such, this coupler and coupler #2 are far from accurate and were a pain to make. However they still work fine and the fit when in staff mode, is very nice.

This next pic is a blueprint of a notched variant version of Coupler 01. The notches would allow for the two saber halves to be slightly rotated once pushed all the way together so that once rotated, the saber halves could not be pulled apart until rotated back. This same design concept can also be applied to coupler # 02.

This pic is of a coupler I did not make and won't make but also allows both sabers to be perfectly identical when separated. The reason I won't make it is because it looks horrible to me. It's the same concept as coupler # 01 but has only one "prong/tongue" per saber instead of three. Also, this is the only coupler that cannot hold itself together with it's other half, outside of the hilts (unless based off coupler # 02).

Next is coupler # 02. Again this one was made with tubes. It's the same design concept as coupler # 01 only with two tubes with a 1/8" wall thickness instead of one tube with a 1/4" wall-thickness. The tubes have a 60 degree offset from each other. This is probably the weakest of all the couplers and as such, should probably not be made from aluminum as seen here. Instead I recommend it be made from harder metals such as brass or much better yet, steel.

This next pic is of coupler # 01 but what I want to show in it also applies to coupler # 02. The parts circled in green need to be filed down much more than what I did for both coupler's 01 and 02. I thought I did a good job on filing them but apparently they are still too sharp, especially on coupler # 02 that coupler gets harder to separate every time it's joined due to those edges digging into the piece beneath them and leaving scratches.

Last but not least is coupler # 03. This is the second easiest coupler to make. Technically one could make this coupler with only one power tool needed. That being a drill press with a vise (preferably on a cross-slide table) or if lacking a drill press, using a mill as a drill press. While a drill press is the only power tool required, a lathe comes in mighty handy for getting the outer diameter and center holes, just right. This coupler takes up much less room in the hilt than the other ones (1.25" less in each half of the saber-staff for a total of 2.5" less space used). However it does not look as cool when separated into two sabers.

The six rods are 1/4" in diameter and are made from 303 stainless steel. They are held in place via metal epoxy. To make sure all the holes line up properly, I used one 2-1/16" long piece of 1.25" round bar and drilled the six outer holes through it without moving it in the vise. The vise was on a cross-slide table so I just moved the table. If you don't have a cross-slide table and have to change the orientation of the vise on your drill press table, just make sure that the orientation of the part being drilled always faces the same way. For example, if the outer diameter axis that is closest to the edge of Hole # 1, is facing perfectly due North when making said hole, make sure that same axis is always facing perfectly due North when drilling all the other holes. This is to make absolutely sure that all the holes are drilled at the same angle and is just one of the reasons why a cross-slide table is preferable over the basic ones that come with a drill press.

After that, I made a mark on both ends of the piece along the same axis, drilled the center hole on the lathe and then cut the piece in half using a hack saw (the marks are so I know which hole on each half aligns with the other). This made for perfect hole alignment and these coupler halves slide together perfectly and smoothly. This coupler is best used with one half of the coupler extending from one hilt bottom by about 1/32". Sure that slightly messes up the whole "both hilts looking identical when separated" thing but it also assures that light does not shine through the saber-staff where the two halves meet, should any imperfections be present in that area.

This is a hole drilling template for coupler #03. When printed at 100% scale, it will print out to the scale for a 1.25" diameter coupler.

Alright, now to sum up...

Three new couplers invented by ARKM being shown alongside the awesome one invented several years ago by Corbin.

I will not be making or selling these and do not consider them my intellectual property, only my invention. As such, I don't care what anyone does or does not do with these designs, even if that someone mass produces them and sells them without me seeing even one penny. I won't come after you.. unless you have Chocodiles (chocolate covered Twinkies from Hostess). I will come after your Chocodiles.

All of these couplers can be scaled down to fit into smaller hilts such as a Hasbro Force FX Darth Maul lightsaber for example.

ARKM is awesome.

Now for the Pros and Cons...

Corbin's Saber-staff Coupler - Pros:

Easiest of all the couplers to make.

Strongest of all the couplers.

Can be made without the use of ANY power tools (via tubes and metal epoxy).

Can have the buttons on both saber halves be along the same axis (or any axis for that matter) when in staff mode without affecting the appearance of the hilt when separated.

Allows for the use of an additional nut and bolt along the center axis for extra strength when in staff mode.

Corbin's Saber-staff Coupler - Cons:

Does not allow both saber halves to be perfectly identical when separated. Geez this is the only con? Gotta love this coupler.

Wait I thought of one more... it was not invented by me.

ARKM's Saber-staff Coupler 01 - Pros:

Allows both saber halves to be perfectly identical when separated.

It's strong.

It looks cool.

ARKM's Saber-staff Coupler 01 - Cons:

Cannot have the buttons on both saber halves be along the same axis when in staff mode without affecting the appearance of the hilt when separated.

Requires a CNC, Wire EDM or mill with a rotary table and divider plate to make properly.

ARKM's Saber-staff Coupler 02 - Pros:

Allows both saber halves to be perfectly identical when separated.

It looks cool. Possibly the coolest looking of all the couplers (subjective).

ARKM's Saber-staff Coupler 02 - Cons:

Cannot have the buttons on both saber halves be along the same axis when in staff mode without affecting the appearance of the hilt when separated.

Requires a CNC, Wire EDM or mill with a rotary table and divider plate to make properly.

It's the most difficult of all the couplers to make.

It's probably the weakest of all the couplers and therefore should not be made out of soft metals such as aluminum. However one made from hard steel would probably be strong enough for heavy dueling.

ARKM's Saber-staff Coupler 03 - Pros:

It's easy to make.

Only requires one power tool, that being a drill press with a vise (and also preferably a cross-slide table). However a lathe comes in handy for getting the outer diameter and center hole, just right.

It's strong.

It takes up much less room in the hilt than the other couplers.

ARKM's Saber-staff Coupler 03 - Cons:

Cannot have the buttons on both saber halves be along the same axis when in staff mode without affecting the appearance of the hilt when separated.

Not all that aesthetically pleasing. It looks like a cattle prod, lol. Hmm, maybe it could be used as one with the right electronics. "Don't tase me bro!" "ZAP!" "Hee hee".

Sticks out the bottom of the hilt 1/4" longer than all the other couplers.

May require one coupler half to extend from the bottom of the hilt by 1/32" (which means the other half is sunk in by 1/32") to avoid seeing light shining through the hilt where the two halves meet.

Well there you have it. I hope you like my new couplers. If you have any questions on how to build one of these for yourself, please let me know. If you want to view the pics at their full size as well as see the non color-coded blueprints, please visit these Photobucket albums...

Corbin's Saber-staff Coupler...

http://s6.photobucket.com/user/Evil-Henchman/library/Corbins Saber Staff Coupler?sort=9&page=1

ARKM's Saber-staff Couplers...

http://s6.photobucket.com/user/Evil...ilts/ARKMs Saber-staff Couplers?sort=9&page=1

Thanks for reading.

Last edited by a moderator: